Calculating phase diagrams involving solid

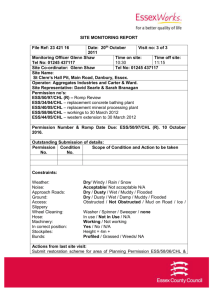

advertisement

J. metamorphic Geol., 1998, 16, 577–588

Calculating phase diagrams involving solid solutions via non-linear

equations, with examples using THERMOCALC

R . P OWE L L ( e -ma i l: rp @ e ar t hs c i. u n ime l b. e d u. a u )1 , T . H O L L AN D2 A N D B . W O RL E Y 1

1 School of Earth Sciences, The University of Melbourne, Victoria 3052, Australia

2 Department of Earth Sciences, University of Cambridge, Cambridge CB2 3EQ, UK

A B S TR A C T

Phase diagrams involving solid solutions are calculated by solving sets of non-linear equations. In

calculating P–T projections and compatibility diagrams, the equations used for each equilibrium are the

equilibrium relationships for an independent set of reactions between the end-members of the phases in

the equilibrium. Invariant points and univariant lines in P–T projections can be calculated directly, as

can coordinates in compatibility diagrams. In calculating P–T and T –x/P–x pseudosections – diagrams

drawn for particular bulk compositions – the equilibrium relationship equations are augmented by mass

balance equations. Lines in pseudosections, where the mode of one phase in the lower variance equilibrium

is zero, and points, where the modes of two phases are zero, can then be calculated directly. The software,

THERMOCALC, allows the calculation of these and a range of other types of phase diagram. Examples

of phase diagrams and phase diagram movies, with instructions for their production, along with the

THERMOCALC input and output files, and the MathematicaTM functions for assembling them,

are presented in this paper, partly in hard copy and partly on the JMG web sites

(http://www.gly.bris.ac.uk/www/jmg/jmg.html, or equivalent Australian or USA sites).

I NTR ODU CT I ON

The advent of large internally-consistent thermodynamic datasets (Helgeson et al., 1978; Holland &

Powell, 1985; Powell & Holland, 1985; Berman, 1988;

Holland & Powell, 1990; Gottschalk, 1997) has meant

that it has become possible to calculate mineral

equilibria involving solid solutions in complex systems

(e.g. Spear & Cheney, 1989; Powell & Holland, 1990;

Symmes & Ferry, 1992; Mahar et al., 1997). In

principle such calculations allow phase diagrams to be

constructed which closely approximate the phase

relationships in rocks.

Several different ways of approaching the calculation

of mineral equilibria involving solid solutions have

evolved out of those advocated in the chemical and

metallurgy literature (e.g. van Zeggeren & Storey,

1970): the Gibbs method (Spear & Cheney, 1989);

direct minimization of Gibbs energy (Wood, 1987;

Connolly, 1990; de Capitani & Brown, 1987) and the

solution of simultaneous non-linear equations (Powell

& Holland 1990). This last approach is the one

followed in the software, THERMOCALC, Powell &

Holland (1988, and succeeding upgrades), which uses

the internally-consistent thermodynamic dataset of

Holland & Powell (1985, 1990, 1998) (e.g. Guiraud

et al., 1990; Baker et al., 1994; Xu et al., 1994; Worley

& Powell, 1998).

The purpose of this paper is to consider the

calculation of phase diagrams involving solid solutions

by solving sets of non-linear equations. Examples of

the application of this approach are calculated with

© Blackwell Science Inc., 0263-4929/98/$14.00

Journal of Metamorphic Geology, Volume 16, Number 4, 1998, 577–588

the software THERMOCALC v2.6 using the April 20,

1996 version of the thermodynamic dataset. The

version of THERMOCALC, current at acceptance of

this paper for publication, this thermodynamic dataset,

datafiles, output files and documentation for the

examples are available from the JMG web sites.

THERMOCALC is available to be downloaded in

DOS, PowerMac and other Mac versions. The material

summarized in Table 1 and the most recent published

dataset are also available from the JMG sites. Current

versions of the software and dataset, as well as

Table 1. Summary of web-based material that is part of this

paper, located at the JMG web site. See also the material

at: http://rubens.unimelb.edu.au/ ~rpowell/THERMOCALC/

THERMOCALC.html for, for example, documentation of

datafile construction and THERMOCALC scripts, as well as

the most recent software and dataset.

Category

Software

Dataset

Documentation

Mathematica functions

Phase diagram movies

Contents

THERMOCALC v2.6 for DOS

THERMOCALC v2.6 for PowerMac

THERMOCALC v2.6 for other Macs (68k Macs)

TH.PD (‘20apr96’) for DOS

TH PDATA1 and THPDATA2 (‘20apr96’) for Mac

getting started

running THERMOCALC

annotated KFMASH datafile

annotated runs of THERMOCALC (logfiles)

assembling phase diagrams with Mathematica

low-level functions (drawline etc)

high-level functions for compatibility diagrams

high-level functions for T –x and P–x pseudosections

full examples of using functions

AFM compatibility diagram at 3 kbar, for 500 to 580 °C

T –x psuedosection for 510–650 °C, for 5 to 10.5 kbar

577

578

R. P OW E L L E T A L .

documentation of other THERMOCALC facilities,

are

at:

http://rubens.its.unimelb.edu.au/~rpowell/

THERMOCALC/THERMOCALC.html

C A L C U LAT IN G P H A S E DI AG RA M S

Calculating phase diagrams involves a number of steps:

1 Choose a model system in which to do the calculations.

A model system is just the chemical system, usually

specified in terms of oxides, in which the equilibria to

be calculated can be represented. This specifies which

phases, and the substitutions within them, that will be

able to be considered. Obviously these phases can only

involve those end-members that occur in the thermodynamic dataset used (or linear combinations of

them). For example, the model system normally used

to consider metapelites is K O–FeO–MgO–Al O –

2

2 3

SiO –H O (or KFMASH) (Thompson, 1957), allowing

2 2

most of the critical minerals, and the FeMg

and

−1

(Fe,Mg)SiAl Al

(Tschermak’s) substitutions in

−1 −1

them, to be considered. This model system is the one

used for the examples in this paper.

2 Formulate the thermodynamics of the phases in the

system. Given that a central part of calculations on

assemblages involving solid solutions is the calculation

of the equilibrium compositions of the phases, the

activity-composition (a–x) relationships of the phases

are needed in algebraic form, in terms of the composi-

tional variables to be calculated. The first stage of this

is matching the required substitutions in each phase

with end-members in the thermodynamic dataset, and

assigning composition variables to the substitutions.

In the case of chlorite in KFMASH, for example, the

FeMg

and (Fe,Mg)SiAl Al

substitutions are

−1

−1 −1

represented by clinochlore [clin, Mg Al Si O (OH) ],

5 2 3 10

8

daphnite [daph, Fe Al Si O (OH) ] and amesite

5 2 3 10

8

[ames, Mg Al Si O (OH) )] end-members. Two

4 4 2 10

8

composition variables are needed, and one choice is

x=Fe/Fe+Mg, reflecting the extent of FeMg , and

−1

y=Al/4, reflecting the extent of (Fe,Mg)SiAl Al

−1 −1

(see Appendix). For each phase, a mixing model needs

to be chosen. The approach followed in formulating

the a–x relationships of KFMASH chlorite in terms

of x and y, in this case in terms of the ideal-mixingon-sites model, is illustrated in Appendix 2. The a–x

relationships for the other phases in the examples are

also summarized in Appendix 2.

