Carry out preliminary site check for concrete roof tiling

advertisement

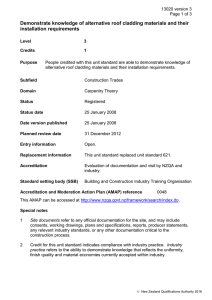

1685 version 4 Page 1 of 4 Carry out preliminary site check for concrete roof tiling Level 4 Credits 8 Purpose People credited with this unit are able to: check delivered concrete roof tiling materials; check roof structure readiness for installation of roofing; identify hazards and plan preventative action; and maintain a safe working environment. Subfield Plumbing, Gasfitting and Drainlaying Domain Roofing Status Registered Status date 27 October 2006 Date version published 22 August 2008 Planned review date 30 April 2013 Entry information Open. Accreditation Evaluation of documentation and visit by NZQA and industry. Standard setting body (SSB) The Skills Organisation Accreditation and Moderation Action Plan (AMAP) reference 0227 This AMAP can be accessed at http://www.nzqa.govt.nz/framework/search/index.do. Special notes 1 Legislation relevant to this unit standard includes but is not limited to the Health and Safety in Employment Act 1992, and the Building Act 2004. 2 Performance must comply with current legislation, regulations, and codes. For more detailed information about which regulations and codes are relevant, please refer to the assessors’ page of The Skills Organisation Ltd website http://www.skills.org.nz. New Zealand Standard (NZS) 4206:1992 Concrete interlocking roofing tiles which is within this unit standard is available from http://www.standards.co.nz. The New Zealand Building Code which is within this unit standard is available from http:\\www.dbh.govt.nz. New Zealand Qualifications Authority 2016 1685 version 4 Page 2 of 4 3 Definitions Company requirements include the policy, procedures, and methodologies of the company. They include requirements documented in company and site health and safety plans, quality assurance documents, and contract work programmes; Site procedures refer to the procedures which are required to be observed for safe work practices at a particular site; Manufacturers’ recommendations refer to product information and product data sheets provided by the manufacturer of any given product. 4 This unit standard applies to both new roof and re-roofing installations. Elements and performance criteria Element 1 Check delivered concrete roof tiling materials. Performance criteria 1.1 Details of site are checked against information on job sheet in accordance with company requirements. Range 1.2 Materials delivered for installation of concrete tile roof are checked against the job sheet for quantity and conformity to specification in accordance with company requirements. Range 1.3 street, lot number, builder. tiles – (colour and profile), ancillary tiles – (colour and profile), battens, underlay, fixings, underlay support. Arrangements are made with the agent and/or supervisor for delivered materials not meeting job sheet defined quality or quantity requirements to be replaced, or shortfalls made up, in accordance with company requirements. Element 2 Check roof structure readiness for installation of roofing. Performance criteria 2.1 Inspection confirms that roof structure meets the requirements of the tiling contractor and NZS 4206:1992. Range bracing, fixing of structural elements, support of overhangs. New Zealand Qualifications Authority 2016 1685 version 4 Page 3 of 4 2.2 Inspection confirms that elements of the structure which affect the quality of the finished roof comply with the tile manufacturer’s recommendations. Range truss and rafter spacing for batten size; height of hip and ridge boards; height of fascia above rafter for batten size; provision of anti-ponding board or cant strip if specified; valley framing; eave and other roof finish construction; top surface line of trusses or rafters to provide even roof surface; straightness and fixing of fascia, ridges, hips, eaves, and valleys; squareness of gable ends; readiness for underlay where specified. 2.3 Inspection confirms that air space between ceiling and roof in skillion roof construction conforms to the requirements of the New Zealand Building Code. 2.4 Roof conditions which prevent roofing work being done are identified and arrangements are made for these to be remedied by the builder to allow completion of the roof in accordance with company requirements. Range 2.5 timber protruding through roof line, incomplete structure or finishes, scaffolding through roof line, missing flashings, gutters or valleys to be installed by others. Where the builder cannot, or will not, make the structure ready for roofing work the supervisor and/or agent is advised in accordance with company requirements. Element 3 Identify hazards and plan preventative action. Performance criteria 3.1 Weather problems which may arise because of the site location are identified, and action required to minimise danger to workers and damage to materials is planned and implemented in accordance with company requirements. Range 3.2 wind, frost, rain and resulting site mud. Elements of the structure which require care and consideration during roofing work are identified and action required to prevent damage to those elements is planned and implemented in accordance with company requirements. Range windows, surface finishes, soffits and fascias/spouting, flashings and gutters, live cables or wires. New Zealand Qualifications Authority 2016 1685 version 4 Page 4 of 4 Element 4 Maintain a safe working environment. Performance criteria 4.1 Work practices are carried out without injury to people or damage to equipment, building, or plant, in accordance with legislation, regulations, codes, health and safety in employment guidelines, and company requirements. 4.2 Personal protective equipment for the task at hand is selected and worn in accordance with manufacturers’ recommendations. Range includes but is not limited to – hard hat, sunblock, ear muffs, safety glasses, gloves, knee pads, high visibility clothing, safety harness. 4.3 Work area is cordoned off and safety notices and notification of work signs are distributed and erected, in accordance with site procedures. 4.4 Work area is kept clear of debris and unnecessary items in accordance with site procedures. Please note Providers must be accredited by the Qualifications Authority, or an inter-institutional body with delegated authority for quality assurance, before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment. Industry Training Organisations must be accredited by the Qualifications Authority before they can register credits from assessment against unit standards. Accredited providers and Industry Training Organisations assessing against unit standards must engage with the moderation system that applies to those standards. Accreditation requirements and an outline of the moderation system that applies to this standard are outlined in the Accreditation and Moderation Action Plan (AMAP). The AMAP also includes useful information about special requirements for organisations wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements. Comments on this unit standard Please contact The Skills Organisation info@skills.org.nz if you wish to suggest changes to the content of this unit standard. New Zealand Qualifications Authority 2016