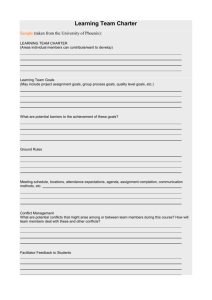

Team Charter Project Title Expectation Attendance Participation Focus Interruptions Preparation Timeliness Decisions Data Application of Six Sigma to reduce variability in gear sizes Example Attendance is required at all team meetings. Changes in meeting times must be made at least 24 hours ahead of time. Team members may not be substituted unless approved by team leader. We will stay on task and on topic, using the Project Charter as our guide. A meeting agenda will be publishedat least one day in advance. Interruptions for emergencies only. Phones turned to silent. All deliverables are expected to be completed in a timely manner. Each meeting will have a published agenda. Meetings will begin promptly as scheduled. We will choose the best decisionmaking method for each situation. We will support decisions made by the team. Team Rule Meetings will start at the agreed time, meetings won’t wait for anyone to start Everyone will give an opinion to contribute to the meeting Development There will be an agenda the team will follow, each one can get a copy or we can project the agenda Do not interrupt when someone is talking Team performance will be quantified weekly Meetings will start and end as scheduled If there is any tie between options we will prioritize Objectives We will rely on data to make decisions. We will rely on data to make decisions Team Charter Project Title Expectation Conflict Application of Six Sigma to reduce variability in gear sizes Example We welcome honest disagreements, as long as everyone is treated with respect. A facilitator will be used if conflict cannot be resolved. Team Rule Every conflict will be attended by the team as a whole. Other Team Member Role Juan Angeles Leonardo Israel Gabriel Flores Rodrigo Team Leader Team Member Mendoza Team Member Team Member Signature Team Charter DATA COLLECT ION PLAN CTQ Metrics Collection Method Analysis Tools Sampling Plan Internal diameter of milled gears Diameter mean of 1,100 +/- 0,001 inches Nondestructive tests, inspections Statistic mean, histograms, inference Interview technicians who perform the process and take a representative sample of day production Sampling Instruction Team members collect random gears during the shifts to measure the internal diameter. PROCESS MAP Operator checks the cutting Gears get into the milling station tool (position, diameter, curent state) Cleaning of milling area Operator collocates the gear into position Operator performs the cutting carefully according to specifications of materials, speed, etc (here is where defects are generated