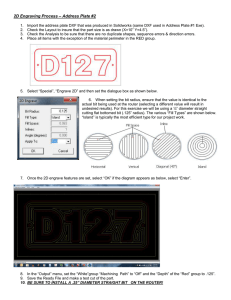

VISUALIZATION OF AUTOMATED PLATE CUTTING OPERATION USING DXF FILE

advertisement

VISUALIZATION OF AUTOMATED PLATE CUTTING OPERATION USING

DXF FILE

NORAZURA BINTI ABD. RAHIM

A project report submitted in partial fulfillment of the

requirements for the award of the degree of

Master of Science (Information Technology – Manufacturing)

Faculty of Computer Science and Information System

Universiti Teknologi Malaysia

APRIL 2008

iii

To all the love I received, my beloved mom and family….

23 years surrounded by love………

and the love of knowledge.

Would like to thank you for being here with me.

iv

ACKNOWLEDGEMENT

My greatest gratitude goes to my supervisor, Dr. Habibollah bin Harun, for

the brilliant ideas, suggestions, helpful guidance and for tolerating with the

mischievous behavior I showed.

Sincere gratitude also goes to my last Manager at Kinn Engineering Works,

Melaka, Mr. Goh Toh Hau, my colleagues at the organization for the idea of this

project and thousands of helps and suggestion towards this project.

Not forgetting to all my friends for their supports and Nuremi Aqmal for his

understanding and helps during implementing this project.

Finally, to my beloved family especially my mom for her supports during my

study here. Thanks a lot.

v

ABSTRACT

This project is going to visualize the automated plate cutting application

using plasma cutter. The problem behind this project is taken from problem aroused

at Kinn Engineering Works, Malacca. But it will not act as the study case, this

project is more to education based. The problems here are how to automate those

application and what are the processes needed in order to automate it. The objective

of this project is to automate the plate cutting operation and to develop a framework

on how the automation could be performed. Due to cost constraint, the scope of this

project was narrow down to just visualize it instead of perform it in real time

application. All the drawing used is in 2 dimension drawing format. The product

design for this project is in the .dwg format (Solidworks) and it will use the dxf file

format as the interchange format file. This project has two main modules which are

dxf reader and the animation of plate cutting process. This project is performed

using project-based methodology. The drawing read by the dxf reader will be

compared to the real drawing for validation purpose, and the animation process will

be justified by the precision of the cutting route path. This system was developed in

the C# and .NET framework environment. There are two results expected which are

the system and the framework for the automated plate cutting application.

vi

ABSTRAK

Projek ini akan menganimasikan proses pemotongan kepingan secara

automatik menggunakan pemotong plasma. Masalah di sebalik pengenalan projek ini

adalah diambil dari masalah yang berlaku di Kinn Enggineering Works, Melaka.

Tetapi, organisasi ini tidak akan bertindak sebagai kajian kes, kerana projek ini akan

dibangunkan lebih berdasarkan pembelajaran. Masalah bagi projek ini adalah

bagaimana aplikasi pemotongan kepingan ini dapat dilaksanakan secara automatik

dan apakah proses – proses yang terlibat bagi mengautomasikan aplikasi ini. Projek

ini dibangunkan bertujuan untuk mengautomasikan proses pemotongan kepingan dan

membangunkan suatu rangka kerja bagaimana pengautomasian ini dapat

dilaksanakan. Berikutan masalah kewangan yang dihadapi, skop projek ini telah

dikecilkan dengan hanya menganimasikan proses pemotongan kepingan secara

automatik tersebut. Projek ini hanya akan meliputi penggunaan lukisan dalam format

2 dimensi sahaja. Rekabentuk produk bagi projek ini adalah dalam format .dwg

(lukisan Solidworks) dan menggunakan fail dxf sebagai fail perantaraan. Projek ini

akan menganimasikan aplikasi sebenar berdasarkan lukisan yang diberi. Sistem ini

mempunyai dua modul utama iaitu pembaca dxf dan penganimasian proses

pemotongan. Projek ini dilaksanakan menggunakan metodologi berdasarkan projek.

Lukisan yang dihasilkan oleh pembaca dxf akan dibandingkan dengan lukisan

sebenar untuk tujuan validasi, dan animasi proses pemotongan akan dijustifikasi

berdasarkan ketepatan laluan pemotongan kepingan yang dilalui. Sistem ini

dibangunkan dalam persekitaran C# dan juga .NET framework. Terdapat dua hasil

jangkaan bagi projek ini iaitu sistem dan juga rangka kerja bagi mengautomasikan

proses pemotongan kepingan tersebut.

vii

TABLE OF CONTENT

CHAPTER

1

2

TITLE

PAGE

DECLARATION

ii

DEDICATION

iii

ACKNOWLEDGEMENT

iv

ABSTRACK

v

ABSTRAK

vi

TABLE OF CONTENT

vii

LIST OF TABLES

x

LIST OF FIGURES

xi

LIST OF APPENDICES

xii

INTRODUCTION

1.1

Introduction

1

1.2

Background of problem

2

1.3

Statement of the Problem

3

1.4

Project Objectives

3

1.5

Project Scope

4

LITERATURE REVIEW

2.1

Introduction

5

2.2

Background of Solidworks

6

2.3

About Plasma Cutting

7

2.4

Automated Plate Cutting Operation

9

(Real Time Application)

2.5

About DXF

10

viii

3

2.5.1 Dxf file format Information

11

2.5.2 Dxf Group Codes

11

2.5.2.1 Header

11

2.5.2.2 Classes

12

2.5.2.3 Tables

15

2.5.2.4 Blocks

16

2.5.2.5 Entities

18

2.5.2.6 Objects

20

METHODOLOGY

3.1

Introduction

22

3.2

Methodology for Developing the Automated

22

Plate Cutting Systems

3.3

4

3.2.1

Problem Definition

23

3.2.2

Data Collection

23

3.2.3

System Developing and Visualization

24

3.2.4 Validation and Testing

24

Methodology of Plate Cutting Framework Development

25

3.3.1

Problem Definition

25

3.3.2

Data Collection

26

3.3.3 Process Verification

26

3.3.4

26

Framework Development

3.3.5 Framework Validation

27

3.4

Hardware Requirement

27

3.5

Software Requirement

27

3.6

Methodology Conclusion

28

ANALYSIS AND SYSTEM DESIGN

4.1

Introduction

29

4.2

Real Time Application Analysis

29

4.3

System Design

30

4.3.1

31

Input Design

ix

4.3.2

5

6

Output Design

32

4.5

Framework Analysis

34

4.6

Conclusion

35

IMPLEMENTATION AND TESTING

5.1

Introduction

36

5.2

System Development

36

5.2.1

Interfaces Development

37

5.2.2

System Programming

39

5.3

System Testing

42

5.4

Framework Development and Testing

44

5.5

Conclusion

45

DISCUSSION AND CONCLUSION

6.1

Introduction

46

6.2

Discussion

46

6.3

Project Advantages

47

6.4

Project Improvement

47

6.5

Suggestion

48

6.6

Conclusion

48

REFERENCE

Bibliography

Appendix A - C

49

50-97

x

LIST OF TABLES

TABLE NO.

TITLE

PAGE

2.1

Variable in the HEADER Section

11

2.2

CLASSES Section in DXF file

12

2.3

CLASSES Section Group Codes

13

2.4

Default Class Values

14

2.5

TABLES Section of DXF file

15

2.6

BLOCKS Section in DXF file

17

2.7

Group Codes by Entities

18

2.8

ACAD_REACTORS Records

19

2.9

ACAD_XDICTIONARY Records

19

2.10

Group Flag bit-coded Values

20

2.11

OBJECTS Section in DXF file

20

xi

LIST OF FIGURES

FIGURE NO.

