Electric Propulsion System for Small Spacecraft

advertisement

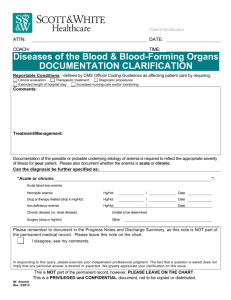

SP2012_2362672 The Design, Development, Manufacture and Test of an Electric Propulsion System for Small Spacecraft Mark Pollard Surrey Satellite Technology Ltd Guildford, United Kingdom, m.pollard@sstl.co.uk Dimitrios Lamprou Surrey Space Centre, University of Surrey Guildford, United Kingdom, d.lamprou@surrey.ac.uk successful RapidEye, Proba-2 and NigeriaSat-2 spacecraft. The propulsion system acted as a test bed for new processes and techniques, and this included the development of a Titanium Metal Matrix Composite tank by TISICS Ltd, although this was not subsequently integrated for this mission. Abstract This paper discusses the design, development, manufacture and test of the electric propulsion system manufactured by SSTL for the UK technology demonstration spacecraft, TechDemoSat-1 (TDS-1). The spacecraft is funded by TSB and SEEDA to serve as an orbital test bed for the emerging technologies from the UK space industry. Acronyms AIT ALM BN COTS CoG EVT FM HCT MEOP MMC OBC PPU QM TechDemoSat-1 does not require a propulsion system to complete the mission; however SSTL opted to design and build the system with internal funds to test new technologies and processes. The SSTL design approach has proved valuable for this task, with the spacecraft schedule lasting less than two years between concept and launch. The TDS-1 propulsion system is equipped with two thrusters; one is an SSTL resistojet and the other is a Hollow Cathode Thruster (HCT) developed by the SSC. This complimentary approach of a resistojet and an efficient electric thruster is an important development allowing small spacecraft to achieve more complicated missions. These two thrusters are useful together, with the resistojet providing a higher thrust for shorter manoeuvre times and the HCT providing low thrust and more efficient operations. Whilst the design of the HCT is not currently optimised, it promises to provide good propulsive efficiencies for small power limited spacecraft and forms an essential component in several other efficient electric propulsion devices in development at the SSC. The development of this unit has included the control electronics, which are also designed to be applicable to a variety of electric thrusters currently in development. SEEDA SSC SSTL TDS-1 TIG TSB Assembly, Integration and Test Additive Layer Manufacturing Boron Nitride Commercial Off The Shelf Centre of Gravity Environmental Test Flight Model Hollow Cathode Thruster Maximum Expected Operating Pressure Metal Matrix Composite On-Board Computer Power Processing Unit Qualification Model South East England Development Agency Surrey Space Centre Surrey Satellite Technology Ltd TechDemoSat-1 Tungsten Inert Gas Technology Strategy Board TechDemoSat-1 The TDS-1 spacecraft is a technology demonstration satellite based on SSTL’s highly capable SSTL150 platform, which formed the core of the RapidEye constellation. TSB and SEEDA have funded the heritage platform and mission, and companies and institutions across the UK are supplying payloads at their own cost in order to obtain flight heritage and display the novel space The feed system is based on the heritage SSTL xenon feed system as flown on the highly 1 technologies available in the UK. The developments on board range from radiation and cosmic ray detectors, to a new on-board computer, to a de-orbit device being developed to help reduce space debris, and a payload to monitor shipping and the maritime environment. A rendering of the TDS-1 spacecraft can be seen in Figure 1. • • • • Qualify a new tank weld geometry Qualify a new system welder Develop an in-house cleanliness verification facility Develop the test and verification approach required for electric propulsion systems Design and System Architecture The propulsion system design is largely based on SSTL’s heritage xenon propulsion system as used on Beijing-1, RapidEye, Proba-2 and NigeriaSat-2. A schematic of the propulsion system can be seen in Figure 2. It comprises an electronic bang-bang regulation system, using feedback from the low pressure transducers, to control series-parallel solenoid valves in order to reduce the nominal 80barA tank pressure to a nominal 1barA plenum pressure. This is used to feed a resistojet and the HCT and can be adjusted to feed both thrusters as described below. Figure 1: TDS-1 Spacecraft SSTL is able to utilise the platform to test new product developments, and the propulsion system is one such