Document 15209738

advertisement

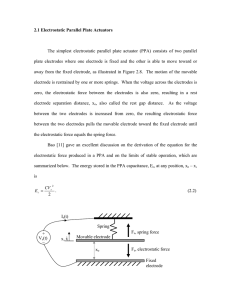

Electro-spark deposition technique is to release in high frequency between metal electrode and base material. Ionization taken place between metal electrode and base material generates a channel, which, brings about high-pressure micro areas as well as instant high temperature on the surface of base material; Meanwhile, micro electric field make ionic-state electrode material infiltrate into the base material, resulting in metallurgical combination. Electro-spark deposition technique is an instant process converting from high temperature to refrigeration; It is not welding, or coating, or element infiltration, simply speaking, it is intervenient. Studying change in surface metallurgical properties and its effect on corrosion and wear resistance by applying E.S.D. process. • Understanding how conversion electrical power to perfect sparking properties to accomplish the ESD principles. • Buildup an electronically-controlled system to manage the process variables (Voltage , Current , electrical capacitance , Spark duration , contact pressure and relative motion speed between electrode and substrate). • Beginning work with DC supply then switch to national amplitude current (50Hz) which has zero mean voltage. After that adding the capacitor to the circuit. • Select base metal like turbine blades used in generators in power stations and fixing degradation causes (corrosion , erosion and cracking . . . etc.) • Depending on the above cases electrode alloy will be selected (usually superalloys). • Increasing the deposition rate and improving its quality depend on the process variables which determined during work. Start Electrical Variables Metallurgical Variables Construct The E.S.D. Machine Fixing Electrical Variables Deposition Process Testing and Optimizing End Select Materials