The Kemper Arena Roof Collapse.Report.doc

advertisement

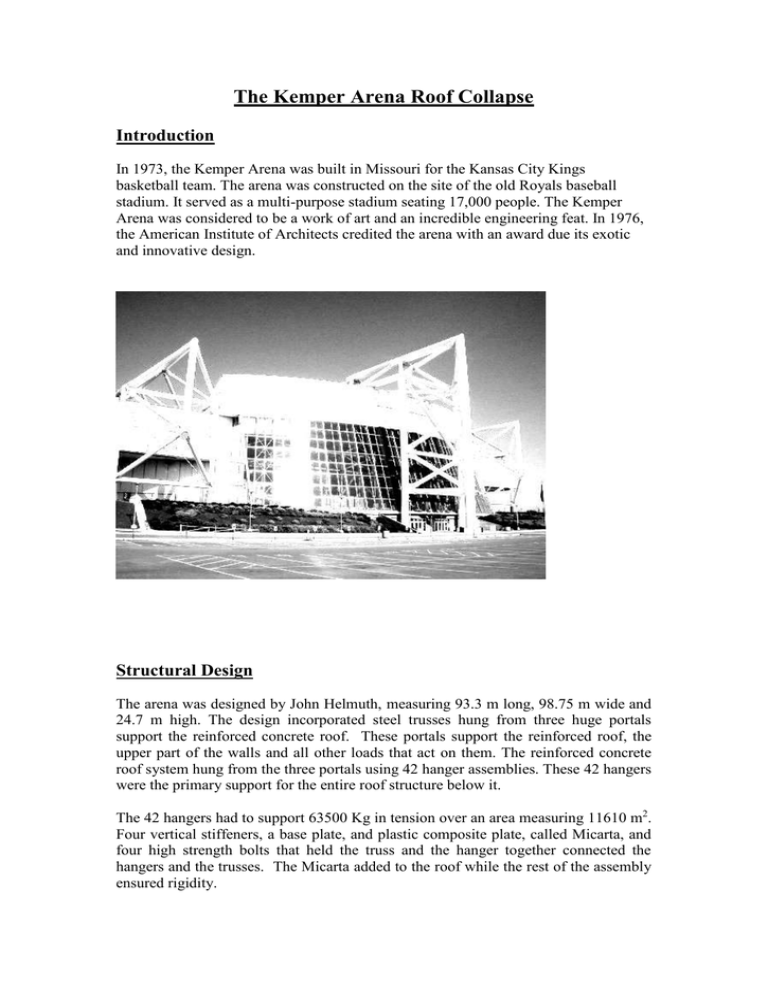

The Kemper Arena Roof Collapse Introduction In 1973, the Kemper Arena was built in Missouri for the Kansas City Kings basketball team. The arena was constructed on the site of the old Royals baseball stadium. It served as a multi-purpose stadium seating 17,000 people. The Kemper Arena was considered to be a work of art and an incredible engineering feat. In 1976, the American Institute of Architects credited the arena with an award due its exotic and innovative design. Structural Design The arena was designed by John Helmuth, measuring 93.3 m long, 98.75 m wide and 24.7 m high. The design incorporated steel trusses hung from three huge portals support the reinforced concrete roof. These portals support the reinforced roof, the upper part of the walls and all other loads that act on them. The reinforced concrete roof system hung from the three portals using 42 hanger assemblies. These 42 hangers were the primary support for the entire roof structure below it. The 42 hangers had to support 63500 Kg in tension over an area measuring 11610 m2. Four vertical stiffeners, a base plate, and plastic composite plate, called Micarta, and four high strength bolts that held the truss and the hanger together connected the hangers and the trusses. The Micarta added to the roof while the rest of the assembly ensured rigidity. Failure Scenario The failure of the roof required a particular set of circumstances. On June 4th, 1979, Kansas City was hit by a ferocious rainstorm, which caused dynamic loading on the roof, due to the combined forces of rain building up at a high rate of 4 inches per hour and 120km/hr winds. The storm was considered a 1 in 10 year storm event. The Kemper Arena roof design had the feature of using the roof as a temporary reservoir in large downpours. The city drainage system would benefit from the limiting of the rate of water that drained from the roof. According to the Kansas City drainage codes, Kemper arena required 55 storm drains. However, only 8 of these drains were fitted in the finished design. The excessive build up of water due to the insufficient drainage lead to water pooling on the roof. The load imposed by the collected rainwater caused the middle of the roof to begin to sag or deflect, inviting more water to accumulate and thus more of a deflection, continuing until the roof became unstable. This is called the ponding effect. This ponding, in association with severely high winds; which had a suction effect, shifting rainwater from the northern end of the roof to the southern end, exerted a massive load on the bolts connecting the roof to the support trusses at the southern end. Eventually the bolts failed and the southern section of the roof collapsed under the load. In a domino effect, the other sections of the roof collapsed in succession. The force of the roof collapse caused the air pressure inside the stadium to rise considerably and ultimately blow out the outer walls. The bolts used as hanger assembly connections were of the specification A490 (4 were used in each connection). These bolts are not designed for variable loading. However, during the 6 years preceding the disaster, the bolts and their connections had been subjected to up to 24,000 oscillations which in turn introduced oscillating variations in the initial tension of the bolts. Metal fatigue, brought on by these oscillations reduced the strength of the bolts considerably. It is estimated that the bolts failed at a one third their design load. Conclusions: The Kemper roof collapsed as a result of several technical oversights. Negligence was shown by not following roof drainage design codes; this shows us how seemingly innocuous or trivial design specifications can have a large impact, and even lead to the structure failing. If the engineers had followed design codes, the ponding effect would not have occurred and the roof would not have collapsed. Another crucial factor was the A490 bolts used in the hangars. Although strong in tension, these bolts failed at only one third of their capacity, due to dynamic loading, which caused fatigue in the metal. This was not considered during design or construction. The choice of bolt was flawed, and the dynamic loading caused by wind and rain ultimately caused the bolts to fail. The 42 hangers had to support 3,000 tons of weight and a wind displacement. The ponding effect, coupled with the metal fatigue of the bolts caused hangar one to fail. Then, this caused the surrounding hangers to fail because they were unable to carry the extra weight of the roof. This inevitably caused a domino effect across all of the hangers on the south end of the roof, and lead to a disproportionate collapse.