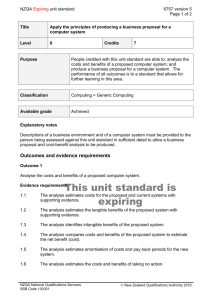

NZQA unit standard 18924 version 6

advertisement

NZQA Expiring unit standard 18924 version 6 Page 1 of 3 Title Control and optimise the glass container forming process Level 4 Credits 20 Purpose People credited with this unit standard are able to control and optimise gob forming and delivery on two types of independent section (IS) machine, and control and optimise the IS machine container forming process. Classification Glass and Glazing > Glass Container Manufacturing Available grade Achieved Entry information Recommended skills and knowledge Recommended: Unit 18920, Perform advanced operations for glass container forming, or demonstrate equivalent knowledge and skills. Explanatory notes 1 All work practices must meet enterprise health and safety requirements. 2 Enterprise means an organisation where training and/or assessment is taking place, and/or where the trainee is employed. 3 Enterprise procedure is defined as actions which comply with the policies, systems, and directives in a particular enterprise. Enterprise procedure must comply with the requirements of the Health and Safety in Employment Act 1992, and subsequent amendments. 4 Definitions Mould gear is components of the blank side and mould side. Blank side components are plunger, thimble, neck ring, blank mould, funnel, baffle. Mould side components are blow mould, mould bottom plate, distributor (vertiflow) plate, blow head, take out grips. Hours of production refer to production equipment run time, and not the total amount of time spent demonstrating the required competencies. 5 Plastics and Materials Processing Industry Training Organisation unit standard designation is Form 4. This unit standard is expiring Competenz SSB Code 8104 New Zealand Qualifications Authority 2016 NZQA Expiring unit standard 18924 version 6 Page 2 of 3 Outcomes and evidence requirements Outcome 1 Control and optimise gob forming and delivery on two types of IS machine. Evidence requirements 1.1 Gob forming and delivery equipment shut down and restart is performed in accordance with enterprise procedure. 1.2 Gob forming and delivery equipment is selected, and is set to optimise production to product requirements. Range 1.3 gob forming and delivery equipment – orifice ring size, needle size, needle height and stroke, sleeve height and speed, differential setting, shear height, shear blade setting, cam selection, shot-gun size, scoop size, trough size, deflector size. Glass conditioning temperatures and depth in forehearth are adjusted and stabilised to optimise glass to product requirements. Outcome 2 Control and optimise the IS machine container forming process. Evidence requirements 2.1 Controls are adjusted to optimise production output and product quality on IS machines in accordance with enterprise requirements. This unit standard is expiring Machine settings are saved to file and new machine settings are loaded in Range 2.2 controls include – machine speed, machine cooling requirement, air pressure settings, machine event timing values, hot-end coating settings, Lehr stacking requirements. Evidence is required for two types of IS machine. accordance with enterprise procedure. Range 2.3 Mould gear modifications are described to meet enterprise production output and product quality requirements. Range 2.4 evidence is required for two types of IS machine. evidence is required for three different modifications. Production data is analysed for trends and corrective action is taken in accordance with enterprise procedure. Range Competenz SSB Code 8104 evidence is required over 200 hours of production. New Zealand Qualifications Authority 2016 NZQA Expiring unit standard 2.5 18924 version 6 Page 3 of 3 Methods for controlling and reducing waste in container manufacturing are described. waste includes – energy, raw materials, glass, manpower, product failure, inefficient production. Evidence is required for three examples of waste. Range This unit standard is expiring. Assessment against the standard must take place by the last date for assessment set out below. Status information and last date for assessment for superseded versions Process Version Date Last Date for Assessment Registration 1 18 December 2001 31 December 2015 Revision 2 13 February 2004 31 December 2015 Revision 3 20 September 2004 31 December 2015 Review 4 20 November 2006 31 December 2015 Review 5 16 April 2015 31 December 2018 Rollover 6 15 October 2015 31 December 2018 Consent and Moderation Requirements (CMR) reference 0134 This CMR can be accessed at http://www.nzqa.govt.nz/framework/search/index.do. Please note Providers must be granted consent to assess against standards (accredited) by NZQA, before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment. This unit standard is Providers and Industry Training Organisations, which have been granted consent and expiring which are assessing against unit standards must engage with the moderation system that Industry Training Organisations must be granted consent to assess against standards by NZQA before they can register credits from assessment against unit standards. applies to those standards. Requirements for consent to assess and an outline of the moderation system that applies to this standard are outlined in the CMR. The CMR also includes useful information about special requirements for organisations wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements. Competenz SSB Code 8104 New Zealand Qualifications Authority 2016