OTEC Program Risks (MS Word)

advertisement

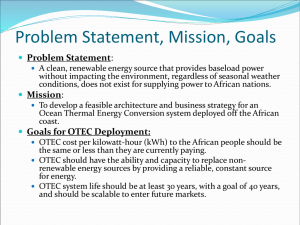

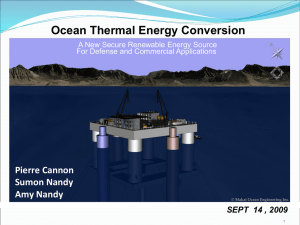

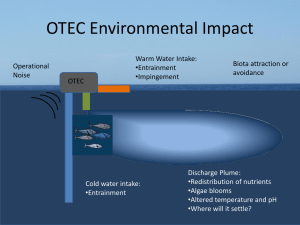

OTEC Program Risks Program Risks Legend Risk Probability Accept Manage Monitor Resolve 70% or greater R15 40 to < 70% R01 R04, R06, R07, R09, R11, R12, 10 to < 40% R13, R14 1 to <10% Neglible 0 to 7 R03, R16 R02 R05, R08, R10 Marginal Critical >7 to 14 >14 to 24 Risk Impact Catastrophic >24 R01 Schedule Managing R02 Technical Work to develop firm and agreed upon stated and derived requirements with customer. Establish Engineering Change review board and engineering change proposals as a vehicle for documenting upscope activities. Monitor activities and only work to customer approved engineering changes. Create a Requirements Integrated Project Team (IPT) with customer. Participants to include stakeholders including: partners, customer, and internal team. IPT will serve to discuss and communicate all requirements changes with team. Project status will be communicated with all parties so that all stakeholders will have an understanding of overall progress of the project. Ensure that Training and Technology manuals are budgeted and reviewed againt logisitics team for accurracy. Provide training material to the customer for final approval for comments prior to final delivery. Work with Utility provider to ensure that proper infastructure is in place prior to Power Purchase Contract is finalized and signed. Provide detailed requirements to local utillity provider early in development phase such that proper eqiupment may be located or installed or ordered for interface with OTEC system. Work with local environmental groups to understand concerns and particular ecosystems in area of platform. Establish working dialog with community groups to understand issues and factor these needs into development of the system. Managing R03 Technical Requirements Creep Active R04 Technical Meeting Requirements and Expectations Plan R05 Technical Training of Personnel Active R06 Cost Stability of Utility Provider Active R07 Technical Active R08 Technical Environmental Impacts Suitable locationg of platform (Best and worse case Work with NOAA to fully understand the ocean bathemetry and average temperture differental, monthy temperature at depth. By understanding enviornmental factors, the distance from shore) most feasible location can be selected. Probability (%) Active Overall Risk Imporance Mitigation Strategy Creation Date Proactively track activities. Reconcile budgeted cost of work performed against acutal cost of work performed on weekly basis. Keep open communication with customer and partners to ensure all parties are aware of any schedule changes or delays. Master Scheduling Planner to update and publish overall schedule to the team to be posted on common shared site for Aggressive Schedule viewing 9/1/2009 6 Schedule monthly Interface IPT working group with partners and suppliers to understand technology interfacing requirements and interface protocols. Ensure Interface Control Documents(ICDs) are submitted, reviewed, and Technology Incompatiblilites agreed upon prior to design finalization. 9/1/2009 5 Schedule Impact Risk ID Risk Category Risk Description Techical Impact Status Cost Impact Program Risk Register 10 0 16 50 10 7 22 30 9/1/2009 4 5 4 13 30 9/1/2009 2 1 2 5 9/1/2009 3 5 3 11 10 9/1/2009 2 2 1 5 5 9/1/2009 1 1 3 5 10 9/1/2009 3 4 2 9 5 10 Status Risk ID Risk Category Risk Description Cost Impact Techical Impact Schedule Impact Overall Risk Imporance Probability (%) Managing R09 1 3 1 5 10 Managing R10 6 2 1 9 5 Managing R11 3 1 3 7 10 Active R12 3 1 1 5 20 Managing R13 3 2 1 6 10 9/1/2009 1 4 1 6 10 Mitigation Strategy Creation Date Leverage subcontractor research performend by the Lockheed Martin customer and select subcontractors with a history exemplory performance and Technical Selection of subcontractors ethics. 9/1/2009 Leverage expertise of partners and involve stakeholders early in process. Technical Selection of major componets Perform market and early prototyping analysis. 9/1/2009 Work with Nigerian Government to select an apporaprete fanufactoring Suitable onshore facility. Work with subcontracs team to identify commercially avaible ships, Schedule/Costmanufacturing facility dry docks, tugs, and similar marine construction crafts. 9/1/2009 Piracy has been an issue for some Oil Refinaries in the Niger Delta. The OTEC system will best practices to insure crew members are safe during there time Technical System security on the platform. 9/1/2009 Size marine cable to handle 15% higher voltage rating that the expected peak power distrobution. Work with local environmental groups to understand the particurlar environment where the cable is to be placed to ensure minimal impact on the Technical Underwater marine cable ecosystem. 9/1/2009 Plan R14 Technical Working Fluid Leaks Managing Managing R15 R16 Cost Technical OTEC Platform Costs Unfamiliar Design Elements Develop a strict maintenance schedule and procedure for the working fluid subsystem. Crew are to follow the documented procedure and OSHA regulations to ensure ammonia spills are handled as mandated in regulations. Perform studies to determine the correct location for the OTEC platform, sizing of heat exchangers, pumps, cold water pipe, and other major subsystem components Leverage expertise of partners and involve stakeholders 9/1/2009 10 1 3 14 75 1 6 2 9 20