Footings-First Draft E-Book 6-27-06

advertisement

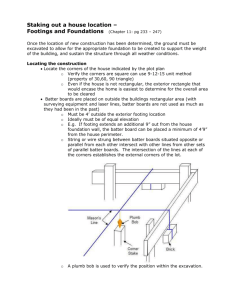

HOMEOWNERS E-BOOK ON TYPES OF FOOTINGS AND HOW TO FORM THEM. Welcome to Homeowners Construction E-books. In this e-book I will cover the basics for installation of footings for various structures. Since footings are the basic foundation piece of any building, it is important that they be designed by a licensed professional who will determine the proper size of the footing. The local soil conditions and the size of the building itself will determine the physical size of the footing needed, steel reinforcement needs, if any, and so on. Footings no matter what is intended to sit upon them such as a wall or a post must always sit upon virgin, undisturbed earth. When excavating for your footing with machinery (backhoe or a powered post hole digger), it is recommended that you dig to within a few inches of the actual depth you need and finish the last few inches by hand. This will prevent you from accidentally disturbing the earth below the bottom of your footing forms. IF you over dig more than you need, place the footing on that level, DO NOT place loose material back into the hole. Your footing will settle when the weight of the concrete is placed on it causing the entire footing to settle. If you have already placed your foundation wall or post on the footing, the result will be a cracked wall or a sunken post. This of course leaves you with a structurally unsound foundation wall or a deck post that sags in one corner. Footing TypesFootings can be formed using scrap lumber, paper tubes, and in some areas, concrete placement is allowed directly to the earth if the hole is shaped properly and the soil is solid enough to hold its shape. Check with your local building department to see if this is acceptable. When a structure such as a home or a garage is built, it is common practice to open excavate the footing trench to allow for the forming and pouring of the footings. If this is your type of project, any sound scrap lumber in the proper dimension of the footing for example 2 x 8, 2 x 10, plywood, etc. is acceptable. Since the footings will be buried, knots or holes in the lumber are no concern as appearance is not important. Multiple paper preformed round footing tubes set in place. Diameter required will be shown on your drawings. Paper tubes most commonly used for decks can be installed, poured and later the portion of the paper exposed above ground can be peeled away to provide a neat finished appearance. As long as the forms are strong enough to hold the weight of the concrete until it dries and the bracing is strong enough to make sure the form does not move during placement of the concrete, you are good to go. Footings are usually square but can be rectangular, round or just about any shape you can form. If you have had your footings designed by a professional, your drawings will show the shape and dimensions of the footings required. Look at your drawings carefully to determine the size and number of footings required. You will most likely want to pour them all at once to save money on the concrete orders. If you are hand mixing the concrete, you may pour them one at a time. A typical footing size may show as 2'-0" x 2'-0" x 10". That will be a 2 foot square footing that is 10 inches high or deep. The drawing will also show the elevation of the top of footing needed. Usually this shown on the footing as (-4'-0" or -8'-0") and so on. This means the TOP of the finished footing is four feet or eight feet below the finished floor of the building. You must set the first floor elevation and then deduct the four feet plus the 10 inches to get to the bottom of the new footing. Sadly it seems it is never a nice even amount like -4'. Due to dimensional lumber sizes, masonry sizes, the elevation will read more like (-4'-4 5/8"). It's OK. It's just a little math work. You want to get it right though. The top of the footing will setup the finished heights of the entire rest of your building. Get it right. Making adjustments later on, if possible at all, can be a nightmare. If you have obtained a building permit for your work, the building inspector will check to see if you have set the form the minimum depth below grade required in your area. They will NOT check your elevation for you. That is your responsibility. Your drawings will tell you all the information you need to properly install the footing in the right place and at the correct elevation. REINFORCEMENTMany footings require reinforcement to strengthen the concrete. Installation is a simple task requiring only a pair of flat nosed pliers and a roll of light gauge tie wire. Your drawing will indicate the size and number of rebar pieces required. If it reads 4-#5 E.W. this means you need a total of 8 pieces of #5 rebar. Rebar is based on 1/8" increments in size so a #5 bar is 5/8" in diameter. #6 is 3/4" and so on. E.W. is shorthand for "each way", not EastWest.. Large rebar mat installed in a footing. Lay the bars on the flat ground using 4 of the bars in each direction perpendicular to each other to form a mat with 4 bars facing East-West and 4 bars facing North-South, one set on top of the other. For a 2' x 2' footing, your bars will be 1'-6" long each. Concrete protocol requires 3" of clearance from the end of each bar to the edge of the concrete. (that is just the way it is). Rebar installed in lineal footings. Using your tie wire, tie at least 50% of the cross points of the rebar. Just wrap the wire around both bars, twist with your pliers to make the tie tight and cut off the wire. Keeping the mat as square as possible, tie enough of the bar intersections to keep the bars from separating when the concrete is placed on top of them. Place the mat in your form keeping it in the bottom 1/3 of the footing height. (again protocol). This will give the maximum strength of your footing concrete. You do not want the rebar to touch either the forms or the earth. The concrete must completely envelop the bars. The best way to set the rebar mat is by hanging it in your form. Using two pieces of scrap lumber long enough to reach across your formwork, just place each piece of lumber about 1/3 of the way in from each side. Using your tie wire, simply hang the mat by wrapping tie wire around the bottom bars of the mat and then tying it to the support lumber. Make