H05VV-F/SJT300V, according to DIN VDE 0281 and UL 62

advertisement

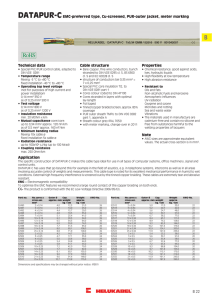

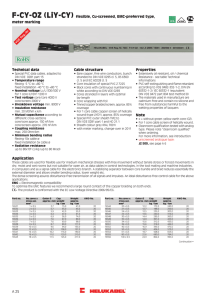

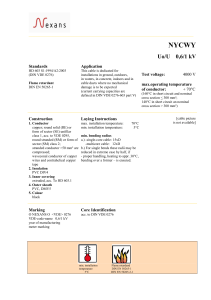

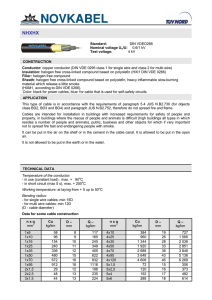

H05VV-F/SJT 300V, according to DINVDE0281 and UL62 Technical data Cable structure Properties Ⴠ PVC control cable to DINVDE0281 part5 and part2, IEC60227-5, HD21.5S3 and UL-Std.62 and CSA22.2 No.49 Ⴠ Temperature range flexing -5 °C to +70 °C fixed installation -40 °C to +70 °C Ⴠ Nominal voltage DIN VDE 0281 = U0/U 300/500 V UL 62 = U 300 V CSA = U 300 V Ⴠ Test voltage 2500 V, 5 min. Ⴠ Breakdown voltage min. 5000 V Ⴠ Spark-Test 6000 V Ⴠ Insulation resistance min. 20 MOhm x km Ⴠ Minimum bending radius approx. 7,5x cable ø Ⴠ Radiation resistance up to 80x106 cJ/kg (up to 80 Mrad) Ⴠ Bare copper, fine wire stranded conductor to DINVDE0295 cl.5, BS6360 cl.5, IEC60228 cl.5, HD383 and UL-Std.62 Ⴠ PVC insulation TI2 to DINVDE0281 part1 and class43 to UL-Std.62 (Table 50.182, UL-Std.1581) according to CSA-Std. C22.2 No49 TypeSJT Ⴠ Core identification according to colour code DINVDE0293-308, one coloured Ⴠ Green-yellow earth core, 3 cores and above Ⴠ Core stranded with optimal lay-length Ⴠ PVC outer jacket TM2 to DINVDE0281 part1 and class43 to UL-Std.62 (Table50.182, UL-Std.1581) according to CSA-Std. C22.2 No49 TypeSJT Ⴠ Jacket colour black, white or grey Ⴠ PVC self-extinguishing and flame retardant according to VDE 0482-332-1-2, DIN EN 60332-1-2/ IEC60332-1 (equivalent DINVDE0472 part804 test methodB) Ⴠ The materials used in manufacture are cadmium-free and contain no silicone and free from substances harmful to the wetting properties of lacquers Note Ⴠ G = with green-yellow earth core; x = without green-yellow earth core. Application These flexible PVC control cables, VDE-HAR-UL-CSA approved, are designed for the export and also for the export-orientated-equipment. These cables are especially suited to use for the appliance with medium mechanical stresses with free movement without tensile stress in households, kitchens and offices, also for household appliances in damp and wet areas, e.g. refrigerators, washing machines, spin-driver etc., as far as this cable is admitted to the relevant specifications of the equipment. These cables are suited to be used for cooking and heating apparatus under the condition that cable does not come in direct contact with hot parts of the apparatus and no other influences or heat. The cables are suitable for fixed installation in furnitures, partition walls, decoration covering and in hollow spaces of prefabricated building parts. They are not suitable for use in open air, in industries (also permitted to tailor workshops and of that kind) and in agriculture plants and for connecting commercial electrical tools. = The product is conformed with the EC