DATAPUR-CEMC-preferred type, Cu-screened, PUR

advertisement

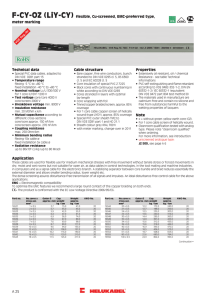

DATAPUR-C EMC-preferred type, Cu-screened, PUR-outer jacket, meter marking B Technical data Cable structure Properties Ⴠ Special PVC/PUR control cable, adapted to DINVDE0281 Ⴠ Temperature range flexing -5 °C to +80 °C fixed installation -40 °C to +80 °C Ⴠ Operating top level voltage (not for purposes of high current and power installation) 0,14 mm² 350 V as of 0,25 mm² 500 V Ⴠ Test voltage 0,14 mm² 800 V as of 0,25 mm² 1200 V Ⴠ Insulation resistance min. 20 MOhm x km Ⴠ Mutual capacitance core/core: up to 0,34 mm² approx. 120 nF/km as of 0,5 mm² approx. 160 nF/km Ⴠ Minimum bending radius flexing 10x cable ø fixed installation 5x cable ø Ⴠ Radiation resistance up to 100x106 cJ/kg (up to 100 Mrad) Ⴠ Coupling resistance max. 250 Ohm/km Ⴠ Bare copper, fine wire conductors, bunch stranded to DINVDE0295 cl.5, BS6360 cl.5 and IEC60228 cl.5 Ⴠ structure of conductors bei 0,35 mm² = 7x0,25 mm² Ⴠ Special PVC core insulation TI2, to DINVDE0281 part1 Ⴠ Cores colour coded to DIN47100 Ⴠ Cores stranded in layers with optimal lay-length Ⴠ Foil taped Ⴠ Tinned copper braided screen, approx. 85% coverage Ⴠ PUR outer sheath TMPU to DINVDE0282 part1, appendixA Ⴠ Sheath colour grey (RAL 7032) Ⴠ with meter marking, change-over in 2011 Ⴠ Chemical resistance: good against acids, lyes, hydraulic liquids Ⴠ High flexibility at low temperature Ⴠ High abrasion resistance Ⴠ Resistant to Oils and fats Non-alcoholic fuels and kerosene Atmospheric influences UV-radiation Oxygene and ozone Microbes and rotting Sea and waste water Vibrations Ⴠ The materials used in manufacture are cadmium-free and contain no silicone and free from substances harmful to the wetting properties of lacquers Note Ⴠ AWG sizes are approximate equivalent values. The actual cross-section is in mm². Application The specific construction of DATAPUR-C makes this cable type ideal for use in all types of computer systems, office machinery, signal and control units. DATAPUR-C has uses that go beyond this for example in the field of acustics, e.g. in telephone systems, intercoms as well as in all areas involving accurate control of weights and measurements. This cable type is noted for its excellent mechanical performance in humid to wet conditions. External high frequency interference is screened out by the tinned copper braiding. These cables are extremely tear and abrasive resistant. EMC = Electromagnetic compatibillity To optimise the EMC features we recommend a large round contact of the copper braiding on both ends. = The product is conformed with the EC Low-Voltage Directive 2006/95/EG. Part no. 52490 52491 52492 52493 52494 52495 52496 52497 52498 52499 52500 52501 52502 52503 52504 52505 52506 52507 52508 52509 52510 52511 No.cores x cross-sec. mm² 2x0,14 3x0,14 4x0,14 5x0,14 7x0,14 10x0,14 12x0,14 14x0,14 18x0,14 21x0,14 25x0,14 2x0,25 3x0,25 4x0,25 5x0,25 7x0,25 10x0,25 12x0,25 14x0,25 18x0,25 21x0,25 25x0,25 Outer Ø Cop. approx. mm weight kg/km 4,0 12,3 4,1 14,0 4,4 15,7 4,8 19,5 5,1 23,4 6,2 28,5 6,5 34,3 6,8 39,9 7,7 51,5 8,0 60,1 8,8 71,9 4,5 14,7 4,7 17,1 5,0 20,6 5,4 24,8 5,8 31,1 7,2 42,0 7,7 51,0 8,1 60,1 9,0 77,9 9,6 91,4 10,7 110,8 Weight approx. kg/km 21,0 25,0 29,0 35,0 41,0 54,0 64,0 74,0 93,0 108,0 128,0 26,0 33,0 38,0 44,0 53,0 79,0 92,0 105,0 128,0 148,0 175,0 AWG-No. 26 26 26 26 26 26 26 26 26 26 26 24 24 24 24 24 24 24 24 24 24 24 Part no. 52512 52513 52514 52515 52516 52517 52518 52519 52520 52521 52522 52523 52524 52525 52526 52527 52528 52529 52530 52531 52532 52533 No.cores x cross-sec. mm² 2x0,34 3x0,34 4x0,34 5x0,34 7x0,34 10x0,34 12x0,34 14x0,34 18x0,34 21x0,34 25x0,34 2x0,5 3x0,5 4x0,5 5x0,5 7x0,5 10x0,5 12x0,5 14x0,5 18x0,5 21x0,5 25x0,5 Outer Ø Cop. approx. mm weight kg/km 5,0 17,0 5,2 20,7 5,6 24,7 6,2 30,1 6,7 38,2 8,4 63,1 8,9 74,2 9,3 85,3 10,2 107,4 10,9 124,1 11,9 147,0 5,4 23,2 5,6 30,1 6,2 35,4 6,7 52,6 7,2 65,3 9,3 88,8 9,7 101,9 10,2 115,1 11,4 141,2 11,9 161,1 13,1 187,9 Weight approx. kg/km 33,0 42,0 48,0 57,0 77,0 111,0 128,0 144,0 175,0 200,0 233,0 38,0 51,0 58,0 77,0 93,0 134,0 155,0 175,0 214,0 245,0 285,0 AWG-No. 22 22 22 22 22 22 22 22 22 22 22 20 20 20 20 20 20 20 20 20 20 20 Dimensions and specifications may be changed without prior notice. (RB01) B 22