Hoima CDM site

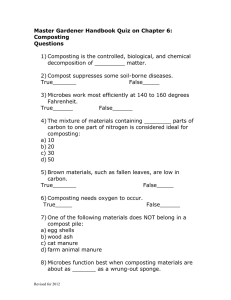

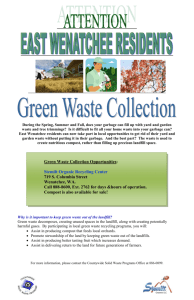

advertisement