ICIS Free Content-China PE PP Market Outlook02.indd

MARKET OUTLOOK: CHINA’S

POLYETHYLENE (PE) AND

POLYPROPYLENE (PP) MARKETS

By: Chow Bee Lin and Amy Yu

The development of shale gas as a competitive feedstock in the

US petrochemical industry has inspired the Chinese PP industry to improve competitiveness through feedstock diversifi cation

China PE, PP offer market opportunities

China’s demand growth for polyethylene (PE) and polypropylene (PP) may have slowed down in recent years, but these markets are still attracting a lot of attention from global players because the rapid capacity expansion of these products in recent years and China’s large population promise signifi cant potential opportunities for both resin suppliers and end-users.

Unit: 10,000 tonne/year

Source: ICIS Chemease

East China: 600,000 tonnes

South China: 1.9m tonnes

North China: 1.15m tonnes

Central China: 540,000 tonnes

Southwest: 450,000 tonnes

Northeast: 0 tonnes

Northwest: 2m tonnes

China’s domestic PP, PE capacity expansion to continue

China’s PE capacity increased at an average annual rate of

10.68% from 2007 to 2013, with the annual capacity rising to 12.885m tonnes in 2013 from 7.115m tonnes in 2007.

According to ICIS Chemease’s data, China’s total annual capacity is expected to increase to 15.385m tonnes in

2017.

Enquire about the China

Polyolefi ns Annual Study –

www.icis.com/enquirechina

Similarly China’s PP capacity also recorded growth, expanding at an average annual rate of 15.28% in

2007-2013. The domestic PP capacity was estimated at

12.825m tonnes in 2013, up from 7.192m tonnes in 2007.

The average annual capacity growth rate in 2007-2013 was estimated to be 14.84%.

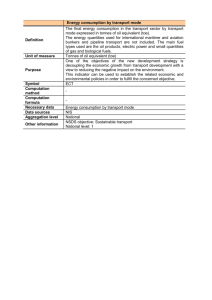

China PP capacity, output and operating rates

2013-2017 (unit: 10,000 tonnes/year, %)

2013 2014 2015 2016 2017

1305.3

1522.3

1780.3

1900.3

1935.3

Granule effi cient capacity

Total effi cient capacity

Utilisation rate

Output forecast

Source: ICIS Chemease

1477.3

1694.3

1952.3

2072.3

2107.3

88% 81% 78% 83% 89%

1303.4

1379.9

1527.3

1724.8

1866.8

Over 95% of PE capacity in China is integrated with ethylene crackers. Sinopec and PetroChina are the two major producers, with their production accounting for the whole supply chain, including feedstock, PE and joint cracking products. The development of shale gas as a competitive feedstock in the US petrochemical industry has inspired the Chinese PP industry to improve competitiveness through feedstock diversifi cation. A number of coal-to-olefi n (CTO) and propane dehydrogenation (PDH) plants are scheduled to be built over the next fi ve years.

These new plants will be cost-competitive in a high-crudeoil-price scenario.

The China primary energy structure features rich coal, lean oil and less gas, and its available coal reserves are about

1,000bn tonnes. Thus, development of the CTO technology is in line with this energy structure. Currently, China has become the largest coal producer and consumer in the world, and coal will remain its major energy resource for a long way into the future. Domestic coal prices in China are lower than international prices, and this offers low economic

© Copyright 2014 Reed Business Information Ltd. ICIS is a member of the Reed Elsevier plc group.

ICIS accepts no liability for commercial decisions based on the content of this report

MARKET OUTLOOK: CHINA’S POLYETHYLENE (PE) AND POLYPROPYLENE (PP) MARKETS

benefi ts to domestic coal producers. The development of the coal chemical industry will turn coal into chemical products with high added value and this will therefore help coal producers to signifi cantly increase their economic benefi ts.

The commissioning of Shenhua Baotou Coal Chemical’s

CTO unit in 2010 indicated the success of the coal-tomethanol technology in China, and paved the way for the development of coal to basic organic chemical production.

Coal to chemical technology has driven the development of the China coal chemical industry, and its strategic signifi cance has been in the easing of China’s petroleum shortages.

Although naphtha-based PE will dominate the domestic market in the short term, coal/methanol-based PE capacity is expected to account for 11% of the China’s total PE capacity by 2017 because of its high returns. PDH capacity will account for 9.3% of China’s total PP capacity by 2017, according to ICIS Chemease’s data.

However, there is scepticism about the viability of the upcoming CTO and PDH projects because of challenges such as environmental concerns, the availability of capital and the supply of coal and propane. A number of local producers have plans to build several coal-to-olefi ns (CTO) plants in China over the next fi ve years, but they may encounter challenges such as stringent environmental policies and a lack of investment capital. China’s CTO capacity is expected to account for 11.11% of its total PE capacity in 2017, up from 2.99% in 2012.

China continues to depend on PE, PP imports

China’s PE imports stood at 8.816m tonnes in 2013, which accounts for around 43.31% of its total demand. China has become a major polyolefi ns market in the world as the other key markets are still reeling from the impact of the uncertain global economic recovery, and the lingering

European sovereign debt crisis. China still relies on imports as its domestic facilities cannot meet its growing demand.

Imports are expected to account for 37.3% of China’s total

PE demand by 2017.

