Tooling Management 1. PURPOSE

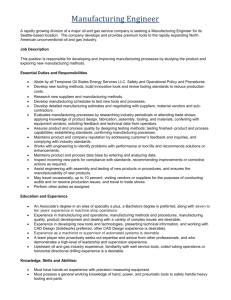

advertisement

SSYYSSTTEEM M PPR RO OC CEED DU UR REE Tooling Management REVISION: 01 PROCEDURE NO.: PTR001 DATE EFFECTIVE: 03/05/01 1. PURPOSE 1.1. The purpose of this document is to establish and implement a system for tooling management, including the identification, storage, retrieval, and disposition of tooling. 2. SCOPE 2.1. This procedure applies to all tooling maintained by (company name). 3. RESPONSIBILITY 3.1. The Stamping Operations Manager, Vice President of Engineering, and Vice President / General Manager of Fabrication Division have the primary responsibility for ensuring compliance of this procedure and to ensure the necessary resources for successful implementation are provided. 3.2. The Sales, Information Services, Purchasing, Engineering, Tool Room, and Production Personnel who support the identification, storage, retrieval, and dispositioning of tooling are responsible for compliance with this procedure. 4. REFERENCE DOCUMENTS 4.1. Quality System Manual 4.2. Quotations (PCS001) 4.3. Order Acceptance (PCS002) 4.4. Order Amendment (PCS003) 4.5. Control of Part Master (PDE003) 4.6. Fabrication Division System Controls (PFD001) 4.7. Information Services (PIS001) 4.8. Advanced Product Quality Planning (PQC004) 4.9. Document & Data Control (PQC008) 4.10. First Article Inspection (PQC007) 4.11. Control of Quality Records (PQC020) 4.12. Tooling Design & Fabrication (PTR002) 4.13. Tooling Repair & Perishable Tooling (PTR003) 5. REQUIRED DOCUMENTS/MATERIAL 5.1. (Company) Computer System 5.1.1. Part Master 5.1.1.1. Tooling Master 5.1.2. Tool Order Menu 5.1.2.1. Tool Order (Enter, Update, & Print Router) Page 1 of 7 SSYYSSTTEEM M PPR RO OC CEED DU UR REE Tooling Management REVISION: 01 PROCEDURE NO.: PTR001 DATE EFFECTIVE: 03/05/01 5.1.2.2. Tool Order Packing Slip (Create, Update, & Print) 5.1.2.3. Tool Room Labor (Codes, Enter, Update, Edit, & Report) 5.2. Tool Assignment Log 5.3. Plant Layout Drawing (FDE008) 5.4. New Die Checklist (FTR004) 5.5. Tooling Disposition Record (FTR010) 5.6. Requisition 5.7. Purchase Order 6. PROCEDURAL REQUIREMENTS 6.1. General Requirements 6.1.1. The tracking and identification of all tooling managed by (COMPANY NAME) shall be per this procedure and primarily via the (COMPANY NAME) Tooling Master. 6.1.1.1. In the case of the Stamping Operations, the design and fabrication of tooling is a primary part of the business (see PTR002 – Tooling Design & Fabrication). All tooling (e.g., dies, tapping fixtures, welding fixtures, assembly fixtures, inspection fixtures, etc.) utilized in the operation shall be identified and tracked via the (COMPANY NAME) Tooling Master. 6.1.1.2. In the case of the Fabrication Division, a procedure for managing (COMPANY NAME) tooling utilized in the various operations shall be established and to the extent applicable it shall include the controls for identification, storage, retrieval, and disposition. 6.1.1.3. In either case, the (COMPANY NAME) Tool Master shall be used to identify and track all customer owned tooling. It shall be Sales / Customer Service’s responsibility to identify ownership either in the Tool Order Router Notes or in the applicable Tool Assignment Log. 6.1.2. The (COMPANY NAME) Tooling Master shall be maintained primarily by the Sales / Customer Service Representative assigned to that customer and/or product, this includes entering new tools, revising and/or modifying current tooling, and dispositioning existing tools. 6.1.2.1. The responsible Customer Service Representative shall be primarily responsible for maintaining the following information: Tool Number Tool Description Tool Type Tool Status Customer Name Customer Identification Number Customer Asset Number (if applicable) Page 2 of 7 SSYYSSTTEEM M PPR RO OC CEED DU UR REE Tooling Management REVISION: 01 PROCEDURE NO.: PTR001 DATE EFFECTIVE: 03/05/01 Scrap/Return Date (when Dispositioned) Scrap/return Reason Code (when Dispositioned) 6.1.2.2. The responsible Engineering Department shall be primarily responsible for entering and maintaining the following fields in the (COMPANY NAME) Tooling Master: Design Date Revision Date Revision Level 6.1.2.3. Production Supervision in conjunction with the Forklift “Jeep” Driver(s) shall assign the tooling location for storage between production jobs and communicate it to the assigned function that has (COMPANY NAME) System rights (i.e., Sales / Customer Service, Information Services’ Data Entry, etc.) for entering this information. 