Aspirin Synthesis Lab Experiment: Procedure & Yield

advertisement

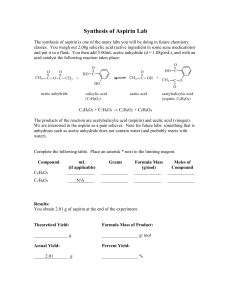

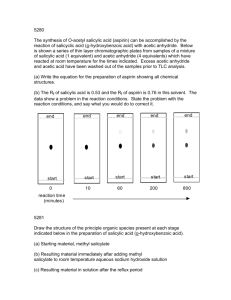

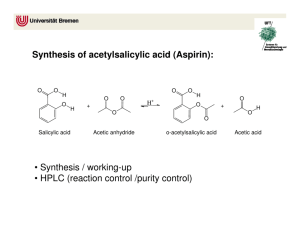

EXPERIMENT 3.8 ASPIRIN SYNTHESIS INTRODUCTION Laboratory experiments in organic chemistry are often centered around obtaining samples of compounds through either extraction from natural sources or synthesis from a set of starting materials. In either case, to arrive at a single compound usually requires that the product sample be put through some further steps of isolation and purification. Finally, when it is believed that the compound has been obtained, it is usually tested to confirm its identity by verification of some chemical and/or physical properties. The objective of this experiment is to perform a synthesis of aspirin followed by a simple purification. The efficiency of the process will be noted by calculation of the percentage yield from the starting materials. The synthesis in our lab will require only one reaction step. As illustrated below, acetic anhydride, C4H6O3 reacts with salicylic acid, C7H6O3 and an acid catalyst to produce aspirin, C9H8O4 and acetic acid, C2H4O2. In the presence of the acid catalyst, the reaction follows a mechanism related to the carboxylic acid and alcohol condensation but in a form that minimizes the presence of water. Since the acetic acid product is both volatile and much more soluble in water it can be separated from it easily during and after the reaction. MATERIALS AND SAFETY The acetic anhydride and phosphoric acid can cause drying and burning of the skin, so please handle them with care. Wear safety eye protection and gloves at all times during the experiment. The aspirin that will be produced will be washed but will be far too impure to take as a pharmaceutical. After weighing the dried product and performing the melting point test, you may dispose of the excess aspirin in the sink or perhaps your instructor will collect it to show you its appearance after more complete drying has occurred. The aspirin will be collected from a reaction mixture using vacuum filtration. Watch and take notes if your instructor demonstrates the use of the filter flask and Buchner funnel set up. Handle these systems with care, making sure that the water trap and filter flask are secured to clamp stations or held firmly by hand while in use. PROCEDURE Use a plastic tray to weigh about 2 grams of salicylic acid and record the mass in the data section. Transfer the powder to your 50 mL Erlenmeyer flask which should be clean and dry. Use one of the dedicated 10 mL graduated cylinders to measure 5.0 mL of acetic anhydride. Do not rinse or clean the cylinder with water. It is critical to keep water away from the acetic anhydride used for the experiment and (of course) from the source bottle. Add the acetic anhydride to the Erlenmeyer flask. Add 5 drops of the 85% phosphoric acid solution to act as an acid catalyst. Promptly wash up any acetic anhydride or phosphoric acid spills. Use a utility clamp to secure the flask in a beaker of tap water on a hot plate or above a Bunsen burner on a wire mesh pad supported by an iron ring. Heat the surrounding water to about 75ºC while using a glass rod to occasionally stir the solution. Control the heating source to maintain this temperature for 15 minutes. After this time has passed, add 2 mL of distilled water very slowly to the flask. This water is added to convert any leftover acetic anhydride to acetic acid which can then be removed from the reaction system by evaporation. Cautiously smell for the vinegar-like odor that indicates this is occurring. After several minutes or after it appears that acetic acid vapors are no longer coming from the mixture, take the flask out of the hot water bath. Add 20 mL of distilled water. Let the flask stand while you prepare an ice-water bath. After a few minutes place the flask in the ice water. You should see some aspirin crystallization at this point. If not, you may try to further promote the crystallization by rubbing a glass rod against the glass inside the flask below the liquid level and continuing to apply the ice bath. If no solid forms, consult the instructor. You may need to repeat the experiment from the beginning making sure of the ingredients and temperature of the reaction. If you have produced solid, use a rubber policeman to collect it on a piece of filter paper in a Buchner funnel set up over a filter flask. While working to transfer as much of the aspirin as possible, chill some distilled water (in a cylinder or squirt bottle) in the vacant ice bath. When the bulk of the solid is on the filter paper, turn off the faucet (source of suction) and pour about 5 mL of chilled water over the sample. Draw this wash liquid off with suction and repeat. Do not be overly concerned if you see small amounts of aspirin passing through the filter paper. Follow the washing with as thorough a drying as time permits. Since one of the report calculations is the percentage yield, excess water will lead to high results. Leave the suction on and manipulate the solid with a stirring rod or spatula to maximize the contact between moving air and the sample. When you are satisfied with the dryness, use a spatula to transfer the aspirin to a weighed or zeroed plastic tray to weigh the amount of product obtained. Next, you will test the melting point of the aspirin. Take your dried sample to room 29-302 where there are melting point device stations. Choose one of the two types of melting point instrument. To use the flat type, a small sample is placed between a pair of thin glass disks and set on the heating pad of the instrument. Use the dial to apply heat while watching for signs of melting (there are magnifying glass stands to set above the sample). Record the temperature when melting begins. The tall, blue devices use capillary tubes. Poke the open end of a tube into your sample then tap the tube to get the sample to the closed end (there is a tall tube you can drop the sample tube in to help). Set the sample tube in a sample hole and turn on the heating cycle. Watch through the magnifying viewer until melting occurs. Record the temperature. Lastly, use the Merck Index of Chemicals to locate the entry for aspirin and record its standard melting point. PRELAB QUESTIONS 1. If you started with exactly 2.000 g of salicylic acid and 5.00 mL of acetic anhydride, calculate the theoretical yield of aspirin. The density of acetic anhydride is 1.08 g/mL. If a team obtains 1.85 g of aspirin product from the reactants used in question 1, what was their percent yield? POSTLAB DATA AND CALCULATIONS a) b) c) d) e) f) g) h) Mass of salicylic acid used Volume of acetic anhydride used Mass of acetic anhydride (density = 1.08 g/mL) Mass of dried aspirin product Theoretical yield of aspirin Percentage yield of aspirin Sample melting point Melting point of pure aspirin (from reference) Discussion Problems and Errors _______________ _______________ _______________ _______________ _______________ _______________ _______________ _______________