example. SSTL and the SSC have invested in the system to prove the complimentary capability of a high thrust resistojet and a low thrust, higher efficiency electric thruster and test new processes and technologies. This will help enhance the capabilities of small propulsion systems and enable new missions for small satellites. Propulsion System Requirements The following is a list of internal requirements that were placed upon the propulsion system: • Adapt and subsequently prove the compatibility of a typical SSTL feed system with an electric thruster • Prove the complimentary operation of a high thrust resistojet alongside a high efficiency electric thruster being fed by a common feed system • Advance the HCT to a flight status • Advance the HCT PPU to a flight status • Gain flight heritage on the HCT and electronics (also utilised by other electric thrusters in development at the SSC) • Accurately characterise the performance of the HCT during in-orbit operations and correlate with ground test data • Qualify a new tank manufacturer Figure 2: TDS-1 Propulsion System Schematic With two thrusters being fed, thruster isolation valves were required. The HCT also required a reduced flow rate, compared to the resistojet, which was achieved using a COTS sintered metal 2 flow restrictor press-fit in a manifold. The system had to fit in the volume of the original SSTL150 propulsion system. Due to the additional valves, pipework and electronics required to support the HCT, a new tank and a new system design was required. Tank With the system volume defined by the available space in the platform, the tank was made as large as possible whilst allowing the system to fit in the space available. This provided a tank which could hold 1.75kg of xenon propellant. This would allow enough propellant to prove the HCT and collect performance data, whilst allowing a useful propulsive capability to be available for the spacecraft. The tank was designed with operator safety as the most important factor, and due to the condensed schedule it was essential the design did not fail during testing. This has resulted in an overdesigned tank, but one that is compatible with a tight schedule and low cost. There are two independent propulsion controllers, with propulsion controller 0 responsible for the resistojet string and propulsion controller 1 responsible for the HCT string. In failure scenarios, both controllers can be operated at the same time meaning either controller can regulate the pressure from tank to plenum for either thruster. The propulsion feed system can be seen in Figure 3. Heritage components were used where possible. These included a fill/drain valve manufactured by SSTL from a COTS Swagelok component, a COTS Swagelok filter, COTS temperature sensors, and aerospace quality pressure transducers procured from Kulite Sensors. SSTL decided to use the opportunity to qualify a new tank manufacturer, and to qualify an improved tank weld geometry. The tank was machined from two solid billets of titanium 6Al-4V and these were joined using an electron beam weld. A qualification tank was produced and subjected to a test campaign which included vacuum cycling, Maximum expected operating pressure (MEOP) cycling, proof pressure cycling, leak checking and pressurisation to >4 times MEOP. The qualification tank passed all of this testing and was shown to be suitable for use. The tank will undergo vibration at spacecraft level. The opportunity also arose to work with TISICS Ltd to develop a tank compatible with the system but manufactured from Titanium metal matrix composites (Ti MMC), rather than the standard monolithic titanium tanks usually flown. The primary aim of TDS-1 is to demonstrate new technologies in the UK which would have a direct benefit to future satellite applications, and this was one such opportunity. Future Ti MMC tanks can provide lighter tank solutions for the same propellant mass, or can allow more propellant to be stored at higher pressures for the same mass and volume of tank. Figure 3: TDS-1 Propulsion Feed System The resistojet used is a standard SSTL product which uses a 30W heater to provide energy to the propellant and increase the specific impulse relative to a cold gas system. It is mounted on a bracket which allows both the pitch and the yaw angles to be adjusted. This allows the resistojet to be aligned such that the thrust vector points through the spacecraft mission average CoG. TISICS manufactured two qualification tanks and a flight tank. The first qualification tank passed the qualification tests which were the same as for the standard machined tank (described earlier). The second qualification tank was vibrated in addition to the other testing, prior to the pressurisation to >4x MEOP, and this also passed. However, it was decided to integrate the standard machined titanium tank into the propulsion system. This decision was taken as the first qualification model The solenoid valves used on the system were spare valves from previous missions and were manufactured by Marotta UK, now Ampac-ISP. These valves have been flight qualified on the Proba-2 propulsion system. 