Laboratory Personnel

advertisement

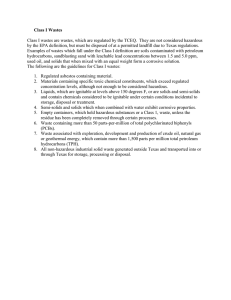

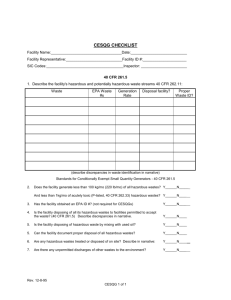

Hazardous Waste Management Bowling Green State University Resource Conservation and Recovery Act (RCRA) “Cradle to grave” management of hazardous wastes Hazardous and Solid Waste Amendments (HSWA) Established three categories of generators • Large quantity generators (LQGs) (Generate 2,200 or more pounds of hazardous waste in a calendar month) • Small quantity generators (SQGs) (Generate more than 220 pounds but less than 2,200 pounds of hazardous waste in a calendar month) • Conditionally exempt generators (CEGs) (Generate no more than 220 pounds of hazardous waste in a calendar month) Hazardous Waste Defined Listed Wastes – Specific and Nonspecific Sources “F” listed wastes “K” listed wastes “P” listed wastes “U” listed wastes “F” Listed Wastes • Non-specific sources • Wastes from common manufacturing and industrial processes – Example: solvents that have been used in cleaning or degreasing operations. • Wastes included on the F-list can be found in the regulations at 40 CFR §261.31 “K” Listed Wastes • This list includes certain wastes from specific industries, such as petroleum refining or pesticide manufacturing. – Certain sludges and wastewaters from treatment and production processes in these industries are examples of source-specific wastes. “P” & “U” Listed Wastes • Must be an unused commercial chemical product. • The difference between the “P” and “U” lists lies in the toxicity of the product. The acutely toxic products are on the P-list and less toxic products are on the U-list. http://www.epa.gov/osw/hazard/wastetypes/pdfs/listing-ref.pdf Characteristic Wastes 1. Ignitable (D001 Waste Code) o • Flash point <140 F 2. Corrosive (D002 Waste Code) • pH < 2 or > 12.5 3. Reactive (D003 Waste Code) • Unstable Air/water reactive • 4. Toxic (D004-D043 Waste Codes) • • Heavy metals Certain pesticides Hazardous Waste Management Plan for BGSU • Divided into two phases. – Phase I: considered as the operational segment and will involve the identification, collection, storage, and final disposal of hazardous wastes which are generated. – Phase II: In addressing the overall picture of a hazardous waste management program, a main emphasis must be placed on waste minimization. Phase I • Determine the quantities of hazardous wastes currently oncampus • Departments that are identified as waste generators will be requested to select a departmental liaison. Phase II • Emphasis must be placed on waste minimization. –Recycling –Alteration in Experimentation –Neutralization Identification • Who • What • When • Where • Quantity Storage of Hazardous Waste Hazardous Waste Storage Facility (HWF) Transportation (Off-site) Disposal • Disposal is performed by BGSU’s hazardous waste disposal contractor – Options • EPA approved landfill • deep well injection • incineration • other thermal destruction • chemical treatment Waste Minimization Program 1.) Substitution 2.) Micro-quantities 3.) Drain disposal 4.) Recycling 5.) Neutralization Substitution • • • • • • • • • • • • • • • 1,2,4-Trichlorobenzene 1,2,4,5-Tetrachlorobenzene 2,4,5-Trichlorophenol 4-Bromophenyl phenyl ether Acenaphthene Acenaphthylene Anthracene Benzo(g,h,i)perylene Dibenzofuran Dioxins/Furans Endosulfan Fluorene Heptachlor Hexachlorobenzene Hexachlorobutadiene • • • • • • • • • • • • • • • Hexachlorocyclohexane, gammaHexachloroethane Methoxychlor Naphthalene Pendimethalin Pentachlorobenzene Pentachloronitrobenzene Pentachlorophenol Phenanthrene Polycyclic Aromatic Compounts (PAC’s) Pyrene Trifluralin Cadmium Lead Mercury Orphan Chemical Program • reduce disposal costs • reduces purchasing costs for new materials