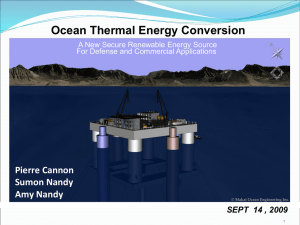

Renewable Energy Sources for Caribbean Territories and SIDS: OTEC M. L. Anderson, 2009 Ocean Thermal Energy Conversion Ocean Thermal Energy Conversion Ocean thermal energy conversion (OTEC) is a method for generating electricity which uses the temperature difference that exists between deep and shallow waters OTEC: What is it? Thermal energy- form of energy that manifests itself as an increase of temp. Method for generating electricity. Runs a heat engine- a physical device that converts thermal energy to mechanical output Uses temp. difference that exists b/w deep & shallow waters. Temperature difference between warm surface water and cold deep water must be >20°C (36°F) for OTEC system to produce significant power. Background Information 60 million km2. (23 million miles2) of tropical seas absorb a tremendous amount of solar radiation. Heat content equal to about 250 billion barrels of oil. If less than 1/10th of 1% of this stored solar energy. converted to electric power, it would supply more than 20 times the total amount of electricity consumed in the U.S. on any given day. Ocean Thermal Energy Conversion (OTEC) Ocean Thermal Energy Conversion produces electricity from the natural thermal gradient of the ocean, using the heat stored in warm surface water to create steam to drive a turbine, while pumping cold, deep water to the surface to recondense the steam. Ocean Thermal Energy Conversion Ocean Thermal Energy Conversion is only viable in the tropical seas, in areas where the thermal gradient between the surface and a depth of 1000m is at least 22°C. Ocean Thermal Energy Conversion (OTEC) Generates power with temperature differential between warm surface water and cooler, deep water Requires temp differential of 36 F 50 kW mini-OTEC plant in Hawaii operated in the ’80s OTEC limited applications – Very costly – Limited suitable sites – can’t justify for electricity – must also desalinize, sustain aquaculture, etc… The Technologies: Ocean Thermal Energy Conversion (OTEC) Ocean’s natural thermal gradient (warm surface waters, cold deep waters) drives power-producing cycle OTEC converts solar radiation to electric power – Tropical seas cover 60 million km2 -- world’s largest solar collector – Solar radiation absorbed on average day equal in heat content to ~250 billion barrels of oil Three types of OTEC systems: open, closed, and hybrid Closed Cycle OTEC In closed-cycle OTEC, warm seawater heats a working fluid, such as ammonia, with a low boiling point, such as ammonia, which flows through a heat exchanger (evaporator). The ammonia vapor expands at moderate pressures turning a turbine, which drives a generator which produces energy. OTEC: Closed Cycle The vapor is then condensed in another heat exchanger (condenser) by the cold, deep-ocean water running through a cold water pipe. The working fluid (ammonia) is then cycled back through the system, being continuously recycled. Open Cycle OTEC In an open-cycle OTEC plant, warm seawater from the surface is the working fluid that is pumped into a vacuum chamber where it is flash- evaporated to produce steam at an absolute pressure of about 2.4 kilopascals (kPa). The resulting steam expands through a low-pressure turbine that is hooked up to a generator to produce electricity. The steam that exits the turbine is condensed by cold, deep-ocean water, which is returned to the environment. If a surface condenser is used, the condensed steam remains separated from the cold ocean water and can be collected as a ready source of desalinated water for commercial, domestic or agricultural use. OTEC Open Cycle System In an open-cycle plant, the warm water, after being vaporized, can be re-condensed and separated from the cold seawater, leaving behind the salt and providing a source of desalinated water fresh enough for municipal or agricultural use. OTEC Hybrid Cycle System Hybrid plants, combining benefits of the two systems, would use closed-cycle generation combined with a second-stage flash evaporator to desalinate water. History Jacques Arsene d’Arsonval 1881- Jacques Arsene d’Arsonval, French physicist, proposed tapping the thermal energy of the ocean. 1930- Georges Claude, d’Arsonval’s student, built the 1st OTEC plant in Cuba. 1935- Claude constructed another plant aboard a 10,000 ton cargo vessel off the coast of Brazil. Weather & waves destroyed both plants before they could become net power generators. History Cont. Ivory Coast 1956- French scientists designed another OTEC plant for Abidjan, Ivory Coast, West Africa. The plant was never completed due to reduced energy costs. Large amounts of cheap oil became available in the 1950’s. 1962- J. Hilbert Anderson & James H. Anderson, Jr. started designing a cycle that focused on developing new, more efficient component design. 1967- patented new "closed cycle" design. History, Con’t. 1970- Tokyo Electric Power Company successfully built & deployed a 100 kW closed-cycle OTEC plant on the island of Nauru. Japan 1981- Became operational Produced about 120 kW of electricity . 