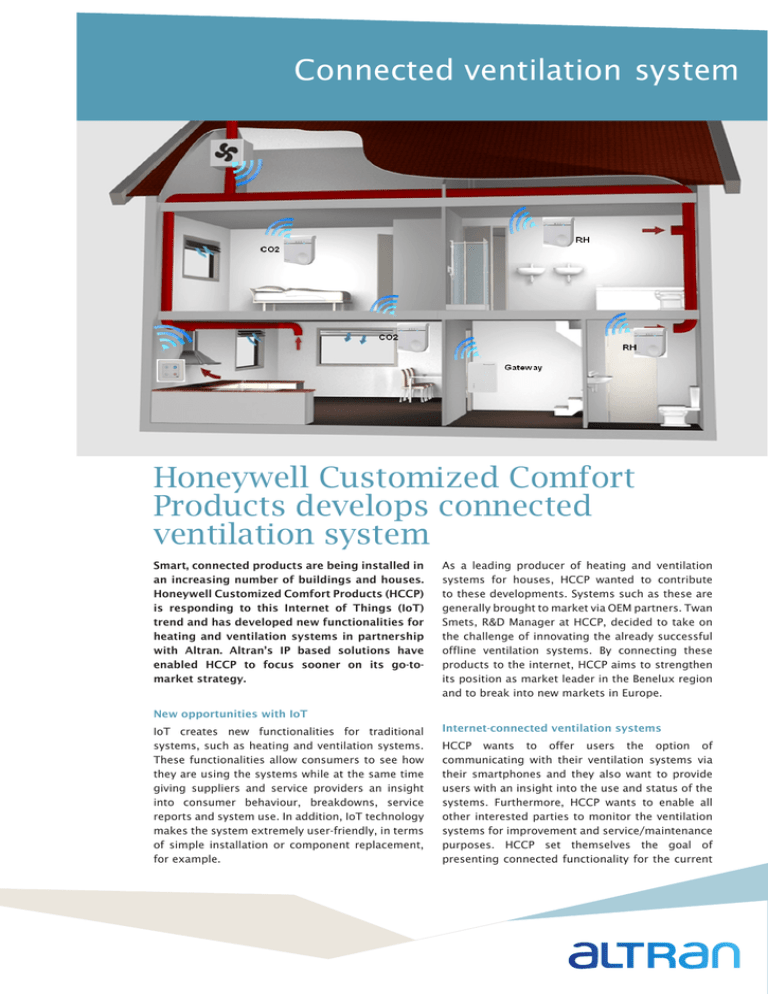

Connected ventilation system

Honeywell Customized Comfort

Products develops connected

ventilation system

Smart, connected products are being installed in

an increasing number of buildings and houses.

Honeywell Customized Comfort Products (HCCP)

is responding to this Internet of Things (IoT)

trend and has developed new functionalities for

heating and ventilation systems in partnership

with Altran. Altran’s IP based solutions have

enabled HCCP to focus sooner on its go-tomarket strategy.

As a leading producer of heating and ventilation

systems for houses, HCCP wanted to contribute

to these developments. Systems such as these are

generally brought to market via OEM partners. Twan

Smets, R&D Manager at HCCP, decided to take on

the challenge of innovating the already successful

offline ventilation systems. By connecting these

products to the internet, HCCP aims to strengthen

its position as market leader in the Benelux region

and to break into new markets in Europe.

New opportunities with IoT

IoT creates new functionalities for traditional

systems, such as heating and ventilation systems.

These functionalities allow consumers to see how

they are using the systems while at the same time

giving suppliers and service providers an insight

into consumer behaviour, breakdowns, service

reports and system use. In addition, IoT technology

makes the system extremely user-friendly, in terms

of simple installation or component replacement,

for example.

Internet-connected ventilation systems

HCCP wants to offer users the option of

communicating with their ventilation systems via

their smartphones and they also want to provide

users with an insight into the use and status of the

systems. Furthermore, HCCP wants to enable all

other interested parties to monitor the ventilation

systems for improvement and service/maintenance

purposes. HCCP set themselves the goal of

presenting connected functionality for the current

generation of ventilation systems to their OEM partners and

the market as quickly as possible. To achieve this goal Smets

needed to find a suitable partner.

HCCP chose Altran, worldwide leader in the field of

innovation and high-tech engineering consultancy. Altran

supports clients by creating and developing new products

and services. It was Altran’s solution for IoT and connectivity

that was the deciding factor for HCCP and the two companies

entered into partnership on the basis of co-creation. By

using Altran’s existing solutions on a licence basis, HCCP

was able to accelerate the process of bringing new products

to market.

The shared vision in terms of IoT and working practices

contributed largely to the success of the partnership.

Dominique de Wit, Solution Manager at Altran, explained:

“Every company and every requirement is different and so we

put a lot of energy into identifying the client’s requirements

or problems before starting to develop a product. We

apply the same principle to our partnership with HCCP and

we have been able to quickly customize and add value by

using existing components. For this project Altran not only

provided technological expertise for subsystem integration,

we also implemented solutions for mobile apps, cloud

storage and embedded software.”

Existing components

HCCP and Altran created an connected ventilation system in

less than six months. Altran supported the development of

the following innovations:

• Protected and encrypted communication on existing low

power hardware with the help of Altran’s picoTCP (TCP/IP

stack) in the form of a licence;

• Protected cloud storage for the collection of data and the

generation of reports with the help of Altran’s Internet of

Things Framework;

• Development of a back office system for administration

and data insight.

“Through these innovations we are able to offer new

functionalities that bring many benefits for both consumers

and stakeholders,” said De Wit. “These functionalities allow

consumers to use an app on their smartphones to operate

their ventilation systems and to request information, such

as the temperature, CO2 level and humidity. And because

the system gathers large amounts of data, stakeholders

have a better understanding of system use. For example,

by analysing the data they will be able to predict when a

altran.nl

– Contact: info@altran.nl

© All rights reserved

problem is likely to occur and therefore anticipate it.

This is also referred to as ‘predictive maintenance’.”

Using Altran’s Internet of Things Framework, which

links product data to the cloud and makes it available to

applications, the first version of protected cloud storage

was realized in less than two months. This approach

was supported through continuous integration software

factory, a way of developing software with continuous

controls and tests so that products can be launched

quickly and safely. The aim is to expand cloud storage to

at least 100,000 ventilation systems within three years.

HCCP’s OEM partners are able to offer this functionality

on the market under their own brand name. There is

a separate cloud storage area available for this which

can be fully personalized. Alongside this, Altran is also

developing multiple applications for a variety of fields

and various target groups, ranging from residents and

contractors to housing corporations.

Agile partnership

HCCP and Altran have worked in an Agile way. “By

working flexibly we were able to identify any problems

very early and by adjusting our working practices during

the process we managed to avoid any stumbling blocks,”

said Smets. “Alongside the connected ventilation system,

we also created a demo kit for OEM partners and this

has led to several partners showing interest in the new

systems. The first OEM partner is already offering the

new ventilation system on the market. This confirms

the success of the HCCP/Altran partnership. In addition,

we can see even more opportunities for linking our

internet-connected products to a smart grid network,”

said Smets.

Realized benefits

Reduction of time-to-market through Agile

way-of-working and deliver value quickly by

combining existing and custom made

building blocks

Development of new functionalities for

traditional systems and increase usability

Insight in order to optimize the system and

maintenance