TITLE

PAGE

2.1

Solidworks Screenshot

6

2.2

Reusable of Parts

7

2.3

Example of tooling setup

9

2.4

Example of Plasma Cutter

9

2.5

Dross Free Plasma Cut Edge

10

2.6

Plasma Cut Edge with Heavy Dross Formation

10

3.1

Methodology for Automation of Plate Cutting Operation

23

3.2

Methodology of Plate Cutting Framework Development

25

4.1

Example of Plasma Cutter

30

4.2

System Design

30

4.3

Example of .dwg Drawing

31

4.4

Example of dxf File

32

4.5

Output Drawing Interface

33

4.6

Output Animation Interface

33

4.7

Framework of Automated Plate Cutting Operation

34

5.1

Main Menu

38

5.2

Drawing Displayed

38

5.3

Visualization of the Cutting Process

39

5.4

Dxf Reader Module

40

5.5

Animation Module

41

5.6

Solidworks Drawing

42

5.7

System’s Drawing

43

5.8

Cutting Process Testing

44

5.9

Framework of Automated Plate Cutting Operation

45

xii

LIST OF APPENDICES

APPENDIX

TITLE

PAGE

A

Introduction to Solidworks

50

B

About DXF

73

C

Project I and II Gantt Chart

95-97

CHAPTER 1

INTRODUCTION

1.1

Introduction

After the Second World War ended around the 1945, manufacturing

technology had achieved their third stage of evolution which is automation

technology era. This technology was proposed in order to replace manual labor and

human operator control with automated operations and control. The objective of this

emerged technology is to have a faster, more reliable, more accurate, more flexible

and less expensive manufacturing processes.

The production automation technology is divided into two interrelated

categories which are manufacturing operation and automation. Manufacturing

operation is concerning with the conversion of raw material into finished product

where the final product will have a few subassemblies combined. Basic equipment

for the manufacturing process is called Machine Tools. Machine Tools are the

machine that capable of producing itself with the help of operator. These Machine

Tools is performing two basic operations which are metal cutting and metal forming.

Metal cutting involves removals of material to create the final shape but metal

forming involves little or no loss of material in creating the final shape.

Kinn Engineering Works is one of the factories that produce machine located

at Taman Perindustrian Merdeka, Melaka. The main product of this company is

produce machine according to their customer needs and customization. So, it is very

important for them to really understand their customer want. Once they received an

2

order, they will draw the machine according to the customer needs and setup the raw

material needed. After that, their mechanical engineer will draft it using the

Solidworks Drawing. From the drawing, their workers will perform the operation

needed. The main thing that they need to do first is cutting the raw material

according to the drawing. Usually, the plate that they used is mild steel or stainless

steel plate.

With the manual process, each worker has to understand and know how to

read the drawing by their own to do the cutting process. This cutting process includes

turning (using lathe), milling, grinding, drilling and also shaping. This project will

emphasize on the plate cutting by convert the Solidworks drawing into the

interchange format file (.dxf) and read by the system that will be developed before

being understand by the motor that will be used to control the cutter.

1.2

Background of the Problem

Business is really emphasized on financing. By the manual system that the

company has, every worker had to really understand on how to read the Solidworks

drawing that have been produced by their mechanical engineer. The problem will

arise if there are new worker in the factory. Their management has to put on training

on him how to read the drawing. This really needs time and money. This is because

of the ability to understand is based on everybody intellectual. The later they

understand, the more money and time needed.

Other problem arise if there is new worker is, waste of product defect. What

happen if the new worker is actually not really understand how to read the drawing?

Of course, they will make mistake on their work. Since there is a mistake, means

there is money and time wasted.

Other alternative that the company can use is using the automation

technology where the programming language is the Programmable Logic Control

(PLC) to cut the plate. But, the limitation of PLC as already known is, it will limit

3

the cutting. It cannot cut all type of shape wanted. Yet, using PLC the flexibility of

production is reduced where if there are changes in the product design, they need to

reprogram the code which has been coded before. Therefore, they made a decision to

use computer as the alternative whereby, they can use the automation technology to

cut the plate instead of human labor and the flexibility of product can be maintained

by using the Soildworks. In reflect of this, this project is proposed to help the

organization solve their problem. The idea is on converting the Solidworks drawing

into the neutral file DXF and read by the system. Then, using the motion control

card, the cutter will communicate with the computer to cut the plate as the drawing.

This is based on the motor used to control the cutter.

1.3

Statement of the Problem

Result from the current framework of cutting operation that they have shows

that the organization does not have a proper framework for its cutting operation and

value added for the organization. Therefore, a framework for the operation is needed

to help them monitor their performance and a system to help them organize the

process better. Developing a framework and a system for the operation will help the

production to answer these several question:

1.4

i.

How to automate the cutting operation?

ii.

What are the processes needed to execute the cutting operation?

Project Objectives

Development of this project is purposely to achieve some solutions of the

current problem. The purposes of the project are:

i.

To develop a system that will automate the plate cutting operation

ii.

To develop a framework of automated plate cutting operation

4

1.5

Project Scope

The project is guided with some constraints and boundaries. The scopes of

the project are as follows:

i.

The Solidworks drawing used is in 2D format drawing

ii.

This project will use DXF file which have converted from the

Solidworks drawing as their input to the system

iii.

Because of cost limitation, this project is not being tested on real time

application, but it wills just visualizing the automated cutting operation.

CHAPTER 2

LITERATURE REVIEW

2.1

Introduction

Automation technology is proposed to replace manual labor and human

operator control with automated operations and control. This will make

manufacturing processes faster, more reliable, more accurate, more flexible and less

expensive. This project will visualize the automated plate cutting operation

performed by plasma cutter. In the real time application, they will cut the plate using

the plasma cutter that being controlled by motor. This motor used is based on the

precision of the product that wants to produce.

Data and information visualization is becoming an increasingly important

tool in scientific research. This is being driven by the increasing use of

computational simulations and digital data acquisition in research, and by the

broadening spectrum of media available for the presentation of research results.

Visualization is a method of computing. It transforms the symbolic into the

geometric, enabling researchers to observe their simulations and computations.

Visualization offers a method for seeing the unseen. It enriches the process of

scientific discovery and fosters profound and unexpected insights. In many fields it is

already revolutionizing the way scientists do science. Visualization embraces both

image understanding and image synthesis. That is, visualization is a tool both for

interpreting image data fed into a computer, and for generating images from complex

multi-dimensional datasets. It studies those mechanisms in humans and computers

6

which allow them in concert to perceive use and communicate visual allow them in

concert to perceive use and communicate visual information. The goal of

visualization is to leverage existing scientific methods by providing new scientific

insight through visual methods. An estimated 50 percent of the brain's neurons are

associated with vision. Visualization in scientific computing aims to put that

neurological machinery to work.

2.2

Background of Solidworks

Soldworks is a very powerful Computer Aided Design (CAD) program which

allows for rapid and accurate development 3-Dimensional mechanical models.

Coupled with powerful 2-Dimensional blueprinting tools, this combination provides

for reproducible and efficient CAD/CAM solutions for today's Engineering industry.

