An Introduction to Nanomechanical testing Nanoindentation

advertisement

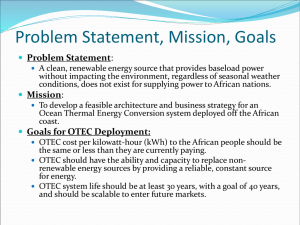

MICRO MATERIALS Bringing nanomechanical measurements into the real-world MEASURING NAN OTEC HNOL OGY An Introduction to Nanomechanical testing Nanoindentation Nanoscratch/nanowear On bio-Materials and other samples Dr Krish Narain, Micro Materials Ltd., Wrexham MICRO MATERIALS MEASURING NAN OTEC HNOL OGY Why do we need nanoindentation? • Coatings are getting more complex • Mechanical properties are critical • If we can understand them then we can engineer better materials • Yield, cost and performance benefits MICRO MATERIALS MEASURING NAN OTEC HNOL OGY • The NanoTest investigates properties on coatings from 5nm to 200 microns • Provides hardness and toughness data of many types • Automated running for multiple analysis • Looks at materials under working conditions • Single, multiple layer or bulk properties MICRO MATERIALS Bringing nanomechanical measurements into the real-world MEASURING NAN OTEC HNOL OGY Key advantages for biomaterials testing • The NanoTest system is based around a pendulum (see next slides for more details) which gives these key advantages for testing biomaterials… • Nanoindentation testing with ultra-low thermal drift (typically 0.005 nm/s or less) • Nanoscratch testing without bending springs • Nanoscale impact/fatigue testing (no other instrument can do this) Micro Materials – Innovation track record MICRO MATERIALS MEASURING NAN OTEC HNOL OGY Founded 1988, based in Wales • Application labs in UK, USA, Germany, Japan • Worldwide support network: LOT Oriel in Europe... Aim: to become the world leader in the development and manufacture of nanomechanical testing equipment Pioneering and progressive approach:• First commercial nano-impact tester for measuring toughness and fatigue resistance • First commercial high temperature nanomechanical testing stage Bringing nanomechanical measurements into the real-world MICRO MATERIALS NanoTest nanomechanical test capability MEASURING NAN OTEC HNOL OGY To use the NanoTest system.. 1) Nanoindentation module to obtain accurate hardness (H) and reduced modulus (Er) values for the coating 2) Scanning module to obtain critical load in scratch test 3) Nano-impact module to assess fracture resistance and durability under dynamic loading 4) High temperature stage to assess coating performance at elevated temperatures (to 750 degrees C) Road-map for development of advanced materials MICRO MATERIALS MEASURING NAN OTEC HNOL OGY Nanoindentation Nano-scratch Nano-impact High temp testing Lab tests at development stage Mechanical properties Design-in reliability Tribological properties Hardness Stiffness Fracture toughness Load support Optimised performance of thin film/coating system Test under industrially relevant conditions …at the nanoscale MICRO MATERIALS Friction Adhesion Resistance to •Abrasive Wear •Sliding Wear •Brittle fracture •Fatigue wear •Dynamic Loading •Corrosion Durable product = Satisfied customer! Nanoindentation principle MEASURING NAN OTEC HNOL OGY unloading substrate coating loading Indentation curve • No other coating substrate technique provides quantitative information about both the elastic and plastic properties of thin films and small volumes • force, displacement and time are recorded throughout indentation of sample by a diamond probe Beyond nanoindentation… Scanning = transverse sample movement during loading Impact = sample oscillation at constant load MICRO MATERIALS Viscoelastic Effects during Indentation MEASURING NAN OTEC HNOL OGY 16 12 250 Polyester 200 150 100 10 8 6 4 Aluminum 50 0 1 mN/s 0.1 mN/s 0.001 mN/s Hold time = 100 sec 14 Epoxy 300 Load (mN) Creep displacement (nm) 350 2 Steel 0 20 40 60 80 Hold time (s) Creep at constant load 100 0 0 500 1000 1500 2000 2500 Depth (nm) Creep effects as a function of loading rate Data: Courtesy Dr Raman Singh, SUNY Stonybrook MICRO MATERIALS MEASURING NAN OTEC HNOL OGY ISO standards – ISO 15477 4 mandatory user calibrations are needed: • Load • Depth • Diamond area function • Frame compliance For example without