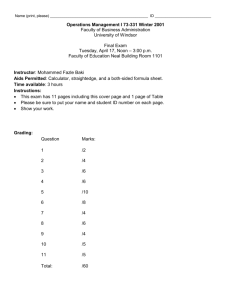

Supply Chain Management

advertisement

Supply Chain Management

Training Module

1

Objectives of the Session

To have an understand of what is meant by the end to end supply chain

To have an understanding of the key elements of supply chain management

To have an understanding of the benefits of being process orientated

To have an understanding of how stock could be managed and for what benefit

To have an understanding of demand management

To have an understanding about the benefits of planning

To have an understanding of Integrated business Planning

2

Surviving in a Global world

With the increase pressures brought about by globalisation and the onset

of new markets offering low labour costs, most western businesses are

finding it difficult to compete with intense pressures to deliver quality and

service at a reduced cost.

In response to the pressures brought about by globalisation many leading

academics believe that Supply Chain Management is the solution for

improving competitiveness and meeting the ever-increasing needs of the

customer

.

3

The importance of SCM in today’s market place is perhaps best summarised

by Christopher (1997) when he states that “Supply Chains compete not companies”

brought about by the additional costs and operational inefficiencies incurred

when organisations work independently.

4

Supply chain costs typically represents 60% to 80% of a company’s

total cost structure and just a 10% reduction can yield a 40% to

50% improvement in pre tax profits” (Wood 1997)

5

The NHS faces similar challenges, with finite resources and an ageing /

growing population how is it going to keep up with the growing demands

placed on it

One thing is for sure, a fragmented approach towards managing

supply chains will not deliver the required end product or service at the

most effective cost.

6

Hence many leading academics are promoting the need for companies

to move away from the traditional buyer/supplier adversarial way of doing

business to one of collaboration, partnerships,supplier networks, (Hines 1996)

(Carlisle and Parker 1989), (Ellram 1991), (Macbeth and Ferguson 1994)

To put it another way “Everyone should be working together to ensure that the

Total Supply Chain is delivering the required goods / service at the lowest

cost . However, in many supply chains you will find that everyone is working

independently / managing their own little piece of the supply chain with little

appreciation or understanding on how their actions affect the overall

performance of the total supply chain

Remember – If the final customer in the Total supply chain is not happy

with quality, cost, delivery, responsiveness, service , then all members of

the supply chain are exposed i.e if the customer, patient / commissioning

provider goes elsewhere everyone loses out irrespective of how well your

part of the supply chain might be functioning

7

What is Supply Chain Management

8

In it’s simplistic form

Supply Chain Management is the management of all activities

involved in Sourcing, Procurement, Manufacturing,

Warehousing & Distribution of a product or service

The main objective being is to fulfill the demands of the

customer( products or services ) using the most efficient use

of resources ( labour , materials , time , money )

9

Supply Chain Management Definitions - Croom et al (2000)

Author

Definition

Tan et al (1998)

Supply Chain management encompasses materials / supply management from the supply of basic raw materials to final product and

possible recycling and re-use. Supply chain management focuses on how firms utilise their supplier’s processes, technology and

capability to enhance competitive advantage. It is management philosophy that extends traditional intra-enterprise activities by bringing

trading partners together with the common goal of optimisation and efficiency.

Saunders (1995)

External chain is the total chain of exchange from original source of raw material, through the various firms involved in extracting and

processing raw materials, manufacturing, assembling, distributing and retailing to ultimate end customers.

Ellram (1991)

A network of firms interacting to deliver product or service to the end customer linking flows from raw material supply to final delivery.

Christopher (1992)

Network of organisations that are involved through upstream and downstream linkages in the different processes and activities that

produce value in the form of products and services in the hands of the ultimate consumer.

Lee and Billington

(1992)

Networks of manufacturing and distribution sites that procure raw materials, transform them into intermediate and finished products and

distribute the finished products to customers.

Kopezak (1997)

The set of entities, including suppliers, logistics service providers, manufacturers, distributors and resellers through which materials,

products and information flows.

JP ( 2007)

A shared vision, a common goal across all supply chain members that encompasses the design, co-ordination and execution of all

activities associated with the supply of a service or product that meets the on-going needs of the final end consumer at the lowest total

cost.

Lee and Ng (1997)

A network of entities that starts with the suppliers’ supplier and ends with the customers’ custom the production and delivery of goods

and services.

