TRONIC (LiYY) flexible, colour coded to DIN 47100, meter marking

advertisement

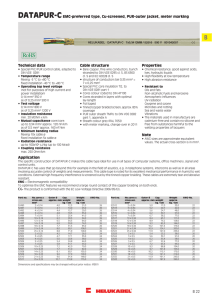

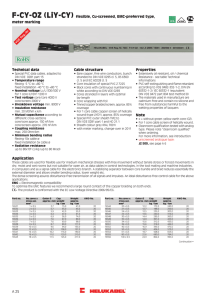

TRONIC (LiYY) flexible, colour coded to DIN 47100, meter marking B Technical data Cable structure Properties Ⴠ Special PVC data cables, adapted to DINVDE0812 Ⴠ Temperature range flexing -5 °C to +80 °C fixed installation -40 °C to +80 °C Ⴠ Nominal voltage (not for purposes of high current and power installation) 0,14 mm² = 350 V ุ0,25 mm² = 500 V Ⴠ Test voltage up to 0,25 mm² 1200 V from 0,34 mm² 2000 V Ⴠ Breakdown voltage up to 0,25 mm² 2400 V from 0,34 mm² 4000 V Ⴠ Insulation resistance min. 20 MOhm x km Ⴠ Capacitance (approx.-value) at 800 Hz 0,14 mm² 120 pF/m ุ 0,25 mm² 150 pF/m Ⴠ Inductance approx. 0,65 mH/km Ⴠ Impedance approx. 78 Ohm Ⴠ Minimum bending radius flexing 7,5x cable ø fixed installation 4x cable ø Ⴠ Radiation resistance up to 80x106 cJ/kg (up to 80 Mrad) Ⴠ Bare copper, fine wire conductors, bunch stranded to DINVDE0295 cl.5 and IEC60228 cl.5 Ⴠ Conductor make-up for 0,14mm² = 18x0,1mm 0,25mm² = 14x0,15mm 0,34mm² = 7x0,25mm Ⴠ Special PVC core insulation TI2, to DINVDE0281 part1 Ⴠ Colour coded to DIN 47100, but without colour repetition Ⴠ Cores stranded in layers with optimal lay-length Ⴠ Special PVC outer sheath TM2, to DINVDE0281 part1 Ⴠ Colour grey (RAL7001) Ⴠ with meter marking, change-over in 2011 Ⴠ Extremely oil resistant, oil-/ chemical Resistance - see table Technical Informations Ⴠ PVC self-extinguishing and flame retardant according to VDE 0482-332-1-2, DIN EN 60332-1-2/ IEC60332-1 (equivalent DINVDE0472 part804 test methodB) Ⴠ The materials used in manufacture are cadmium-free and contain no silicone and free from substances harmful to the wetting properties of lacquers Note Ⴠ AWG sizes are approximate equivalent values. The actual cross-section is in mm². Ⴠ HELUKABEL®-TRONIC is also available in paired version (e.g. HELUKABEL®-PAAR-TRONIC20x2x0,14mm²). Ⴠ screened analogue type: TRONIC-CY (LiY-CY), see page B 9 Application These cables are used for flexible use with free movement without tensile stress or forced movements in dry, moist and wet rooms but not suitable for open air, wherever the construction requirements call for a minimum outer diameter, TRONIC is the suitable cable to use. This applies especially to such areas as tool making and machine industries as well as electronic, computer, measurement and control sectors. = The product is conformed with the EC Low-Voltage Directive 2006/95/EG. Part no. 18001 18002 18003 18004 18005 18006 18007 18008 18009 18010 18011 18012 18013 18014 18015 18117 18016 18017 18018 18019 18020 18021 18022 18023 18024 18025 18026 18027 18028 No.cores x cross-sec. mm² 2x0,14 3x0,14 4x0,14 5x0,14 6x0,14 7x0,14 8x0,14 10x0,14 12x0,14 14x0,14 16x0,14 18x0,14 20x0,14 21x0,14 24x0,14 25x0,14 27x0,14 30x0,14 32x0,14 36x0,14 40x0,14 42x0,14 44x0,14 48x0,14 52x0,14 56x0,14 61x0,14 80x0,14 100x0,14 Outer Ø Cop. approx. mm weight kg/km 3,3 2,7 3,5 4,0 3,7 5,4 4,0 6,7 4,3 8,1 4,3 9,4 5,1 10,7 5,6 13,4 5,7 16,1 6,0 18,8 6,5 21,5 6,8 24,2 7,1 26,9 7,1 28,2 7,5 32,3 7,7 33,6 7,7 36,3 8,5 40,3 8,8 43,0 9,3 48,4 9,6 54,0 9,9 56,0 10,4 59,0 10,5 65,0 11,0 70,0 11,3 75,0 11,6 82,0 13,0 108,0 14,7 135,0 Weight approx. kg/km 13,0 16,0 19,0 22,0 25,0 28,0 35,0 41,0 48,0 53,0 59,0 65,0 70,0 77,0 87,0 91,0 97,0 108,0 114,0 126,0 139,0 146,0 153,0 164,0 173,0 187,0 204,0 280,0 370,0 AWG-No. 26 