Jidoka - FreeQuality

advertisement

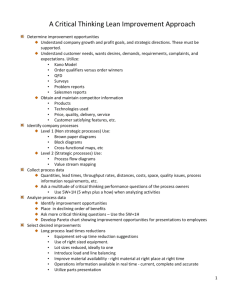

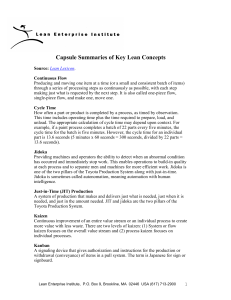

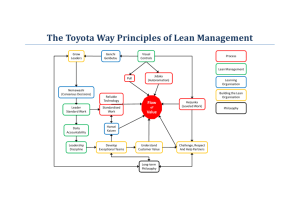

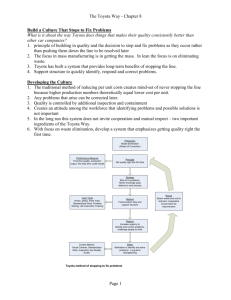

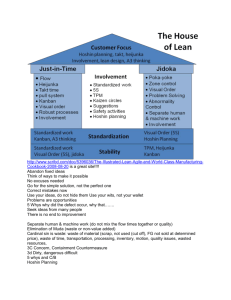

JIDOKA Mac Hu What Will Be Covered • • • • • What is Jidoka? Role of Jidoka How your firm can benefit from Jidoka A closer look at Jidoka How it works What Will Be Covered • • • • Real World Examples Exercises Summary Reading, References, Info Lists What is Jidoka? • Automation with a human touch • Practice of stopping a manual line or process when something goes amiss • Also known as Autonomation What is Jidoka? • Quality built-in to the process • First used by Sakichi Toyoda at the beginning of the 20th century • A pillar of the Toyota Production System Role of Jidoka • Autonomation is an important component of Lean Manufacturing Strategy for highproduction, low- variety operations, particularly where product life cycles are measured in years or decades. How Your Organization Can Benefit From Jidoka • Jidoka helps to detect a problem earlier • Jidoka avoids the spread of bad practices • A level of human intelligence is transferred into automated machinery How Your Organization Can Benefit From Jidoka • No defective products produced • Tremendous improvement in productivity A Closer Look at Jidoka – manufacturing high quality products • The word traces its roots to the automatic loom invented by the founder of the Toyota Group • A built-in device for making judgments • Opposed to a machine that simply moves under the monitoring and supervision of an operator A Closer Look at Jidoka -- Concept A Closer Look at Jidoka— ”Autonomation” clarification • Automation vs. Autonomation (自動化) (自働化) • Labor Reduction vs. Quality Improvement • Increases technicality vs. Reduces technicality How It Works • Adds human judgment to automated equipment • Minimizes poor quality • Makes the process more dependable • Gives the employee responsibility and authority to stop production In The Real World “If Jidoka is not practiced then you can not attain a very high level quality and productivity will suffer since you are not catching problems.” Mr. Tomo Harada, 35 years with Toyota Motor Corporation in a variety of management positions In The Real World “One of NUMMI’s basic concepts is that quality should be ensured in the production process itself. This concept, known as Jidoka, means not allowing problems to pass from one work station to the next.” Production System Statement, NUMMI (New United Motor Manufacturing, Inc.) Exercises Q1: What is Jidoka? Q2: How would your organization benefit from implementing Jidoka? Q3: What is the role of Jidoka? SUMMARY • Jidoka, also known as “Autonomation”, means automation with a human touch. • Jidoka, first used by Sakichi Toyoda, the founder of Toyota, is one of two pillars of the Toyota Production System. • Jidoka is an important component of Lean Manufacturing Strategy for high-production, low- variety operations. SUMMARY • Jidoka helps to detect a problem earlier and avoids the spread of bad practices. • Jidoka results in high-quality products and makes improvement in productivity. • Autonomation is different from automation. Reading List & References • Strategos, Inc. http://www.strategosinc.com/ • Toyota Motor Corporation http://www.toyota.co.jp/ • FredHarriman.com – Kaizen Basics http://www.fredharriman.com/ • Art of Lean, Inc. http://artoflean.com/ Reading List & References • New United Motor Manufacturing, Inc. http://www.nummi.com/ • MONDEN, YASUHIRO, Toyota Production System, Third Edition, Industrial Engineering & Management Press, Atlanta, Georgia, USA, 1998. • OHNO, TAIICHI, Toyota Production System- Beyond Large Scale Production, Productivity Press, 1988. For More Information • Automotive Manufacturing & Production, July 2001, v113 i7 p64. • The Financial Times, December 13, 2001, p13. Imai, Masaaki. Kaizen. New York: McGraw-Hill, Kaizen Institute, 1986. • The Just-In-Time Breakthrough. Rath & Strong, Inc.: John Wiley & Sons, Inc., 1988. • Management Review, June 1997, v86 i6 p36. Sepehri, Mehran. Just-In-Time, Not Just In Japan. American Production & Inventory Control Society, Inc., 1986.