sure the mat is in the bottom 1/3 of the footing when you are done. Another method is to pour concrete into the form until it is 1/3 full, level out the concrete and then place the mat into the wet concrete. Complete filling the form until you are done. This is easier but if working alone it is just another task you have to do besides pouring the concrete. Vibrate your form by lightly tapping on the sides of the form with a hammer to consolidate the concrete and remove any air pockets. Finish off the top of the footing level with the forms and you may be done. If you are using round paper for tubes for a deck you may need to set an anchor bolt for the post hanger. If you are pouring a lineal footing for a wall, Typical lineal footing forms in place. You may have to install a "key" slot and rebar for the wall supports. Look for what is called a "section" on your drawings. If a key slot is required it will show it. This can be formed with a 2 x4 hammered down into the wet concrete and slid along to form the key slot. The concrete must be wet enough but not too wet or the slot will refill and not too dry or you won't be able to form it. A little hand work with a trowel will do a fine job. Shows lineal footing with key formed to lock foundation wall in place. Many foundation walls require what is called rebar dowels to be placed in the footing. You will want to have these dowels pre-bent and ready BEFORE YOU START POURING YOUR CONCRETE. A word of caution here as well. Splattered concrete can cause severe damage to your eyes and skin. Wear safety glasses or goggles whenever working with wet concrete. Any concrete you get on your skin should be washed off as quickly as possible to avoid skin burns. Shows footings formed with rebar dowels tied into place before concrete is poured. Dowels are typically bent in an L shape with a short horizontal leg and longer vertical leg. Your drawing will tell you how long these legs need to be. An example will read #5 dowels, 4'OC, 12"x36", I.F. This means you are to use # 5 rebar (5/8"), bent with the short leg 12" long and long leg 36" long. The vertical rears will go 2" in from the inside face of the wall. They are to be placed 4' (48") on center starting from the centerline of the wall in one corner and proceeding around the foundation. When you come to a corner you will have more than likely, less than the 4' spacing so just add an extra bar at that point so each corner has a bar in the center. Keep the bars as straight as possible. The advantage to installing them before the pour is you don't have to rush around trying to get them in before the concrete is too dry. The disadvantage is you have to finish the top of the concrete around each bar. "Wet sticking" rebar is sometimes frowned upon by architects if the concrete is moved around too much. If you carefully insert the rebar in the wet concrete making sure you have full contact with the concrete If is usually Ok. You cannot have holes around each bar when you are done. Layout and marking of the footing forms as to where the dowels go, is a must. You simply will not have the time nor likely the energy to do it after the concrete is poured. Once the concrete is hard, it is too late. If the dowels are not installed your building inspector will reject the work. Leveling of forms-Before you are ready to pour the concrete you must make sure your forms are level. Using a simple 3 point level (Nikon) and a ruler, you can with a helper take elevations every 5-10 feet or so and make sure all the forms are the same height. The footings may have a step or two in them which is determined by the grades on the site. Make sure each area is level within itself. If your foundation is masonry, the steps normally measure no more than 16" high. If the foundation is poured concrete, larger steps can be done. Ask your architect for the maximum step allowed. In any case, each step must be level to allow for a level surface for the foundation walls to sit upon. In warmer climates footings may sit almost on grade. In colder Northern climates, footings may be 4, 5 or even more feet below the ground to the bottom of the footings. This will protect against frost heave during very cold weather. CLEANUPOften ignored is the cleanup portion of footing work. It is required and foolish not to, to remove all lumber from the excavation before you backfill. In many parts of the country termites are a serious problem. Wet wood buried underground is a tasty morsel for these guys and when their done eating whatever is buried, they will move UP into the building above. Remove all wood, paper, tar buckets or other items that are not made of earth. You want a clean excavation when you start backfilling. I have failed more than one job over the years because the builder thought the open excavation was a landfill. The unknowing future homeowner inherits a potential problem and the builder saves $5 on cleanup costs. Take the time to do it right. Tar bucket residue can weep into the soil and if you are on a private well, could contaminate your drinking water. Closing Footings are a critical part of any structure that is going to sit upon them. Take your time to get them located properly, set at the correct elevation and the rest of your work will become much easier to do. As a purchaser of this e-book you are entitled to one months FREE email support for your project. I cannot offer structural information as that must be done by a licensed professional in the state you reside in but I can offer many tips and tricks or if you need additional information on a particular item regarding footings, feel free to email me and I will get right back to you as quickly as possible. Every area of the country has its own design criteria for different kinds of footings. Warmer areas allow for the use of pre-made footing blocks available at big box stores. Your local building department will gladly advise you as to the minimum required depth of footings in your area. Thank you for visiting and if you gained some information you didn't know from my book you will visit again. Feel free to print a copy for later reference during the work. author: Peter Ackerson This E-Book cannot be re-printed or re-published without the express written consent . A homeowner or municipal building department is free to print for self-reference but in no case for retail sale or other use.