6.2. Tool Identification 6.2.1. The applicable Customer Service Representatives shall maintain a Tool Assignment Log, which controls the assignment of the Tool Number. 6.2.1.1. The Tool Number shall be linked with the customer part via the (COMPANY NAME) Tooling Master, and the format for the Tool Number shall contain an Alpha that identifies each individual tool from a set of tools associated with a single part (e.g., 10460A, 10460B, 10460C, etc.). 6.2.2. The Tool Room shall be responsible for placing the Tool Number from the (COMPANY NAME) Tooling Master for Tooling utilized in the Stamping Operations. The Engineering Department for Fabrication shall be responsible for placing the Tool Number from the (COMPANY NAME) Tooling Master on Fabrication tooling. The primary method of placing the Tool Number on the tooling shall be as follows: 6.2.2.1. For tooling fixtures the primary method of identification shall be etching and/or metal stamping. 6.2.2.2. For dies the typical method of identification shall be as follows: 6.2.2.2.1. Until the Sample Run Submission to the customer the Tool Number shall be painted on the tool. 6.2.2.2.2. After the Sample Run and before the Production Run, tags shall be affixed to the tool with the Tool Number, Customer Name, Part Number and material information. 6.2.2.2.3. A weight tag shall be affixed to the upper half of the die that identifies: Tonnage Stroke Upper Die Weight Complete Die Weight 6.2.2.2.4. Permanent asset tags shall also be affixed to the tool, when supplied by the customer. Page 3 of 7 SSYYSSTTEEM M PPR RO OC CEED DU UR REE Tooling Management REVISION: 01 PROCEDURE NO.: PTR001 DATE EFFECTIVE: 03/05/01 6.3. Tool Storage & Retrieval 6.3.1. Current Production Tools shall be stored at the location assigned in the (COMPANY NAME) Tooling Master. The Tool Storage locations can be determined from the Plant Layout drawings located at various places in the plant. 6.3.2. Tools to be serviced (maintenance or repair) shall be tagged per the Tooling Repair procedure (PTR003) and placed on the designated Service Shelf near the Tool Room. 6.3.2.1. Tools that cannot fit on the Service Shelf shall be placed back in their assigned locations after being properly tagged for service. 6.3.3. The Tool Room Supervisor / Lead Person shall coordinate with the Jeep Driver as to the Tools to be serviced or repaired. 6.3.4. Tools to be used in Production shall be identified on the Job Router and retrieved by the Jeep Driver when requested by the Production Supervisor / Set-Up Personnel. 6.4. Dispositioning Tools 6.4.1. 6.4.2. Sales Engineering or Customer Service shall primarily be responsible for coordinating the dispositioning of Customer Tooling. The following are the typical signs that the tooling needs dispositioning: The Customer’s Part has been Obsoleted The Part has become Inactive No Customer Orders are being placed. If the Customer has not requested that the tools be returned or scrapped and the tooling has not been used for an extended period of time, then Sales Engineering or Customer Service shall work with the customer to determine whether the tool is to be: Kept in Service Returned to the Customer or Other Location Scrapped. 6.4.3. If the tool is to be taken out of service, then it shall be dispositioned on the (COMPANY NAME) Tooling Master as Inactive, Scrap, or Returned. Engineering shall also enter the Date Dispositioned and the Reason Code. 6.4.4. The Sales Engineer or Customer Service Representative shall generate a Tooling Disposition Record and submit to the Tool Room Supervisor / Lead Person for processing. 6.4.5. The Tool Room Supervisor / Lead Person shall ensure that the authorized disposition is carried out and the completed actions documented on the Tooling Disposition Record. Page 4 of 7 SSYYSSTTEEM M PPR RO OC CEED DU UR REE Tooling Management REVISION: 01 PROCEDURE NO.: PTR001 DATE EFFECTIVE: 03/05/01 6.4.6. Upon completing the Tooling Disposition Record the Tool Room Supervisor / Lead Person shall return it to the originating Sales Engineer or Customer Service. 6.4.7. The Sales Engineer or Customer Service Representative shall retain the completed Tooling Disposition Record. 