John G. Weenig

Jidoka

Engineering Quality

into our Processes

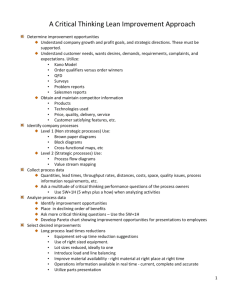

Objectives

• Learn about jidoka

• What techniques from jidoka could help us

improve our operations?

• Does jidoka have application for processes

other than manufacturing?

Material Covered

•

•

•

•

•

•

Meaning of jidoka

Origins of jidoka

How jidoka works

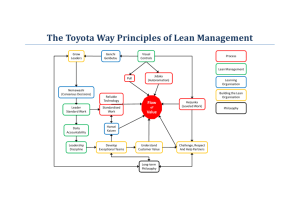

Jidoka and the Toyota Production System

Using jidoka

Finding more on jidoka

Jidoka

Jidoka – A Japanese term made of three kanji

characters:

Ji – self

Do – movement, motion

Ka – -ize, to be or become

Jidoka

• Jidoka literally means: automation or

autonomation

• Jidoka: A quality control method that involves

thorough, automatic inspection of every product as

it moves through the conversion process.

• Ninbennoaru jidoka

• Taiichi Ohno

• Pursuit of Waste Elimination

Major Benefits

• Quality assurance

• Cost reduction

• Employee fulfillment

– lower turnover rate

– Improved productivity

• Continuous process improvements

What is Jidoka for?

• Jidoka makes any production problems selfevident by stopping production whenever

problems occur.

• Accompanies JIT or lean manufacturing

• Continuous improvement - Kaizen

• Why? Expose the truth

• Find the problems, bring them forth, and fix

them

• Do it once & once and for all

A metaphor

•

•

•

•

•

•

Completion homework in school

What kind of behavior did that encourage?

Everyone tries to do homework

Yoda “Do or do not, there is no try”

That is Jidoka

Only good quality homework is received by the

teacher and poor work is unacceptable

• Preventing defective work is paramount

How Toyota uses jidoka

• Two deployments:

– Human

– Machine

Human

• Andon – A cord that runs the length of the

production line that when pulled will stop

the entire production line.

Andon Board

Green light – Normal operation

Yellow light – Assistance needed

Red light – Line has been stopped

Andon Board at Denso

Employee Behavior

• Common defects, errors, and problems are

recorded on an easel near the work station

• Daily reviews by team leaders of what

problems exist and their solutions

• Employees proactively seek solutions to

unresolved problems

Machine

• Poka-yoke: Machines are set-up to prevent

defects before they can occur.

– Examples

– Automobile cabin lights turn off when left on

too long

– Washing machines won’t run if the lid is left

open

Wastes Eliminated:

•

•

•

•

•

Rework

Scrap

Waste in movement

Overproduction

Excessive waiting

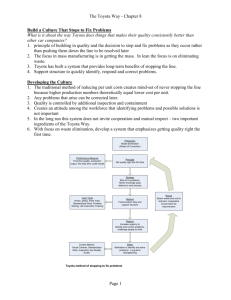

How it used to work

•

•

•

•

A defect is detected by a line worker

Rationalization

Rework or dissatisfaction

Status Quo – Problem might reoccur

Under Jidoka

• A defect is detected

• A line worker pulls the andon cord, which

summons a team leader

• A team leader and worker identify causes

• Solutions implemented

• Cost of line stoppage incurred, but it

incentivizes us to improve

Toyota Production System (TPS)

• At Toyota’s Georgetown, KY Plant…

Workstation

0%

70%

100%

Toyota at Georgetown

Andon cord area

Floor markings

Let’s try it

• Music begins to play and a light on the andon

board begins to flash yellow. What does this

mean?

• What happens if the team leader pulls the andon

cord after a first pull?

• What happens if a solution to a problem cannot be

found?

• Is jidoka a proactive or reactive approach to

continuous improvement?

Summary

• Jidoka: Makes any production problems

self-evident by stopping production

whenever problems occur.

• Put Toyota on the map

• Bedfellow of lean manufacturing &

continuous improvements

• It is organizational learning at its best

Sources and additional readings

Foster, S.T., Managing Quality, Pearson Prentice Hall, NJ, 2007

Miltenburg, John, One-piece flow manufacturing on U-shaped production lines: A tutorial.,IIE Transactions, Vol.33 Issue 4,

p303, April 2001.

Mishina, Kazuhiro; Takeda, Kazunori, Toyota Motor Manufacturing, U.S.A., Inc., President and Fellows of Harvard

College © 1992.

Monden, Yauhiro, Toyota Production System, Georgia: Institute of Industrial Engineers. 1983.

Young, Mark S., A Framework for Successful Adoption and Performance of Japanese Manufacturing Practices in the United

States, The Academy of Management Review © 1992.

Flynn, Barbara B.; Sakakibara, Sadao; Schroeder, Roger G., Relationship between JIT and TQM: Practices and

Performance, The Academy of Management Journal © 1995.

Toyota’s Official website: www.toyota.co.jp/en/vision/production_system/jidoka.html Accessed:03/24/2007