H. C. Starck, Inc.1

advertisement

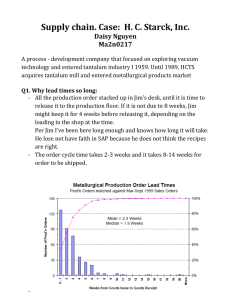

H. C. Starck, Inc.1 Question 1: The average lead time was estimated at 7 weeks. Average manufacturing time was 2 weeks. Analysis showed that longer more than longer time, up to 2 week, was utilized from the point the sales orders were released to the point when stock rooms issued material for processing. This process was still largely manual and SAP R/3 system was not used. The general feeling was that this metric was running at eight to fourteen weeks, mostly due to the long manufacturing time, but there was no hard data. The sales department felt that if lead-time could be reduced to three weeks, they would have a substantial advantage in the marketplace, and would realize incremental sales volume. Lee agreed that lead-time was important, but cautioned about focusing solely on lead-time, and not overall cycle time, which is the length of time it takes material to physically flow through the manufacturing process: We need to reduce cycle time as well as lead-time. Larry [the company president] got burned once on a lead-time reduction project. The distributors ended up taking all the benefit. The typical production routing used a made-to-order policy with either 4 inch bar of quater inch sheets as the starting material. Depending on the final product the material passed through multiple process orders before ending up as final product. To expedite on lead time sales team often entered hard orders on probable sales, hoping that the operations team would begin fabrication even before the order is placed and the order would be read by the time customer placed their orders. Sometimes these worked well but often the SAP system required orders have delivery dates and so the sales team made up dates. Question 2: - Drum beat meetings and implementation of SAP R/3 The company should continue with the practice of drum beat (DB) meetings as they are a good means to reduce distortions in communications, identifying urgencies and expediting resolution of pressing issues. However, the current purpose of DB meetings is to communicate production and sales urgencies which should not be the case. SAP R/3 should be immediately implemented for the production planning stage and the process of issuing multiple production orders should be done away with by homologation of input parts. - Multiple Product Orders: The problem of issuance of multiple production orders will also be minimized once we focus on key SKUs as suggested in the inventory rationalization model. One more purpose of the DB meetings could be to iron out continuous issues with the implementation of SAP for PPC (Production, planning and control). However the discussion on planning should be kept out of preview consciously by those attending the meeting. - Cost Savings from raw material inventory Reduction: H C Starck maintains large quantities of raw material inventory. The total cost saving from reducing inventory levels and making the production a just in time (JIT) process would reduce the cost as shown below. The company can begin by hiving off the raw material procurement division, and develop the same as a centre of excellence, supplying quality raw material. Question 3: The sales department felt that if lead-time could be reduced to three weeks, they would have a substantial advantage in the marketplace, and would realize incremental sales volume. That is the benefit of reducing the time. However, since end items could be produced in a single production operation, but which items should be stocked, and at what levels? That can be the costs from reducing the lead times.