DAF – you can measure Martens hardness – but this is only applicable to Micro Hardness measurements according to ISO standards Bringing nanomechanical measurements into the real-world MICRO MATERIALS MEASURING NAN OTEC HNOL OGY The NanoTest pendulum MICRO MATERIALS Advantages of the pendulum include… • large samples possible • calibrated contact load • high temperature stage • sample oscillation (impact) • options such as pin-ondisk wear testing and 2D levelling stage • symmetrical indents • scratching in high stiffness direction NanoTest platform system MEASURING NAN OTEC HNOL OGY a flexible nanomechanical property testing centre... 2 loading heads Nano - 10 µN - 500 mN Micro - 0.1 N - 20 N 3 modules Indentation Scanning Impact 10 options including High temp testing Continuous compliance Pin-on-disk wear Microscopes/AFM 3D imaging NT head MT head Microscope Stage Assembly +Z +Y +X Repositioning to 0.5 µm Transfer stage (indenter/microscope) NanoTest Options MICRO MATERIALS MEASURING NAN OTEC HNOL OGY NanoTest options… • High Temperature Stage • Automatic 2D levelling stage • High Load Head (20 N) • Micro-scale Pin-on-disk • Continuous Compliance • Humidity Control • Spherical Indentation • Powder Adhesion • Acoustic Emission • High Resolution Microscope • Zoom Microscope • In-situ AFM • Piezo stage Imaging • Open access to signals MICRO MATERIALS MEASURING NAN OTEC HNOL OGY How homogeneous is my coating? An example of nanoindentation as a QA tool • rapid, automatic scheduling of arrays of indentations - 10,000 points per single run - or 100 scratches Indentation: mapping (1) MICRO MATERIALS Nanoindentation of bone MEASURING NAN OTEC HNOL OGY Nanoindentation into osteonal bone… • NanoTest high resolution microscope used to exactly place indents • Osteonal bone is stiffer than interstitial bone MICRO MATERIALS Bone: Nanoindentation creep MEASURING NAN OTEC HNOL OGY Bone is viscoelastic, so to obtain accurate H and E values, the tests need:• Slow loading • Long hold period at max. load for creep (180s) • Good thermal drift (as creep recovery can be important) Creep of osteonal bone fitted to a log function • Only the NanoTest system has additional software for investigating this creep deformation – which provides additional characterisation information on rate and extent of creep MICRO MATERIALS MEASURING NAN OTEC HNOL OGY Use of Nanoindentation to assess new candidate surface modification technologies for biomedical applications Data from European project “Ion Beam Surface Modification of Polymers for Improved Friction and Wear Properties” Micro Materials Ltd (UK) University of Birmingham (UK) Technical University of Clausthal (Germany)) SC Plasmaterm (Romania) Hungarian Academy of Sciences (Hungary) Wear resistance predicted from H/E ratio correlates to Pin-on-Disk wear tests and Nano-tribology results Follow-up project – dynamic loading and fatigue MICRO MATERIALS No thermal drift correction necessary… MEASURING NAN OTEC HNOL OGY Loading history on polymer = load then hold for 30 s Variation in loading curve and creep with loading rate displacement (nm) 100 80 after 60 before 40 creep 20 0 0.0001 0.001 0.01 0.1 loading rate (mN/s) 1. After 30s hold period at maximum load depth is the same in very slow and fast tests 2. Only an instrument with negligible thermal drift could perform these tests, with loading rates varying by x300 Nanoindentation of PEO/Clay Nanocomposites MICRO MATERIALS MEASURING NAN OTEC HNOL OGY Improving polymer performance… 1 • to produce advanced materials with improved mechanical properties by PEO intercalation between clay layers 2 • to accurately characterise their nanomechanical properties so synthetic and fabrication methods can be optimised 2 key aims… Nanoindentation of polymer-clay nanocomposites… Ben Beake (MML), Shuaijin Chen, J Barry Hull and Fengge Gao (Polymer Engineering Centre, Nottingham Trent) MICRO MATERIALS Nanoindentation of PEO/Clay Nanocomposites MEASURING NAN OTEC HNOL OGY Pure PEO PEO/ 20 % clay Indentation on melt-synthesised PEO Very high hardness at High clay loadings Low hardness influenced by creep? G-105 clay/solution-synthesised PEO • Hardness and stiffness of PEO film are dramatically improved by addition of high clay loading Ben Beake*, Shuaijin Chen J. Barry Hull and Fengge Gao J Nanosci. Nanotech. 