3 The single spiral heater employed for the laboratory HCT has been replaced by two bifilar spiral heaters (primary and redundant). A 0.3mm diameter tantalum wire is used for increased heater robustness at the expense of increased current requirement to reach temperature. Thicker wire diameters of up to 0.5mm were tested but they proved difficult to form in the required dimensions. Hot to cold heater junctions are formed by swaging the wire in 0.5mm internal diameter, 0.8mm outer diameter tantalum tubes. The resulting conductor has a 0.8mm outer diameter, which reduces heat dissipation on the section of heater wire outside the ceramic heater body and increases heater life and mechanical robustness. Heater leads for power return are terminated on the cathode tube by resistive welding. Heater live wires are connected to insulated interfaces inside the HCT by TIG welding to bolts. burst at a lower pressure than expected (but still >4 x MEOP) and due to the tight schedule the cause could not be fully determined by the time system manufacture was occurring. The project has allowed TISICS to advance their designs and gain some important experience and understanding, and has brought the prospect of TI MMC tanks closer. More information regarding the Ti MMC tank can be found in [2]. Hollow Cathode Thruster The HCT is being developed in a joint SSC/SSTL venture. The HCT operation is based on field enhanced thermionic emission. A low work function insert is heated by an external heater to ~1100ºC. Xenon propellant supplied to the HCT is ionised by electrons emitted from the cathode and plasma is formed internally in the HCT between the insert (ground or ‘cathode’) and an anode electrode (keeper). The anode electrode is kept at positive voltage by the PPU and current is drawn from the insert via the plasma formed. The discharge to the keeper electrode is self-sustained once initiated, i.e. no heater power is needed. The heater body is manufactured from boron nitride (BN) AX05 as in the laboratory HCT. The keeper is made from molybdenum, the cathode tube is tantalum, and the ceramic insulations on the cooler parts of the HCT are machined from BN Grade M26 for increased mechanical performance. A radiation shield made out of 0.025mm tantalum foil encapsulates the heater reducing the heater power requirement to initiate the discharge. The radiation shield is resistive welded on the cathode tube-heater assembly. The HCT can provide increased specific impulse capability for small satellites with the trade offs being a higher power consumption and a lower thrust than a resistojet. The HCT requires 50-60W during heating and 40-60W during discharge at nominal conditions. Higher power levels will be ground-tested. Tests performed on the ground indicate that the HCT will provide 85s of specific impulse and 1.5mN of thrust [3]. To ensure the thruster is accurately characterised in orbit despite of the low thrust produced, the HCT is off pointed from the spacecraft centre of gravity. The performance will then be calculated based on disturbance torques observed off of the reaction wheels. This will provide a more accurate characterisation of the thruster performance compared to measuring performance from the orbital change exerted on the spacecraft. Figure 4: FM HCT (right) and QM1 HCT (left) The HCT on TDS-1 is an iterative development based on the SSC laboratory model that has undergone testing and performance evaluation [3] [4]. The thruster operates in the enclosed keeper configuration with a keeper/cathode separation of 1 mm and utilises a porous tungsten insert impregnated with earth metal oxides, often referred to as a type S insert. The FM design ensures survivability during launch and maximises thruster operating lifetime. The QM1 and FM HCT’s can be seen in Figure 4. They are shown in their assembled state with the feed pipes and fittings attached. The flight harness is shown but has not been attached to the electrical