After producing a model using Solidworks, designers can test the design (using

Cosmos) by Finite Element Analysis (FEA) before anything is physically built. Once

a design is finalized, the Solidwork's model could be easily converted into a

Parasolid file for machining or molding. Solidworks files also work seamlessly with

AutoCAD, Catia, and Pro/E files / documents as well. Below is the example of

Solidworks screenshot.

Figure 2.1

Solidworks Screenshot

SolidWorks is a powerful 3D modeling program. The models it produces can

be used in a number of ways to simulate the behavior of a real part or assembly as

7

well as checking the basic geometry. One of the advantages of using Solidworks is

the ability to reuse objects. Solidworks let the user to draw an object using the

assembly format. Then, whenever they need to draw another object that may need

any part that already have, so it can be reused again. This helps the user to minimize

their time spending a lot. Figure 2.2 shows an example of this advantage. Steps on

how to create a 2D drawing using Solidworks will be shown in Appendix A.

Figure 2.2

2.3

Reusable of Parts

About Plasma Cutting

In simplest terms, plasma cutting is a process that uses a high velocity jet of

ionized gas that is delivered from a constricting orifice. The high velocity ionized

gas, that is, the plasma, conducts electricity from the torch of the plasma cutter to the

work piece. The plasma heats the work piece, melting the material. The high velocity

stream of ionized gas mechanically blows the molten metal away, severing the

material. Plasma cutting can be performed on any type of conductive metal - mild

steel, aluminum and stainless are some examples. With mild steel, operators will

experience faster, thicker cuts than with alloys.

8

Oxyfuel cuts by burning, or oxidizing, the metal it is severing. It is therefore

limited to steel and other ferrous metals which support the oxidizing process. Metals

like aluminum and stainless steel form an oxide that inhibits further oxidization,

making conventional oxyfuel cutting impossible. Plasma cutting, however, does not

rely on oxidation to work, and thus it can cut aluminum, stainless and any other

conductive material. While different gasses can be used for plasma cutting, most

people today use compressed air for the plasma gas. In most shops, compressed air is

readily available, and thus plasma does not require fuel gas and compressed oxygen

for operation.

Plasma cutting is typically easier for the novice to master, and on thinner

materials, plasma cutting is much faster than oxyfuel cutting. However, for heavy

sections of steel (1 inch and greater), oxyfuel is still preferred since oxyfuel is

typically faster and, for heavier plate applications, very high capacity power supplies

are required for plasma cutting applications.

Plasma cutting is ideal for cutting steel and non-ferrous material less than 1

inch thick. Oxyfuel cutting requires that the operator carefully control the cutting

speed so as to maintain the oxidizing process. Plasma is more forgiving in this

regard. Plasma cutting really shines in some niche applications, such as cutting

expanded metal, something that is nearly impossible with oxyfuel. And, compared to

mechanical mean of cutting, plasma cutting is typically much faster, and can easily

make non-linear cuts.

But yet, there is limitation for plasma cutting compared to oxyfuel. The

plasma cutting machines are typically more expensive than oxyacetylene, and also,

oxyacetylene does not require access to electrical power or compressed air which

may make it a more convenient method for some users. Oxyfuel can cut thicker

sections (>1 inch) of steel more quickly than plasma.

9

Figure 2.3

Example of tooling setup

Figure 2.4 Example of Plasma Cutter

2.4

Automated Plate Cutting Operation (Real Time Application)

In the real time application, after the Solidworks drawing is converted into

DXF file and read by the system, it will being sent to the cutter to perform the

application. It uses motor as the controller of the cutter. In this case, the cutter that

being used is plasma cutter. The selection of cutter used is defined by the thickness

of the product produced. If the range of the plate is 1mm – 10mm then the best cutter

is plasma cutter. But if the range is between 10mm – 15 mm the best cutter is oxyplasma. The selection of the controller uses is defined by the precision of the product

produced. There are several types of motor that can be used for this application such

as servo motor, stepper motor, speed control motor, DC motor and the most

10

economic and least precise is the induction motor (AC). It is needed to install the I/O

card and high speed counter card into the computer used to let the computer send the

impulse to the motor as an input to start cutting the plate. Following is the example

of high precise of edge cutting and less precise of edge cutting, tools setup and

plasma cutter:

Figure 2.5

Dross Free Plasma Cut Edge

Figure 2.6

Plasma Cut Edge with Heavy

Dross Formation

2.5

About DXF

Neutral file is one of the format that being used by most of CAD system.

There are many types of neutral files such as IGES, STEP, DXF and others. In this

project, DXF file was chosen, this because of its compatibility to drawing field. DXF

is representing as Data Exchange Format. It is a format for storing vector data in

ASCII or binary files. It is used by AutoCAD and other CAD software for data

interchange. DXF files are convertible to ARC/INFO coverage. It is needed to

convert the Solidworks drawing to DXF file to let the C# read the drawing which had

been drawn using Solidworks.

11

2.5.1

DXF File Format Information

This chapter is describing about the DXF file format further. It has the

technical information needed to let the system developed could read the DXF file

format produced. DXF file is including 6 main sections which are Header, Classes,

Tables, Blocks, entities and objects. Each of this section has their own role to make

sure the system could read the DXF file.

2.5.2

DXF Group Codes

This chapter describes the DXF group codes found in DXF files and

encountered by AutoLISP and ARX applications. The first section provides general

information about DXF group codes. It lists the group codes in numerical order and

organizes them by object type.

2.5.2.1 Header

The HEADER section of the DXF file contains settings of variables associated with

the drawing. Each variable is specified in the header section by a 9 group giving the

variable's name, followed by groups that supply the variable's value. Applications

can retrieve the values of these variables with the getvar function. The following is

an example of the HEADER section of a DXF file:

Table 2.1

0

Variable in the HEADER Section

Beginning of HEADER section

SECTION

2

HEADER

9

Repeats for each header variable

12

$<variable>

<group code>

<value>

0

End of HEADER section

ENDSEC

2.5.2.2 Classes

The CLASSES section holds the information for application-defined classes whose

instances appear in the BLOCKS, ENTITIES, and OBJECTS sections of the

database. It is assumed that a class definition is permanently fixed in the class

hierarchy and all fields are required. More information regarding this issue could be

fine in the appendix B. The following is an example of the CLASSES section of a

DXF file:

0

Table 2.2 CLASSES Section in DXF file

Beginning of CLASSES section

SECTION

2

CLASSES

0

CLASS

1

<class dxf record>

2

<class name>

3

<app name>

90

Repeats for each entry

13

<flag>

280

<flag>

281

<flag>

0

End of CLASSES section

ENDSEC

Each entry in the CLASSES section contains the groups described in the following

table.

Group Code

Table 2.3

Description

0

Record type (CLASS). Identifies beginning of a CLASS record.

1

Class DXF record name. These should always be unique.

2

C++ class name. Used to bind with software that defines object

CLASSES Section Group Codes

class behavior. These are always unique.

3

Application name. Posted in Alert box when a class definition

listed in this section is not currently loaded.

90

Proxy capabilities flag. Bit coded value that indicates the

capabilities of this object as a proxy.

0 = No operations allowed (0)

1 = Erase allowed (0x1)

2 = Transform allowed (0x2)

4 = Color change allowed (0x4)

8 = Layer change allowed (0x8)

16 = Linetype change allowed (0x10)

32 = Linetype scale change allowed (0x20)

64 = Visibility change allowed (0x40)

127 = All operations except cloning allowed (0x7F)

128 = Cloning allowed (0x80)

255 = All operations allowed (0xFF)

32768 = R13 format proxy (0x8000)

280

Was-a-proxy flag. Set to 1 if class was not loaded when this DXF

14

file was created, and 0 otherwise.