2002 vol 2, 73-79. Nanoindentation of PEO/Clay Nanocomposites MICRO MATERIALS MEASURING NAN OTEC HNOL OGY The variation with clay is striking when creep data are fitted to d = A ln(Bt + 1) A Influence of creep on hardness… 200 180 160 140 120 100 80 60 40 20 0 0.25 0.2 0.15 0.1 0.05 0 0 20 40 60 80 % G-105 Clay Good fit to logarithmic creep equation A determines extent of creep B determines rate of creep More clay – slows creep process Explains small decrease in hardness at low loading MICRO MATERIALS Depth profiling with the load-partial-unload technique MEASURING NAN OTEC HNOL OGY Plasma-polymers deposited at 100 W and 25 W power… 100 W 25 W 25 W 100 W 20 cycle load-partial-unload experiment – takes 30 mins B MICRO MATERIALS Mapping hardness and modulus MEASURING NAN OTEC HNOL OGY Nanomechanical properties of burnt polyurethane foams in resin 450 450 5.5-5.75 400 5-5.25 300 4.75-5 250 4.5-4.75 z 300 250 100 3.75-4 100 50 3.5-3.75 50 375 350 325 300 275 250 225 200 175 150 125 100 75 50 25 0 0 3.25-3.5 400 150 200 200 4-4.25 300 4.25-4.5 150 0 125-150 150-175 175-200 200-225 225-250 250-275 275-300 300-325 325-350 350-375 350 100 300 400 100 200 5.25-5.5 350 200 5.75 4.75 5.25 3.75 4.25 2.75 3.25 1.75 2.25 0.75 1.25 0.25 5.5 4.5 3.5 2.5 1.5 0.5 5 4 3 2 1 0 0 400 z 0 y y Modulus (GPa) Hardness (MPa) optical image Nano-mechanical properties of heterogeneous, multi-phase soft samples can be quantitatively mapped Ultra-low load nanoindentation MICRO MATERIALS MEASURING NAN OTEC HNOL OGY Ultra-low load (10 µN) testing of soft samples IPP Repeat Indentations 0.012 0.01 Load (mN) 0.008 0.006 0.004 0.002 0 0 5 10 15 20 25 30 Depth (nm) • For slow loading excellent thermal stability is necessary MICRO MATERIALS Room Temperature or real temperature MEASURING NAN OTEC HNOL OGY The standard nanoscale mechanical/tribological test techniques are very useful… Nanoindentation – mechanical properties (hardness, modulus, creep) Nanoscratch – tribological properties (resistance to abrasive/sliding wear) But… • All material properties are temperature-dependent MICRO MATERIALS MEASURING NAN OTEC HNOL OGY NanoTest hot stage … Thermal shield For clarity, separate diamond heater not shown Insulation Heater element Damping plate Thermocouple Power supply + temperature controller MICRO MATERIALS Nanoindentation of Si(111) MEASURING NAN OTEC HNOL OGY At room temperature Si(111) undergoes phase changes… At slow unloading rate the popout only in room temp data Phase changes:Si-I diamond-type to Si-II β-tin on loading …to Si-XII and Si-III on slow unloading 200 deg. C 29 deg. C “Pop-out” during unloading Nanoindentation Parameters:- • Different unloading slopes as test temperatures increases • Elastic modulus reduced by 27% at 200 degrees C Loading rate = 1.67 mN/s Hold period at maximum load = 5s Unloading rate = 0.56 mN/s MICRO MATERIALS • No observable “pop-out” at slow unloading rates • Implications for microelectronics processing/applications Nanoindentation of solgel coatings on Si MEASURING NAN OTEC HNOL OGY 20 µm spheroconical indenter Room temp modulus agrees well with Berkovich data Modulus drops with temperature Er [GPa] Reduced modulus solgel coating on Si as function of temperature 10 9.5 9 8.5 8 7.5 7 6.5 6 100C RT 0 50 100 depth [nm] Data courtesy Philips Research, Netherlands 150 MICRO MATERIALS Nanoindentation testing of NiTi at high temperature MEASURING NAN OTEC HNOL OGY The NiTi shows shape memory behaviour above the transition temperature AJ Muir Wood, V Gergely and TW Clyne, Gordon Laboratory, Dept of Materials Science and Technology, University of Cambridge. Proc SPIE 2004 (in press) MICRO MATERIALS MEASURING NAN OTEC HNOL OGY High temperature friction Fused quartz rod Thermal shield Diamond holder Test probe Double force transducer Thermal insulation MICRO MATERIALS MEASURING NAN OTEC HNOL OGY Friction coefficient at RT and 200ºC Friction coefficient Influence