terminals. Thermocouples are attached at various positions for ground testing to characterise the heat loss. The conductive path of the HCT to the spacecraft is minimised by use of Ti 6Al-4V brackets. The 4 bracket interfacing directly to the HCT is provided by EADS Innovation Works. It has been manufactured using Additive Layer Manufacturing (ALM) giving flight heritage to a component made by this manufacturing process. An intermediate wedge between the ALM HCT bracket and the spacecraft is also made from Ti 6Al-4V in order to ensure low thermal conduction to the spacecraft during HCT operation and high stiffness during launch. various back up modes to be employed only in the case of component failure. Figure 5 shows a graph of the bang-bang pressure regulation with the system reducing the tank pressure of 80 BarA down to an average plenum pressure of 1.5 BarA. The plenum pressure limits for this test were 1.0 BarA lower limit and 2.0 BarA upper limit. Manufacture As per SSTL’s standard low cost, heritage approach, the system was manufactured using hand TIG welded joints and 37 degree AN flare fittings. The tubing used is commercial grade stainless steel tubing. As the TDS-1 propulsion system is a test bed, a new supplier was used and qualified for the welding. As part of investment at SSTL, it was decided to bring the precision cleaning of propulsion hardware in house to lower costs and provide more flexibility and control during the manufacture of our systems. The TDS-1 propulsion system was used as a test bed to establish the procedures required and successfully prove the set-up. Figure 5: Bang-bang pressure regulation With the feed system operation confirmed, the feed system and propulsion controller were temporarily integrated with the spacecraft to allow the operation using the OBC to be verified at an early stage. Propulsion System Test Approach The testing was split into several elements: • Component level testing • Propellant feed system and resistojet testing (including propulsion controller) • HCT and HCT PPU testing • HCT and feed system integrated testing • Propulsion system check-out at spacecraft level HCT and HCT PPU Testing Three HCTs were manufactured to provide a flight model (FM) and two qualification models (QMs). One of the QMs acts as a flight spare. The QMs were used to characterise the thruster performance given a range of input parameters, prove the design through vibration and shock tests, and prove the performance did not change pre and post vibration to qualification levels. The FM HCT was subjected to an acceptance test including performance measurements pre and post acceptance vibration. This allowed the performance envelope of the FM to be correlated to the QM performances, allowing less firing time to be accumulated on the FM at ground testing. Due to the low vacuum requirement for HCT operation, the HCT is not fired at spacecraft level EVT. Risk mitigation activities during the spacecraft test campaign include propulsion system communication with the propulsion module and HCT PPU processors and HCT PPU health-check using dummy loads. Propellant Feed System The HCT PPU was debugged and verified to work effectively as a power supply for the HCT starting sequence and steady state operation using dummy loads. For the topology of the HCT PPU, see [3]. The following verification tests were performed on The propulsion feed system was tested on its own, with full functionality testing to verify pressure regulation for both the resistojet and the HCT. This included characterising the feed system at a range of tank pressures, and testing the system using 5 the HCT PPU each time a component modification was performed and before the HCTs were fired: • High Voltage supply (150V) was verified to operate at 150V constant voltage mode and 0.5A constant current mode for the start-up of the HCT • HCT start-up spike on the High Voltage line was tested by shorting live to ground • Heater Supply was verified to operate at 18V constant voltage mode and up to 6A constant current mode • Low voltage supply was verified to operate at 30V constant voltage and up to 6A • constant current • Low voltage supply and heater supply were verified to work in series • All PPU switches were checked • Telemetry and telecommands were verified to be received and acknowledged • Data logging achieved on PC with a CAN card These series of tests mitigated the risks to the integrated testing of the HCT and HCT PPU with the rest of the propulsion system of TDS-1. HCT – Propulsion Module Integrated Testing