Solutions Mid 1

advertisement

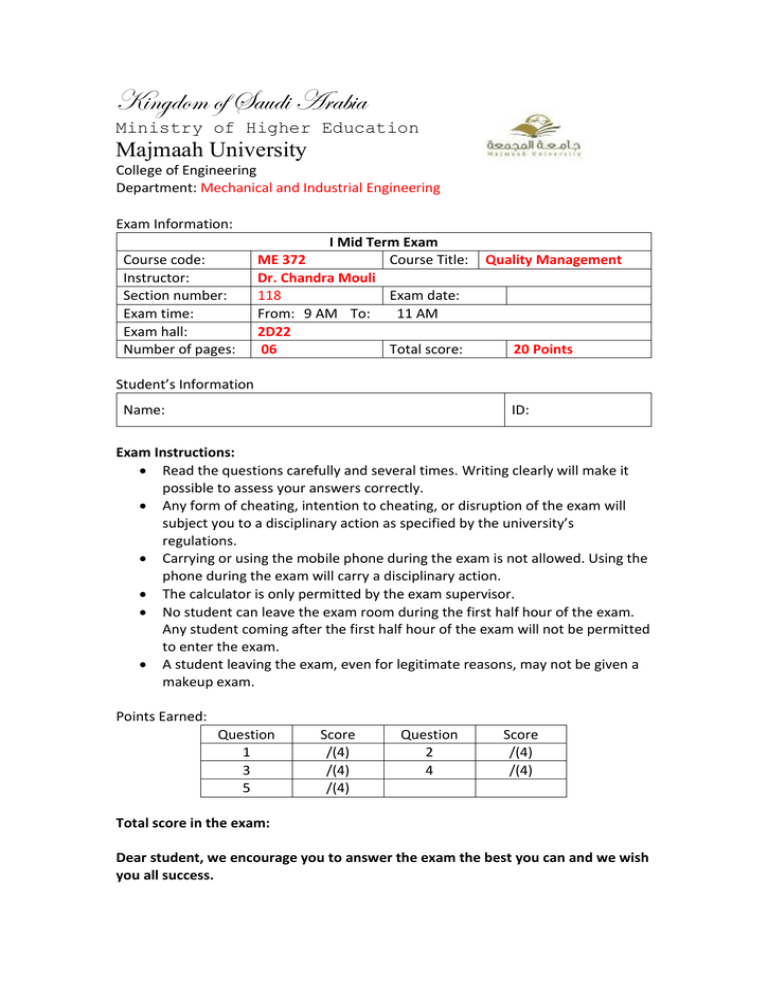

Kingdom of Saudi Arabia Ministry of Higher Education Majmaah University College of Engineering Department: Mechanical and Industrial Engineering Exam Information: Course code: Instructor: Section number: Exam time: Exam hall: Number of pages: I Mid Term Exam ME 372 Course Title: Dr. Chandra Mouli 118 Exam date: From: 9 AM To: 11 AM 2D22 06 Total score: Quality Management 20 Points Student’s Information Name: ID: Exam Instructions: Read the questions carefully and several times. Writing clearly will make it possible to assess your answers correctly. Any form of cheating, intention to cheating, or disruption of the exam will subject you to a disciplinary action as specified by the university’s regulations. Carrying or using the mobile phone during the exam is not allowed. Using the phone during the exam will carry a disciplinary action. The calculator is only permitted by the exam supervisor. No student can leave the exam room during the first half hour of the exam. Any student coming after the first half hour of the exam will not be permitted to enter the exam. A student leaving the exam, even for legitimate reasons, may not be given a makeup exam. Points Earned: Question 1 3 5 Score /(4) /(4) /(4) Question 2 4 Score /(4) /(4) Total score in the exam: Dear student, we encourage you to answer the exam the best you can and we wish you all success. Answer all Questions Each Question carries 4 Points 1. Define Quality. Explain the need for improvement of Quality Points (1+3) The term "quality" has a relative meaning. This is expressed by the ISO definition: "The totality of features and characteristics of a product or service that bear on its ability to satisfy stated or implied needs". In simpler words, one can say that a product has good quality when it "complies with the requirements specified by the client". Most important definitions of quality are Conformance to specifications measures how well the product or service meets the targets and dimensions of a machine part may be specified by its design engineers as 3 _ .05 inches. This would mean that the target dimension is 3 inches but the dimensions can vary between 2.95 and 3.05 inches. Similarly, the wait for hotel room service may be specified as 20 minutes, but there may be an acceptable delay of an additional 10 minutes. Also, consider the amount of light delivered by a 60 watt light bulb. If the bulb delivers 50 watts it does not conform to specifications. As these examples illustrate, conformance to specification is directly measurable, though it may not be directly related to the consumer’s idea of quality. Fitness for use focuses on how well the product performs its intended function or use. For example, a Mercedes Benz and a Jeep Cherokee both meet a fitness for use definition if one considers transportation as the intended function. However, if the definition becomes more specific and assumes that the intended use is for transportation on mountain roads and carrying fishing gear, the Jeep Cherokee has a greater fitness for use. You can also see that fitness for use is a user-based definition in that it is intended to meet the needs of a specific user group. 2. Define cost of Quality What are the components of Cost of Quality explain the optimal quality (1+1+2) The cost associated with the quality of a work product. Cost of quality is the amount of money a business loses because its product or service was not done right in the first place. From fixing a warped piece on the assembly line to having to deal with a lawsuit because of a malfunctioning machine or a badly performed service, businesses lose money every day due to poor quality. For most businesses, this can run from 15 to 30 percent of their total costs. Cost of Quality (COQ ) 1. Cost of Control (Conformance) Prevention Cost Appraisal Cost 2. Cost of not controlling (Non-conformance) Internal Failure Cost External Failure Cost Four categories of costs contribute to an organization’s overall COQ: 1. Internal failure costs - costs associated with defects found before the customer receives the product or service 2. External failure costs - costs associated with defects found after the customer receives the product or service 3. Appraisal costs - costs incurred to determine the degree of conformance to