281

Is-an-entity flag. Set to 1 if class was derived from the AcDbEntity

class and can reside in the BLOCKS or ENTITIES section. If 0,

instances may appear only in the OBJECTS section.

AutoCAD registers the classes listed in the following table (note that this may not be

a complete list of the classes found in a DXF file depending on the applications

currently in use on your system).

DXF Record Name

Default Class Values

Table 2.4

C++ Class Name Code 2 Code

Code

Code 1

Code

90

280

281

DICTIONARYVAR

AcDbDictionaryVar

0

0

0

HATCH

AcDbHatch

0

0

1

IDBUFFER

AcDbIdBuffer

0

0

0

IMAGE

AcDbRasterImage

127

0

1

IMAGEDEF

AcDbRasterImageDef

0

0

0

IMAGEDEF_REACT

AcDbRasterImageDefRe

1

0

0

OR

actor

LAYER_INDEX

AcDbLayerIndex

0

0

0

LWPOLYLINE

AcDbPolyline

0

0

1

OBJECT_PTR

CAseDLPNTableRecord

1

0

0

OLE2FRAME

AcDbOle2Frame

0

0

1

RASTERVARIABLE

AcDbRasterVariables

0

0

0

SORTENTSTABLE

AcDbSortentsTable

0

0

0

SPATIAL_INDEX

AcDbSpatialIndex

0

0

0

SPATIAL_FILTER

AcDbSpatialFilter

0

0

0

S

15

2.5.2.3 Tables

The order of the tables may change, but the LTYPE table always precedes the

LAYER table. Each table is introduced with a 0 group with the label TABLE. This is

followed by a 2 group identifying the particular table (APPID, DIMSTYLE,

LAYER, LTYPE, STYLE, UCS, VIEW, VPORT, or BLOCK_RECORD), a 5 group

(a handle), a group 100 (AcDb Symbol Table subclass marker), and a 70 group that

specifies the maximum number of table entries that may follow. Table names are

output in uppercase characters. The DIMSTYLE handle is a 105 group not a 5 group.

The tables in a drawing can contain deleted items, but these are not written to

the DXF file. As a result, fewer table entries may follow the table header than are

indicated by the 70 group, so do not use the count in the 70 group as an index to read

in the table. This group is provided so that a program that reads DXF files can

allocate an array large enough to hold all the table entries that follow.

Following this header for each table are the table entries. Each table item

consists of a 0 group identifying the item type (same as table name, such as LTYPE

or LAYER), a 2 group giving the name of the table entry, a 70 group specifying flags

relevant to the table entry (defined for each following table), and additional groups

that give the value of the table entry. The end of each table is indicated by a 0 group

with the value ENDTAB. The following is an example of the TABLES section of a

DXF file.

Table 2.5

0

TABLES Section of DXF file

Beginning of TABLES section

SECTION

2

TABLES

0

TABLE

2

<table type>

5

Common table group codes,

repeats for each entry

16

<handle>

100

AcDbSymbolTable

70

<max. entries>

0

Table entry data, repeats,

<table type>

for each table record

5

<handle>

100

AcDbSymbolTableRecord

.

. <data>

.

0

End of table

ENDTAB

End of TABLES section

0

ENDSEC

Both symbol table records and symbol tables are database objects. At a very

minimum, with all prevailing usage within AutoCAD, this implies that a handle is

present, positioned after the 2 group codes for both the symbol table record objects

and the symbol table objects.

2.5.2.4 Blocks

The BLOCKS section of the DXF file contains all the block definitions. It

contains the entities that make up the blocks used in the drawing, including

anonymous blocks generated by the HATCH command and by associative

dimensioning. The format of the entities in this section is identical to those in the

17

ENTITIES section. All entities in the BLOCKS section appear between block and

endblk entities. Block and endblk entities appear only in the BLOCKS section. Block

definitions are never nested (that is, no block or endblk entity ever appears within

another block-endblk pair), although a block definition can contain an insert entity.

External references are written in the DXF file as block definitions, except

that they also include a string (group code 1) that specifies the path and file name of

the external reference.

The block table handle, along with any xdata and persistent reactors, appears

in each block definition immediately following the BLOCK record, which contains

all of the specific information that a block table record stores. Therefore, each block

definition has the following sequence of records: The following is an example of the

BLOCKS section of a DXF file:

0

Table 2.6

BLOCKS Section in DXF file

Beginning of BLOCKS section

SECTION

2

BLOCKS

0

BLOCK

5

<handle>

100

AcDbEntity

8

<layer>

100

AcDbBlockBegin

2

<block name>

70

<flag>

10

Begins each block entry

(a block entity definition)

18

<X value>

20

<Y value>

30

<Z value>

3

<block name>

1

<xref path>

0

One entry for each entity definition within the block

<entity type>

.

. <data>

0

ENDBLK

End of each block entry

(an endblk entity definition)

5

<handle>

100

AcDbBlockEnd

0

End of BLOCKS section

ENDSEC

2.5.2.5 Entities

The following table shows group codes that apply to all symbol table entries.

Optional codes are shown in gray. When you refer to the table of group codes by

entity type, which lists the codes associated with specific entities, keep in mind that

the codes shown here can also be present.

Group code

-1

Table 2.7

Group Codes by Entities

Description

APP: entity name (changes each time a drawing is

opened)

19

0

Entity type (table name)

5

Handle (all except DIMSTYLE)

105

Handle (DIMSTYLE table only)

102

Start of application defined group "{application_name".

For example, "{ACAD_REACTORS" indicates the start

of the AutoCAD persistent reactors group

application-defined

Codes and values within the 102 groups are application-

codes

defined.

102

End of group, "}"

100

Subclass marker (AcDbSymbolTableRecord)

The following table shows the group codes that are output if persistent reactors have

been attached to an object.

Group

Table 2.8

Description

ACAD_REACTORS Records

code

102

"{ACAD_REACTORS" indicates the start of the AutoCAD persistent

reactors group

330

Soft pointer ID/handle to owner dictionary

102

End of group, "}"

The following table shows the group codes that are output if an extension dictionary

has been attached to an object.

Group

Table 2.9

Description

ACAD_XDICTIONARY Records

code

102

"{ACAD_XDICTIONARY" indicates the start of an extension

dictionary group.

360

Hard-owner ID/handle to owner dictionary.

102

End of group, "}".

20

Common 70 group flag bit-coded values are described in the following tables.

Additional 70 group values that apply to LAYER, STYLE, and VIEW table entries

are described in those tables.

Table 2.10

Bit-

Group Flag bit-coded Values

Description

coded

value

16

If set, table entry is externally dependent on an xref.

32

If this bit and bit 16 are both set, the externally dependent xref has been

successfully resolved.

64

If set, the table entry was referenced by at least one entity in the

drawing the last time the drawing was edited. (This flag is for the

benefit of AutoCAD commands. It can be ignored by most programs

that read DXF files and need not be set by programs that write DXF

files.)

2.5.2.6 Objects

Objects are similar to entities, except that they have no graphical or geometric

meaning. All objects that are not entities or symbol table records or symbol tables are

stored in this section. This section represents a homogeneous heap of objects with

topological ordering of objects by ownership, such that the owners always appear

before the objects they own. The following is an example of the OBJECTS section of

a DXF file:

Table 2.11

0

OBJECTS Section in DXF file

Beginning of OBJECTS section

SECTION

2

OBJECTS

0

Beginning of named object

21

DICTIONARY

5

dictionary (root dictionary

object)

<handle>

100

AcDbDictionary

3

Repeats for each entry

<dictionary name>

350

<handle of child>

0

Groups of object data

<object type>

.

