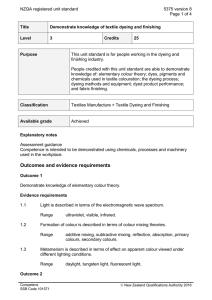

NZQA unit standard 5403 version 8

advertisement

NZQA Expiring unit standard 5403 version 8 Page 1 of 4 Title Dye textile materials in a paddle dyeing machine Level 3 Purpose Credits 9 This unit standard is for people working in the dyeing and finishing industry. People credited with this unit standard are able to: demonstrate knowledge of paddle dyeing; prepare and operate a paddle dyeing machine; and carry out batch end procedures. Classification Textiles Manufacture > Textile Dyeing and Finishing Available grade Achieved Entry information Critical health and safety prerequisites Recommended for entry: Unit 5392, Demonstrate knowledge of textile dyeing and finishing safety, or demonstrate equivalent knowledge or skills. Explanatory notes 1 Dyeing is considered to include bleaching, insect resist treatment and other chemical treatments carried out in the dyeing process. 2 Competence must be shown with the type of paddle dyeing machine installed in the workplace. 3 Performance of the elements must comply with the Health and Safety in Employment Act 1992. 4 The disposal or discharge of dyestuffs, chemicals, wastes, and packaging materials must be carried out according to the requirements of the Resource Management Act 1991. 5 Definitions Workplace procedures refer to the verbal or documented procedures for performing activities including health and safety, operational, environmental, and quality management requirements. They refer to manuals, manufacturer's specification, codes of practice, or policy statements. Product specifications refer to the document which accompanies each manufacturing order. This specifies all of the parameters for production of the yarn batch. This may include the fibre specification, the shade, dye bath parameters, machinery to be used and finishing procedures. This is often called a Yarn Lot Record Card. Competenz SSB Code 101571 New Zealand Qualifications Authority 2016 NZQA Expiring unit standard 5403 version 8 Page 2 of 4 Outcomes and evidence requirements Outcome 1 Demonstrate knowledge of paddle dyeing. Evidence requirements 1.1 Paddle dyeing is described in terms of the process steps. Range 1.2 Dyes and chemicals used in the workplace for paddle dyeing are described in terms of their nature, function, and safe handling requirements. Range 1.3 chemical mixing, load preparation, pre-dyeing treatments, dyeing cycle, post-dyeing treatments, after-treatments, rinsing, unloading, liquor discharge and disposal. dyestuffs, dyeing assistants, auxiliary chemicals. Paddle dyeing machine and related equipment are described in terms of their function and operation. Range dye machine, paddle, side tanks, dye machine controls. Outcome 2 Prepare and operate a paddle dyeing machine. Range application of dyestuffs and after-treatments. Evidence requirements 2.1 Substrate is identified according to product specifications. 2.2 Machine is prepared and operated in accordance with workplace procedures. 2.3 Substrate is prepared for loading according to product specifications and workplace procedures. Range 2.4 Machine is emptied and cleaned to prevent contamination from the previous dyeing. Range 2.5 quantity for load, bagged if bagging required by product specifications. vessel, side tank, drain plug clear and in place. Machine loading and preparation are according to workplace practices. Range Competenz SSB Code 101571 quantity according to product specifications, paddle free to turn, liquor level set. New Zealand Qualifications Authority 2016 NZQA Expiring unit standard 2.6 Machine is operated and monitored during operation. Range 2.7 5403 version 8 Page 3 of 4 dyestuff and chemicals added to side tank, liquor operating level maintained. Samples are taken according to workplace procedures. Outcome 3 Carry out batch end procedures. Evidence requirements 3.1 Machine and work area are cleaned to prevent contamination. Range 3.2 vessel, side tanks, paddle, plug and drain. Any machine faults are reported according to workplace procedures. faults may include but are not limited to – steam leaks, paddle blades secure, bearings, lubrication. Range This unit standard is expiring. Assessment against the standard must take place by the last date for assessment set out below. Status information and last date for assessment for superseded versions Process Version Date Last Date for Assessment Registration 1 25 October 1995 31 December 2019 Revision 2 8 August 1997 31 December 2019 Revision 3 18 July 2000 31 December 2019 Revision 4 10 October 2001 31 December 2019 Revision 5 15 January 2004 31 December 2019 Rollover 6 25 July 2007 31 December 2019 Review 7 17 April 2009 31 December 2019 Review 8 19 May 2016 31 December 2019 Consent and Moderation Requirements (CMR) reference 0030 This CMR can be accessed at http://www.nzqa.govt.nz/framework/search/index.do. Please note Providers must be granted consent to assess against standards (accredited) by NZQA, before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment. Competenz SSB Code 101571 New Zealand Qualifications Authority 2016 NZQA Expiring unit standard 5403 version 8 Page 4 of 4 Industry Training Organisations must be granted consent to assess against standards by NZQA before they can register credits from assessment against unit standards. Providers and Industry Training Organisations, which have been granted consent and which are assessing against unit standards must engage with the moderation system that applies to those standards. Requirements for consent to assess and an outline of the moderation system that applies to this standard are outlined in the Consent and Moderation Requirements (CMR). The CMR also includes useful information about special requirements for organisations wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements. Competenz SSB Code 101571 New Zealand Qualifications Authority 2016