of Temperature on Friction Coefficient 0.5 200C 0.4 0.3 0.2 0.1 Room temp. 0 0 50 100 150 200 250 Scan distance (microns) 1 mm dia. stainless steel ball + glass substrate Scan speed 4 µm/s Normal load 4 mN MICRO MATERIALS Stiction at 400ºC MEASURING NAN OTEC HNOL OGY 1 mm dia. stainless steel ball + glass substrate Scan speed 4 µm/s Normal load 4 mN Friction coefficient Stiction at 400C and a Load of 4 mN 2 1.5 1 0.5 0 0 50 100 150 200 250 Scan distance (microns) 1 mm dia. stainless steel ball + glass substrate Scan speed 4 µm/s Normal load 0.4 mN Friction coefficient Stiction at 400C and a Load of 0.4 mN 14 12 10 8 6 4 2 0 0 50 100 150 Scan distance (microns) 200 250 MICRO Influence MATERIALS of temperature on adhesion MEASURING NAN OTEC HNOL OGY Adhesion of Stainless Steel to Glass 100 Displacement (nm) 50 0 -1 -0.5 0 0.5 1 1.5 2 2.5 3 3.5 -50 RT 400C -100 -150 -200 -250 Load (mN) 1 mm dia. stainless steel ball + glass substrate MICRO MATERIALS Nano-and Micro-scratch test principle MEASURING NAN OTEC HNOL OGY Sample motion during loading makes nano-scratch tests possible… transverse sample motion with XYZ stage loading coating substrate 1. Force, displacement, friction, acoustic emission and time are recorded throughout the scratching of a test sample by a diamond probe 2. Can test much thinner coatings and more local scratch behaviour than conventional scratch test MICRO MATERIALS Nanoscratching of thin hard ta-C films on Si for MEMS MEASURING NAN OTEC HNOL OGY Carbon films on Si as protective overcoats for hard disk, MEMS Friction Precise determination of Critical load (Lc) for film failure • Friction force data • Displacement data • Microscopy 50 µm Depth 100 µm Track end MICRO MATERIALS MEASURING NAN OTEC HNOL OGY As hydroxyapatite is the main Calcium Phosphate in bone, it is being considered as a biocompatible coating for artificial joint replacements NanoTest system has been used to evaluate the abrasive wear resistance of HA coating… Nanoscratch testing MICRO MATERIALS Nanotribology MEASURING NAN OTEC HNOL OGY Multi-pass sub-critical load scratch testing 2, 4, 6 dplast 1, 3, 5, 7 dtotal Experimental parameters: 25 µm Rockwell probe scratch load:- ramped to 1 mN topography load 0.1 mN scan speed 0.5 µm/s Nano-scratching wear of PET film Repeat scratches over the same wear track reveal gradual wear of oriented polyester [PET] film Nanotribology MICRO MATERIALS MEASURING NAN OTEC HNOL OGY 2 different PET samples clear differences in nano-scratching wear with processing history... • extent of ploughing • differences in elastic recovery (dp/dt) Evaluate sliding wear resistance of different coating formulations dplast dtotal Biaxially drawn PET film - 50% crystalline dplast dtotal Uniaxially drawn PET film ~ 30% crystalline BD Beake (MML) and GJ Leggett (UMIST), Polymer 2002, 43, 319-327. MICRO MATERIALS Evaluation of Dental Composites MEASURING NAN OTEC HNOL OGY Dental composite materials used to be evaluated by standard macroscale test methods – but results were inconsistent NanoTest wear depth data for repeat scratches on common composites… Scratch depth (microns) So the NanoTest is being used to rapidly evaluate the abrasion resistance of new improved composite materials The new composites in this study were shown to have better abrasion resistance than conventional materials MICRO MATERIALS Nano-impact testing MEASURING NAN OTEC HNOL OGY The need for dynamic testing Materials can fail by fatigue not overload so optimisation based on nanoindentation/scratch may be insufficient for applications where materials are exposed in service and/or in processing to fatigue wear or erosive wear (impact wear) Dynamic nanomechanical tests (nano-impact and contact fatigue) have been developed by Micro Materials to address this problem MICRO MATERIALS Impact MEASURING NAN OTEC HNOL OGY Nano-impact testing - simulating fatigue wear and failure 2 different methods… Sample oscillation Pendulum impulse impact • High frequency oscillation • High cycle fatigue MICRO MATERIALS • Accurately controlled impacts • Known energy to failure • Wear mechanisms 1N load repetitive