Integrated testing of the HCT with the propulsion module is performed at the SSC vacuum chamber facilities and simulates as accurately as possible the operation of the propulsion system while in flight. An important modification in the firing sequence between ground and orbit is the time that the propellant starts to flow. During flight operation of the HCT, the propellant flow starts 1020s before the discharge starts, during the heating of the HCT. In ground testing the propellant flows before the heating of the HCT starts to reduce the risk of poisoning the insert. Several propellant flows between 10 and 25sccm are to be tested to ensure that the HCT can start under any nominal conditions. Lower flow rates will be tested on the QMs using a laboratory set-up. The ability of both the prime and redundant heaters to start the HCT was tested on both QMs. The start time averaged at 300s with a +/-5% variation. The HCTs were then fired using laboratory power supplies to fully characterise the performance. The objectives of the integrated tests are as follows: • Verify tank purging and filling procedures • Correlate the flight system flow with the laboratory xenon flow controller • Confirm maximum and minimum regulation pressures to be used when operating the HCT for nominal firings • Perform firings at different flow rates to the HCT • Confirm the HCT characterisation with ground equipment is equivalent to the flight representative operation • Characterise conductive heat loss through HCT secondary structure • Confirm the flight firing sequence and scripts to be used The HCT PPU was used to fire the HCTs in the SSC vacuum chambers using a laboratory mass flow controller. In Figure 6 the heating-start up and thrusting sequences are shown. In the case depicted the QM2 is fired with a heat up time of 330s. The total time is 2000s (34 minutes) and various throttle levels are commanded to the PPU. The response of the HCT and PPU are nominal and are annotated. The test results of the mass flow correlation of the propulsion feed system with the laboratory xenon flow controller are shown in Figure 7. Due to the much lower flow rates required by the HCT compared to the resistojet, the regulation band to be utilised is smaller, with a difference of just 0.10 bar between the upper and lower plenum limits. This provides a stable flow rate for the HCT to operate effectively. The resisojet requires a higher flow rate so wider regulation bands are used. This of course helps to reduce the number of cycles on the valves. The average plenum pressure can be modified to change the flow rate and thus the thrust obtained, and the regulation band can be reduced Figure 6: Telemetry from the HCT PPU during a full firing sequence with QM2 6 or widened. As the graph shows, the system is highly adaptable and configurable in flight to allow a large range of flow rates to be utilised as appropriate. Figure 8: HCT profile and feed pressure profile during an integrated test with the TDS-1 feed system Figure 7: Selected plenum pressure regulation profiles for the HCT and resistojet For the integrated testing, the propulsion controller and HCT PPU are to be controlled through a CAN card and using scripts to maximise autonomy, capture the flight system telemetry and prove the in-orbit firing operation. To ensure the safety of the HCT, a dry run through was conducted using the feed system and dummy loads connected instead of the HCT. The run through was conducted successfully, allowing the HCT to be connected. Several firings were then conducted using the TDS-1 flight feed system coupled with the HCT and HCT PPU. All firings were successful, and were performed at three different average flow rates to characterise the thrusters, with this data then being correlated to data obtained during earlier firings in the laboratory set up. A graph of the first firing can be seen in Figure 8, with Figure 9 shows a close up of the firing. The plenum pressure was cycled between 2.45 BarA and 2.55 BarA, providing a flow rate of ~20 sccm of xenon. The propellant flow occurred throughout the heating and cooling cycle for this ground test to ensure the cathode was not poisoned. It took 51/2 minutes to heat the cathode until discharge occurred, and this was followed by a 41/2 minute firing. The system operated as expected in all firings. The integrated testing was proved to be successful and the system was shown to operate as designed. Figure 9: Close up of the HCT profile during the initial firing shown in Figure 8 AIT/EVT implications The cathode insert