Low-Voltage Directive 2006/95/EG. Part no. No.cores x cross-sec. mm² 28034 2x1 28066 2x1 28050 2x1 28035 3G1 28067 3G1 28051 3G1 28036 4G1 28068 4G1 28052 4G1 28037 5G1 28069 5G1 28053 5G1 28038 2x1,5 28070 2x1,5 28054 2x1,5 28039 3G1,5 28071 3G1,5 28055 3G1,5 28040 4G1,5 28072 4G1,5 28056 4G1,5 28041 5G1,5 28073 5G1,5 28057 5G1,5 Jacket colour black grey white black grey white black grey white black grey white black grey white black grey white black grey white black grey white Outer Ø approx. mm 7,3 7,3 7,3 7,8 7,8 7,8 8,6 8,6 8,6 9,4 9,4 9,4 7,9 7,9 7,9 8,4 8,4 8,4 9,3 9,3 9,3 10,4 10,4 10,4 Cop. Weight AWG-No. weight approx. kg/km kg/km 19,2 56,0 17 19,2 56,0 17 19,2 56,0 17 28,8 73,0 17 28,8 73,0 17 28,8 73,0 17 38,4 86,0 17 38,4 86,0 17 38,4 86,0 17 48,0 105,0 17 48,0 105,0 17 48,0 105,0 17 28,8 82,0 16 28,8 82,0 16 28,8 82,0 16 44,0 96,0 16 44,0 96,0 16 44,0 96,0 16 58,0 117,0 16 58,0 117,0 16 58,0 117,0 16 72,0 144,0 16 72,0 144,0 16 72,0 144,0 16 Part no. No.cores x cross-sec. mm² 28042 2x2,5 28074 2x2,5 28058 2x2,5 28043 3G2,5 28075 3G2,5 28059 3G2,5 28044 4G2,5 28076 4G2,5 28060 4G2,5 28045 5G2,5 28077 5G2,5 28061 5G2,5 28046 2x4 28078 2x4 28062 2x4 28047 3G4 28079 3G4 28063 3G4 28048 4G4 28080 4G4 28064 4G4 28049 5G4 28081 5G4 28065 5G4 Jacket colour black grey white black grey white black grey white black grey white black grey white black grey white black grey white black grey white Outer Ø approx. mm 9,2 9,2 9,2 10,0 10,0 10,0 10,9 10,9 10,9 12,2 12,2 12,2 10,6 10,6 10,6 11,5 11,5 11,5 12,4 12,4 12,4 14,1 14,1 14,1 Cop. Weight AWG-No. weight approx. kg/km kg/km 48,0 118,0 14 48,0 118,0 14 48,0 118,0 14 72,0 152,0 14 72,0 152,0 14 72,0 152,0 14 96,0 192,0 14 96,0 192,0 14 96,0 192,0 14 120,0 243,0 14 120,0 243,0 14 120,0 243,0 14 76,8 195,0 12 76,8 195,0 12 76,8 195,0 12 115,0 235,0 12 115,0 235,0 12 115,0 235,0 12 154,0 300,0 12 154,0 300,0 12 154,0 300,0 12 192,0 361,0 12 192,0 361,0 12 192,0 361,0 12 Dimensions and specifications may be changed without prior notice. (RN01) N 12 N H05VV-F/SJT 300V, according to DINVDE0281 and UL62 Technical data Cable structure Properties Ⴠ PVC control cable to DINVDE0281 part5 and part2, IEC60227-5, HD21.5S3 and UL-Std.62 and CSA22.2 No.49 Ⴠ Temperature range flexing -5 °C to +70 °C fixed installation -40 °C to +70 °C Ⴠ Nominal voltage DIN VDE 0281 = U0/U 300/500 V UL 62 = U 300 V CSA = U 300 V Ⴠ Test voltage 2500 V, 5 min. Ⴠ Breakdown voltage min. 5000 V Ⴠ Spark-Test 6000 V Ⴠ Insulation resistance min. 20 MOhm x km Ⴠ Minimum bending radius approx. 