Import

Export

Chinese PP import and export forecast

(10,000 tonnes/year)

2013

485

14

2014

480

18

2015

465

22

2016

425

23

2017

430

25

Source: ICIS Chemease

Enquire about the China

Polyolefi ns Annual Study –

www.icis.com/enquirechina

China imported 5.0139m tonnes of PP in 2013, down by 2.36% year on year, which was much higher than the previous year’s growth rate of 0.2%. The global PP market outlook has been clouded by uncertainty in the global economy since the 2008 global fi nancial crisis. Amid the uncertainty, China plays an increasingly important role as the world’s production base and major petrochemical market. China is expected to import more PP resins in the coming years, with the bulk of the supply coming from the

Middle East, where PP capacity expansion is expected to be driven by competitive feedstock costs.

China PE, PP demand growth to continue

China’s apparent PE demand was at 20.355m tonnes in 2013, up by 13.17% on a year-on-year basis, and its apparent PP demand was at 18.179m tonnes in 2013, up by 9.58% year on year. China plays an important role in the global PE and PP markets, with an increasing number of global suppliers vying for a share of the Chinese market.

China’s key PE applications are plastics fi lms, household wares and plastics packaging material. Margins in these application sectors are thin because of fi erce competition.

Hence, most plastics processing factories are located close to large-population areas. Some plastics processing producers moved to southwest China and central China in recent years because of the higher wages, rental and taxes in coastal areas. The plastics processing sector in south

China has shrunk signifi cantly mainly because Chinese exporters have suffered from the appreciation of the

Chinese currency and reduced export orders.

East China has been the largest PE market in the country for many years, with PE consumption increasing rapidly from 2005. Consumption is estimated to reach around

6.57m tonnes in 2012 (36% of total national consumption).

South China is the second largest PE market in the country. Consumption in south China was estimated to reach around 4.90m tonnes in 2012 (27% of total national consumption). Local export-oriented producers were heavily hit by the 2008 European debt crisis.

© Copyright 2014 Reed Business Information Ltd. ICIS is a member of the Reed Elsevier plc group.

ICIS accepts no liability for commercial decisions based on the content of this report

MARKET OUTLOOK: CHINA’S POLYETHYLENE (PE) AND POLYPROPYLENE (PP) MARKETS

PE consumption in north China was estimated to reach

2.47m tonnes in 2012 (14% of total national consumption).

PE applications in north china are mainly agricultural fi lms and plastic pipes. Most agricultural fi lm producers are in north China, particularly in Shandong, Hebei and Henan.

Shandong has one of the three largest vegetable farms in the world. Shouguang, Zibo and Yantai are also production bases of agricultural fi lms. The agricultural fi lms industry in north China will produce more medium- and high-quality products, optimise its industry structure and improve its product quality, as the country’s agricultural sector will increasingly move towards environmentally friendly, energysaving and functional agricultural fi lm products. As a result of urbanisation, plastic pipe production will become a key industry in north China. For example, development of the

Bohai Sea region will create a large demand for various types of plastic pipes.

Wider application fi elds for PP resins

A slowdown in the Chinese economy has affected demand for plastics since 2012. But the country’s PP consumption has continued to increase steadily with the development of a wide range of new applications. The new applications in

PP emphasise four key property requirements: high melt strength, high crystallisation, high-melt fl ow rate and high transparency. PP resins with such properties are replacing other plastics resins in many applications. Local producers, including Shanghai Petrochemical, Shanghai Secco and

Yanshan Petrochemical, have responded to the new application trends by developing the capability to produce

PP resins with high transparency properties. PP producers in China are incapable of producing resins with high melt strength or high crystallisation because of a lack of technical knowledge.

Greater infl uence from LLDPE, PP futures

Correlations between PP futures and PP spot price

Unit: CNY/tonne Price gap

11,000

10,900

10,800

10,700

10,600

10,500

10,400

10,300

10,200

10,100

10,000

700

600

500

400

300

200

100

0

28 Feb 1 Mar 2 Mar 3 Mar 4 Mar 5 Mar 6Mar 7Mar

PP futures settlement prices Price gap = Domestic spot PP Flat Yarn prices - PP futures settlement prices

Source: ICIS Chemease/Dalian Commodity Exchange

Enquire about the China

Polyolefi ns Annual Study –

www.icis.com/enquirechina

As a result of urbanisation, plastic pipe production will become a key industry in north China

Linear low density polyethylene (LLDPE) futures trades on the Dalian Commodity Exchange (DCE) have gained signifi cant momentum in recent years, exerting greater infl uence on the sentiment in the PE spot physical market.

Many local traders have started activity in LLDPE futures, a market which often sees marked swings in line with the volatile domestic and international fi nancial markets. DCE launched a PP fl at yarn futures contract on 28 February

2014 and transaction volume had increased quickly over the fi rst few weeks of trading.

* Information and data used for this article were taken from ICIS annual

studies: China Polypropylene (PP) Annual Study and Polyethylene

(PE) Annual Study

In-depth analysis and forecasts for China’s PE and

PP markets (2013-2017)

Each in-depth study offers detailed insight into individual petrochemical markets in China and answers important questions about the future. The annual studies gives you a better understanding of domestic market developments and how they impact your business plans by providing you with data and analysis of price trends, as well as supply and demand, cost and arbitrage, and forecast data up to 2017.

The studies serve as a comprehensive source of detailed data that helps support your decisions on production and investment as well as identify opportunities and risks in China’s domestic PP and PE markets.

Enquire about the China Polyolefi ns Annual Study

– www.icis.com/enquirechina

© Copyright 2014 Reed Business Information Ltd. ICIS is a member of the Reed Elsevier plc group.

ICIS accepts no liability for commercial decisions based on the content of this report