7. PROCEDURAL FLOW (See Next Page for the Flow) Page 5 of 7 SSYYSSTTEEM M PPR RO OC CEED DU UR REE Tooling Management REVISION: 01 PROCEDURE NO.: PTR001 BEGIN THE TOOLING MANAGEMENT PROCESS Sales / Customer Service Receives Customer Order for New or Revised Tooling Enters the Tooling Description into the Tooling Log AND If New, Assigns a Tooling Number for Identification & Tracking Purposes Enters the Tooling into the (Company) Tool Master for use in the (Company) Part Master for all Production Jobs Generates a Tool Order Router from the (Company) Tool Room Menu & Distributes to Applicable (Company) Functions Applicable Engineering See PTR002 for Design & Fabrication B Tool Room Customer Order Skip if Number is present on Corrected Tooling (Company) Computer System (Company) Tool Master Upon Receipt of the Tool marks the Tool Number per the Tooling Master Prepares Tool for (Company) Production Equipment Tooling Assignment Log Unless FAIR was performed at Tooling Supplier Primarily the Design Date and Revision Information If being Fabricated Outside, Generates a Requisition for a Tooling Purchase Order that Establishes the Requirements for Fabrication with the Tooling Supplier Purchase Requisition Production Supervision & Tool Room Performs Sample Run & Establishes the Set-Up Parameters for the Tooling Obtains Purchase Order from Purchasing and Issues to Applicable Tooling Supplier Purchase Order Submits Samples per Tooling Order Including those for QC to perform a First Article Inspection FAIR Acceptable for Submission to Customer? Tool Room New Die Checklist Yes Affix Tag(s) to the Tooling with the applicable Information Manages Any Corrections by the Tooling Source (see PTR002) Performs CheckOut of New Tooling by Completing a New Die Checklist B Tool Room Sales / Customer Service Distribution is Typically to the Applicable Production Planning Team Performs Maintenance & Repair of Tooling per PTR003 Monitors Customer Orders for Identification of Obsolete Parts & Tooling Coordinates the Dispositioning of Obsolete Tooling A PTR001 p1.vsd 9/23/2005 6:41:48 AM Page 6 of 7 A 100% Dimensional Layout Per APQP Planning Record (see PQC004) Applicable Engineering Assigns a Storage Location and Enters it into the Tooling Master Upcoming Samples Schedule Typically a Set-Up Procedure Form for Dies and Other Set Up Sheets for Secondary Operations (i.e., Welding, etc.) No Production Supervisor/ Jeep Driver Typically Weekly Reports From the Tooling Source Production Schedule Schedules a Sample Run at (Company) using the Press Identified on the Part Master Distribution is Typically to the Applicable Production Planning Team Upon completion of the Drawings, enters applicable information into the (Company) Tool Master Fixtures Made By (Company) are also Identified Typically by etching but any Method is Acceptable Performs Tooling Tryouts Production Control Tool Order Router Tool Drawing(s) Upon Completion of the Fabrication and/or Corrections, Requests a Sample Run at (Company) by Issuing An Upcoming Samples Schedule Typically Painted on Dies A PTR001 Begins the process of Designing the Tool and Determining who to place the Fabrication Order with Monitors the Fabrication through its Completion DATE EFFECTIVE: 03/05/01 END THE TOOLING MANAGEMENT PROCESS SSYYSSTTEEM M PPR RO OC CEED DU UR REE Tooling Management REVISION: 01 PROCEDURE NO.: PTR001 DATE EFFECTIVE: 03/05/01 8. RECORDS 8.1. (COMPANY NAME) Computer System 8.1.1. Tooling Master 8.1.2. Part Master 8.2. Tool Assignment Log 8.3. Plant Layout Drawing (FDE008) 8.4. New Die Checklist (FTR004) 8.5. Tooling Disposition Record (FTR010) 9. REVISION HISTORY REVISION LEVEL DATE OF REVISION SECTIONS 00 9/14/99 All 01 02/19/01 All DESCRIPTION OF CHANGE Re-Issue of Procedure for QS-9000 Registration The majority of the changes are due to the Organizational Change where the Tool Room went under the Stamping Operations Manager from the VP of Engineering. Those changes that are not are due to corrective and preventive actions required by CPARs initiated during internal Quality System Audits. Section 7 was added to help see the inter-relationships between the recently established organizational responsibilities. 01 Correction 03/05/01 7.0 The concept of Press Grouping was added to the step involving the scheduling of the F.A.I.R. 10. AUTHORIZATION POSITION HELD BY AUTHORIZATION SIGNATURE OR INITIALS Page 7 of 7