10

Supply Chain Activities can be classified into three categories

Strategic

Deals with decisions that have a long lasting effect. This typically includes

decisions regarding

Number of locations, size / capacity of warehouses / distribution centers

manufacturing plants and flow of materials through the logistics network

Strategic Partnerships with suppliers, distributors, and customers,

Product Design – different designs are easier to produce, uses less materials,

easier to store, cheaper to distribute

IT infrastructure, to support supply chain operations.

11

Tactical

Decisions that are typically updated between once a quarter to once a year.

Includes:

Sourcing contracts and other purchasing decisions.

Production decisions, including contracting, locations, scheduling

Inventory policies, including quantity, location, and quality of inventory.

Transportation strategy, including frequency, routes, and contracting.

Benchmarking of all operations against competitors and implementation of

best practices

12

Operational

Refers to day to day decisions such as

Distribution planning, truck loading

Production scheduling

Demand planning and forecasting,.

Procurement

Inbound operations,.

Manufacturing Transformation operations

Outbound operations, including all fulfillment activities and transportation to

customers.

13

Supply Chain Management - Process Design and Management

Whether Strategic, Tactical or Operational, Supply Chain Management moves

away from functions or indiviidual activities and is more concerned with integrating

activities into key supply chain processes.

A process is defined as a collection of activities designed to produce a specfic

output . All Processes have inputs such as materials, labour, energy and

outputs such as inputs to other processes or perhaps products or serivces

14

Supply Chains are the sum of many processes, people,

system. All seamlessly working together to achieve the desired

Supply Chain Objectives

When trying to understand the complexities of Supply Chains

It might be helpful to view them as “SYSTEMS”

15

Exercise

Your customer complains that they are out of a stock i.e stock is not available

when required

What could be the reasons for stock-out?

Breakout in teams and list possible reasons. 15 minutes only

16

Possible reasons for Stock outs ( Not an exhaustive list )

Requisition / order not raised

Order held waiting Senior Management Trust approval

Order lost

Order placed within suppliers lead-time

Order placed within total lead-time

Order placed for wrong code or pack factor

Safety stock levels not correct

Stock lost

Stock misplaced

High surge in demand that was known not communicated

Unplanned High surge in demand

Seasonal demand not forecasted

Incorrect goods received against order

Goods received / damaged – waiting to be returned

Account on hold due to outstanding payment

The above reasons can apply to every member of the total supply chain

17

Suppliers

Central

Store

Main R&D

Primary

Distribution

Department

Buffer Stock

Intermediate

Distribution

End User

Safety Stock

Departmental

Channels

R

Pathology

D

R

Stores

Supplier Base

Hotel

Services

R

D

I

Top-up

I

Ad Hoc orders

Ad Hoc orders

R

D

I

D

Pharmacy

R

D

R

Pathology

I

Top-up

Hotel

Services

I

Ad Hoc requests

HSDU

Others

D

R

Catering

R

R

Estates

HSDU

Others

D

Wards

Replenishment / Top-up

D

Direct Delivery

Ad Hoc orders/ VMI/ Consignment stock

R

D

Catering

Estates

I

Point of Use

End Users

Pharmacy

Direct Delivery

VMI /Consignment stock

Final

Distribution

R

Clinics

R

Theatres

Source: NHS Logistics

18

As with any system, effective supply chain management is about the management

of the total supply chain through effective feedback loops and controls being in

place so that the supply chain can be monitored and adjusted to achieve the

desired common business goals

19

Performance Metrics

If You don’t measure it you can’t manage it ?

Performance Metric Measurements can be one means of ensuring

that effective feed-back loops / controls are in place to ensure that

the Supply Chain is performing in line with business needs. To

achieve this aim performance metrics have to be in place throughout

the entire supply chain

When benchmarking, care should be taken to ensure that data

definitions / formula’s, time frames are the same otherwise risk of

measuring different things

Remember - Supply Chain Management is not about direct ownership and

control, it’s more concerned about the integration of activities/ processes

across conventional boundaries i.e dept, functions, organizations

20

Typical Attributes of Performance Metrics

Service Management

Supply Chain Cost Structure

Efficiency

Responsive / Flexibility

Quality

21

Key Product

Stages

Number of weeks

Stock

£

S C Cost Build –Up

Raw

Material

Producti

on

Local

W/H

2

1

12

Production

Inte’al

W/H

3

Distr

Centre

2

Distribution

Local

Depot

Hospital

store

2

5

Ward

Store

2

Patient

4

Acute

NHS Internal Cost

PCT

Material Flow

Information Flow –

Current

Information Flow –

Desired

22

Team Learning

What potential benefits would there be if all members of the supply chain

worked together across the extended enterprise ( no boundaries )

Tip – look at strategic, tactical and operational slides to guide you

23

Examples of potentials benefits of Supply Chain Collaboration

Share technical skills and competencies along the supply chain

Shared information, e.g demand , eliminate surprises

Process Management - Decide where and who is best to perform each task.

