Leveraging Simulation Throughout Product Design

Electro-Motive Diesel

Train Locomotives

United States of America

www.emdiesels.com

®

ANSYS Mechanical™ Solution

Overview

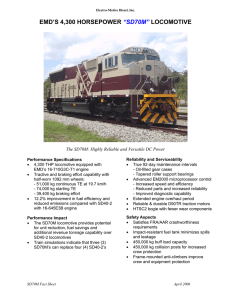

Electro-Motive Diesel (EMD) is the world’s largest supplier of diesel-electric

locomotives for commercial railroad applications including freight hauling, intercity

passenger, commuter, switching, industrial and mining. Since the early 1930s, the

company has produced more than 58,000 locomotives for customers in over 73

countries. EMD also is a global provider of diesel power engines for marine

propulsion, offshore and land-based oil well drilling rigs, and stationary power

generation. Headquarters, engineering and parts-manufacturing operations are

located in LaGrange, Illinois, with final assembly in London, Ontario, from which

products are shipped to customers around the world. One of the company’s major

new products is the SD70ACe locomotive, which uses an alternating-current drive

system to develop continuous tractive effort (pulling force) of 157,000 pounds for

pulling heavy freight trains as well as higher-speed intermodal trains. A directcurrent drive model also is available for operations requiring somewhat lower

traction levels.

EMD used ANSYS software throughout development of the SD70ACe

diesel locomotive.

Example Images here

Testimonial

“We absolutely could not design locomotives competitively without

extensive use of analysis from concept through release to

manufacturing. Physical testing on these large, complex structures

must be kept to a minimum, and we use simulation to guide the

design, verify that engineering specifications are being met, and help

validate the final design. The robust capabilities of ANSYS software

enables us to perform critical structural, vibration, modal and

durability analyses throughout the development cycle. Moreover, the

integration of modeling, solution and post-processing capabilities

within a single package helps team members study design

alternatives, perform what-if simulations, and exchange ideas

quickly. This facilitates collaboration and breaks down organizational

and functional barriers, allowing design and analysis groups to work

together toward our company goal of continuing to develop and build

the best locomotives on the market today.”

R. Thomas Scott

Manager, Noise Vibration and Structural Analysis

ANSYS Mechanical verified that the underframe structure met design

specifications for withstanding tension and compression loads of one

million pounds.

The entire locomotive was modeled to study overall product behavior

and avoid unforeseen problems during final validation tests.

Challenge

Solution

To maintain its strong leadership position, EMD

was under pressure in developing the SD70ACe

to meet demands of performance, reliability, fuel

economy, crashworthiness and operator comfort.

Locomotives must operate economically and

safely for decades under harsh conditions with a

minimum of downtime. Durability of components

undergoing repeated fatigue cycles is a major

concern. Most units log more than 1 million miles

during the first six years of operation and have a

useful life of nearly 30 years, with some major

components lasting more than 50 years in the

used equipment market. Achieving these goals

while shortening the development cycle is

particularly challenging because of significant

time and cost factors associated with running

physical tests on such large, complex machines.

Benefits

EMD met these challenges with engineering

simulation throughout design from the conceptual

stages of development. By using simulation as a

verification and validation tool, EMD minimized

physical testing while shortening development time

and optimizing structural characteristics of the

SD70ACe. ANSYS Mechanical software was a key

element in this simulation strategy. Structural analysis

was used in evaluating stress, deflection and

harmonics of components, especially in guiding

designers in sculpting the basic shape and topology of

parts early in development. The software also was

used in detailed analysis of suspension dynamics,

vibration isolation mounting of the cab and other

subsystems, as well as in the development of the

crankcase, cylinder heads, piston rods and other

reciprocating parts of the locomotive’s diesel engine.

The use of analysis throughout product development

was instrumental in helping EMD launch the

SD70ACe on schedule and within budget. ANSYS

software enabled analysts and designers to optimize

the design of individual components and assemblies

as well as the overall locomotive structure. By

studying alternative configurations, the product

development team was able to make informed

decisions on trade-offs among stiffness, weight and

natural frequency requirements, for example.

Structural analysis of both the engine and the full

locomotive played a key role in increasing fuel

efficiency while maintaining high durability and

operator comfort with minimized vibrations throughout

the structure. The new product builds on EMD’s

reliability performance of locomotives that railroads

around the world use to pull heavy freight trains.

©2005 ANSYS, Inc. All Rights Reserved.

www.ansys.com