RELIABILITY OF MARINE TRANSPORTATION IN MIRI OIL AND GAS ACTIVITIES

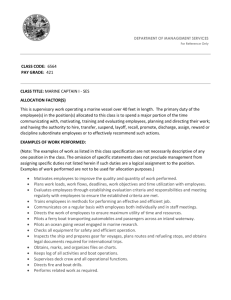

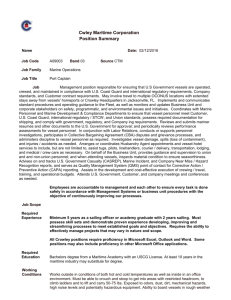

advertisement