Ensure is process is designed to perform the desired objective with minimal

Cost , waste , time lags

Agree / jointly decide where to position safety stock ( no need to work blindly )

Utilize supply chain infra-structures i.e. warehousing, vehicles,

Jointly agree IT strategy platform to improve cost structure, communications

/ flow of information decision making process. Is a shared platform viable?

Collaborate on strategy sourcing options, consider joint ventures

How can all member of the supply chain work together on new product development

24

Initiatives ?

Traditional Supply Chain

Figure

D. Walters, P Jones

25

The Constituents of an Integrated Supply Chain

Patient Care

Efficiency/Effectiveness

Integration

Co-ordination

Choice of Partners

Use of information and

communication

technology

Network organisation &

inter-organisational

collaboration

Process orientation

Leadership

Advanced planning

Foundations

Logistics, commissioning, purchasing and supply

26

Demand

27

Alignment of demand and capacity to meet Patient needs

Demand

- Demand is the future needs of the patient

Capacity - Is the products or resources available to meet patient demand

If Demand and Capacity are not balanced, this will ultimately lead to

- Excess Capacity

- Backlog - Inability to keep up with demand leading to waiting lists,

supply shortages

28

How do we predict future demand ?

29

Business Plan

Understand Business Plan

Build a Supply Chain Strategy that will support the achievement of

Business Plan. This include understanding current levels of

demand and what needs to be done to support expected future

volumes ( demand ). Any significant changes / investment in the supply

chain needs to be identified, approved and planned for

30

Demand

Two types of Demand

Dependant

Independent

Independent Demand

Describes the type of demand for a product or service which is independent of

demand for other items

Dependent Demand

Where demand for one item is linked to demand for another item

31

Demand

Can be either Historical or Planned ( i.e Forecasted )

Main potential problems using Historical demand to predict Future

demand

- Extrapolation of historical demand may not be a true representation

of future demand

- Different levels of demand variability

- Possible Seasonal

- New Products ( limited demand history )

- Products being phased out

- Integrity of demand data ?

32

Other attributes to predict Future demand

- Backlog

- Forward Patient Schedules / Standard procedural packs

- Incidences per population % growth levels

Known problems

- Lack of forward patient schedules

- Stability / accuracy of patient schedules

- Lack of standard procedural packs

33

If forecasts using historical demand or patient forward schedules

are not aligned to business plan this needs to be identified so that

differences can be identified and management can agree the final

numbers driving the supply chain

34

Demand Management Example

Parcel b4 12am

Parcel 2 days

DHL

PARCELINE

PARCELFORCE

PARCELINE

PARCELFORCE

£1.75

£0.75

£0.74

£0.71

Price per Kg

Price per Kg

£0.70

£1.50

£1.50

£1.25

£1.15

£1.14

£1.09

£1.08

£1.07

£1.05

£0.65

£0.65

£0.62

£0.60

£0.59

£1.07

£1.00

£0.88

£0.56

£0.55

£0.93

£0.53

£0.87

£0.53

£0.81

£0.50

£0.75

20kg

40kg

60kg

Weight

100kg

20kg

40kg

60kg

Weight

100kg

Inventory

Why hold stock - Customer not prepared to wait

If customers are prepared to wait consider classifying item as

non stocked

If supply is reliable, demand is constant ( no variability ) and lead-times

are frozen with no variability, do we need to hold safety stock ?

Safety stock is required to compensate for

Fluctuations in customer demand patterns, noise, trends, seasonality

Fluctuations in supplier lead-times

Manufacturing supply problems

Desired service levels

36

Inventory

One of the objectives of those who work in Supply Chain is to make sure

that Inventory is available at the right time and quantity to meet the needs

of the patient. This is paramount if the NHS are going to achieve the

shared NHS objectives which have been outlined.

The level of Inventory required will depend on the following factors

Demand during lead-time ( replenishment frequency + lead-time from

identifying need to availability of product )

Safety stock to cover demand and lead-time fluctuation during lead-time.