contact testing reveals clear differences…. MEASURING NAN OTEC HNOL OGY Collaboration with Ito Tecnologia Cerámica, Castellon, Spain Impact at high load = Contact fatigue testing • A and C fracture easily but B and D do not fracture within 500s • Can we correlate with fracture toughness data? • Can we correlate with microstructure? MICRO MATERIALS MEMS: nanostructured Si and SiO2 MEASURING NAN OTEC HNOL OGY Fracture and fatigue wear by Nano-impact testing Unimplanted SiO2 1 x 1016 N cm-2 implanted SiO2 Damage regimes in the impact test: 1 = before impact 2 = plastic deformation 3 = slow crack growth (fatigue) 4 = abrupt failure and material removal 5 = further slow crack growth 1 impact every 4 s in these tests • Fatigue resistance from time-to-failure • Ion-implantation improves toughness BD Beake (MML), J Lu, Q Xue, and T Xu, (all Lanzhou Institute of Chemical Physics) Proc FMC8 2003 MICRO MATERIALS Nano-impact mapping of biomaterials MEASURING NAN OTEC HNOL OGY Grids of impacts to determine differences in toughness/ductility… Variation in fatigue properties across finger nail of 42 yr old woman 500 Impact depth (nm) 100 200 300 400 500 400 2500-3000 position 300 (microns) 2000-2500 200 1000-1500 100 600 1500-2000 Collaboration in progress with Universities of Limerick and Lancaster 500-1000 0-500 position (microns) • Initial results suggest the nano-impact test can be used to identify osteopaenia (2-5 times greater risk of osteoporosis in later life) • No other nanoindentation system has the capability to do nano-impact so no other system can investigate toughness and fatigue at the nanoscale MICRO MATERIALS Fatigue and Fracture Wear of ta-C films MEASURING NAN OTEC HNOL OGY 80 nm on Si 80 nm on Si 60 nm on Si 5 nm on Si Damage mechanism in the impact test: before impact - plastic deformation - slow crack growth (fatigue) - abrupt failure and material removal - further slow crack growth • time-to-first-failure to rank impact resistance • some plastic deformation of the substrate does occur (depth at failure) MICRO MATERIALS MEASURING NAN OTEC HNOL OGY DLC: is it tough enough for your application? Diamond-like-carbon (DLC) has high hardness and low friction so it is being considered for many applications But its fatigue properties have not been fully tested – this is particularly important as It is prone to poor adhesion It has been considered as an inert coating for biomedical devices The NanoTest is being used to investigate the toughness and durability of DLC coatings to fatigue wear with the nano-impact facility… MICRO MATERIALS Impact failure of 550 nm DLC film on Silicon MEASURING NAN OTEC HNOL OGY Coating debonding - adhesion failure Abrupt depth change at failure > film thickness CVD Coating Deposition RF Power Coating fracture – cohesive failure Depth change at failure less than film thickness Nano-impact shows how deposition conditions influence coating performance • Time-to-failure • Failure mechanism BD Beake et al, Diamond and Related Materials, 11, 1606, 2002 MICRO MATERIALS MEASURING NAN OTEC HNOL OGY Nano-impact can be used to assess the toughness and adhesion of DLC coatings under industrially relevant conditions DLC suffers from brittleness DLC suffers from high stress DLC suffers from poor adhesion DLC suffers from poor resistance to fatigue Nano-impact is a very quick and easy way to optimise DLC performance Next slide shows typical brittle fracture and debonding of DLC after repetitive contacts (impact) MICRO MATERIALS MEASURING NAN OTEC HNOL OGY Nano-impact can assess DLC performance 1. Under a range of contact conditions (I.e. from light to severe loading) – important since many tests are too gentle 2. Quickly 3. Provides clear-cut time-to-failure data 4. Microscopy confirms failure mode…(see next slide) 5. Can test on actual component MICRO MATERIALS Nano-impact results on commercial DLC MEASURING NAN OTEC HNOL OGY Hydrogenated DLC (a-C:H) 50 µm Ring-cracking Hydrogen-free DLC (a-C) 50 µm Delamination occurs for the DLC on the left – it is not suitable for severe contact conditions Mapping variations in high-strain rate deformation