3 Decide on which phase diagrams are to be constructed.

This decision will depend mainly on what geological

problem is being addressed. Important types of

diagrams are:

$ A P–T projection, usually a key phase diagram,

shows the stable invariant points and univariant (or

reaction) lines for all of the bulk compositions in the

system. A P–T projection for KFMASH, constrained

Fig. 1. P–T projection for KFMASH

(+mu+q+H O); the in-excess phases

2 in the reactions labelling

are not included

the univariant lines, as is usual for such

diagrams. See Table 3 for the

abbreviations used.

C ALC ULATING PHA SE DIA GRA MS

Fig. 2. AFM compatibility diagram for KFMASH

(+mu+q+H O) at P=6 kbar and T =560 °C.

2

by stipulating the presence of muscovite, quartz and

H O (i.e. with mu+q+H O ‘in excess’), is shown in

2

2

Fig. 1. Such diagrams are the familiar petrogenetic

grids of the literature.

$ Compatibility diagrams show the mineral assemblages, and ranges of mineral solid solutions, at

specified P–T , for all of the bulk compositions in the

model system. A compatibility diagram for AFM, with

mu+q+H O in excess, is shown in Fig. 2.

2

$ P–T pseudosections show just those phase relationships for a particular bulk composition. A P–T

pseudosection for a model pelite composition in AFM,

with mu+q+H O in excess, is shown in Fig. 3.

2

$ T –x or P–x pseudosections show the phase relationships for a particular bulk composition line, at specified

P or T respectively. A T –x pseudosection for AFM,

with mu+q+H O in excess, is shown in Fig. 4.

2

Pseudosections are important because in systems with

solid solutions, it is not usually obvious which parts

of the equilibria in a P–T projection will be seen by a

particular bulk composition, given that the compositions of the phases vary along the univariant lines

(compare Figs 3 & 4 and Fig. 1).

The diagrams in Figs 1–4 were calculated with the

program THERMOCALC, using the a–x relationships

in the Appendix (see Table 3 for the phase and endmember abbreviations used). Although there are other

types of phase diagrams that can be drawn, for example

with activities or chemical potentials on the axes, it is

the calculation of the types of diagram in Figs 1–4

that will be the focus in this paper.

4 Build up the phase diagram via calculations on the

equilibria involved. Each mineral equilibrium calculation involves setting up and solving a mathematical

problem, as outlined in the next section for calculation

579

Fig. 3. P–T pseudosection in KFMASH (+mu+q+H O) for a

2

‘common’ pelite composition: Al O =41.89, MgO=18.19,

3

FeO=27.29, and K O=12.63 (in2 mol%).

2

Fig. 4. A T –x pseudosection in KFMASH (+mu+q+H O),

for a composition line along which FeO:MgO varies, with2 x=

FeO/(FeO+MgO), and Al O =41.89, FeO+MgO=45.48, and

2 3composition line goes through

K O=12.63 (in mol%). This

the2 composition used in Fig. 3.

in terms of sets of non-linear equations. Generating a

phase diagram usually involves many such calculations.

The calculations are computationally intensive so they

are usually carried out by computer: THERMOCALC

580

R. P OW E L L E T A L .

is software that performs such calculations. Phase

diagrams can be drawn from THERMOCALC output

using MathematicaTM functions which are made available here. These functions allow single phase diagrams

to be drawn, as well as phase diagram movies to be

constructed. THERMOCALC can also produce tabdelimited tables for importing into other graphical

software for manipulation and plotting.

C O N S T R U C TI O N A L F E AT U R E S OF P H A S E

D I A G R AM S

In the calculation of phase diagrams such as Figs 1–4,

it is necessary to understand their constructional

features. Such features of P–T projections, involving

invariant1 points and univariant lines, are generally

familiar. The constructional features of compatibility

diagrams are illustrated in Fig. 5. The tie triangles

(divariant equilibria) in the full system (within the

triangle) as well as the divariant equilibria in the

subsystems (edges of the triangle) specify much of the

geometry, including the apices of the one-phase fields

(quadrivariant equilibria). The edges of the one phase

fields can be determined via the adjacent trivariant

equilibria. In cases such as this, in which Fe–Mg is the

dominant substitution, the edges are close to being

straight; in other systems, such edges can be strongly

curved.

Pseudosections involve the invariant and univariant

equilibria they inherit from P–T projections, as well as

additional boundary lines and points. In a P–T

pseudosection these inherited equilibria are just those

parts of the P–T projection ‘seen’ by the bulk

composition being considered (compare Figs 1 & 3).

In a T –x pseudosection these inherited equilibria occur

as horizontal lines, spanning the range of bulk

compositions that ‘sees’ an equilibrium. The boundary

lines and points separate fields of different variance;

across lines the variance changes by one, and through

points by two, e.g. Fig. 6(iii), 7(iv). Divariant fields

adjoin univariant lines, separated by trivariant fields

that emanate from points along the univariant lines,

e.g. Fig. 6(i), 7(ii). The boundary points and lines can

be most easily discussed with a new notation, which

takes advantage of the fact that at lines one mode has

gone to zero, and at points two modes have gone to

zero. Labelling is carried out in terms of the lower

variance assemblage involved, with the names of phases

with zero modes given in brackets, see Figs 6 & 7. So

for example in Fig. 6(iii), going from the g–chl–bi

divariant field, through the point at 8 kbar and 580 °C,

into the chl quadrivariant field, the modes of bi and g

go to zero at the point. The point is therefore labelled

‘chl ( bi g)’. Similarly, in going down T at 10 kbar from

the g–chl–bi divariant field into the g–chl trivariant

field into the chl quadrivariant field, the two lines

crossed are labelled ‘chl g ( bi)’ and ‘chl (g)’. The zero

mode aspect of the boundary lines and points also

provides a means of calculating them directly, as

shown below.

H O W C A L C U LAT IO N S A R E S ET UP WI T H

NON- LINEAR EQUATIONS

The organization of phase diagram calculations is

predicted on the way the calculations are to be carried

out. Setup of calculations for use in a non-linear

equations solver, rather than, for example, a Gibbs

energy minimizer, is outlined here.

Fig. 5. The constructional features of the AFM compatibility

diagram in Fig. 2. The numbers give the variance of the

corresponding field. Part (i) focusses on a full-system divariant

field; (ii) focusses on the chlorite one-phase field; its apices are

defined by the corresponding apices of the full and subsystem

divariant fields; (iii) focusses on the KFASH divariant fields

that define the left hand edge of the diagram, (iv) focusses on

the KMASH divariant fields that define the right hand edge.

1for an n component system, involving p phases, the variance v

is equal to n−p+2, otherwise known as the phase rule.

Invariant: v=0; univariant: v=1; divariant: v=2; and so on.

Calculating P–T projections and compatibility diagrams

A non-linear equations approach is suited to calculating equilibria of a specified variance. Thus, the

calculation of P–T projections and compatibility

diagrams is straightforward. So, if the position of the

[bi,cd] invariant point in Fig. 1 is to be calculated,

the equilibrium ctd–st–chl–g–mu–q–H O is addressed.