. <data>

0

ENDSEC

End of OBJECTS section

CHAPTER 3

METHODOLOGY

3.1

Introduction

Project is performed based on the planning that was planned before. This

planning is important to make sure the project flow is going smooth and can be

finished on time. There are two methodology involved in this project which are for

developing the automated plate cutting system and for developing the framework of

the automated plate cutting operation. Since the research for this topic is not really

widened, the methodology used for this project is a project-based.

3.2

Methodology for Developing the Automated Plate Cutting System

Following is the methodology used to develop the automated plate cutting

system as shown in Figure 3.1 Methodology for Automation of Plate Cutting

Operation

.

23

Problem Definition and

Formulation

Data Collection

System Developing &

Visualization

Validation &

Testing

Figure 3.1

3.2.1

Methodology for Automation of Plate Cutting Operation

Problem Definition

To formulate the problem occurred in the organization, the method used is

discussion and interview with the System Manager, Mr. Goh Toh Hau. At this phase,

the entire problem regarding this application will be defined then formulated.

Besides, the objective, scope, technology used, hardware and software are defined in

this stage also. Problem definition is important whereby it shows how important this

project is to make as a research. At this time also, a list of title is proposed in order to

choose the best topic to make as a project.

3.2.2

Data Collection

Once the topic is chosen, then all the problem background is formulate. After

the idea to overcome the problem occurred was defined, all the data needed to

24

perform the project is collect during the industrial visit. Since the organization is not

implemented the machine yet, all the machine illusion is proposed during the

industrial visit by their engineer. The mechanical part used like the cutter, motor and

others is based on the specification set by the organization. All these ideas is just to

use as education purpose only, not going to implemented at the organization.

3.2.3

System Developing and Visualization

This is the phase where the interfaces and programming is coded to automate

the operation. The programming language used for this developing process is C#.

This is because of its compatibility and ease in the manufacturing application. This

project also visualizes the cutting process using C# language. At this stage, all the

information is collected as a reference to do the programming.

3.2.4

Validation and Testing

The validation process for the first module (dxf reader) is performed by

comparing the real drawing (in the format .dwg) with the drawing read by the dxf

reader (the system). Since there is limitation in costing for this project, the testing

phase will be done by visualization. It will visualize the automated plate cutting

operation from it starts getting the input from the system until it finish cutting the

plate either it’s performed as the drawing or not. The validation of the visualization

process will be comparing with the real application video. But, comparing step

cannot be done thoroughly because of field constraint. This phase will be repeated

with the previous phase, whereby if there is still any mistake has in the system,

developing process will be repeated.

25

3.3

Methodology of Plate Cutting Framework Development

The methodology used for developing the framework is similar as the system

at certain point. Following is the methodology defined to develop the framework of

plate cutting operation:

Problem Definition and

Formulation

Data Collection

Process

Verification

Framework

Development

Framework

Validation

Figure 3.2

3.3.1

Methodology of Plate Cutting Framework Development

Problem Definition

As mentioned above, this first stage is similar like the methodology used to

get the real problem happened in the organization which by interviewing and

discussion. But, for the framework the problem formulation is actually forced by the

problem to develop the automated system. Because, whenever to automate the

application, there is no guidance to let others know how actually the process is could

26

be done. So, by developing a framework it will help others to refer to the step taken

in order to perform application like this project.

3.3.2

Data Collection

To develop the framework, all the processes involved in the automated

cutting operation are collected during this phase whereby also during the industrial

visit. All those processes is including the processes to perform the plasma cutting as

manually and automated operation. For the automated operation it is as proposed by

the Kinn Engineering Works’s system manager Mr. Goh Toh Hau.

3.3.3

Process Verification

From all the processes collected, it will be verified the only needed process to

perform this operation. This is the most important stage to develop the framework of

the operation, because if the process chosen is wrong, then the framework is going

wrong. This verification step is done theoretically not tested on real application.

3.3.4

Framework Development

Since the needed process is defined, this is the stage where all the processes

are being put in the right order to create a framework. This framework is developed

based on project performed. It does not based on any testing performed before. This

step is performed together with the previous step (processes verification) to let the

framework developed in well organized.

27

3.3.5

Framework Validation

Since this project is performed based on education purposed, the framework

validation is just done by validate with the supervisor. There is no practically

validation performed to ensure the precision of the framework. This is based on the

logic of the framework.

3.4

Hardware Requirement

The following is the minimum specification set to run this system:

3.5

i.

Personal computer with the Pentium III processor

ii.

Random Access Memory (RAM) – 256 MB RAM.

iii.

40 GB of hard disk.

iv.

Mouse

v.

Keyboard

vi.

Monitor screen

vii.

Graphic Card

Software Requirement

To run this system, the software specification needed is including

programming language C# to develop the system, this including the animation of the

cutter movement. Solidworks 2007 is using to draw the drawing to be the input for

the system and will be convert to dxf to be the interchange format file. All the

interfaces of the system is developed using .NET framework while .paint is used to

hold the cutter image that being used in the animation.

28

3.6

Methodology Conclusion

Overall project development is based on project-based. There are two main

things that going to develop which are the system to automate the cutting process and

the flow of the automation proposed. Since the project is developed for education

purposed, all the methodology used is also simply driven from this project idea.

CHAPTER 4

ANALYSIS AND SYSTEM DESIGN

4.1

Introduction

This chapter will analyze all the elements involved in this project due to its

implementation after this, these including the analysis about the organization, the real

application and the process that will involve in the system that going to develop.

4.2

Real Time Application Analysis

In the real time application, the plate cutting is performed manually (human

labor to cut the plate), so there are several hardware involve in this project. This

including electrical motor, cutter, plate, encoder and motion control card. The motor

is used as a controller to the cutter. The type of motor used is based on the product

precision and cost provided. For the animation of this project, the motor used is the

induction motor which is the cheapest motor. This type of motor needs the encoder to

communicate with the computer. Beside, it is needed to install the I/O card and the

high speed counter card to the computer used in order to let them communicate. This

project uses the plasma cutter as the cutter to cut the plate. This plasma cutter is

using the combination of gas and oxygen before it’s burned. The high pressure of this

combustion will used to cut the plate. Usually, the plate used is from the Mild Steel

or Stainless Steel material. Figure 4.1 shows the example of plasma cutter.

30

Figure 4.1

4.3

Example of Plasma Cutter

System Design

Basically, this system involved two main modules which are dxf reader and

animation. For the first modules, this system will read file in the dxf format where it

has been saved in the hard disk. Once the system read the file, it will upload the

drawing onto the canvas prepared.

The next module will be performed in order to represent the real application

(plate cutting). The user needs to press start button to start the application. Here, the

system will animate the route path of the drawing as it is cutting the plate according

to the drawing path (in the real application). This application design is as shown in

the Figure 4.2 below.

User

Open Drawing File

Figure 4.2

System Design

Start Cutting

31

4.3.1

Input Design

Input specification is about the data key in or imported by the user into the

system using keyboard and mouse. For this system, the input key in by the user is the

drawing that has been converted into dxf file. The first modul (dxf reader) will read

the drawing and open it in the canvas provided. Below is the example of drawing in

.dwg that has been converted into dxf file (which has been saved in text format).