MICRO MATERIALS MEASURING NAN OTEC HNOL OGY Grids of impacts to determine differences in toughness/ductility… Mapping of fatigue properties across crab shell Toughness map for ABS 25wt% rubber 21 18 15 nm 0 3 6 200-240 0 9 12 15 18 21 950 650 800 350 240-280 3 500 280-320 6 Impact depth (nm) 50 320-360 200 360-400 12 position 9 (microns) 200 position (microns) 50 position (microns) 5000-6000 4000-5000 3000-4000 2000-3000 position (microns) • At this highly localised scale the ductility varies with distribution of micron/sub-micron sized rubber particles in the ABS matrix Applications in Milling Prediction • Nano-scale ductility of crab shell varies across the shell • Finer “mesh sizes” can be used to investigate this behaviour at much smaller scale Collaboration in progress with University of Maryland MICRO MATERIALS Indentation: viscoelastic materials MEASURING NAN OTEC HNOL OGY Testing the viscoelastic properties of thin films and small volumes requires the ability to access a wide range of strain rates The NanoTest system has far greater strain rate choice than other systems because 1. Ultra-slow loading, long creep tests etc, are possible due to excellent thermal stability (~0.0010.01 nm/s) 2. Very high strain rates accessible – use nanoimpact Impact behaviour: brittle and ductile materials MICRO MATERIALS MEASURING NAN OTEC HNOL OGY Repetitive impact tests on brittle and ductile materials More ductile Less ductile • Little plastic deformation before failure • Clear fracture event(s) • Time-to-failure characterises impact resistance MICRO MATERIALS • Focus on ability to absorb energy • More plastic deformation = more ductile • Less plastic deformation = less ductile Nano-impact – ductile materials MEASURING NAN OTEC HNOL OGY Nano-impact of Rubber-modified ABS Polymer 1 impact every 7 s; 5 mN impact force; spherical test probe Incorporation of 25 % rubber leads to greater depth change on repetitive impact at the same position Nano-impact - a new method of ductility testing MICRO MATERIALS MEASURING NAN OTEC HNOL OGY • Rubber incorporation improves ability to absorb energy on impact by deforming plastically rather than fracturing (improved ductility) 5 repeat impact tests at each composition Variation in impact-induced plastic deformation with rubber loading change in crater volum e during im pacting (um )^2 Very reproducible behaviour - error bars are smaller than symbols Geometric considerations used to convert depth to volume 1000 800 600 400 200 0 0 5 10 15 20 25 rubber w t% loading The technique has considerable potential in evaluating the local fatigue behaviour and ductility of thin polymer films that are not capable of being tested by conventional methods that were designed for bulk samples Ben Beake, Steve Goodes, Jim Smith and Fengge Gao, J Mater Res (2004) 237-247. MICRO MATERIALS MEASURING NAN OTEC HNOL OGY New innovations • Liquid cell • In two beta sites • Nanofretting About to got Beta-site status Bringing nanomechanical measurements into the real-world MICRO MATERIALS MEASURING NAN OTEC HNOL OGY Conclusions 1. Nanoindentation is fast becoming an essential tool in the optimisation of the mechanical and tribological properties of thin coated systems and advanced materials, for applications where hardness and stiffness are important. 2. The pendulum arrangement has key advantages for reliable scratch testing. Scratching occurs in high stiffness direction for pivot and direct calibration of tangential (frictional) forces are possible. 3. Nano-scratch and nano-wear tests can accurately reveal differences in coating adhesion and wear resistance of coatings and bulk materials. This information can be used to aid materials processing and coating design. 4. Together, the combination of nanoindentation, nanoscratch and nanoimpact provides much information on the plastic, elastic, adhesive, fatigue wear and fracture properties of biomaterials MICRO MATERIALS THANK YOU FOR LISTENING MEASURING NAN OTEC HNOL OGY HOW TO FIND FURTHER INFORMATION: www.micromaterials.co.uk • references • customer profiles • application notes krish@micromaterials.co.uk