F-CY-OZ (LiY-CY) flexible, Cu-screened, EMC

advertisement

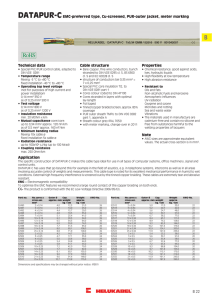

F-CY-OZ (LiY-CY) flexible, Cu-screened, EMC-preferred type, meter marking Technical data Cable structure Properties Ⴠ Special PVC data cables, adapted to DINVDE0281 part13 Ⴠ Temperature range flexing -5 °C to +80 °C fixed installation -40 °C to +80 °C Ⴠ Nominal voltage U0/U 300/500 V for 1 core (LiYDY) 1200 V Ⴠ Test voltage core/core 4000 V core/screen 2000 V Ⴠ Breakdown voltage min. 8000 V Ⴠ Insulation resistance min. 20 MOhm x km Ⴠ Mutual capacitance according to different cross-sections core/core approx. 150 nF/km core/screen approx. 270 nF/km Ⴠ Coupling resistance max. 250 Ohm/km Ⴠ Minimum bending radius flexing 10x cable ø fixed installation 5x cable ø Ⴠ Radiation resistance up to 80x106 cJ/kg (up to 80 Mrad) Ⴠ Bare copper, fine wire conductors, bunch stranded to DINVDE0295 cl.5, BS6360 cl.5 and IEC60228 cl.5 Ⴠ Core insulation of special PVC Z7225 Ⴠ Black cores with continuous numbering in white according to DINVDE0293 Ⴠ Cores stranded in layers with optimal lay-length Ⴠ Core wrapping with foil Ⴠ Tinned copper braided screen, approx. 85% coverage Ⴠ For 1 core cable copper screen of helically wound (type LiYDY), approx. 85% coverage Ⴠ Special PVC outer sheath TM2,to DINVDE0281 part1 and HD21.1 Ⴠ Sheath colour grey (RAL7001) Ⴠ with meter marking, change-over in 2011 Ⴠ Extensively oil resistant, oil-/ chemical Resistance - see table Technical Informations Ⴠ PVC self-extinguishing and flame retardant according to VDE 0482-332-1-2, DIN EN 60332-1-2/ IEC60332-1 (equivalent DINVDE0472 part804 test methodB) Ⴠ The materials used in manufacture are cadmium-free and contain no silicone and free from substances harmful to the wetting properties of lacquers Note Ⴠ x = without green-yellow earth core (OZ). Ⴠ For 1 core cable screen of helically wound. Ⴠ Cleanroom qualification tested with analog type. Please note "cleanroom qualified" when ordering. For more information, see introduction Ⴠ unscreened analogue type: JZ 500, see page A 6 Application These cables are used for flexible use for medium mechanical stresses with free movement without tensile stress or forced movements in dry, moist and wet rooms but not suitable for open air, as data cables in control technologies, in the tool making and machine industries, in computers and as a signal cable for the electronics branch. A stabilizing separator between core bundle and braid reduces essentially the external diameter and allows smaller bending radius, lower weight etc. The dense screening assures disturbance-free transmission of all signals and impulses. An ideal disturbance-free control cable for the above applications. EMC = Electromagnetic compatibillity To optimise the EMC features we recommend a large round contact of the copper braiding on both ends. = The product is conformed with the EC Low-Voltage Directive 2006/95/EG. Part no. 16531 16532 16533 16534 16535 16536 16537 16538 16539 16540 16541 16542 16543 No.cores x cross-sec. mm² 1x0,5 2x0,5 3x0,5 4x0,5 5x0,5 6x0,5 7x0,5 8x0,5 10x0,5 12x0,5 14x0,5 16x0,5 18x0,5 Outer Ø Cop. approx. mm weight kg/km 3,7 15,0 5,7 35,0 5,9 42,0 6,4 47,0 6,9 56,0 7,6 67,0 7,6 69,0 8,7 80,0 9,6 94,0 9,7 108,0 10,2 116,0 11,0 129,0 11,5 145,0 Weight approx. kg/km 41,0 45,0 55,0 61,0 74,0 89,0 98,0 117,0 135,0 157,0 190,0 210,0 217,0 AWG-No. 20 20 20 20 20 20 20 20 20 20 20 20 20 Part no. 16544 16545 16546 16547 16548 16549 16550 16551 16552 16553 16554 16555 16556 No.cores x cross-sec. mm² 20x0,5 21x0,5 24x0,5 25x0,5 30x0,5 32x0,5 34x0,5 36x0,5 40x0,5 50x0,5 61x0,5 80x0,5 100x0,5 Outer Ø Cop. approx. mm weight kg/km 12,2 172,0 12,7 188,0 13,5 235,0 13,6 240,0 14,4 