Figure 4.3

Example of .dwg drawing

32

0

SECTION

2

HEADER

9

$ACADVER

1

AC1015

9

$ACADMAINTVER

70

6

9

$DWGCODEPAGE

3

ANSI_1252

9

$INSBASE

10

0.0

20

0.0

30

0.0

9

$EXTMIN

10

0.0

20

0.0

30

0.0

9

$EXTMAX

10

Figure 4.4

Example of dxf file

4.3.2 Output Design

Output design is the result produced after running some process using the

input given by user. There are outputs that will be produced by this system which are

the drawing produced by the dxf reader and also the animation route path produced

by the animation module. Below is the example of output interfaces.

33

Figure 4.5

Figure 4.6

Output Drawing Interface

Output Animation Interface

34

4.5

Framework Analysis

The analysis for the framework is done after all the processes involved were

collected and analyzed during the real time application analysis. At this stage, only

the important processes are selected to put in the framework. This process is

important to make sure the framework built is correct and efficient. But, for this

project it will not implement the entire steps in the framework developed due to its

constraint as told in the chapter 1 before. The framework is developed by doing a

discussion with the system manager and also the employee involved. Below is the

framework developed after the analysis process completed.

Convert Solidworks Drawing

into DXF Format file

Definition of DXF

file

Send Impulse to

motor

Start Cutting

Figure 4.7

Framework of Automated Plate Cutting Operation

To automate the cutting process, it starts with converting the Solidworks

drawing into DXF file format (this is done using the Solidworks converter have by

the Solidworks software). After converting, it will be sent to the system to let the

engine read and understands the DXF file (done by the dxf reader module in the

system). Once it understood the format, it will send the impulse to the motor to tell

the motor about the motion should be done by the cutter (this step is using the high

35

speed counter card installed in the computer to let it communicate with the motor).

The final step is cutter starts the cutting process as being told by the motor.

4.6

Conclusion

As a conclusion, this chapter is describing about system design like the

interfaces, input and output specification and etc. Overall, the system design was

developed interactively whereby if there is still any mistake or changes according to

the user need. This chapter is important because it could give the idea on how certain

system is developed.

CHAPTER 5

IMPLEMENTATION AND TESTING

5.1

Introduction

This chapter involved the system developing (coding activity) and testing.

Every module in this project was being developed during this phase. After the system

was developed, the testing stage is performed to ensure that the system running as

planned before. Every single function is being tested with the given input. During

project I phase, the input expected is in the format .dwg which is Solidworks drawing

format. But, it was changed in the implementation phase whereby the input will be in

the format of .dxf. It was converted using Solidworks before it is being sent to the

system. Since there are 2 objectives of this project, there also have two developing

and testing process conducted whereby another one is the framework of plate cutting

operation implementation and testing.

5.2

System Development

The implementation of this project is being done in C# and .NET framework

environment. There are 2 modules defined in this project which are dxf reader and

visualization module. For the dxf reader, this project covers line, rectangle, polyline,

circle, and arc. It is not cover the freehand drawing. Next, for the visualization

module, it is just representing the real application. In the real application, after the

37

system read the dxf, it will send all the coordinate of the drawing to the motor to

perform the cutting process (transfer into bit that can be understands by the motor).

But, by just visualizing the cutting process, it is performed based on the

mathematical algorithm to read each type of shape of the input. There are 2

algorithms involved in this module which are Bersenhem algorithm and arc

algorithm where the Bersenhem algorithm is used to read line and the arc algorithm

is used to read arc and circle.

5.2.1

Interfaces Development

This system use menus editor to control the system running. There are 2 main

menu involved which are File and Help. For the File menu, it has 2 sub menu which

is Open and Exit. Once the Open menu is clicked, it will pop up the directory to

choose the file desired. This menu allows the system to read the dxf file format and

display it on the canvas provided in the system. Once the dxf file format have been

read and displayed on the canvas, there are another 4 generated menu in type of

button displayed together on top of the drawing. It is play, pause, stop and show

animated route. The play, pause and stop button is used to control the animation

process and the show animated route is used to show or hide the route of the

animation performed. Another sub menu under the file menu is Exit, where if the

user clicks onto it, it will exit the system (close). The other side main menu is just

form about the project. Below is the example of system interface developed.

38

Figure 5.1

Figure 5.2

Main Menu

Drawing Displayed

39

Figure 5.3

5.2.2

Visualization of the Cutting Process

System Programming

C# is one of the most powerful language and very desirable to performed

application that involved drawing like this project. It is object-oriented based where

it helps the developer in saving their developing time. Besides, using C# it has the

built in function to read shape. So, it makes the programming became easier. Below

is the part of function used for the dxf reader module.

40

using

using

using

using

System;

System.Collections;

System.Drawing;

System.Drawing.Drawing2D;

namespace DXFImporter

{

#region Shape class - abstract

public abstract class Shape

{

protected Color contourColor;

protected Color fillColor;

protected int lineWidth;

public int shapeIdentifier;

public int rotation;

public bool highlighted;

public abstract Color AccessContourColor

{

get;

set;

}

public abstract Color AccessFillColor

{

get;

set;

}

public abstract int AccessLineWidth

{

get;

set;

}

public abstract int AccessRotation

{

get;

Figure 5.4

Dxf Reader Module

As similar as dxf reader module, the animation module is also developed

using C#. The cutter (supposed to be plasma cutter) is saved in the format .png and

the animation of cutting process is done on the canvas. All the interfaces including

cutter, canvas, menus and etc is design using the .NET framework and being called

using C#. Below is the example code to perform the animation module.

41

using

using

using

using

using

using

System;

System.Collections;

System.Collections.Generic;

System.Drawing;

System.Drawing.Drawing2D;

DXFImporter.Properties;

namespace DXFImporter

{

#region Amry: CutterAnimationToolkit class

/// <summary>

/// Helper class containing methods related to the cutter

image animation process.

/// </summary>

static class CutterAnimationToolkit

{

static Image cutterImage;

public static IEnumerable<Point>

EnumeratePointsInBresenhamLine(Point p1,

{

int deltax = Math.Abs(p2.X between the x's

int deltay = Math.Abs(p2.Y between the y's

int x = p1.X; // Start x off

int y = p1.Y; // Start y off

Point p2)

p1.X); // The difference

p1.Y); // The difference

at the first pixel

at the first pixel

int xinc1;

int xinc2;

if (p2.X >= p1.X) // The x-values are increasing

{

xinc1 = 1;

xinc2 = 1;

} else // The x-values are decreasing

{

xinc1 = -1;

xinc2 = -1;

}

int yinc1;

int yinc2;

if (p2.Y >= p1.Y) // The y-values are increasing

{

yinc1 = 1;

yinc2 = 1;

} else // The y-values are decreasing

{

yinc1 = -1;

yinc2 = -1;

Figure 5.5

Animation Module

42

5.3

System Testing

System testing for this project is performed through both module, which are

dxf reader module and animation module. For the dxf reader module, the validation

is being looked on the ability of the system to read the input (.dxf file) and display

the image as it was (in the .dwg drawing). This stage is really important because the

correct input read will ensure the correct coordinate given to the cutter (in the real

application). Below is the example of the input from its real drawing (.dwg

Solidworks drawing) and after it was converted to .dxf and being read by the dxf

reader in this system.

Figure 5.6

Solidworks Drawing

43

Figure 5.7

System’s Drawing

After the drawing go through the first testing phase successfully, it

will being tested on the next testing stage which is the animation or visualization

testing. Since the real application is still not being implemented, the testing phase is

conducted by comparing the animation done either it is according to the drawing

coordinate or not (the precision of the cutting process animation). This can be shown

by the animated route path on the canvas. Since the second module is representing on

the plate cutting process, so it is important to make sure every single coordinate is

being sent correctly. For this part, the most critical section on implementation the

system is develop the algorithm to read all types of shape given by the input.

