ARTIFICIAL LIFT

Electrical Submersible Pumps (ESP)

Electrical Submersible Pumping Systems

Q-MAX™ Gas Bypass Systems

Halliburton’s Q-MAX™ Gas Bypass is the most efficient

gas mitigation product in the electrical submersible

pumps (ESP) industry. The Q-MAX Gas Bypass is

designed to increase the production of ESPs in oil wells in

which a high concentration of gas is the productionlimiting factor. The patented separation technology

enables gas bubbles to expand and separate from the

liquid more freely. Hundreds of field installations in the

largest shale oil basins have shown that Halliburton’s QMAX Gas Bypass operates in higher gas oil ratio (GOR)

conditions and draws wells to pressures that were

previously unattainable with ESPs.

Environments

• Unconventional oil wells

• High-GOR wells unable to efficiently separate gas

by using standard gas-separation equipment

• Conversion wells from gas lift to ESP

• Gas-well dewatering

• Horizontal wells

• Gas-slugging wells

Features

• Patented separation system for high-GOR environments

for drawdown maximization

The Q-MAX Gas Bypass can be installed in conjunction

with a rotary gas separator and a pump charger. This

system is available in various restrictor sizes to tailor the

most efficient range of gas separation. In combination with

a variable speed drive, the system is capable of mitigating

gas slugs in horizontal wells to an extent that has not been

possible in the ESP industry.

• Abrasive resistant construction for sandy environments

• Flexible constructions enabling efficiency maximization

at different ranges

Benefits

• Expands production range through drawdown

maximization

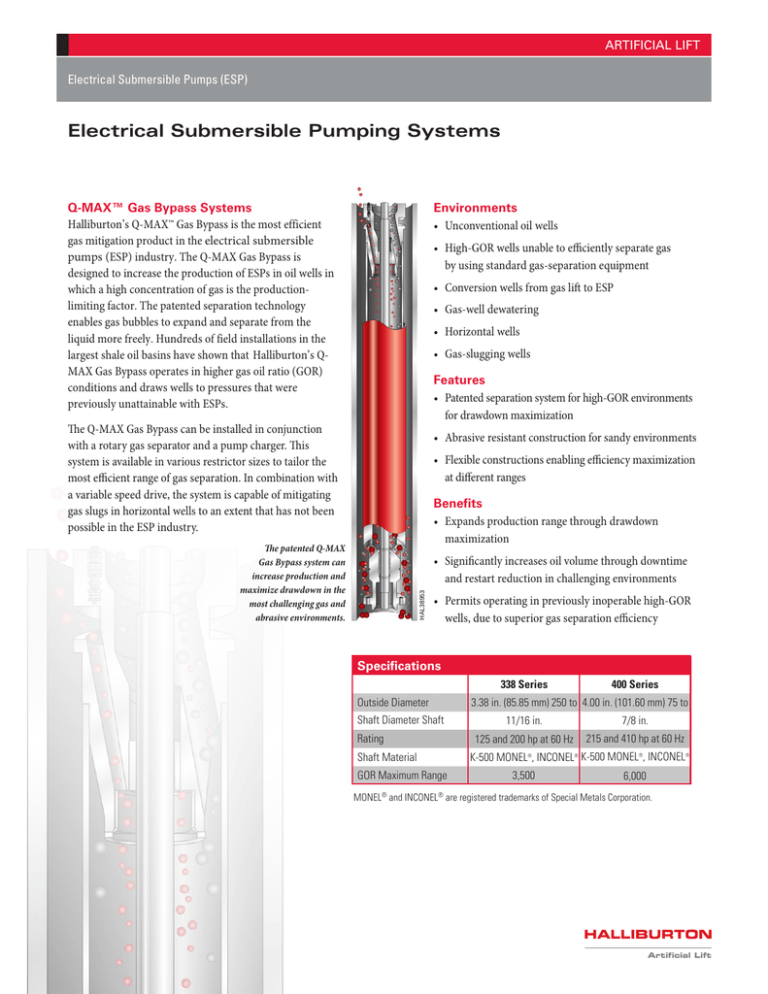

The patented Q-MAX

Gas Bypass system can

increase production and

maximize drawdown in the

most challenging gas and

abrasive environments.