7,5x cable ø Ⴠ Radiation resistance up to 80x106 cJ/kg (up to 80 Mrad) Ⴠ Bare copper, fine wire stranded conductor to DINVDE0295 cl.5, BS6360 cl.5, IEC60228 cl.5, HD383 and UL-Std.62 Ⴠ PVC insulation TI2 to DINVDE0281 part1 and class43 to UL-Std.62 (Table 50.182, UL-Std.1581) according to CSA-Std. C22.2 No49 TypeSJT Ⴠ Core identification according to colour code DINVDE0293-308, one coloured Ⴠ Green-yellow earth core, 3 cores and above Ⴠ Core stranded with optimal lay-length Ⴠ PVC outer jacket TM2 to DINVDE0281 part1 and class43 to UL-Std.62 (Table50.182, UL-Std.1581) according to CSA-Std. C22.2 No49 TypeSJT Ⴠ Jacket colour by request Ⴠ PVC self-extinguishing and flame retardant according to VDE 0482-332-1-2, DIN EN 60332-1-2/ IEC60332-1 (equivalent DINVDE0472 part804 test methodB) Ⴠ The materials used in manufacture are cadmium-free and contain no silicone and free from substances harmful to the wetting properties of lacquers Note Ⴠ G = with green-yellow earth core; x = without green-yellow earth core. Ⴠ Colour code: 0 = RAL 5015, blue 1 = RAL 6018, green 2 = RAL 8003, brown 3 = RAL 1021, yellow 4 = RAL 3000, red 5 = RAL 2003, orange 6 = RAL 4005, violet 7 = gold 8 = dusky gold Ⴠ Please add the individual part no. for order with the identification colour code. Further colours on request. Application These flexible PVC control cables, VDE-HAR-UL-CSA approved, are designed for the export and also for the export-orientated-equipment. These cables are especially suited to use for the appliance with medium mechanical stresses with free movement without tensile stress in households, kitchens and offices, also for household appliances in damp and wet areas, e.g. refrigerators, washing machines, spin-driver etc., as far as this cable is admitted to the relevant specifications of the equipment. These cables are suited to be used for cooking and heating apparatus under the condition that cable does not come in direct contact with hot parts of the apparatus and no other influences or heat. The cables are suitable for fixed installation in furnitures, partition walls, decoration covering and in hollow spaces of prefabricated building parts. They are not suitable for use in open air, in industries (also permitted to tailor workshops and of that kind) and in agriculture plants and for connecting commercial electrical tools. = The product is conformed with the EC Low-Voltage Directive 2006/95/EG. Part no. 3110_ 3111_ 3112_ 3113_ 3114_ 3115_ 3116_ 3117_ No.cores x cross-sec. mm² 2x1 3G1 4G1 5G1 2x1,5 3G1,5 4G1,5 5G1,5 Outer Ø Cop. approx. mm weight kg/km 7,3 19,2 7,8 28,8 8,6 38,4 9,4 48,0 7,9 28,8 8,4 44,0 9,3 58,0 10,4 72,0 Weight approx. kg/km 56,0 73,0 86,0 105,0 82,0 96,0 117,0 144,0 AWG-No. Dimensions and specifications may be changed without prior notice. (RN01) N 13 17 17 17 17 16 16 16 16 Part no. 3118_ 3119_ 3120_ 3121_ 3122_ 3123_ 3124_ 3125_ No.cores x cross-sec. mm² 2x2,5 3G2,5 4G2,5 5G2,5 2x4 3G4 4G4 5G4 Outer Ø Cop. approx. mm weight kg/km 9,2 48,0 10,0 72,0 10,9 96,0 12,2 120,0 10,6 76,8 11,5 115,0 12,4 154,0 14,1 192,0 Weight approx. kg/km 118,0 152,0 192,0 243,0 195,0 235,0 300,0 361,0 AWG-No. 14 14 14 14 12 12 12 12