2

Similarly, if the coordinates of the corners of

the g–chl–bi divariant triangle in Fig. 2 are to be

C ALC ULATING PHA SE DIA GRA MS

581

Calculating an invariant point, say [bi, cd] at about

P=12 kbar and T =595 °C on Fig. 1, will involve

solving a set of non-linear equations consisting of the

equilibrium relationships for reactions, forming an

independent set, written between the end-members of

the phases in the equilibrium being considered

0=DG°+RT ln K

1

1

0=DG°+RT ln K

2

2

e

Whereas DG° is just a function of P–T , the equilibrium

k

constant, K , is, in general, a function of P–T and the

k

compositions of all the phases whose end-members are

involved in the reaction. The P–T and these compositions are the unknowns that are solved for. For [bi,cd]

on Fig. 1 an independent set of reactions is:

(1) 72mctd+11py+3ames=8mst+17clin ;

(2) 8mst+17clin+6ky=84mctd+11py ;

(3) 10mst+19clin+3q=96mctd+13py ;

(4) 39mctd+4py=4mst+7clin+3H O ;

2

(5) 8fst+17daph+6ky=84fctd+11alm ;

(6) 10fst+19daph+3q=96fctd+13alm ;

(7) 39fctd+4alm=4fst+7daph+3H O ;

2

(8) 8mst+14clin+3cel=72mctd+11py+3mu ;

(9) 8fst+14daph+3fcel=72fctd+11alm+3mu ;

Fig. 6. The constructional features of part of the P–T

pseudosection in Fig. 3, indicating the necessary calculations to

define the lines and points. The numbers give the variance of

the corresponding field. In parts (i–iii), points and lines are

labelled in terms of the lower variance adjacent assemblage,

with the phase(s) whose modes are zero there being given in

brackets. Part (i) focusses on the g+chl=st+bi univariant

line, showing its relationship to adjoining trivariant fields that

terminate on it; (ii) focusses on the g–chl–bi divariant field, its

boundary lines at higher P being with trivariant fields, whereas

the lower P boundary is the univariant; and (iii) focusses on

the chl quadrivariant field.

calculated, the equilibrium g–chl–bi–mu–q–H O is

2

addressed. The approach can be extended to the

calculation of all of the equilibria of a particular

variance in a system. Calculating all of the equilibria

of variance, v, involves looking at all of the different

combinations of n−v+2 phases chosen from the p

phases in the system. There will be

p( p−1) ... (n−v+4)(n−v+3)

p

=

Cn−v+2

(n−v+2)(n−v+1) ... (2)(1)

of these (in the absence of composition degeneracies

amongst the phases).

using the abbreviations in Table 3, and the corresponding set of equilibrium relationships can be written out.

For example, the first one is

A

B

(ast )8(achl )17

mst clin

0=DG°+RT ln

1

(actd )72(ag )11(achl )3

mctd

py

ames

which becomes, on substituting for the activity

expressions in the Appendix

0=DG°+RT

1

{(1−x )4}8{16(1−x )5(1−y )2y2 }17

st

chl

chl chl

×ln

{(1−x )}72{(1−x )3}11{(1−x )4y4 }3

ctd

g

chl chl

Given that each DGo is a function of P and T , these

nine equations are in nine unknowns: P, T , x , x ,

st ctd

x, x , y , x

and y . Therefore they can be

g chl chl mu

mu

solved, giving the P–T coordinate of the invariant

point on the P–T projection, as well as the equilibrium

compositions of the coexisting minerals there.

(THERMOCALC gives P=12.2 kbar, T =595 °C,

x =0.865, x =0.662, x =0.830, x =0.436, y =

st

ctd

g

chl

chl

0.556, x =0.701 and y =0.793). See also Table 4

mu

mu

for the results of calculations around the [ctd,cd]

invariant point in Fig. 1, that terminates st+bi stability

to higher pressure at P=10 kbar and T =623 °C.

Calculating the g–chl–bi–mu–q–H O divariant equi2

A

B

582

R. P OW E L L E T A L .

Fig. 7. The constructional features of part of the T –x pseudosection in Fig. 4, indicating the necessary calculations to define the lines

and points. The numbers give the variance of the corresponding field. In parts (ii–iv), points and lines are labelled as in Fig. 3. Part

(i) shows the AFM diagram at the temperature of the g+chl=st+bi univariant equilibrium, showing where the bulk composition line

of the T –x diagram plots at this temperature, in projection from the calculated compositions of muscovite; (ii) focusses on the g+chl=

st+bi univariant line; (iii) focusses on the g–chl–bi divariant field, with the apex at x=1 given by the corresponding KFASH

univariant equilibrium; (iv) focusses on the chl quadrivariant field.

librium as a tie triangle on a compatibility diagram

(e.g. Fig. 2), a set of seven independent reactions is:

(1) clin+ames+4q=3py+8H O ;

2

(2) 5py+3daph=5alm+3clin ;

(3) clin+east=ames+phl ;

(4) ames+cel=clin+mu ;

(5) 3ames+2phl+6q=py+3clin+2mu ;

(6) 2ann+mu+6q=alm+3fcel ;

(7) 6daph+mu+3fcel=7alm+4ann+24H O .

2

giving seven equilibrium relationships in terms of nine

variables: P, T , and the compositions x , x , y , x ,

g chl chl bi

y , x and y . To calculate this equilibrium, two

bi mu

mu

variables must be fixed. Fixing P and T , as appropriate

for a compatibility diagram (P=6 kbar, T =560 °C in

Fig. 2), the compositions of the coexisting phases in

the equilibrium can be calculated by solving the

equilibrium relationships. The coordinates of the calculated compositions of the phases can then be plotted

on a compatibility diagram. The coordinates of biotite,

the only phase in this equilibrium which is not already

in the plane of the compatibility diagram, is found by

projecting from the calculated composition of the

muscovite. (THERMOCALC at P=6 kbar and T =

560 °C gives the {A,F,M} coordinates to be g: {0.250,

0.704, 0.046}, chl: {0.190, 0.558, 0.251} and bi: {−0.228,

Table 2. Notation (units used are kJ, K and kbar and

temperatures are quoted in °C).

Symbol

P

T

a

x

aj

i

x

i

y

i

R

DG°

k

n

p

s

c

v

p

j

xj

i

cj

i

x

i,j

s

[k]

x^n

Meaning

pressure

temperature

activity

composition

activity of end-member i in phase j

composition variable, Fe/Fe+Mg, for phase i

composition variable relating to Tschermak’s substitution for phase i

gas constant (0.0083144 kJ K−1)

Gibbs energy of reaction for reaction k

number of components in a model system

number of phases in an equilibrium

Total number of end-members in the phases in an equilibrium

number of composition variables set (i.e. given values) in an equilibrium

variance

modal proportion of phase j in an equilibrium

proportion of end-member i in phase j

number of molecules of component i in end-member j

site fraction of element i on site j

standard deviation

reaction not involving phase k (i.e. k-out)

in Table 8, means x to the power of n

0.871, 0.356}. The calculated AFM coordinates of the

stable divariant fields at P=6 kbar and T =560 °C, as

shown in Fig. 2, are summarized in Table 5.

To generalize, considering an n-component model

system, if phase k involves e end-members, then it

k

involves e −1 composition variables. For p phases in

k

the equilibrium, there will be Sp e ¬s end-members

k=1 k

of phases, and Sp

(e −1)=s−n composition

k=1

k

C ALC ULATING PHA SE DIA GRA MS

Table 3. Abbreviations and full names of the phases and endmembers, and the formulae of the end-members, used in the

KFMASH examples. The end-member abbreviations are those

understood by THERMOCALC.

Phase

abbrev.

Phase

full name

mu

muscovite

bi

biotite

chl

chlorite

cd

cordierite

ctd

chloritoid

st

staurolite

g

garnet

and

ky

sill

q

HO

2

andalusite

kyanite

sillimanite

quartz

fluid

End-member

abbrev.

End-member

full name

Formula

Table 5. Summary of the THERMOCALC output for the

stable KFMASH divariant triangles at P=6 kbar and

T =560 °C, giving the AFM coordinates on the compatibility

diagram in Fig. 2. The coordinates of biotite are calculated by

projection from the calculated composition of muscovite in this

divariant equilibrium.