Besides, the validation also will be justified by the mechanical engineer at Kinn

Engineering Works either it is similar to the real application or not, but of course it

will have the field constraint. Figure 5.8 below will shows the animation performed

by the system from the input given.

44

Figure 5.8

5.4

Cutting Process Testing

Framework Development and Testing

After all the processes needed were analyzed in the third stage, it will be put

in the right order following to the step performed. Once the framework was ready,

the validation will be performed by the project supervisor. Below is the framework

developed and have been satisfied for this project (it is regarding to the real

application).

45

Convert Solidworks Drawing

into DXF Format file

Definition of DXF

file

Send Impulse to

motor

Start Cutting

Figure 5.9

5.5

Framework of Automated Plate Cutting Operation

Conclusion

Overall, this section is describing the implementing of the idea of this project.

It starts with developing the interfaces, the programming and until the testing phase

to ensure the idea of this project is delivered in a correct manner.

CHAPTER 6

DISCUSSION AND CONCLUSION

6.1

Introduction

This chapter is the last part of doing project, whereby it is going to discuss

everything that going through during the project implementation time. It starts with

setting the objective, scope, collecting data, set the methodology, developing system

and the last one is testing. This chapter also covers the result of this project, their

enhancement, maybe the weaknesses, suggestion and concludes all the chapters have.

6.2

Discussion

At the first proposal, this project was proposed to develop a system using the

Visual Basic 6 (VB6) based on the ease of using it. But, when it comes to the

developing stage, the idea was changed to use C#, this regarding to the sources that

could be referred to. Besides, C# also provides much more new tools and features

that can be used for this project.

During the project I also, the system is expected to have converter tools that

can convert the Solidworks drawing to the dxf file (as in the initial finding chapter).

But, when it comes to the developing stage again it had been changed. This is

because, it is much better and easier to convert the .dwg drawing to the .dxf file using

47

the converter have by the Solidworks aoftware and make the dxf converted as the

input to the system.

Since there are few changes made in the developing stage, the output also a

bit difference from the expectation. The output for this project is going to be, the

framework of the automated plate cutting process, the interface of the system, the dxf

that being read by the system, instead of dxf file that being generated (from the first

proposal), and also the animation or visualization of the cutting process. Yet, since

there is no converter function for this system, the validation process is also change,

where the dxf file (which is the input) is no need to be validated by the MasterCAM

software.

6.3

Project Advantages

The advantages of this project are it could help to reduce the labor and

product defect cost, this regarding to its objective to automate the cutting application.

Besides, it also produced a framework that can be guidance to others who want to

make the automated application like this.

6.4

Project Improvement

The weakness of this project is due to the algorithm to read the coordinate (to

animate). From the animation performed, it is lack of precise when it goes to the arc,

and circle shape. This project also not covered the freehand drawing for both of their

modules, dxf reader and the animation.

48

6.5

Suggestion

In order to improve the system, it can improve the algorithm to read the

freehand drawing for the dxf reader module. And for the animation module, the

improvement can be done on the algorithm to get the precise coordinate on arc, circle

and much better for the freehand drawing. From the education view, it is useful if the

animation of the plate cutting process can be saved in the format of video or etc. So,

other people could review or use it for any educational purpose later.

6.6

Conclusion

As a conclusion, to do a project is it important to have a well prepared plan.

From there we are going to know what exactly that we should find and work on. And

it is good to have an expectation about the achievement (initial findings), because

from there we will know either our expectation is really relevant or not to our

project. But, the expectation is not supposed to be the same as the result that we

going to get at the end. For this project the result is seems to achieve the objective

even it have a bit changes made from its original idea and during the real

implementation.

49

BIBLIOGRAPHY

Anderson T. (2006). Visual Basic in Easy Steps (1st ed). Warwickshire U.K.:

Microsoft Corporation.

Bemis B. L. and Settles G. S. (1998). Visualization of Liquid Metal, Arc, and Jet

Interactions in Plasma Cutting of Steel Sheet. 8th International Symposium on

Flow Visualization.

Mohd Azahary bin Abdul Aziz (2001). Terjemahan Imej TIFF kepadaFormat Fail

DXF. Degree. Universiti Teknologi Malaysia, Skudai.

Mohd Haziman bin Mohd Shah (2002). Terjemahan Imej TIFF kepadaFormat Fail

DXF (Volume II). Degree. Universiti Teknologi Malaysia, Skudai.

Richard P. and Fitzgerald J. (2006). Introduction to AutoCAD®:2006 A Modern

Perspective.(1st ed). United States of America : Prentice Hall.

Getting to know (and love) Solidworks

Data : 20 April 2008

http://catalogimages.wiley.com/images/db/pdf/0764595555.excerpt.pdf

How Plasma Cutter Works

Data : 20 April 2008

http://science.howstuffworks.com/plasma-cutter.htm

Introduction to Solidworks

Data : 20 April 2008

http://www2.warwick.ac.uk/fac/sci/eng/euo/modules/year1/es174/studentreso

urce/cae/swtut04a

Plasma Cutting : Determining if it's Right for You and What to Look for in a

Machine

Data : 20 April 2008

http://www.lincolnelectric.com/knowledge/articles/content/plasma.asp

What is Solidworks

Data ( 20 April 2008)

http://cadbright.com/Solidworks_Explained.htm

APPENDIX A

(Introduction to Solidworks)

51

Start SolidWorks

Start SolidWorks by clicking on the SolidWorks icon in the opening window.

Our network doesn’t let the program write files to the normal location the program

expects, so when warning messages appear, cancel them or browse to your H: drive

if asked for a file loation. Eventually, you’ll see the screen shown here, or something

like it. If you get the ‘Novice User’ box just cancel it. There may be a ‘tips’ window

too, it’s worth reading these as you get to know the software. Shut down the tips

window for now.

In SolidWorks we can build Parts, Assembies and Drawings. We’re going to start by

creating a new part. Later we’ll build that into an assembly and then create an

engineering drawing of the whole thing.

1. Click on File, move the cursor over New.

2. A dialog box appears, listing the types of document you can create.

3. Move the cursor and click on Part.

Your screen should look something like that shown here now.

The toolbars at the top of the screen may also be in slightly different positions

to those shown but you can move these around if you wish. The screen colour may

also be different but this too can be changed to your preference.

I’ve labeled some of the important things on the screen but it’s important to realize

that some of these will change depending on what you’re doing with the software.

52

Have a look at the Feature Manager that I’ve labeled. Notice that there are three tilted

squares marked Front, Top and Right. You always get these Sketch Planes free at the

start of each part. If you let your cursor move over them you’ll see red lines or a

rectangle appear in the Graphics Area.

Making the Crankshaft

We’re going to start by creating the crankshaft shown here. This will be done

by using the Extrude method to create cylinders for the shafts and the wedge shape

for the web. Creating solids always starts with one or more Sketches which are a

major part of SolidWorks. They’re usually 2 dimensional and are used in various

ways to generate the 3 dimensional forms that make up a solid object. We’ll start

with a sketch to create the wedge shaped ‘web’ that connects the shafts.

1. Click on Front in the Feature Manager window

to select the Front Sketch

Plane. A red rectangle in the graphics area should turn green with square dots. The

Front sketch plane is now active – notice it’s highlighted in blue in the feature

manager too.

