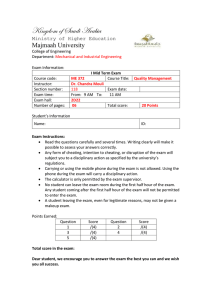

Operation Analysis 1 • Operation Planning and Control • Quality Control

advertisement

Operation Analysis 1 • Operation Planning and Control • Quality Control Operation Planning and Control Outline: • What is Supply Chain? • Production and Operation Analysis • Warehousing and Logistics • Human Factors What Is Supply Chain? Supply Chain is … Supply Chain Management is … Supply Chain Entities are … Operation Planning Control Demand Forecasting Operations Planning Inventory Planning & Control Operation Scheduling Dispatching and Progress Control Dispatching, Data Acquisition, Corrective Action, Measure of Effectiveness Just-In-Time (JIT) “Stockless Production” Method to reduce inventory level Requirements: Smooth Material Flow Reduced Setup Time Reduced Supplier Lead Time Zero-Defect Components Disciplined Shop Floor Control Material Handling, Distribution, and Routing Material Handling Equipment Concepts Conveyors, industrial trucks, cranes and hoists, containers and racks, elevators and lifts, Automatic Storage and Retrieval System (ASRS), and Automatic Guided Vehicles (AGV) Principles of Material Handling Planning, systems, material flow, simplification, gravity, space utilization, unit size, mechanization and automation, equipment selection process, standardization, adaptability, dead weight, utilization, maintenance, control, obsolescence, capacity, performance, and safety principles. Quantitative Techniques Transportation programming, Assignment technique, and Hungarian Method AGV Picture ASRS Picture Distribution Warehouse Location • Analytical technique: tedious • Easier: simulation Operations Management • Routing • Logistic Systems (adequate inventories of FG, supplying WH, and customers in an efficient and effective way) Extra Information for Material Handling BUCKET BRIGADE A way of organizing workers on a flow line so that the line balances itself (Prof. Bartholdi, Georgia Institute of Technology) Benefits: • A reduced need for planning and management (“Self Balancing”) • Production becomes more flexible and agile (“Self Tuning”) • Throughput is increased (“Spontaneously optimal division of work”) • Reduced 2ndary labor and improved quality (“Min WIP”) • Training and coordination are simplified because it is easy for workers to know what to do next Role-Play Time!! Question: Our class is opening a Virtual Factory currently employed 4 workers. – Pick up the rubber band using a pin, pencilchopstick, ruler, and hand – Put check mark on the items you have picked We have a stack of orders. Each order requires different amount for different items. How can we improve the system? Bucket Brigade Position: Slowest Fastest Whenever the fastest finishes a product: Push off the order Walk back to take over the work of his predecessor Predecessor walks back and so on, until the first worker walks back to start a new product Work is "pulled" into the system by the last, fastest worker What Did We Learn? Beginning: out of balance Afterward: quickly gravitate to the optimum partition of work Quality Management Outline Quality Management Definition Quality Control Concepts Quality Dimension and Cost The Seven Tools of Quality Control Methods Quality Improvement Quality Management Definition Definition Quality management is a method for ensuring that all the activities necessary to design, develop and implement a product or service are effective and efficient with respect to the system and its performance. Quality Management can Be considered to have three main components: • Quality Control • Quality Assurance • Quality Improvement Focus: product / service quality, System / Process The Differences… Quality Control: is the ongoing effort to maintain the integrity of a process to maintain the reliability of achieving an outcome. Quality Assurance: is the planned or systematic actions necessary to provide enough confidence that a product or service will satisfy the given requirements for quality. Quality Improvement: is the purposeful change of a process to improve the reliability of achieving an outcome. Quality Concepts W. Edward Deming 85% of quality problems within an organization or a company is a management responisbility. This is well known as the “common causes”. Introduced 14 points of management obligations in order to produce successfully. Suppliers must be evaluated based on both price and quality. The use of customer input to derive quality requirements. Mass inspection should only be used for critical opeartions. Quality Concepts (Cont’d) Joseph M. Juran Introduced the concept of Quality as “fitness for use” including quality of design, conformance, and performance, all parameters of fitmess for use. Introduced Quality Cost Model and emphasize the importance of maintaining good vendor relations. Companies must undertsand the needs of their customers. Company waste must be reduced. Companies need to do things right the first time. Quality Concepts (Cont’d) Philip B. Crosby Definition of Quality: Conformance to requirements. Every individual produce product / service and has customers. The individual is a customer of someone else. Quality achievement is a rational approcah through preventing the occurence of defects or errors. Standard performance: zero defects (no errors allowed) Measuring Parameter: quality cost, the sum of all costs a company invests into the release of quality product or service. Quality Dimension in Manufacturing • Performance: the conformance of product to its primary function. • Feature: the specific attribute of a product • Reliability: the ability of a product to perform and maintain its function in routine circumstances. • Conformance: the ability of a product to meet certain requirements or standar tha has been determined • Durability: product’s ability to endure its usable life over a long period of time. • Servicability: the ease to repair a product and the ease of obtaining replecement of broken or damaged components. • Aesthetic: the philosophical notion of the beauty of a product. • Perception: product’s image that has to do with customer’s fanatism and loyalty that will trigger repeat orders / buyers. Quality Cost Expenditure in manufacturing or service that is in excess of that which would have been incurred if the product had been built exactly right the first time. Including: quality planning, production design, processing, training, information on quality parameters, inspection, and testing equipment. Also included in quality cost: scrap, rework, process failure, process delay, discounted selling price, customer’s compalin, product claim, warranty claim, legal claim and (market loss). The Seven Tools of Quality Cause and Effect (Fishbone Diagram) Check Sheet The Seven Tools of Quality Control Chart Histogram The Seven Tools of Quality Pareto Chart Scatter Diagram The Seven Tools of Quality Stratification: A technique that separates data gathered from a variety of sources so that patterns can be seen (some lists replace "stratification" with "flowchart" or "run chart“). Quality Improvement Methods ISO 9001 Quality Funfction Deployment (QFD) Kaizen (continual improvement) Six Sigma (based on SPC) PDCA (plan-do-check-act) Quality Circle Taguchi Method Toyota Production System (adapted to become Lean Manufacturing) Total Quality Management (TQM) BPR – Business process reengineering Total Quality Management TQM is a management approach for an organization, centered on quality, based on the participation of all its members and aiming at long-term success through customer satisfaction, and benefits to all members of the organization and to society. TQM is a management strategy aimed at embedding awareness of quality in all organizational processes. TQM has been widely used in manufacturing, education, call centers, government, and service industries, as well as NASA space and science programs. It is aimed to reduce variation from every process so that greater consistency of effort is obtained. TQM Roles in Company Image Saving Increase Market Share Product accountability Export Opportunity Quality Management Planning Design and Build: including structure, process dan its implementation by top management. Deployment: Processes are broken down into documented sub-processes, supported by institution of training related to each particular sub-process. Control. Measurement. Review. Improvement.