Divariant

mu

cel

fcel

phl

ann

east

clin

ames

daph

crd

hcrd

fcrd

mctd

fctd

mst

fst

py

alm

gr

and

ky

sill

q

HO

2

muscovite

celadonite

Fe celadonite

phlogopite

annite

eastonite

clinochlore

amesite

daphnite

cordierite

hydrous cordierite

Fe cordierite

Mg chloritoid

Fe chloritoid

Mg staurolite

Fe staurolite

pyrope

almandine

grossular

andalusite

kyanite

sillimanite

quartz

water fluid

KAl Si O H

3 3 12 2

KMgAlSi O H

4 12 2

KFeAlSi O H

4 12 2

KMg AlSi O H

3

3 12 2

KFe AlSi O H

3

3 12 2

KMg Al Si O H

2 3 2 12 2

Mg Al Si O H

5 2 3 18 8

Mg Al Si O H

4 4 2 18 8

Fe Al Si O H

5 2 3 18 8

Mg Al Si O

2 4 5 18

Mg Al Si O H

2 4 5 19 2

Fe Al Si O

2 4 5 18

MgAl SiO H

2

7 2

FeAl SiO H

2

7 2

Mg Al Si O H

4 18 7.5 48 4

Fe Al Si O H

4 18 7.5 48 4

Mg Al Si O

3 2 3 12

Fe Al Si O

3 2 3 12

Ca Al Si O

3 2 3 12

Al SiO

2

5

Al SiO

2

5

Al SiO

2

5

SiO

2

HO

2

variables. The number of reactions between the

end-members that make up an independent set is the

number of end-members minus the number of components, s-n (Powell & Holland, 1988). Given that there

is a non-linear equation for each reaction in the

independent set, these relationships indicate how many

583

Phase

st–g–chl

st

g

chl

st

chl

ky

g

chl

bi

st–chl–ky

g–chl–bi

A

F

M

0.692

0.250

0.199

0.692

0.207

1.000

0.250

0.190

−0.228

0.294

0.702

0.542

0.274

0.356

0.014

0.048

0.259

0.033

0.437

0.704

0.559

0.871

0.046

0.251

0.356

unknowns can be solved for, and therefore how many

must be set, because the s-n equations can only be

solved for s–n unknowns. The number of things that

have to be set in order for an equilibrium to be

calculated can be represented in terms of degrees of

freedom, equal to the number of unknowns, (s–p)+2,

minus the number of equations, s–n, giving n–p+2. So

the number of degrees of freedom is just the variance.

Setting unknowns may involve setting P and/or T , or

setting compositional variables, as would be done, for

example, in calculating composition isopleths on a

P–T diagram. Therefore, by variance, v:

v=0. For an invariant equilibrium, a point on a P–T

diagram, all the unknowns can be solved for. With

no composition variables set, the equilibrium

Table 4. Summary of the THERMOCALC output for the equilibria around the [cd, ctd] invariant point at P=10 kbar and T =

623 °C in the P–T projection shown in Fig. 3. First is the calculated coordinates of the invariant point itself, with the uncertainties

(1s) arising from the uncertainties on the thermodynamic data, followed by the calculated coordinates of the univariant lines. The

P and T of the invariant point are only slightly correlated (r =−0.133).

PT

(a)

s

[ky]

[bi ]

[chl]

[g]

[st]

P ( kbar)

T (°C)

x

10.0

0.8

6.0

8.0

10.0

12.0

14.0

6.0

8.0

10.0

12.0

14.0

6.0

8.0

10.0

12.0

14.0

6.0

8.0

10.0

12.0

14.0

6.0

8.0

10.0

12.0

14.0

623

7

572

600

623

644

662

649

640

623

599

569

670

650

623

589

549

585

605

623

639

654

583

605

623

639

653

0.818

0.0203

0.937

0.884

0.817

0.737

0.642

0.752

0.782

0.818

0.859

0.902

0.895

0.855

0.818

0.786

0.761

0.859

0.838

0.818

0.797

0.776

st

x

g

0.771

0.0192

0.911

0.846

0.770

0.685

0.590

0.686

0.725

0.771

0.823

0.877

0.862

0.813

0.771

0.735

0.708

0.885

0.830

0.770

0.705

0.635

x

chl

0.362

0.0258

0.604

0.466

0.361

0.277

0.209

0.279

0.315

0.362

0.427

0.515

0.394

0.377

0.362

0.347

0.333

0.542

0.442

0.361

0.295

0.239

y

chl

0.565

0.0091

0.593

0.579

0.565

0.552

0.539

0.580

0.573

0.565

0.557

0.549

0.609

0.587

0.565

0.544

0.523

0.610

0.587

0.565

0.544

0.523

x

bi

y

0.384

0.0250

0.638

0.496

0.383

0.292

0.217

0.356

0.0483

0.417

0.386

0.355

0.326

0.297

0.574

0.468

0.383

0.315

0.259

0.429

0.406

0.384

0.363

0.343

0.578

0.471

0.383

0.310

0.247

0.493

0.425

0.355

0.284

0.213

0.448

0.400

0.355

0.313

0.274

0.446

0.399

0.355

0.314

0.275

bi

x

mu

0.620

0.0253

0.812

0.713

0.619

0.527

0.437

0.509

0.559

0.620

0.691

0.772

0.752

0.680

0.619

0.569

0.528

0.646

0.632

0.620

0.608

0.596

0.768

0.692

0.619

0.550

0.482

y

mu

0.822

0.0161

0.860

0.841

0.821

0.801

0.780

0.863

0.843

0.821

0.796

0.767

0.879

0.852

0.821

0.784

0.739

0.889

0.857

0.821

0.782

0.741

0.877

0.850

0.821

0.791

0.759

584

R. P OW E L L E T A L .

involves n+2 phases; the P–T of the point, and the

compositions of all the phases in the equilibrium,

can be solved for. For c composition variables set,

the equilibrium involves n+2−c phases. For

example, a divariant assemblage involving n phases,

with two composition variables set, corresponding

to the intersection of two isopleths, is (effectively)

invariant, and the P–T and remaining composition

variables of the equilibrium can be solved for.

v=1. For a univariant equilibrium, a line on a P–T

diagram, if one of the unknowns is set (i.e. one of P,

T and the composition variables), then the remaining

unknowns can be solved for. With no composition

variables set, the equilibrium involves n+1 phases,

and, given, say, P, the T and the compositions of all

of the phases can be solved for. For c composition

variables set, the equilibrium involves n+1−c

phases. For example, a divariant assemblage involving n phases with one composition variable set, is a

line on a P–T diagram (an isopleth), the equilibrium

is (effectively) univariant and, given, say, P, the T

and the remaining compositions of the phases can

be solved for.

v=v. For a v-variant equilibrium, if v of the unknowns

are set (i.e. v of P, T and the composition variables),

then the remaining unknowns can be solved for. For

v≤2, and no composition variables set, the equations

cannot be solved. With no composition variables

set, the equilibrium involves n+2−v phases; for c

composition variables set, the equilibrium involves

n+2−v−c phases.

Calculating pseudosections

The calculation of P–T and T –x/P–X pseudosections

(Figs 3 & 4) with the non-linear equation approach is

greatly aided by augmenting the non-linear equations

formed by the set of 0=DGo+RT lnK equations with

a set of equations derived from mass balance constraints. For the specified bulk composition that is

being used for the calculation, these additional equations relate the mole proportion of each component in

the bulk composition with the sum of the calculated

mineral compositions multiplied by their modal proportions. In other words, the bulk composition must

be able to be made up of an assemblage of the phases

of interest. Of course the phases in the assemblage

must each have non-negative modal proportions.

