Collect, grade, and pack eggs, and clean processing equipment and

advertisement

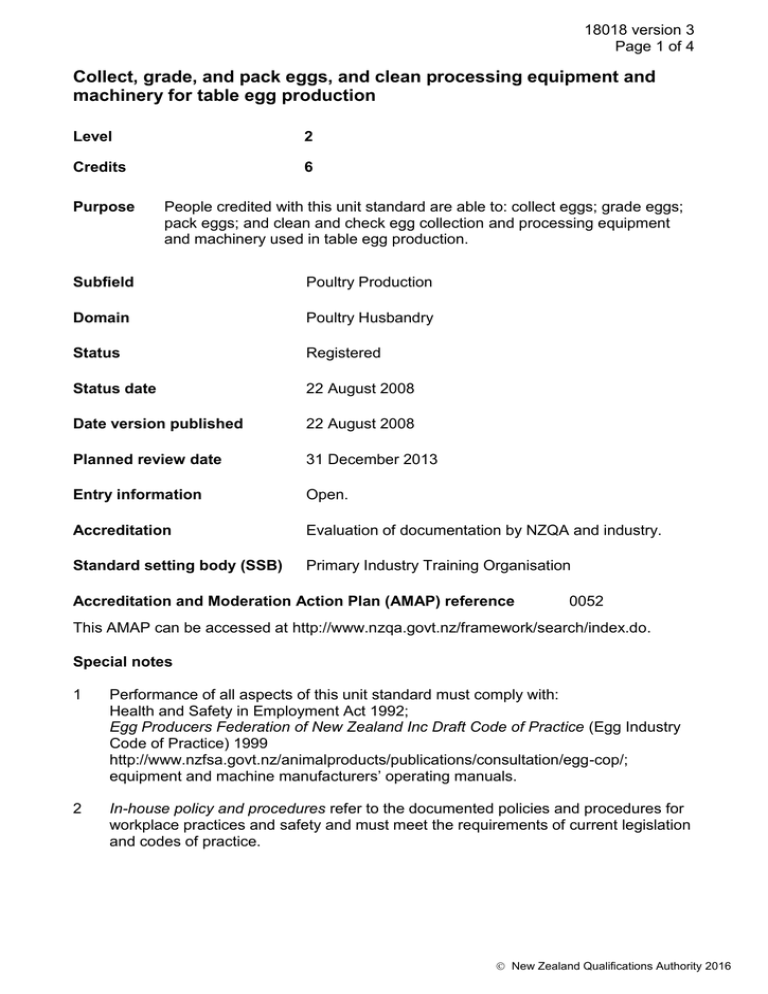

18018 version 3 Page 1 of 4 Collect, grade, and pack eggs, and clean processing equipment and machinery for table egg production Level 2 Credits 6 Purpose People credited with this unit standard are able to: collect eggs; grade eggs; pack eggs; and clean and check egg collection and processing equipment and machinery used in table egg production. Subfield Poultry Production Domain Poultry Husbandry Status Registered Status date 22 August 2008 Date version published 22 August 2008 Planned review date 31 December 2013 Entry information Open. Accreditation Evaluation of documentation by NZQA and industry. Standard setting body (SSB) Primary Industry Training Organisation Accreditation and Moderation Action Plan (AMAP) reference 0052 This AMAP can be accessed at http://www.nzqa.govt.nz/framework/search/index.do. Special notes 1 Performance of all aspects of this unit standard must comply with: Health and Safety in Employment Act 1992; Egg Producers Federation of New Zealand Inc Draft Code of Practice (Egg Industry Code of Practice) 1999 http://www.nzfsa.govt.nz/animalproducts/publications/consultation/egg-cop/; equipment and machine manufacturers’ operating manuals. 2 In-house policy and procedures refer to the documented policies and procedures for workplace practices and safety and must meet the requirements of current legislation and codes of practice. New Zealand Qualifications Authority 2016 18018 version 3 Page 2 of 4 Elements and performance criteria Element 1 Collect eggs. Performance criteria 1.1 Egg collection is carried out the required number of times during the day in accordance with in-house procedures. 1.2 Eggs are placed point down in collection trays causing minimal damage and breakages. 1.3 Visual appraisal of eggs is carried out, and defective eggs are identified and separated in accordance with in-house procedures. Range examples – broken eggs, damaged eggs, floor eggs, abnormal shape, size too big or small, dirty, cracked or weak shelled. 1.4 Egg numbers are recorded, and fluctuations in egg numbers are noted and reported in accordance with in-house procedures. 1.5 Sample of eggs from each age group of birds is weighed and recorded, and variations from target are identified and reported in accordance with in-house procedures. 1.6 Biosecurity requirements are met in accordance with in-house procedures. Range movement between sheds, use of footbaths, change of overalls, personal hygiene. Element 2 Grade eggs. Performance criteria 2.1 Grading equipment and machinery are set up for operation in accordance with manufacturer’s specifications. 2.2 Eggs are candled, and defective eggs are identified and disposed of in accordance with the Egg Industry Code of Practice. Range 2.3 defective eggs could include external stain, dirt or cracks, meat and blood spots. Eggs are graded into minimum weight standards in accordance with the Egg Industry Code of Practice. New Zealand Qualifications Authority 2016 18018 version 3 Page 3 of 4 2.4 Protective clothing is worn in accordance with the Egg Industry Code of Practice. 2.5 Biosecurity requirements are met in accordance with the Egg Industry Code of Practice. Range 2.6 movement between sheds, use of footbaths, change of overalls, personal hygiene. Documentation is maintained in accordance with the Egg Industry Code of Practice. Element 3 Pack eggs. Performance criteria 3.1 Cartons and packaging are checked for quality prior to use in accordance with the Egg Industry Code of Practice. Range clean, intact, unused. 3.2 Eggs are placed in cartons causing no damage or breakages. 3.3 Cartons are labelled in accordance with the Egg Industry Code of Practice. Range 3.4 ‘best before’ date, supplier’s details. Documentation is maintained in accordance with the Egg Industry Code of Practice. Element 4 Clean and check egg collection and processing equipment and machinery used in table egg production. Performance criteria 4.1 Egg collection and processing equipment, and machinery are cleaned and sanitised in accordance with in-house procedures. 4.2 Egg collection equipment and machinery are checked for function, and faults are identified and reported in accordance with in-house procedures. 4.3 Safe working practices are observed at all times in accordance with the Health and Safety in Employment Act 1992. New Zealand Qualifications Authority 2016 18018 version 3 Page 4 of 4 Please note Providers must be accredited by NZQA, or an inter-institutional body with delegated authority for quality assurance, before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment. Industry Training Organisations must be accredited by NZQA before they can register credits from assessment against unit standards. Accredited providers and Industry Training Organisations assessing against unit standards must engage with the moderation system that applies to those standards. Accreditation requirements and an outline of the moderation system that applies to this standard are outlined in the Accreditation and Moderation Action Plan (AMAP). The AMAP also includes useful information about special requirements for organisations wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements. Comments on this unit standard Please contact the Primary Industry Training Organisation standards@primaryito.ac.nz if you wish to suggest changes to the content of this unit standard. New Zealand Qualifications Authority 2016