26 26 26 26 26 26 26 26 26 26 26 26 26 26 26 26 26 26 26 26 26 26 26 26 26 26 26 26 Part no. 18029 18030 18031 18032 18033 18034 18035 18036 18037 18038 18039 18040 18114 18041 18042 18043 18118 18044 18045 18046 18047 18115 18048 18049 18050 18051 18052 18053 18054 No.cores x cross-sec. mm² 2x0,25 3x0,25 4x0,25 5x0,25 6x0,25 7x0,25 8x0,25 10x0,25 12x0,25 14x0,25 16x0,25 18x0,25 19x0,25 20x0,25 21x0,25 24x0,25 25x0,25 27x0,25 30x0,25 32x0,25 36x0,25 37x0,25 40x0,25 42x0,25 44x0,25 48x0,25 52x0,25 56x0,25 61x0,25 Outer Ø Cop. approx. mm weight kg/km 3,8 4,8 3,9 7,2 4,3 9,6 4,7 12,0 5,3 14,4 5,3 16,8 5,7 19,2 6,6 24,0 6,8 28,8 7,2 33,6 7,6 38,4 8,1 43,2 8,1 46,0 8,6 48,0 8,6 50,0 9,4 60,0 9,5 61,0 9,5 65,0 10,3 72,0 10,9 77,0 11,3 86,0 11,3 89,0 11,6 96,0 12,0 101,0 12,6 106,0 12,7 115,0 13,3 125,0 13,9 134,0 14,3 146,0 Weight approx. kg/km 18,0 22,0 26,0 30,0 36,0 42,0 49,0 57,0 66,0 75,0 84,0 72,0 84,0 101,0 107,0 120,0 132,0 140,0 156,0 164,0 182,0 190,0 200,0 211,0 225,0 245,0 263,0 280,0 305,0 AWG-No. 24 24 24 24 24 24 24 24 24 24 24 24 24 24 24 24 24 24 24 24 24 24 24 24 24 24 24 24 24 Continuation Ⴇ B4 TRONIC (LiYY) flexible, colour coded to DIN 47100, meter marking Part no. 18055 18056 18057 18058 18059 18060 18061 18062 18063 18064 18065 18066 18067 18068 18069 18070 18071 18096 18072 18073 18074 18075 18116 18076 18077 18078 18079 18080 18081 18082 18083 18084 No.cores x cross-sec. mm² 80x0,25 100x0,25 2x0,34 3x0,34 4x0,34 5x0,34 6x0,34 7x0,34 8x0,34 10x0,34 12x0,34 14x0,34 16x0,34 18x0,34 20x0,34 21x0,34 24x0,34 25x0,34 27x0,34 30x0,34 32x0,34 36x0,34 37x0,34 40x0,34 42x0,34 44x0,34 48x0,34 52x0,34 53x0,34 61x0,34 80x0,34 100x0,34 Outer Ø Cop. approx. mm weight kg/km 16,5 192,0 18,2 240,0 4,2 6,5 4,4 9,8 4,8 13,1 5,4 16,3 5,9 19,6 5,9 22,8 7,0 26,1 7,6 32,6 7,7 39,2 8,4 45,7 8,8 52,0 9,3 59,0 9,9 65,0 9,9 69,0 10,5 78,0 10,7 82,0 10,7 88,0 11,8 98,0 11,8 104,0 12,9 118,0 12,9 121,0 13,3 131,0 14,0 137,0 14,0 144,0 14,7 157,0 15,4 170,0 15,4 183,0 16,3 199,0 18,8 264,0 21,0 327,0 Weight approx. kg/km 450,0 590,0 22,0 30,0 43,0 54,0 58,0 61,0 73,0 82,0 102,0 108,0 126,0 143,0 160,0 166,0 186,0 192,0 206,0 226,0 245,0 285,0 292,0 318,0 330,0 370,0 405,0 430,0 440,0 610,0 880,0 1050,0 AWG-No. 24 24 22 22 22 22 22 22 22 22 22 22 22 22 22 22 22 22 22 22 22 22 22 22 22 22 22 22 22 22 22 22 Part no. 18085 18086 18087 18088 18089 18090 18091 18092 18093 18103 18101 18094 18102 18095 18104 18097 18098 18099 18100 18105 18106 18107 18108 18109 18110 18111 18112 18113 No.cores x cross-sec. mm² 2x0,5 3x0,5 4x0,5 5x0,5 6x0,5 7x0,5 8x0,5 10x0,5 12x0,5 16x0,5 20x0,5 24x0,5 30x0,5 40x0,5 2x0,75 3x0,75 4x0,75 5x0,75 7x0,75 8x0,75 10x0,75 12x0,75 16x0,75 20x0,75 2x1 3x1 2x1,5 3x1,5 Outer Ø Cop. approx. mm weight kg/km 4,6 9,6 4,8 14,4 5,4 19,2 5,9 24,0 6,4 28,8 6,4 33,6 7,2 38,4 8,4 48,0 8,4 58,0 10,0 77,0 11,2 96,0 11,8 116,0 13,2 144,0 15,2 192,0 5,2 14,4 5,4 21,6 5,9 29,0 6,7 36,0 7,3 50,0 8,6 58,0 9,6 72,0 9,7 86,0 11,1 115,0 12,4 144,0 5,5 19,2 5,8 29,0 6,2 29,0 6,7 43,0 Dimensions and specifications may be changed without prior notice. (RB01) Standardised process control and visualisation of an extrusion system at our Windsbach factory. B5 Weight approx. kg/km 40,0 46,0 55,0 64,0 73,0 81,0 97,0 116,0 135,0 168,0 213,0 241,0 303,0 391,0 47,0 54,0 66,0 80,0 110,0 125,0 148,0 176,0 220,0 276,0 56,0 71,0 75,0 90,0 AWG-No. 20 20 20 20 20 20 20 20 20 20 20 20 20 20 18 18 18 18 18 18 18 18 18 18 17 17 16 16