Situations where one or two phases have zero modes

are particularly relevant, as they correspond to

the lines and points in pseudosections, as discussed

above.

As can be seen in the following, the zero mode

character of the lines and points in pseudosections can

be utilized in calculations. For the n-component system

considered above, there will be a mass balance equation

for each component, giving n equations additional to

the equilibrium relationships involved. There are also

p additional variables, the modes of the phases. Then

the total number of equations is s-n+n, i.e. s equations,

in s-n+p+2, i.e. s+2 unknowns. So, if two things are

specified, the number of equations equals the number

of unknowns regardless of the number of phases involved.

This means that equilibria of any variance can be

calculated, once a bulk composition is specified (see

also Spear, 1986). The value of including the mass

balance constraints in calculations comes in setting

one or two modal proportions to zero. On a P–T

pseudosection, with one mode set to zero, an equilibrium (involving any number of phases) defines a P–T

line (i.e. is effectively univariant). With two modes set

to zero, an equilibrium defines a P–T point (i.e. is

effectively invariant). On a T –x pseudosection (at fixed

P ), with one mode set to zero, an equilibrium

(involving any number of phases) defines a T –x line,

and with two modes set to zero, an equilibrium

defines a T –x point. This means that the lines and

points that make up pseudosections can be calculated

directly.

The above approach can be seen in calculating the

divariantquadrivariant point, ‘chl ( bi g)’ on a P–T

pseudosection, occurring at 8 kbar and 580 °C on

Fig. 3. The divariant equilibrium, chl–bi–g, involves

the same set of seven independent reactions between

the end-members of the phases as listed above in the

compatibility diagram example. So there are seven

equilibrium relationships, in the nine unknowns, P, T ,

x , x , y , x , y , x and y . Rather than fixing P

g chl chl bi bi mu

mu

and T as in the above, the equilibrium relationships

are augmented with mass balance constraints. With

constraints for K O, FeO, MgO, Al O , and the

2

2 3

additional unknowns, the modal proportions, p , p ,

chl bi

p and p , the required P–T point can be calculated

g

mu

directly, once p and p are both set to zero. Mass

bi

g

balance constraints are not needed for SiO and H O

2

2

because quartz and H O2 correspond to these compo2

nents. The mass balance constraints that are needed

involve combinations of the composition and mode

variables. For example, for MgO, using the information

in Appendix 2 for converting composition variables

into mineral compositions

MgO=p {cclin xchl +cames xchl +cdaph xchl }

chl MgO clin MgO ames MgO daph

+p {cphl xbi +ceast xbi +cann xbi }

bi MgO phl MgO east MgO ann

+p {cpy xg +calm xg }

g MgO py MgO alm

+p {cmu xmu+ccel xmu+cfcel xmu }

mu MgO mu MgO cel

MgO fcel

In this, p , for example, is the modal proportion of

bi

biotite in the equilibrium, xbi , is the proportion of the

phl

end-member phlogopite in the biotite, and cphl is the

MgO

number of MgO in the formula of phlogopite. On

substituting the expressions for the proportions of the

end-members in the phases in terms of the composition

2H O is used here as a component and as a phase, with the

2

meaning

given by the context.

C ALC ULATING PHA SE DIA GRA MS

variables this constraint becomes

GA

B

2

MgO=p

5 1− x (3−y )−(2y −1)

chl

chl

chl

5 chl

H

+4(2y −1)

chl

GA

A

A B

H

1

+p 3 1−x 1− y

−y +2( y )

bi

bi

bi

bi

3 bi

+p {3((1−x ))}

g

g

+p {x (1−y )}

mu mu

mu

The coordinates of ‘chl ( bi g)’ on the P–T and T –x

pseudosections as calculated by THERMOCALC are

given in Table 6, section (ii) and Table 7, section (i).

In the latter case, the coordinates are determined via

the locus of the P–T point with bulk composition, with

the T –x position of the point at the fixed pressure of

the pseudosection found by interpolation, or by

running THERMOCALC over an appropriately

narrow composition range.

The calculation of a line on a P–T or T –x

pseudosection is illustrated with the trivariant

quadrivariant line, ‘chl ( bi)’. This runs down pressure

from the ‘chl ( bi g)’ point on Fig. 3, and to more

magnesium bulk compositions from this same point

on Fig. 4. The trivariant equilibrium, chl–bi, is represented by an independent set of five reactions:

(1) ames+cel=clin+mu ;

(2) clin+east=ames+phl ;

Table 6. Summary of THERMOCALC output that relate to the

calculation of the P–T pseudosection in Fig. 3, the p being the

k

modal proportions of the phases in the assemblage. The

mineral

composition information is omitted. (i) the g–chl–bi–st

univariant assemblage calculated with the modes of st and g,

and g and chl, set to zero, so determining the terminations of

the corresponding trivariant fields on the univariant line; (ii) the

bi–chl–g divariant field calculated with the modes of bi and g

set to zero, so determining the position of the apex of the chl

quadrivariant; (iii) the bi–chl–g divariant field calculated with

the mode of bi set to zero, so determining the position of the

boundary between the bi–chl–g divariant field and the g–chl

trivariant field; and (iv) the bi–chl trivariant field calculated with

the mode of bi set to zero, so determining the position of the

boundary between the bi–chl trivariant and the chl

quadrivariant fields. For (i) and (ii) the calculated uncertainties

(1s) on the positions of the P–T points are also given.

P (kbar)

i

s

s

ii

s

iii

iv

7.3

0.8

6.3

0.9

8.0

0.6

9.0

10.0

11.0

12.0

5.0

6.0

7.0

8.0

T (°C)

590

5

577

6

580

6

590

600

609

609

521

541

561

581

p

st

p

g

p

p

chl

bi

p

mu

0.207

0

0

0.575

0.217

0

0

0.444

0.102

0.454

0

0

0.495

0

0.505

0.088

0.158

0.219

0.273

0.407

0.337

0.276

0.222

0.495

0.495

0.495

0.495

0

0

0

0

0

0

0

0

0.505

0.505

0.505

0.505

0.505

0.505

0.505

0.505

585

Table 7. Summary of THERMOCALC output relating to

generating the T –x pseudosection in Fig. 4, with the mineral

composition information omitted: (i) the bi–chl–g divariant

field calculated with the modes of bi and g set to zero, so

determining by interpolation the position of the apex of the chl

quadrivariant field; (ii) the bi–chl–g divariant field calculated

with the mode of chl set to zero, so determining the position of

the boundary between the bi–chl–g divariant and the bi–g

trivariant fields; and (iii) bi–chl trivariant field calculated with

the mode of bi set to zero, so determining the position of the

boundary between the bi–chl trivariant and the chl

quadrivariant fields. The prop column refers to the

proportional position along the bulk composition line.

i

ii

iii

P (kbar)

T (°C)

prop

p

g

5.1

5.5

5.8

5.8

6.0

6.6

7.0

7.4

6.0

6.0

6.0

6.0

6.0

6.0

6.0

6.0

6.0

6.0

528

535

541

541

545

556

563

572

541

554

567

545

543

542

540

538

535

532

0.050

0.100

0.150

0.150

0.179

0.250

0.300

0.350

0.050

0.100

0.150

0.200

0.300

0.400

0.500

0.600

0.700

0.800

0

0

0

0

0

0

0

0

0.430

0.413

0.399

p

chl

0.495

0.495

0.495

0.495

0.495

0.495

0.495

0.495

0

0

0

0.495

0.495

0.495

0.495

0.495

0.495

0.495

p

bi

0

0

0

0

0

0

0

0

0.130

0.164

0.192

0

0

0

0

0

0

0

p

mu

0.505

0.505

0.505

0.505

0.505

0.505

0.505

0.505

0.440

0.423

0.409

0.505

0.505

0.505

0.505

0.505

0.505

0.505

(3) 5clin+3mu=4ames+3phl+7q+4H O ;

2

(4) daph+4fcel=3ann+mu+7q+4H O ;

2

(5) 5ames+5fcel+4clin+daph+5mu .