HAL38953

• Significantly increases oil volume through downtime

and restart reduction in challenging environments

• Permits operating in previously inoperable high-GOR

wells, due to superior gas separation efficiency

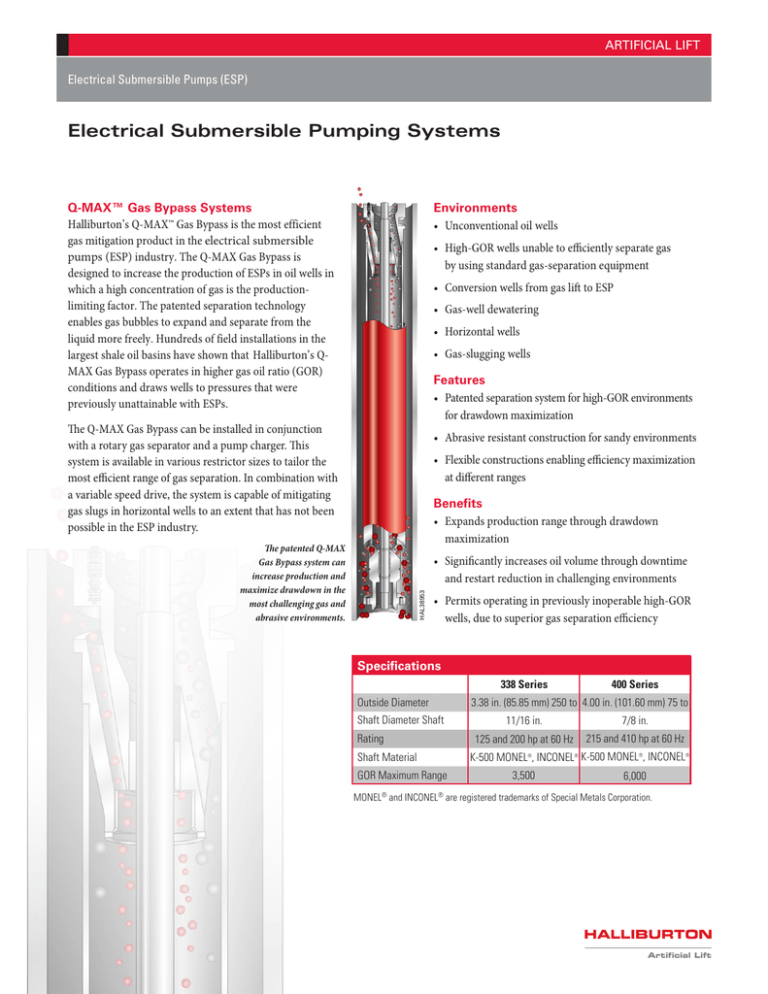

Specifications

338 Series

Shaft Diameter Shaft

Rating

11/16 in.

7/8 in.

125 and 200 hp at 60 Hz

215 and 410 hp at 60 Hz

K-500 MONEL®, INCONEL® K-500 MONEL®, INCONEL®

Shaft Material

GOR Maximum Range

®

400 Series

3.38 in. (85.85 mm) 250 to 4.00 in. (101.60 mm) 75 to

Outside Diameter

3,500

6,000

®

MONEL and INCONEL are registered trademarks of Special Metals Corporation.

Artificial Lift

ARTIFICIAL LIFT

Maximized Drawdown and Increased Production

A North American operator wanted to increase well drawdown

and stimulate gas production in a well previously produced by

gas lift where its 2,280 GOR prohibited ESP usage. Halliburton

installed the Q-MAX Gas Bypass in the ESP equipment string for

gas separation. After 12 months of operation, gas production

increased to 1,168 Mcf/d from 650 Mcf/d with pump intake

pressure drawdown of 850 psi.

Pump intake

pressure

400 600

drawdown of

850 psi

200

800

1000

0

psi

Incremental

gas volume of

80%

Separation Champion

In North America, a well’s 3,250 GOR created intermittent

operations and threatened the viability of the dual pay zone

completion. Halliburton proposed a test in which the well

would produce 30 days with a competitior’s rotary gas

separator (RGS) and then the RGS would be placed with a

Q-MAX Gas Bypass. After 20 days, the oil production of the

competitior’s RGS was 154 b/d (25 m3/d) with gas lock and

intermittent operations. The Q-MAX system’s oil production

was 95% larger at 300 b/d (48 m3/d), had continuous

operations, and drew the well down from 1,000 to 300 psi.

Pump intake

pressure

reduced

from 1,000 psi

to

300 psi

400 600

200

800

1000

0

psi

Total volume

increased

from 154 b/d

to 300 b/d

ARTIFICIAL LIFT

Delivery

All of the ESP pumps are fully integrated into Halliburton’s industry-leading,

customer-oriented global service network. Beginning at the manufacturing

plant in China, which has provided high-quality ESP systems for operators

across the globe for over a decade, and then to the Halliburton Field

Service Technician who supervises the installation and startup of the

pumps on site, Halliburton’s quality-management system helps solve

challenges at any stage of the process for operators in mature

fields, unconventional resources, and deepwater. Control

of this work flow enables continuous improvement in

the hydraulic designs so that they fit customer-specific

requirements, improve operating efficiencies, and adapt

to the dynamic conditions of the oil field.

Halliburton’s Artificial Lift offerings help operators

increase recoverable hydrocarbons by selecting the

optimal lift method over the life of the well cycle

to enhance well drawdown and provide reliable

on-stream times that can maximize revenue and

decrease costly well interventions, leading directly to

increased customer profitability. Another important

value to the customer is the ability of our Artificial Lift

representative to collaborate across other Halliburton

product lines so that the recommended solution is

optimal not only from the pump selection point of view

but also as it relates to delivering value to the reservoir.

Halliburton’s foundry provides high-quality

ESP stages and assembled/tested pumps for

a variety of customers and applications all

across the world.

Halliburton’s process entails the latest

technology in hydraulics, metallurgy,

machining, and assembly, and the

quality is assured through the rigorous

quality-management system.

Halliburton technicians accompany the

ESP systems to the field and supervise the

installation and startup to maximize success.

ARTIFICIAL LIFT

FAST

FACTS

Founded

Employees

1919

Nearly

75,000

Operational

Countries

Research

Centers

Corporate

Headquarters

80

15

Houston

Dubai

Customers

National, International,

and Independent

entities worldwide

Halliburton Locations

Halliburton Headquarters

Halliburton Research Centers

© 2013 HALLIBURTON. ALL RIGHTS RESERVED.

1

For more information, contact your local Halliburton representative

or visit us on the web at www.halliburton.com

© 2014 Halliburton. All rights reserved. Sales of Halliburton products and services will be in accord solely with the terms and conditions contained in the

contract between Halliburton and the customer that is applicable to the sale.

H011155 7/14

www.halliburton.com

Artificial Lift