90 kW was used to power the plant & the remaining electricity used to power a school & several other places on Nauru. Set a world record for power output from an OTEC system where the power was sent to a real power grid. OTEC Development The Tokyo Power Company built a 100 kW shore-based closed cycle pilot power plant on the island of Nauru, in 1981. The pilot plant achieved a net output of 31.5 kWe during continuous operation, proving the principle of OTEC is a viable energy alternative. The plant is now decommissioned. Postage stamps commemorating the OTEC pilot project located on Nauru. India and OTEC The government of India has taken an active interest in OTEC technology. India has built and plans to test a 1 MW closed-cycle, floating OTEC plant. Land Based Plants …Have both advantages and disadvantages over shelf based and floating plants. Unlike those plants that are on the ocean shelf or floating in the open ocean, land based plants do not require long cables or anchors that are very expensive. They require less maintenance and can be installed in areas that are sheltered from storms which could possibly destroy the plant. In addition, land based plants can support mariculture using desalinated water. However, land based plants are subject to the extremes of the surf zone, heavy seas and storms. This causes stress on the water supply and discharge pipes. The problem could be helped if the pipes were buried in trenches, or if the plant were moved into water 10-30 meters deep, but this presents erosion problems as well. Shelf-Based Plants OTEC plants can be placed on the continental shelf, down to depths of no more than 100 meters. The same kind of construction that is used to build offshore oil rigs would be used to build shelf-based plants. These plants would have problems with product delivery and the stressors of the open ocean. Working these plants in water 100 meters deep also presents problems and these plants are more expensive than the land-based plants. Floating Plants They are not tied to a land base and therefore require long and expensive cables that would get tangled and need repair. If the base was not kept stable, the cold water pipe might break, especially during high seas and storms. However, this problem could be solved by using flexible polyethylene to attach the pipe to the bottom of the plant along with joints and collars. Instead of using a warm water pipe, the floating OTEC plant could simply draw in the warm water from the surface. But, storms and high seas can interrupt the water flow and cause major damage to the plant. US OTEC Development The US has taken the lead in OTEC/DOWA development, primarily through work carried out at the National Energy Laboratory of Hawaii (NELHA) at Keahole Point. The first real breakthrough was in 1979 with the successful operation of ‘Mini-OTEC’, a 50 kWe closed-cycle demonstration plant, becoming the worlds first net power producing OTEC plant. History Continued 1974- United States became involved in OTEC research Natural Energy Laboratory of Hawaii Authority was established. Has become one of the world's leading test facilities for OTEC technology. 1980- two laws enacted to promote commercial development of OTEC technology. Ocean Thermal Energy Conversion Act, and the Ocean Thermal Energy Conversion Research, Development, and Demonstration Act . Natural Energy Laboratory, Hi. NELHA, Hawaii In 2001 NELHA established an ocean energy park at Keahole Point. It uses cold deep seawater that is pumped to the surface to produce energy, air-conditioning, desalination, fish farming and agriculture. Additional OTEC projects are being considered for Hawaii. In 2006 , the Kailua-Kona opencycle OTEC plant operated by PICHTR generated 225 kW gross of electricity and 104 net. This plant is part of a $12-million, five year project, with a majority of the power used by NELHA. NELHA, Hawaii Over 9,000 gallons/minute of seawater pours in from 13 upright white plastic pipes. As the pressure drops to that of 70,000 feet, the 72oF water goes ballistic in the vacuum chamber. As less than 0.5% of the incoming ocean water becomes steam, huge amounts of water must be pumped through the plant to create enough steam to run the large, low pressure turbine. The quantities of water needed limits the open-cycle system of no more than 3MW of gross power, as the bearing support system for larger turbines is not practical. In comparison, a large nuclear reactor can produce 1,000 MW. The real advantage of this system is the by-products such as large quantities of desalinated water, air conditioning and ocean minerals. Location: Cayman & Puerto Rican Trenches The Cayman Islands , Cuba, Jamaica, and all of the islands off of the Puerto Rican Trench are all ideal locations for OTEC technology, These are the deepest parts of the Caribbean, over four miles deep. For a shore-based plant, an additional requirement is topography that allows access to very deep water (1km or deeper) directly offshore, conditions that exist at certain tropical islands, coral atolls, and a limited number of continental sites. In the United States, potential sites include Hawaii, Puerto Rico, and the continental shelf off the Gulf of Mexico. Ocean Thermal Energy Conversion OTEC plants can either be built onshore or on offshore floating platforms. Energy can be transported via seafloor cable, just a short distance from platform to grid. The OTEC platforms could be located in shallow water, right on the edge of the trench, which is a huge escarpment like structure that plunges straight down. Proposed Lockheed OTEC System More Potential OTEC Sites The OTEC platforms could be