So there are five equilibrium relationships, in the eight

unknowns, P, T , x , y , x , y , x

and y .

chl chl bi bi mu

mu

Augmenting with mass balance constraints for K O,

2

FeO, MgO, Al O , with the additional unknowns, p ,

2 3

chl

p , and p , there are nine equations in 11 unknowns.

bi

mu

On setting p to zero, the set of equations defines a

bi

P–T line for a particular bulk composition, as in Fig. 3,

as well as a T –x line at fixed pressure across a bulk

composition range, as in Fig. 4. The corresponding

calculated coordinates are given in Table 6, section (iv),

and in Table 7, section (iii).

Determining the stability of calculated equilibria

Not addressed in the above development is the

determination of the stability of equilibria. When all

the invariant and univariant equilibria in a P–T

projection are calculated, many or most will be

metastable. The stability of the equilibria can be

determined by applying Schreinemakers Rule3 to the

univariant lines around each invariant point, then

putting the invariant points together. With the resulting

P–T projection, determining the stable equilibria in

compatibility diagrams and pseudosections is generally

straightforward.

3the metastable extension of the reaction not involving phase i

(i-out or [i]) lies between i-producing reactions (e.g. Zen, 1966).

586

R. P OW E L L E T A L .

In the context of determining which assemblage is

the most stable one at a particular P–T , for a particular

bulk composition, the minimization of the Gibbs

energy of the system can be utilized. From the last

subsection, with the mass balance constraints included,

equilibria of any variance can be calculated if two

unknowns are fixed. Choosing these to be P–T , it is

straightforward, if laborious, to loop through all the

possible divariant and higher equilibria in the system,

determine the Gibbs energy of each assemblage if it

can be calculated, and identify the one with the

smallest Gibbs energy. Such an approach, applied at a

series of P–T points along a P–T line, is very effective

in getting started in constructing pseudosections, in

identifying (stable) lines that may then be calculated

by the method of the last subsection.

In conclusion, the software THERMOCALC is built

around a non-linear equation solver, and it involves

an implementation of the material covered above. As

a consequence, the features of P–T projections, compatibility diagrams, P–T pseudosections and T –x/P–x

pseudosections can be calculated directly. Aspects of

this are discussed in Appendix 1.

Table 8. (Continued)

cd 3

g2

chl 3

2

fcrd

1

2

hcrd

bulk 1 1

1

2

bulk 1 1

x(cd) 0.45

h(cd) 0.7

py

1

1

check 0

alm

1

1

bulk 1 1

check 1

x(g) 0.9

clin

16

3

ames

east

mu 3

Table 8. Main part of a THERMOCALC datafile for

KFMASH, showing the coding of the a–x relationships etc

used in the examples, using the a–x relationships from the

Appendix. Everything after a % on a line is treated as a

comment and is ignored by THERMOCALC, allowing the

annotation of datafiles. See the documentation on the web for

details of datafile construction. See Table 3 for the

abbreviations of the phases and the end-members.

ctd 2

1

1

check 0

fst

1

1

bulk 1 1

check 1

x(st) 0.92

mctd 1

1

check 0

fctd

1

1

bulk 1 1

check 1

x(ctd) 0.91

1

1

−1

1

4

% a(mst)=(1−x)^4

0

0

1

1

1

1

1

1

4

%

bulk 1 1

check 0 1

x( bi) 0.5

y( bi) 0.49

mu

1/4 3

fcel

1

1

−1

1

1

1

1

1

1

1

1

1

% a(fctd)=x

%

x=Fe/(Fe+Mg)

check 0 1

1/4 4

check 0 0

1/4 4

bulk 1 2

ky q

0

0

check 1 0

1/4 4

bulk 1 2

a(fst)=x^4

% x=Fe/(Fe+Mg)

% a(mctd)=(1−x)

check 0 0

1/4 4

bulk 1/3 2

cel

mst

check 1 1/2

1

2

bulk 1 1

check 0 1

x(chl) 0.5

y(chl) 0.6

phl

1/4 4

ann

A P P EN D I X 1 : U SI N G THE R M O C A L C

st 2

check 0 1/2

16

3

bulk 1/5 2

We thank F. Spear, D. Pattison and J. Brady for their

helpful comments. We also thank all those friends and

others who have laboured with THERMOCALC, who

have helped in its evolution over the years, including

J. Baker, M. Guiraud, T. Will, G. Xu, K. Stuwe,

J. Arnold, E. Maher, C. Carson, among others.

The software THERMOCALC allows phase diagrams to be

calculated, as in Tables 4–7. In using THERMOCALC, provision

of the a–x relationships for the minerals is done via a datafile, of

which for example Table 8 is a part. Although for a few solid

solutions the mixing model to use is fixed by the way the

thermodynamic data for the end-members were extracted (see

Holland & Powell, 1990), in general the user can code whichever

mixing model is thought to be appropriate (within the Margules

1

daph

bi 3

ACKNOWLEDGEMEN TS

crd

check 1 0

x(mu) 0.75

y(mu) 0.95

HO

2

1

1

0

1

0

1

0

0

1

1

1

1

1

1

1

1

−1

−1

1

−1

1

−1

1

1

1

2

1

2

1

1

2

2

2

1

2

1

% a(crd)=(1−x)^2 *

%

(1−h)

% a(fcrd)=x^2 *

%

(1−h)

2

1

% a(crd)=(1−x)^2 *

%

h

% x=Fe/(Fe+Mg)

% h=H O pfu

2

% a(py)=(1−x)^3

1

1

−1

1

3

0

1

0

1

1

1

1

3

1

1

1

0

1

1

1

−1

−1

1

1

2

2

5

2

2

% x=Fe/(Fe+Mg)

% a(clin)=16 (1−x)^5 *

%

(1−y)^2 *

%

y^2

0

1

0

0

3

1

1

1

1

1

1

−1

1

2

−1

1

2

2

1

2

5

2

2

% a(daph)=16 x^5 *

%

(1−y)^2 *

%

y^2

1

0

−1

1

1

1

−1

1

2

1

2

2

4

4

% a(ames)=(1−x)^4 *

%

y^4

% a(alm)=x^3

1

2

1

1

1

1

1

1

−1

−1

1

−1

1

2

2

2

3

2

1

1

% x=Fe/(Fe+Mg)

% y=oct A1/2

% a(phl)=1/4 (1−x)^3 *

%

(2−y)^2 *

%

(1+y) *

%

(1−y)

0

2

1

1

0

3

1

1

1

1

1

1

1

−1

1

−1

1

−1

1

2

2

2

1

2

3

2

1

1

% a(ann)=1/4 x^3 *

%

(2−y)^2 *

%

(1+y) *

%

(1−y)

1

0

1

2

0

1

1

1

1

1

−1

1

1

−1

1

1

2

2

2

2

2

1

2

1

% a(east)=1/4 (1−x)^2 *

%

y*

%

(1+y)^2 *

%

(2−y)

1

2

0

1

1

1

1

−1

1

2

2

2

2

1

1

% x=Fe/(Fe+Mg)

% y=oct Al

% a(mu)=1/4 (1+y)^2 *

%

(2−y) *

%

y

1

1

1

2

1

1

1

1

1

1

1

1

−1

−1

1

−1

−1

−1

1

2

2

2

1

2

1

1

1

2

% a(cel)=1/4 (1−x) *

%

(1−y) *

%

(1+y) *

%

(2−y)^2

0

1

1

2

0

1

1

1

1

1

1

1

1

−1

1

−1

1

−1

1

2

2

2

1

2

1

1

1

2

% a(fcel )=1/4 x *

%

(1−y) *

%

(1+y) *

%

(2−y)^2

% x=Fe/(Fe+Mg)

% y=oct Al−1

family). Output from THERMOCALC, processed by Mathematica

functions made available here, can be used for assembling phase

diagrams and phase diagram movies. The mechanics of datafile

construction, running THERMOCALC, and assembling phase

C ALC ULATING PHA SE DIA GRA MS

587

diagrams, is covered in detail on the web. Additionally on the web

are QuickTime compatibility diagram movies for AFM, running

from 500 to 580 °C at 3 kbar, and a T –x diagram movie for AFM,

running from P=5 to 10.5 kbar, and the information needed to

construct them.