2. Click on the Sketch icon

, just above the feature manager. Notice that the

modeling tool icons are now drawing tools like lines, arcs and rectangles etc. Press

the Create Circle button

. Move the cursor (now a pen shape) to the intersection of

the two red arrows in the middle of the screen. You’ve got there when a red dot

appears and the cursor gets an orange square beneath it.

3. Click the left mouse button and move the cursor upwards. A circle should now be

‘rubber-banding ‘, centered where you first pressed with radius to the cursor position.

Notice the radius reading changing as you move. Make the circle about 3mm radius

for now, you’ll adjust this to the precise size later.

53

4. Click the left mouse button to finish creating the circle which should go green.

Double left click and it will go blue. Roll back the scroll wheel on the mouse to

enlarge the view of the circle until the size of a 10 pence piece. Try moving the view

around on screen by holding down the ctrl key while dragging with the scroll wheel

pressed. If the circle goes elliptical you’ve probably let go of the ctrl key too early –

recover the view using the Standard Views button

then clicking Normal To

.

5.

Press the Centerline button

. Hover the cursor over the centre of your circle and

click when you get the red blob. Notice the symbol under the cursor change to an

orange square; orange symbols mean that you’re at some kind of snap point. Move

the cursor rightwards and a dashed line will stretch from the centre. The line should

snap to horizontal (or vertical), as it gets close. Click when the line looks like the

picture.

6. Now for another circle, this time about 14mm radius and with its centre on the

centerline just drawn. You should be able to do this without much help, remember to

watch for the spikey orange symbol when placing the centre on the centerline. Click

when your circle looks something like the next picture. Remember that we can easily

re-size things later on when we add the precise dimensions.

7.

Next we’re going to create the straight edges to form the wedge shaped profile. Press

the Create Line button

. Move the cursor to somewhere near the upper left of the

small circle, watch for the spikey orange symbol and left click. Move the cursor

54

beyond the top right of the large circle and click. Repeat this procedure to get an

angled line at the bottom too, giving you something like the next picture.

8. Now we need to tidy up the outline ready for the extrusion process. ‘Hygienic’

geometry, joining precisely at the corners, without extra fragments of lines is the key

to easy solid modeling. A little practice and you’ll soon get it right first time but be

prepared for a bit of frustration at first.

9.

The Trim tool

is very useful for clipping off extra bits of lines or arcs. You’ll

probably need to hunt for it as it’s off the default screen. Look for the ‘More Icons’

button,

near the top right of the graphics area. This will show you what you’ve

been missing. Click the trim tool and snip away the extra bits and pieces until you get

something like the next drawing.

10.

11.

You might notice that my sketch is a bit lumpy around the left hand circle. This is

because I wasn’t very thorough with the trimming job. Zooming in ( click

and

stretch a box around the bit you want to enlarge), gave me the next view, showing

the extra geometry. Trim one of these bits away so there’s no overlap. As you’ll see

55

in a moment, it doesn’t matter which bit we trim. Your geometry may be neater than

mine and you may not need to do this. Zoom all,

will show everything if you tried

a close-up view.

12.

Next we’ll add some geometric Relations to the sketch. We want the straight lines to

be tangential to the small, left hand circle. Click on the Pointer Icon

and click on

the small left circle (what’s left of it), then hold the ctrl key while selecting one of

the straight edges. These two clicks should turn the geometry green. At the left of the

screen you should see the Property Manager window look something like the next

picture. Notice the two Selected Entities, and look for the Tangent button near the

bottom. Click this and the selected line and arc will jump to make them tangential.

Repeat this with the other pair.

13. The final step is to set a few dimensions so the sketch precisely defines the shape

wanted. Find and click the Smart Dimension button

; It’s toward the left of the

horizontal toolbar above the graphics area. Let’s set the radius of the two arcs first.

Hover the cursor over the left hand arc. When it goes red click the left button. Move

the curser to the left and you should see an arrow with a text-box follow you. When

this is in a sensible place, left click again and the dimension is added. Now double

click on the number itself and you’ll get an edit box to change it to the right value 3mm radius for the left one. Repeat this with the right hand arc but make this

12.5mm radius.

56

14.

Now for the distance between the two arc centres. With the dimension tool still

selected, hover over the centre of the left hand arc and left click when a red blob

appears. It should go green. Hover over the right hand arc’s centre and when the red

blob appears here, press the left mouse button and drag upwards to see a linear

dimension stretch from the centres. Release and click again when it’s in a sensible

spot. Double click on the number to change it to the 12.5mm we want.

15. Angles next! Still using the dimension tool, click on the centre-line we drew near

the beginning. It should go green. You’ll also have a blue dimension line following

you that looks like the wrong thing. Simply click on one of the straight sloping lines

and it’ll change to an angular measure. Drag the text box to a sensible spot and click

again to fix it. Double click and edit both angles to 30 degrees. Hopefully you now

have something like me.

16.

At long last we’re ready to extrude this shape into a solid object. It doesn’t always

take this long but I’ve introduced dimensioning and relations as well as a selection of

sketching tools too. Find and click the Exit Sketch icon

at the top right of the

graphics area. Looking in the Feature Manager window you should now see Sketch1

at the bottom of the tree. Click on this to highlight it. Now click on the Features

57

on the left of the lower horizontal toolbar. That toolbar will now get the

button

solid modeling tools instead of sketch tools. Click on the Extruded Base/Boss button

and your sketch should swing round to an Isometric orientation and acquire some

thickness and a pale yellow tint.

17. The Feature Manager window shows the various parameters controlling the way

the extrusion happened. In particular, look for the distance control

, and the

extrusion method. A Blind extrude means that it has a set thickness, starting

from the sketch plane. Experiment with the Mid-Plane option if you like, but the

others need other geometry defined before they’ll work. Click on the tick when

you’ve set the distance to 3mm. and the yellow preview should turn grey – a solid

part at last!

18. Try holding down the middle mouse button while moving the mouse and you’ll

see the part rotate about three axes. Rolling the mouse wheel will zoom in and out.

Holding the middle mouse button down with the ctrl key pressed will pan the view.

A bit of practice and you’ll be able to get any view you wish.

Adding the Shafts

1. This is going to be easy. All we need to do is draw a circle on the face of the bit

we’ve just made and extrude it for the right distance. First make sure your cursor is

the basic pointer – click on

if not. Now click on one of the large flat faces of the

crank web. It should go green like mine…

2. We could sketch a circle and then extrude it but I’ll describe a short- cut. Click on

the Features icon

and then on the Extruded Base/Boss button

. You should

now be in sketcher mode and the program knows you want to extrude with the sketch

when finished.

3. We need to draw a circle at the centre of the large arc which is a bit tricky with the

isometric view we have here. Luckily we can get a view normal to the face selected.

58

Find and press the Standard Views icon

and then press the Normal To button

from the drop down list.

4. Click on the Circle button

and draw a circle about 4mm diameter, centered on

the large arc. Click the tick to finish it. To make sure the circle really is concentric

with the large arc we’re going to add another relation. Click on the pointer icon

if

the cursor is something different and then click on the large arc (which should go

green), hold the ctrl key and click on the new circle which should also go green. The

Property Manager should appear in the left hand pane with an entry for the green arc

and circle. Click on the Concentric button

in the property manager, click the tick

and the circle becomes tied to the centre of the arc.

5.

Use the dimension button

to set the diameter of the circle to 4mm if you’ve not

done this already.

6. Close the sketch with the Exit Sketch button

, and you should see a pale yellow