Dr. Chandra Mouli

advertisement

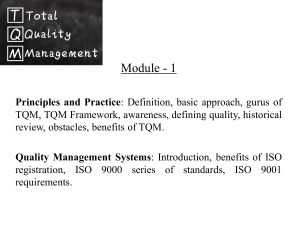

Majmaah University College of Engineering Department of Mechanical Engineering Course Syllabus Instructor Name Course Title: Prerequisite: Academic Year: Lecture Times: Office Hours Dr. Chandra Mouli ME 372 Cr.Hrs: 04 Quality Management Course code: STAT 101 NA Tues: 11-11.50 Co-requisite: Tutorial Time: 2014-15 2nd Semester: Mon: 3-3.50; Tue: 9-10.50 Exercise: 11-11.50 -Lab Time: Monday 11-1. PM 003-2-38-5 Office number Course Objectives This course aims to achieve the following objectives 1 Understand basics of Quality Management and, develop an appreciation of quality management theory, principles, and practices. 2 Implement quality improvement efforts using teams. 3 Use quality improvement tools and practices for continuous improvement. 4 Develop strategies for organizational change and transformation. Student Learning Outcomes Course Learning Outcomes By the end of this course the students will be able to 1 Understanding the need for improvement of quality in manufacture and service system 2 Ability to Function on multi-disciplinary teams for quality improvement 3 Understand the impact of engineering solutions in a global and societal context 4 Use the statistical techniques, and modern engineering tools for improvement of quality 5 Recognize the need development of strategies for continuous improvement of quality ABET Student Outcomes a,e a,e a,e a,e J,k Assessment S.No 1 2 3 4 5 6 S.No 1 2 3 4 5 6 Methods of Assessment First exam Second exam Exercise questions and participation Quiz and homework assignments Report, Project or Assignment Final Exam Total Assessed Learning Outcomes Maximum Score a, i a, i d d 20 20 10 10 0 40 100 a, i, e Course Contents Short Description Introduction: Definition of quality, Characteristics of Quality, Dimensions of quality, Quality planning, Quality costs – Value of Quality, Cost of Quality Vs Value of Quality Total Quality Management: Basic concepts of total quality management – Historical review – Principles of TQM – Concepts – Quality council –Quality statements –Strategic planning–barriers to TQM implementation. Statistical Quality Control: The seven tools of quality – Statistical fundamentals – Measures of central tendency and dispersion – Population and sample – Normal curve – Control charts for variables and attributes – Process capability analysis– Concept of six sigma – Acceptance Sampling: Sampling plans, Single, Double and Multiple sampling plans TQM Tools: Benchmarking – Reasons to benchmarking-Benchmarking process-Quality Function deployment (QFD)-Quality Circles– QFD process-Benefits Taguchi quality loss function – Total Productive Maintenance (TPM) Quality Systems: Need for ISO 9000 and other quality systems – ISO 9000:2000 Quality system – Elements – Implementation of quality system – Documentation – Quality auditing – TS 16949 – ISO 14000 –Concept – Requirements and benefits. Total Textbook: References: Week 1,2 and 3 4 and 5 6,7,8 and 9 10 and 11 12 and 13 14 and 15 15 Books Introduction to Statistical Quality Control, Douglas C. Montgomery, John Wiley & Sons, 2001 Quality Planning & Analysis, J. M, Juran & F. M. Gryna, Mc GRAW-HILL International Editions, 1993