One aspect of using THERMOCALC to perform mineral

equilibrium calculations that is worth emphasizing is its ability to

propagate uncertainties in the thermodynamic data of the endmembers of the phases through calculations. These data uncertainties

are generated along with the thermodynamic data themselves as a

consequence of the way the data are generated (see below; also

Powell & Holland, 1993). The magnitude of the uncertainties on the

thermodynamic data reflect how well they are constrained by the

various experimental data used to calculate them. It is always

worthwhile calculating the uncertainties on equilibria, e.g. Tables 4(i),

6(i,ii), to give an indication of how well known the equilibria are.

Such an error propagation calculation as done by THERMOCALC

omits any contribution from errors in the formulation of a–x

relationships. However, in the absence of gross a–x errors, generally,

if uncertainties arising from the thermodynamic data are small, they

are likely to remain small overall. Of course, if uncertainties arising

from the thermodynamic data are large, they can only get larger if

other sources of uncertainty are also included. On this basis, the

position of the [ctd,cd] invariant point in Fig. 1, Table 4(i), is

relatively well known, with an uncertainty of about 1.5 kbar (2s),

whilst the pressure of [cd,as] is much less well-known (±>4 kbar).

The position of this point is obviously sensitive to the data used in

its calculation. In considering a whole phase diagram, the uncertainties on the positions of points and lines will usually be strongly

correlated, so care is required in developing on overall picture of

uncertainties. For example it can be asked if different topologies in

a P–T projection can be stable within error: can [cd,as] be at a

lower pressure than [g,cd] in Fig. 1 (so making both invariant

points metastable, and a different topology apply)? To answer this

requires knowing the correlations, because it is not sufficient to say

that the uncertainties on the two points overlap.

THERMOCALC can be used to perform calculations additional

to those addressed here. These include the geothermometry/

geobarometry calculations called average P–T methods (Powell &

Holland, 1994), as well as phase diagram calculations not involving

solid solutions (e.g. Powell & Holland, 1988). These latter calculations are simple to perform as the datafile needed requires just a

list of the phases (end-members) involved, and the results include

not only the positions of the equilibria but also the stability

relationships (see Powell & Holland, 1988).

amesite

[Mg ]M1[Al ]M2[Si ]T1[Al ]T2O (OH) .

4

2

2

2

10

8

The composition variables to use are not prescribed, although

some may be easier to use in calculations than others. A reasonable

choice is one that brings out the substitutions involved in the phase,

so define:

APPENDI X 2 : ACTI V IT Y- COMPOSI T ION A ND

B U L K C O M P O S IT I ON R E L AT I O N S H IP S F O R

M I N ER A L S I N K F M A S H

From the expression for y

chl

p

=2y −1

ames

chl

and substituting this into the expression for x

chl

2

p

= x (3−y )

chl

daph 5 chl

In any mineral equilibrium calculation involving solid solutions, the

thermodynamics of the phases need to be expressed in terms of their

compositional variables. Then, once a calculation is done, and the

equilibrium values of the compositional variables are found, the

bulk composition of the phase must be constructed, for example for

writing reactions or plotting the compositions on a compatibility

diagram. These processes are illustrated for chlorite in KFMASH.

The corresponding expressions for the other minerals are also

given below.

The starting point is deciding which end-members to include and

what a–x model to use. For chlorite in KFMASH, clinochlore (clin),

daphnite (daph) and amesite (ames), constitute an independent set

of end-members, if the FeMg and (Fe,Mg)SiAl Al substitutions

−1

−1 −1

are to be considered. The a–x relationships will be modelled using

ideal-mixing-on-sites, with Al mixing on two octahedral sites

(designated M2) and two tetrahedral sites (designated T2) (Holland

& Powell, 1990). Thus the end-members can be written:

clinochlore

[Mg ]M1[MgAl ]M2[Si ]T1[SiAl ]T2O (OH) ;

4

2

10

8

daphnite

[Fe ]M1[MgAl]M2[Si ]T1[SiAl ]T2O (OH) ;

4

2

10

8

Aloct

Fe

and y =x

=

x =

chl

Al,M2

chl Fe+Mg

2

Then the site fractions can be written in terms of x

and y :

chl

chl

=1−x

x

=x

Mg,M1

chl

Fe,M1

chl

x

=(1−x )(1−y ) x

=x (1−y ) x

=y

Mg,M2

chl

chl

Fe,M2

chl

chl Al,M2

chl

x

=0

x

=1

Al,T1

Si,T1

x

=y

x

=1−y

Al,T2 chl

Si,T2

chl

Then, for clinochlore using ideal mixing on sites:

x

a =16x4

x

x

x2 x

x

clin

Mg,M1 Mg,M2 Al,M2 Si,T1 Al,T2 Si,T2

in which the 16 is a normalization constant forcing a =1 for pure

clin

clinochlore (e.g. Powell, 1978, p. 70). This is necessary because both

the M2 and T2 sites have more than one element on them in pure

clinochlore. Substituting the site fractions into the ideal mixing

activity expression gives

a =16(1−x )5(1−y )2y2

clin

chl

chl chl

The same logic for daph and ames gives

a

=16x5 (1−y )2y2

daph

chl

chl chl

a

=(1−x )4y4

ames

chl chl

Following an equilibrium calculation, there will be values of x

chl

and y which can then be used to reconstitute the chlorite. This is

chl

done via expressions for the proportions of the end-members, p ,

clin

p

and p

, in the chlorite in terms of x and y . A start is

daph

ames

chl

chl

made by writing the definitions for x and y in terms of the p’s:

chl

chl

5p

5p

Fe

daph

daph

=

=

x =

chl Fe+Mg

5p

+5p +4p

5−p

daph

clin

ames

ames

in which the multiplier on p comes from the number of atoms of

k

Fe or Mg in the formula unit of k. The last step comes from the fact

that p +p

+p

=1. Similarly

clin

daph ames

p +p

+2p

1+p

Aloct

daph

ames=

ames

= clin

y =

chl

2

2

2

and, by difference

2

p =1− x (3−y )−(2y −1)

clin

chl

chl

5 chl

The a–x relationships of staurolite, chloritoid and garnet are

particularly simple to represent in terms of their composition

variables, in each case x is Fe/Fe+Mg. Thus, for their end-members:

=(1−x )4 a =x4 ;

mst

st

fst

st

=1−x ) a =x ;

mctd

ctd

fctd

ctd

a =(1−x )3

a =x3 .