This includes transport / manufacturing delays etc

Desired Service Levels - Implications of being out of stock

37

Review level

Review level Formula = ( usage rate x lead-time ) + safety stock

If the stock falls below the re-order level more stock needs to be ordered

Included in stock should be all open orders that are due for delivery

Within the supplier’s lead-time

38

Target Stock Levels

The target stock level is the maximum stock level which can be used

To calculate order quantities

It differs from the review level approach as review levels fix the order quantity

And vary the order frequency. TSL’s fix the order frequency and vary the order

quantity

TSL = {(Usage rate x ( lead-time + review period)} + safety stock

Safety stock is slightly modified to compensate for review period. It now

becomes

z factor x std dev x

√ Lead-time + review period

39

Target Stock Levels

Order qty = TSL – free stock – supply order outstanding

If using TSL’s , make sure that they are continually updated in

line with usage rates and lead-times

40

EOQ

Typically EOQ stock levels are on the high side

Ordering and stock holding costs are assumed to be fixed

Demand is assumed to be regular and ignores batching and timing

EOQ ignores balancing of stocks which is a important factor in

some manufacturing operations

41

EOQ

Lowest Total cost ( EOQ )

Total carrying cost

Costs

Total Order costs

42

Order Size

Potential Benefit of Introducing Economic Order

Quantity Concept

Parcel b4 9am

DHL

Order Weight

Number of

deliveries

Cost per

Delivery

Total Cost

18.89

39499

£41.74

1,648,696

40.00

18653

£67.20

1,253,515

60.00

12435

£88.16

1,096,328

100.00

7461

£137.34

1.024.748

PARCELFORCE

£2.25

£2.18

£2.00

£1.89

Price per Kg

£1.75

£1.52

£1.50

£1.41

£1.40

£1.30

£1.25

£1.15

£1.00

£0.95

£0.75

20kg

40kg

60kg

100kg

Weight

Delivery rates based upon carrier information

Case Study - Theatres

44

Disadvantages of holding stock

Storage costs, space , heating , lighting, rent etc

Money tied up in Inventory

Interest charges if money has to be borrowed

Obsolescence

Product Expiry

Pilferage

Money tied up in Inventory could be used elsewhere

Materials Handling / storage equipment

Insurance

It is estimated that the above costs can be equivalent to up to 20% of the cost

of the Inventory held

45

How can we reduce the need to hold Inventory Levels

46

Pareto Analysis Curve

Cum % Turnover

120.00

100.00

80.00

60.00

A

B

C

40.00

20.00

0.00

1

2

3

4

5

6

7

8

9

10

Items

47

Classification of Inventory using Pareto Analysis

Characteristics

Policy

Methods

A items

Tight control, close supervision

Frequent monitoring

Few Items

JIT approach

Accurate records

High Percentage of Turnover

Sophisticated forecasting

Service level policy

B items

Lean stock policy

Rely on sophisticated system

Important items

Use classic stock control

Calculated safety stock

Significant Turnover

Manage by exception

Limit order value

Management and exception

reporting

C items

Minimal supervision

Simple system

Many items

Supply to order where possible

Avoid stock outs

Low turnover value

Zero or high safety stock policy

Infrequent ordering

48

J.I.T Just in Time

JIT is an inventory strategy designed to have product only when it

is needed and NOT just in case

JIT is a pull system, as soon as one product is used it

automatically triggers the replenishment of that item

Must be a joint strategy with key suppliers, one member of the

supply chain will find the risks associated with JIT to be very high

The advances of technology such as EDI makes JIT possible

49

Supply Chain Leadership

50

Supply Chain Management – Skills Required

Supply Chain Management is about Process Management. Ideally Supply

Chain Leaders need to have an in-depth knowledge / high level of technical

pro-efficiency within their own profession as well as having a good understanding

of other business disciplines to fully appreciation the effects of Supply chain

interconnectivity

Main constituents

In-depth Knowledge / technical competencies in Supply Chain Management

Basic Management Skills ( Including communication skills)

Broad understanding of business disciplines

51

STRATEGY

DELIVERY

MANAGEMENT

CLINICAL

CAPABILITY

CLINICAL

ACTIVITY

MANAGEMENT

CLINICAL

PROCEDURE

MANAGEMENT

COMMISSIONING &

MARKETING

INNOVATION /

TECHNOLOGY

LDP PLANNING

PROCESS

OPPORTUNITY

ANALYSIS &

SELECTION

CLINICAL ACTIVITY

PLANNING

TRIALLING &

EVALUATION &

APPROVAL

IMPLEMENTATION

IMPLEMENTATION

CAPACITY

MANAGEMENT

(INT. & EXT.)

MATERIALS

MANAGEMENT

SERVICE POINT

MANAGEMENT

IMPLEMENTATION

52

Supply Chain Skills Profile

Supply Chain Management

In-depth knowledge of

Broad Knowledge of Business disciplines

53