NZQA unit standard 881 version 6

advertisement

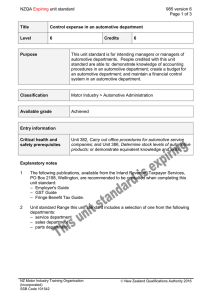

NZQA Expiring unit standard 881 version 6 Page 1 of 4 Title Test, service, and repair an automotive air conditioning system Level 4 Credits 4 Purpose This unit standard is for people in the automotive repair industry. People credited with this unit standard are able to: test an automotive air conditioning system for operation; service an air conditioning system; and repair an automotive air conditioning system. Classification Motor Industry > Automotive Air Conditioning Available grade Achieved Entry information Critical health and safety prerequisites Unit 15373, Demonstrate knowledge of automotive air conditioning, or demonstrate equivalent knowledge and skills. Explanatory notes 1 The following legislation, standards, and their amendments are to be consulted and followed where applicable: Health and Safety in Employment Act, 1992; Ozone Layer Protection Act, 1996; MTA (Motor Trade Association) Automotive Air Conditioning Code of Practice. 2 This unit standard and unit standard 15373 may lead to certification as an Automotive Air Conditioning Technician by the NZ Motor Industry Training Organisation. People should consult the MTA Industry Code of Practice for details regarding this certification. 3 Reference to suitable tools and equipment means industry approved tools and equipment that are recognised within the industry as being the most suited to complete the task to a professional and competent manner with due regard to safe working practices. 4 Because of the particular nature of this unit standard, it is essential that the practical assessment evidence is obtained from commercial jobs in the workplace under normal workplace conditions. NZ Motor Industry Training Organisation (Incorporated) SSB Code 101542 New Zealand Qualifications Authority 2016 NZQA Expiring unit standard 881 version 6 Page 2 of 4 Outcomes and evidence requirements Outcome 1 Test an automotive air conditioning system for operation. Evidence requirements 1.1 Safety precautions are taken to prevent situations that could be dangerous to people and the environment. Range cleanliness, ventilation, eye protection, gloves, protective clothing, working with a pressurised system, running the engine, awareness of moving parts, heating components and smoking, using air conditioning equipment, recovery and storage of refrigerant. 1.2 Suitable tools and equipment are selected and used to enable tests to be performed. 1.3 Test gauges are connected according to system manufacturer's instructions. 1.4 Level of refrigerant charge is determined after operating the system at maximum cooling for ten minutes. 1.5 Any blockages and other malfunctions are identified and located with the aid of diagnostic charts, tables, and gauges. 1.6 The efficiency of the system is determined by measuring and comparing evaporator air inlet and outlet temperatures and humidity levels. Outcome 2 Service an air conditioning system. Evidence requirements 2.1 Safety precautions are taken to prevent situations that could be dangerous to people and the environment. Range cleanliness, ventilation, eye protection, gloves, protective clothing, working with a pressurised system, running the engine, awareness of moving parts, heating components and smoking, using air conditioning equipment, recovery and storage of refrigerant. 2.2 Suitable tools and test equipment are selected and used to enable the service work to be carried out. 2.3 Refrigerant is recovered from the system, and is stored in a manner that complies with the Code of Practice and recovery station equipment instructions. NZ Motor Industry Training Organisation (Incorporated) SSB Code 101542 New Zealand Qualifications Authority 2016 NZQA Expiring unit standard 881 version 6 Page 3 of 4 2.4 The system is evacuated and then charged, to the specified level, with a refrigerant and compressor oil that comply with the Code of Practice and manufacturer's specifications. 2.5 The need to replace the filter-drier is determined according to the equipment manufacturer's specifications. 2.6 The filter-drier is replaced in compliance with the manufacturer's instructions and with the Code of Practice. 2.7 The vehicle operator is advised to operate the air conditioning system for a minimum of 10 minutes a week, regardless of season. Outcome 3 Repair an automotive air conditioning system. Evidence requirements 3.1 Safety precautions are taken to prevent situations that could be dangerous to people and the environment. Range cleanliness, ventilation, eye protection, gloves, protective clothing, working with a pressurised system, running the engine, awareness of moving parts, heating components and smoking, using air conditioning equipment, recovery and storage of refrigerant. 3.2 Suitable tools and equipment are selected and used to enable system repairs to be carried out. 3.3 Joints and connections are repaired to eliminate any leaks, in a manner that complies with the Code of Practice and vehicle manufacturer's specifications. 3.4 Faulty refrigeration components are rectified to restore full serviceability of the system, in a manner that complies with the Code of Practice and vehicle manufacturer's specifications. 3.5 Faulty electrical wiring and components are repaired and/or replaced to restore full serviceability of the system, in a manner that complies with the Code of Practice and vehicle manufacturer's specifications. Replacement information This unit standard has been replaced by unit standard 24443 and unit standard 24444. This unit standard is expiring. Assessment against the standard must take place by the last date for assessment set out below. NZ Motor Industry Training Organisation (Incorporated) SSB Code 101542 New Zealand Qualifications Authority 2016 NZQA Expiring unit standard 881 version 6 Page 4 of 4 Status information and last date for assessment for superseded versions Process Version Date Last Date for Assessment Registration 1 29 October 1993 31 December 2016 Review 2 4 October 1996 31 December 2016 Review 3 26 February 1999 31 December 2016 Review 4 25 January 2008 31 December 2020 Rollover 5 19 November 2010 31 December 2020 Rollover 6 22 August 2014 31 December 2020 Consent and Moderation Requirements (CMR) reference 0014 This CMR can be accessed at http://www.nzqa.govt.nz/framework/search/index.do. Please note Providers must be granted consent to assess against standards (accredited) by NZQA, before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment. Industry Training Organisations must be granted consent to assess against standards by NZQA before they can register credits from assessment against unit standards. Providers and Industry Training Organisations, which have been granted consent and which are assessing against unit standards must engage with the moderation system that applies to those standards. Requirements for consent to assess and an outline of the moderation system that applies to this standard are outlined in the Consent and Moderation Requirements (CMR). The CMR also includes useful information about special requirements for organisations wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements. NZ Motor Industry Training Organisation (Incorporated) SSB Code 101542 New Zealand Qualifications Authority 2016