quality requirements 4. Prevention Costs - Costs incurred to keep failure and appraisal costs to minimum. From the above figure it can be understood that quality at which the total cost curve is minimum 3. Present the sequential steps to be followed for Strategic Quality Planning It sets the long term direction of the organization in which it wants to proceed in future. Can be defined "As the process of deciding on objectives of the organization, on changes on this objective, on the resource used to obtain these objectives and on the policies that are to govern the acquisition use and disposition of these resources" The steps to achieve strategic quality are 4. Explain the Total Quality Management Model A holistic approach to long-term success that views continuous improvement in all aspects of an organization as a process and not as a short-term goal. It aims to radically transform the organization through progressive changes in the attitudes, practices, structures, and systems. Total quality management transcends the product quality approach, involves everyone in the organization, and encompasses its every function: administration, communications, distribution, manufacturing, marketing, planning, training, etc. Coined by the US Naval Air Systems Command in early 1980s, this term has now taken on several meanings and includes (1) commitment and direct involvement of highest-level executives in setting quality goals and policies, allocation of resources, and monitoring of results; (2) realization that transforming an organization means fundamental changes in basic beliefs and practices and that this transformation is everyone's job; (3) building quality into products and practices right from the beginning; (4) understanding of the changing needs of the internal and external customers, and stakeholders, and satisfying them in a cost effective manner; (5) instituting leadership in place of mere supervision so that every individual performs in the best possible manner to improve quality and productivity, thereby continually reducing total cost; (6) eliminating barriers between people and departments so that they work as teams to achieve common objectives; and (7) instituting flexible programs for training and education, and providing meaningful measures of performance that guide the self-improvement efforts of everyone involved. 5. What are the barriers for implementation of Total Quality Management? TQM is management philosophy that seeks to integrate all organizational functions (marketing, finance, design, engineering, production, customer etc) to focus on meeting customer needs and organizational objectives. TQM views an organization as a collection of processes. It maintains that organizations must always strive to continuously improve these processes by incorporating the knowledge and experiences of workers. Implementation of Quality The implementation of total quality is similar to that of other decentralized control methods. In developing TQM, companies need to understand how consumers define quality in both goods and services offered. If a company pays more attention to quality in its production processes, fewer problems are bound to occur when the product is in the customers’ hands. Management should make a commitment to measure the performance of a product relative to its quality through customer surveys, which can help managers to identify design, manufacturing or any other process that has a bearing on the quality of a product or service, and therefore provide an opportunity for continuous improvement. An obstacle is an object, a thing, an action or a situation that causes an obstruction. Obstacles can be physical, social, economic, technological or political. There are a number of barriers that face the process of TQM implementation. Discussed below are some of the barriers or obstacles that total quality management face during implementation 1. Competitive markets 2. Bad attitudes/abdication of responsibility/management infallibility 3. Lack of leadership for quality 4. Deficiency of cultural dynamism 5. Inadequate resources for total quality management 6. Lack of customer focus 7. Lack of effective measurement of quality improvement 8. Poor Planning 9. Lack of management commitment 10. Resistance of the workforce 11. Lack of proper training/Inadequate Human Resource Development