in the HCT is sensitive to poisoning at elevated temperatures, unless vacuum is of 1x10-5 mbar or less. This means the HCT cannot be tested during AIT or even EVT when there is a risk that the local pressure around the insert may remain this high. Sub-system level testing is critical to prove the system operation. The propulsion feed system itself can still be tested during AIT and EVT, including short resistojet firings during the cold and hot cycles at EVT, and by exhausting a small amount of propellant through a cold HCT. To maximise the components that can be tested at AIT/EVT stages, the HCT PPU outputs will be sourced to dummy loads simulating the various HCT firing phases. This only leaves the HCT thruster itself which is not 7 tested during the AIT and EVT phases. This is a standard approach for electric propulsion systems. through AIT and EVT to test as much of the system as possible. Future TDS-1 has provided a test mission to develop new propulsion technologies and processes which will enhance the propulsion systems built by SSTL. The system can be advanced for future missions. SSTL has designs for a high performance resistojet which can achieve ~60 seconds of specific impulse. These would allow the system to be improved providing an even more capable electric propulsion system for small power limited spacecraft. Acknowledgements The authors would like to acknowledge the following for their help with this project: Andrew Devereaux, Mick Drube, David Gibbon, Alan Hill, Dr. Sabrina Pottinger, Dr. Aaron Knoll, Theodoros Theodorou, Lourens Visagie, Dr. Sarah Nash. The HCT can be further optimised to improve performance, especially in the terms of specific impulse. Lower mass flow rates and power input to the HCT are planned for testing. Life testing of the HCT must also be performed, in terms of discharge time and heater cycles. Ground testing can identify areas of improvement in the start-up and operating procedures to maximise the lifetime of the HCT in orbit. References [1] The Design, Build, Test and In-orbit Performance of Low cost Xenon Warm Gas Propulsion Systems, M. Pollard, Space Propulsion 2010, San Sebastian, Spain [2] Fibre reinforced titanium matrix composites for xenon propellant tanks, S. Kyle-Henney, M. Pollard, Space Propulsion 2012, Bordeaux, France The HCT itself is an integral part of further electric thruster developments currently being undertaken at the SSC and the TDS-1 mission is allowing flight heritage and data to be gained which will derisk future developments. The electronics design will also be fed into these developments, allowing small capable power electronics to be proven for the family of electric thrusters at the SSC. [3] Hollow cathode thruster design and development for small satellites. D.Lamprou et al. International Electric Propulsion Conference, Wiesbaden, Germany. [4] Impact of plasma noise on a direct thrust measurement system. Review of Scientific Instruments, 83, 033504 (2012); doi: 10.1063/1.3692740 Conclusion The TDS-1 spacecraft has provided an important flight opportunity which SSTL and the SSC have taken advantage of. The standard SSTL xenon feed system has been adapted to provide propellant to both a resistojet and a new electric thruster. The result is a highly complementary system using a high thrust resistojet coupled with a more efficient electric thruster which allows small power limited spacecraft to have more propulsion capability and flexibility. The system can be further improved for small spacecraft with the addition of a higher performing resistojet and further optimisation of the HCT. The system is also applicable to larger spacecraft where there is more power available, potentially allowing a resistojet to be coupled with a higher power, higher performing electric thruster. [5] Additive layer manufacturing for integrated propulsion systems, S. Nash, C. Turner, P. Shaw, V. Lappas, Space Propulsion 2012, Bordeaux, France [6] Design and development and In-Flight Performance of a Low Power Resistojet Thruster, D. Gibbon, A. Baker, D. Nicolini, D. Robertson, C. Dye, 39th AIAA Joint Propulsion Conference & Exhibit, Huntsville, Alabama [7] A Xenon Resistojet Propulsion System for Microsatellites, I. Coxhill, D. Gibbon, 41st AIAA Joint Propulsion Conference & Exhibit, Tucson, Arizona The project has provided a mission on which the limitations of having an electric thruster can be solved, for instance the more extensive component and sub-system level testing that was required to prove the system, and the dummy loads required 8