295,0 14,9 301,0 15,6 312,0 15,6 318,0 16,9 343,0 18,5 406,0 19,7 508,0 22,6 680,0 24,9 804,0 Weight approx. kg/km 240,0 250,0 300,0 314,0 360,0 425,0 433,0 446,0 475,0 573,0 653,0 784,0 995,0 AWG-No. 20 20 20 20 20 20 20 20 20 20 20 20 20 Continuation Ⴇ A 25 F-CY-OZ (LiY-CY) flexible, Cu-screened, EMC-preferred type, meter marking Part no. 16557 16558 16559 16560 16561 16562 16563 16564 16565 16566 16567 16568 16569 16570 16571 16572 16573 16574 16575 16576 16577 16578 16579 16580 16581 16582 16583 16584 16585 16050 16051 16052 16053 16054 16055 16056 16057 16058 16059 16060 16061 16062 16063 16064 16065 16066 16067 16068 16069 16070 16071 16072 16073 No.cores x cross-sec. mm² 1x0,75 2x0,75 3x0,75 4x0,75 5x0,75 6x0,75 7x0,75 8x0,75 10x0,75 12x0,75 14x0,75 16x0,75 18x0,75 19x0,75 20x0,75 21x0,75 24x0,75 25x0,75 27x0,75 30x0,75 32x0,75 34x0,75 36x0,75 37x0,75 40x0,75 50x0,75 61x0,75 80x0,75 100x0,75 1x1 2x1 3x1 4x1 5x1 6x1 7x1 8x1 10x1 12x1 14x1 16x1 18x1 20x1 24x1 25x1 28x1 30x1 34x1 40x1 50x1 61x1 80x1 100x1 Outer Ø Cop. approx. mm weight kg/km 4,0 19,0 6,1 40,0 6,3 52,0 6,8 60,0 7,4 71,0 8,2 80,0 8,2 91,0 9,6 110,0 10,3 137,0 10,5 142,0 11,3 180,0 11,9 200,0 12,7 212,0 12,7 230,0 13,3 238,0 14,0 246,0 14,9 270,0 15,0 281,0 15,0 304,0 15,8 320,0 16,7 342,0 17,2 345,0 17,2 350,0 17,2 361,0 18,6 369,0 20,3 461,0 21,7 540,0 24,8 711,0 27,6 900,0 4,6 21,0 6,4 50,0 6,7 60,0 7,2 71,0 8,0 88,0 8,7 97,0 8,7 111,0 10,1 127,0 11,2 150,0 11,4 184,0 12,0 196,0 12,8 209,0 13,5 260,0 14,3 317,0 16,0 320,0 16,2 349,0 17,0 408,0 17,0 441,0 18,5 486,0 19,9 510,0 21,8 625,0 23,3 702,0 26,6 920,0 29,7 1120,0 Weight approx. kg/km 44,0 59,0 66,0 77,0 93,0 113,0 130,0 145,0 180,0 202,0 225,0 275,0 292,0 308,0 320,0 378,0 435,0 415,0 435,0 450,0 484,0 502,0 535,0 592,0 610,0 777,0 900,0 1210,0 1445,0 47,0 65,0 81,0 98,0 127,0 144,0 158,0 197,0 232,0 260,0 302,0 345,0 380,0 440,0 495,0 534,0 595,0 616,0 741,0 835,0 1025,0 1200,0 1440,0 1610,0 AWG-No. 18 18 18 18 18 18 18 18 18 18 18 18 18 18 18 18 18 18 18 18 18 18 18 18 18 18 18 18 18 17 17 17 17 17 17 17 17 17 17 17 17 17 17 17 17 17 17 17 17 17 17 17 17 Part no. 16074 16075 16076 16077 16078 16079 16080 16081 16082 16083 16084 16085 16086 16087 16088 16089 16090 16091 16092 16093 16094 16095 16096 16097 16098 16099 16100 16101 16102 16103 16104 16105 16106 16107 16108 16109 16110 16111 16112 16113 16114 16115 16116 16117 16118 No.cores x cross-sec. mm² 1x1,5 2x1,5 3x1,5 4x1,5 5x1,5 7x1,5 8x1,5 10x1,5 12x1,5 14x1,5 16x1,5 18x1,5 20x1,5 24x1,5 25x1,5 28x1,5 30x1,5 35x1,5 40x1,5 50x1,5 61x1,5 80x1,5 100x1,5 1x2,5 2x2,5 3x2,5 4x2,5 5x2,5 7x2,5 12x2,5 2x4 3x4 4x4 5x4 7x4 2x6 3x6 4x6 5x6 7x6 2x10 3x10 4x10 5x10 7x10 Outer Ø Cop. approx. mm weight kg/km 5,0 27,0 7,0 63,0 7,5 80,0 8,1 97,0 9,0 119,0 9,8 147,0 11,4 170,0 12,6 193,0 12,8 267,0 13,5 283,0 14,4 315,0 15,5 374,0 16,4 396,0 18,2 458,0 18,4 526,0 19,1 541,0 19,1 555,0 20,8 645,0 22,6 725,0 24,7 885,0 26,4 1100,0 30,3 1324,0 33,6 1641,0 5,8 39,0 8,3 96,0 9,0 144,0 9,8 148,0 10,9 181,0 11,9 255,0 15,8 441,0 9,8 120,0 10,6 174,0 11,5 230,0 12,7 273,0 14,0 316,0 11,7 173,0 12,5 240,0 13,8 305,0 15,3 439,0 16,9 505,0 14,7 255,0 15,7 350,0 17,3 535,0 19,2 592,0 21,4 810,0 Weight approx. kg/km 70,0 88,0 100,0 126,0 160,0 208,0 244,0 316,0 338,0 383,0 424,0 479,0 545,0 690,0 705,0 810,0 830,0 890,0 1060,0 1440,0 1700,0 2000,0 2500,0 50,0 130,0 167,0 195,0 223,0 344,0 522,0 185,0 240,0 310,0 400,0 500,0 268,0 330,0 415,0 509,0 672,0 425,0 500,0 783,0 856,0 1300,0 AWG-No. 16 16 16 16 16 16 16 16 16 16 16 16 16 16 16 16 16 16 16 16 16 16 16 14 14 14 14 14 14 14 12 12 12 12 12 10 10 10 10 10 8 8 8 8 8 Dimensions and specifications may be changed without prior notice. (RA01) A 26 A