H.C. Starck, Inc.

advertisement

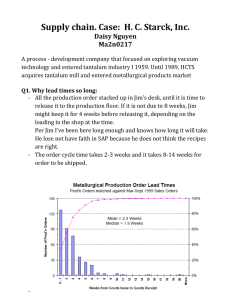

Ms.Chanatip Dansirisanti MA2N0204 陳美清 H.C. Starck, Inc. 1. What are the lead times so long? To begin, H.C. Starck, Inc. experienced lead times that were longer than expected because there was a belief that the manufacturing time was taking far too long, although no hard data was provided to support this. SAP was often ignored and a manual paper based process was used to transmit the order from sales to operation. Lee Sallade focusing on it solely would be a significant error in all aspects. He felt that in addition to controlling lead time that overall cycle time needed to be accounted for, as well, which may have also led to the lead times lasting for such an extended period of time. First step to create SO had been implemented reducing to 1 business day or less. Second step to create PO was still taking 2 weeks. GI-GR small portion of lead time (<25%). The problem lay in SO to GI phase-all that time between when the sales department entered order in SAP and when plant actually started manufacturing. Also, the fact that the company had Ta reduction and powder manufacturing operations in Japan, Thailand and Germany. However, the Newton, MA location in the United States was the only plant that possessed the melting and mill capabilities needed in order to fulfill customer orders. This meant that any orders that needed to be melted or passed through the mills needed to be sent from the locations overseas to the Newton, MA location, which in turn, would create bottlenecks for production and longer lead times. 2. How might Starck reduce or affect the lead times? Starck may implement SAP system for planning and scheduling. The products that are in demand should be manufactured and available in stock. Starck should predict an accurate future demand, therefore, company be able to hold intermediate inventory. Pick stocking points based on risk pooling benefits, lead time reduction, volume. Also, determine inventory requirements based on inventory model such base stock. Order expedition should be exception then a rule. Moreover, Starck should manage to eliminate delays of paper work. All in all, company should cycle time for each process order. 3. What are the costs from reducing the lead times? What are the benefits from reducing the lead times? Reducing lead times improves inventory management; reduce inventory, better planning, better customer service and in long term reducing lead-time is increased sales. Moreover, it can create new accounts and new business as well as protect current business from switching to substitutes or Chinese competitor.