py

g

alm

g

In considering biotite, using the compositional variables

a

a

Fe

and y =2x

=Aloct

x =

bi

Al,M2

bi Fe+Mg

with Al mixing with the Fe+Mg on two octahedral sites (M2), and

588

R. P OW E L L E T A L .

Al with the Si on two tetrahedral sites (T2), then

x

=1−x

Mg,M1

bi

x

A

y

x

=(1−x ) 1− bi

Mg,M2

bi

2

x

=

Al,T2

B

Fe,M1

x

1+y

bi

2

=x

bi

A

B

y

y

=x 1− bi x

= bi

Fe,M2

bi

Al,M2

2

2

x

=

Si,T2

1−y

bi

2

and the ideal mixing on sites expressions for the biotite end-members

are:

1

a = (1−x )3(2−y )2(1+y )(1−y );

phl 4

bi

bi

bi

bi

1

a = x3 (2−y )2(1+y )(1−y );

ann 4 bi

bi

bi

bi

1

a = (1−x )2y (1−y )2(2−y ).

east 4

bi bi

bi

bi

In considering muscovite, using the compositional variables

Fe

and y =x

=Aloct−1

x =

mu

Al,M2

mu Fe+Mg

with Fe+Mg mixing with the Al on two octahedral sites (M2), and

Al with the Si on two tetrahedral sites (T2), then

x

x

Mg,M2

=(1−x )

mu

y

= mu

Al,T2

2

A B

1−y

bi

2

x

x

=x

Fe,M2

Mu

Si,T2

A B

1−y

1+y

bi x

bi

=

Al,M2

2

2

y

=1− mu

2

and the ideal mixing on sites expressions for the muscovite

end-members are:

1

a = (1+y )2(2−y )y ;

mu 4

mu

mu mu

1

a = (1−x )(1−y )(1+y )(2−y )2;

mu

mu

mu

mu

cel 4

1

a = x (1−y )(1+y )(2−y )2.

fcel 4 mu

mu

mu

mu

R E FE R E N C E S

Baker, J., Holland, T. J. B. & Powell, R., 1994. The effect of

Tschermak solid solutions on assemblages in aluminous calcpelites. Contributions to Mineralogy and Petrology, 118, 48–59.

Berman, R. G. 1988. Internally-consistent thermodynamic data

for minerals in the system Na O-K O–CaO–MgO–FeO–

2 . Journal

2

Fe O –Al O –SiO –TiO –H O–CO

of Petrology,

3 2 3

2

2 2

2

29,2 445–522.

de Capitani, C. & Brown, T. H. 1987. The computation of

chemical equilibrium in complex systems containing non-ideal

solutions. Geochemica et Cosmochimica Acta, 51, 2639–2652.

Conolly, J. A. D., 1990. Multi-variable phase diagrams: an

algorithm based on generalized thermodynamics. American

Journal of Science, 290, 666–718.

Gottschalk, M., 1997. Internally consistent thermodynamic data

for rock forming minerals. European Journal of Mineralogy,

9, 175–223.

Guiraud, M., Holland, T. J. B. & Powell, R., 1990. Calculated

mineral equilibria in the greenschist — blueschist — eclogite

facies in Na O–FeO–MgO–Al O –SiO –H O: methods,

2 3

2 Contributions

2

results and 2geological applications.

to

Mineralogy and Petrology, 104, 85–98.

Helgeson, H. C., Delany, J. M., Nesbitt, H. W. & Bird, D. K.,

1978. Summary and critique of the thermodynamic properties

of rock-forming minerals. American Journal of Science, 278A,

229.

Holland, T. J. B. & Powell, R., 1985. An internally consistent

thermodynamic dataset with uncertainties and correlations: 2:

Data and results. Journal of Metamorphic Geology, 3, 343–370.

Holland, T. J. B. & Powell, R., 1990. An internally-consistent

thermodynamic dataset with uncertainties and correlations:

the system Na O–K O–CaO–MgO–MnO–FeO–Fe O –

2

2 . Journal of Metamorphic

2 3

Al O –SiO –TiO –C–H

–O

2 3 8,289–124.

2

2 2

Geology,

Holland, T. J. B. & Powell, R., 1998. An internally consistent

thermodynamic data set for phases of petrological interest.

Journal of Metamorphic Geology, 16, 309–343.

Mahar, E. M., Baker, J. M., Powell, R., Holland, T. J. B. &

Howell, N., 1997. The effect of Mn on mineral stability in

metapelites. Journal of Metamorphic Geology, 15, 223–238.

Powell, R., 1978. Equilibrium T hermodynamics in Petrology.

Harper and Row, New York.

Powell, R. & Holland, T. J. B., 1985. An internally consistent

thermodynamic dataset with uncertainties and correlations: 1:

Methods and a worked example. Journal of Metamorphic

Geology, 3, 327–342.

Powell, R. & Holland, T. J. B., 1988. An internally consistent

thermodynamic dataset with uncertainties and correlations: 3.

Application methods, worked examples and a computer

program. Journal of Metamorphic Geology, 6, 173–204.

Powell, R. & Holland, T. J. B., 1990. Calculated mineral

equilibria in the pelite system. KFMASH (K O–FeO–

MgO–Al O –SiO –H O). American Mineralogist, 75,2367–380.

2 2 T. J. B., 1993. Is Least Squares an

Powell, R. 2 &3 Holland,

appropriate methodology to be used in the extraction of

thermodynamic data from experimentally-bracketed mineral

equilibria? American Mineralogist, 78, 107–112.

Powell, R. & Holland, T. J. B., 1994. Optimal geothermometry

and geobarometry. American Mineralogist, 79, 120–133.

Spear, F. S., 1986. The Gibbs method, Duhem’s Theorem, and

P–T–X(Fe–Mg–Mn) relations in pelites. EOS, T rans. AGU,

67, 407.

Spear, F. S. & Cheney, J. T., 1989. A petrogenetic grid for pelitic

schists in the system K O–FeO–MgO–Al O –SiO –H O.

2 3149–164.

2 2

Contributions to Mineralogy2 and Petrology, 101,

Symmes, G. H. & Ferry, J. M., 1992. The effect of whole-rock

MnO content on the stability of garnet in pelitic schists

during metamorphism. Journal of Metamorphic Geology,

10, 221–237.

Thompson, J. B., 1957. The graphical analysis of mineral

assemblages in pelitic schists. American Mineralogist, 42,

842–858.

Thompson, J. B., 1979. The Tschermak substitution and reactions

in pelitic schists. In: Problems in Physicochemical Petrology

(in Russian) (eds Zharikov, V. A., Fonarev, V. I. & Korikovskii,

S. P.), Moscow Academy of Science, Moscow. pp. 146–159.

Wood, B. J., 1987. Thermodynamics of multicomponent systems

containing several solid solutions. Reviews of Mineralogy,

17, 71–95.

Worley, B. & Powell, R., 1998. Singularities in NCKFMASH

(Na O–CaO–K O–MgO–FeO–Al O –SiO –H O). Journal of

2

2

2 2

Metamorphic

Geology,

16, 169–188.2 3

Xu, G., Will, T. M. & Powell, R., 1994. A calculated petrogenetic

grid for rocks in the system K O–FeO–MgO–Al O –

2 3

SiO –H O, with particular reference2 to contact metamor2

2

phosed pelites. Journal of Metamorphic Geology, 12, 99–119.

Zen E-an, 1966. Construction of PT diagrams for multicomponent systems after the method of Schreinemakers – a geometric

approach. United States Geological Survey Bulletin, 1225, 56.

van Zeggeren, F. & Storey, S. H., 1970. T he Computation of

Chemical Equilibria. Cambridge University Press, Cambridge,

UK. 176 pp.

Received 3 March 1997; revision accepted 20 January 1998.