located in shallow water, right on the edge of the trench, which is a huge escarpment like structure that plunges straight down. The South Pacific and Molokai, Hawaii. American Territories such as Guam, American Samoa and US Gulf Coastal areas. Caribbean islands adjacent to deep-sea trenches. Military and security uses of large floating plant -ships with major life-support systems such as power, desalinated water, cooling and aquatic food. Ships such as this could save many lives and relieved great suffering in natural disaster areas such as the 2004 EQ/T in Banda Ache, Thailand, Indonesia, and Sri Lanka. OTEC Grazing plant-ship. OTEC Efficiency The thermal gradient gives OTEC a typical energy conversion of 3 to 4%, whereas conventional oil or coal fired steam plants, often have temperature differentials of 500oF, yielding thermal efficiencies of 30 to 35%. Remember, the greater the difference between hot and cold temperatures, the greater the efficiency of the energy conversion system. So to compensate for its low thermal efficiency, OTEC has to move a tremendous amount of water. It takes 20 to 40% of the power generated to pump the water through intake pipes in and around an OTEC system. This is why, almost 100 years after the idea was first conceive, OTEC researchers are still striving to develop plants that will consistently produce more energy than is needed to run the pumps, and that will operate in the corrosive marine climate, to justify the development and construction. Ocean Thermal Energy Conversion Benefits of OTEC: Dependable constant energy source Fresh drinking water Air conditioning Refrigeration Sea salt & minerals Agricultural and Maricultural uses Drawbacks: Still in the developmental / experimental stage. Benefits Promotes competitiveness and international trade Enhances energy independence and energy security Promotes international sociopolitical stability Reduce greenhouse gas emissions resulting from burning fossil fuel In small island nations promotes self-sufficiency minimal environmental impacts improved sanitation and nutrition Economic Benefits Helps produce fuels such as hydrogen, ammonia, and methanol Produces base load electrical energy Produces desalinated water for industrial, agricultural, and residential uses Provides air-conditioning for buildings Provides moderate temperature refrigeration Potential to provide clean, cost effective electricity for the future Desalinated Water Desalinated water can be produce from either open-cycle or hybrid OTEC plants. In an open-cycle plant, the warm water, after being vaporized, can be re-condensed while being kept separate from the cold seawater, leaving behind the salt and providing a source of desalinated water fresh enough for municipal or agricultural use. The condensate is relatively free of impurities and can be collected and sold to local communities where freshwater supplies are limited. How OTEC is used Aquaculture is the cultivation of aquatic organisms. Aquaculture, also known as aquafarming, implies the cultivation of aquatic populations under controlled conditions. Cold, deep seawater brought up by OTEC pipes is nutrient-rich and parasite and free, and can be pumped into onshore ponds producing algae or other products in a controlled system. At the National Energy Laboratory of Hawaii (NELHA), private companies have already profited from raising lobsters, flounder, and high-protein algae in mariculture ponds fed by the cold water. This cold water has also been used to grow temperate crops such as strawberries in Hawaii's tropical climate. The tremendous volume of water pumped required to run an OTEC plant, when funneled out to a mariculture facility will reduce disease and contamination in growing ponds, enabling marine life, such as shrimp, to be grown in higher densities. The low-cost refrigeration, can also be used to upgrade or maintain the quality of indigenous fish, which tend to deteriorate in hot, tropical climates. Mariculture How OTEC is used The cold seawater delivered to a plant can be used in chilled-water coils to provide air-conditioning for buildings Also supports chilled soil agriculture. Seawater Air Conditioning In tropical locations, air conditioning is one of the largest uses of electricity in homes and businesses. Seawater air conditioning (SWAC) pumps cold seawater (5oC; 41oF) to a station via a deep-sea pipeline to a cooling station on shore, where it is used to cool freshwater, which is then piped to a building’s air conditioning system via chilled-water coils. The seawater is returned to the ocean through a pipe and diffuser system. Currently, both of the two main buildings at the National Energy Laboratory of Hawaii Authority (NELHA) in KailuaKona on Hawaii are effectively air conditioned by cold seawater pumped through OTEC pipes. References "Ocean Thermal Energy Conversion." Energy Savers. 30 DEC 2008. U.S. Department of Energy. 3 May 2009 <http://www.energysavers.gov/renewable_energy/ocean/index.cfm/mytop ic=50010>. "Ocean Thermal Energy Conversion." National Renewable Energy Laboratory. 3 May 2009 <http://www.nrel.gov/otec/what.html>. "Ocean Thermal Energy Conversion." Wikipedia. 20 Apr 2009. Wikimedia Foundation, Inc.. 3 May 2009 <http://en.wikipedia.org/wiki/Ocean_thermal_energy_conversion>. Striving for a Sustainable Future: Environment Energy Economics Equity Education