ACOUSTIC ENERGY HARVESTER FABRICATED USING SOL/GEL LEAD ZIRCONATE TITANATE THIN FILM

advertisement

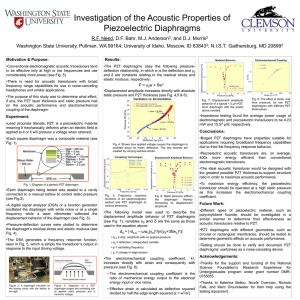

ACOUSTIC ENERGY HARVESTER FABRICATED USING SOL/GEL LEAD ZIRCONATE TITANATE THIN FILM Shu Kimura, Tomohisa Sugou, Syungo Tomioka, Satoshi Iizumi, Kyohei Tsujimoto, Yasushiro Nishioka* Department of Precision Machinery Engineering, College of Science and Technology, Nihon University, 7-24-1 Narashinodai, Funabashi, Chiba 274-8501, Japan *Presenting Author: nishioka@eme.cst.nihon-u.ac.jp Abstract: Energy harvesters integrable on smart sensor systems have been strongly demanded. Horowitz et al. have recently reported on a MEMS acoustic energy harvester using a lead zirconate titanate (PZT) thin film as a diaphragm. Shinoda et al. also reported on similar acoustic energy harvesters with improved performances fabricated using sol/gel PZT thin film processes, and suggested that the PZT acoustic energy harvester may be suitable for use as a possible power source for silicon integrated circuits. This paper presents further improved power generation performances of PZT MEMS acoustic energy harvesters fabricated using improved PZT capacitor fabrication processes. The PZT acoustic energy harvester with the diaphragm diameter of 1.2 mm fabricated using a sol/gel process generated the highest energy density of 98 µW/m2 under the sound pressure level of 100 dB (0.01 W/m2) at 18.8 kHz. Keywords: acoustic energy harvester, PZT INTRODUCTION As advanced integrated circuits (ICs) approach the physical limits of miniaturization, new technology innovations for those ICs have been strongly demanded. Recently, the integration of complimentary metal oxide semiconductor (CMOS) circuits and microelectromechanical systems (MEMS) to increase the values of these devices has been proposed. This is called “More than Moore” concept. It was also pointed out that advantageous devices are those that can operate independently from outer power circuits. The key for this concept is to realize micropower sources integrable on the CMOS chips. Sudou et al. proposed to integrate a power generator with an antenna on a CMOS chip, and it generates power by receiving alternate electromagnetic fields [1]. It will also be interesting to investigate various possible energy sources integrable on IC chips. Horowitz et al. have recently reported on a MEMS acoustic energy harvester that contained a PZT piezoelectric film as a diaphragm [2]. The energy harvester generated power by receiving sound pressure to the diaphragm. PZT films have been extensively studied since they have superior ferroelectricity and piezoelectricity [3-5]. PZT films have also been applied to ferroelectric memories, and it has been demonstrated that PZT capacitor fabrication processes are compatible with conventional CMOS processes [5,7]. Therefore, it is expected that the PZT acoustic energy harvester that can be integrated on CMOS IC chips can be a candidate power source for integrated smart systems. Shinoda et al. proposed to integrate a PZT energy harvester on IC chips [8], and it can receive power from an acoustic field (see Fig. 1). They reported that higher generated power could be realized by vibrating PZT diaphragms at the third resonance frequency. In this paper, we report on further improved performances of PZT acoustic energy harvesters that use first resonance vibrations. Sound pressure Fig. 1: Concept of an integrated system with energy harvester, CMOS circuits, and MEMS. DEVICE STRUCTURE The structure of the device investigated here is schematically shown in Fig. 2. A piezoelectric capacitor with the diaphragm structure of Al/PZT/Pt/Ti was formed on an SiO2. The cavity underneath the diaphragm was fabricated on a silicon wafer. The principle of power generation of this device is as follows. When sound pressure is applied from the upper direction of the device, the diaphragm vibrates resulting in the deflection of the diaphragm of the PZT piezoelectric capacitor. The deflected PZT capacitor generates a voltage difference between the two electrodes. In this manner, electrical power is generated. The output voltage becomes maximum when the sound frequency is equal to the resonance frequency of the diaphragm. The bonding pad (250 × 250 µm2) connecting to the upper electrode was placed apart from the diaphragm so that the vibration of the diaphragm was not disturbed. The first resonance frequencies of the diaphragm with different diameters were estimated using the ANSYS software for the finite element analysis. The estimated first resonance frequency for the diaphragm with the diameter of 2.0 mm was 6.25 kHz, and that with the diameter of 1.2 mm was 18.7 kHz. These resonance frequencies are summarized along with the measured resonance frequency results in Table I. Al (upper electrode, 0.1 µm) PZT (1 µm) Pt/Ti (lower electrode, 0.2 µm) SiO2 (1.5 µm) Si (300 µm) Fig. 2: Structure of fabricated energy harvester with PZT diaphragm. Table I: Estimated frequencies for the first resonance mode for diaphragm with different diameters. procedures. Firstly, the PZT thin films were spincoated on the lower electrode, Pt(100 nm)/Ti(100 nm), on the silicon substrate. The PZT films were deposited by the sol-gel method. The PZT sol-gel solution is “PZT-20” supplied by Kojundo Chemical Laboratory, Co, Ltd. The PZT solution was dropped on the Pt/Ti substrate and spin-coated for 3 s at the rotation speed of 500 rpm and then for 20 s at the rotation speed of 3200 rpm. The chip was dried on a hot plate in air ambient for 5 min at 120 ºC, and dried again for 6 min at 300 ºC. After those processes were repeated twice, the chip was sintered at 700 ºC for 5 min using a rapid thermal anneal furnace in oxygen atmosphere to crystallize the PZT films. The PZT thin film of 1 µm thickness was formed by repeating five times the processes described in Fig. 4. More detailed PZT thin film fabrication processes were described in many publications [9]. Spin coating of PZT solution 500 rpm, 3 s 3200 rpm, 20 s Twice Resonance frequency (kHz) Diaphragm diameter (µm) 1200 18,7 1400 12,95 1600 10,19 1800 8,26 2000 6,25 Drying in air ambient o 120 C, 5 min 5 times Prebaking in air o 300 C, 6 min Power MEMS Power Amp Resister Pre Amp Sintering o 700 C, 5 min Function Generator Osilloscope Fig. 3: Experimental setup for measuring the resonance frequencies and the generated power. The resonance frequencies were measured using the characterization system described in Fig. 3. AC sinusoidal voltage signals with different frequencies were generated by the function generator and amplified by the power amplifier. The amplifier was connected to the speaker. The gain of the power amplifier was modified to generate a requested sound pressure at the PZT energy harvester. An amplifier with a gain of 10,000 was used to amplify the output voltage signals from the energy harvester. The voltage between both terminals of the energy harvester or of the load resister was measured using an oscilloscope. DEVICE FABRICATION Figure 4 shows the PZT film deposition Fig. 4: PZT thin film deposition processes by sol-gel method. These procedures were repeated 5 times to form 1 µm-thick PZT film. The device fabrication processes used in this research are described below. A Si substrate of 300 µm thickness with 1.5-µm-thick SiO2 was prepared. The Pt/Ti layer was deposited by sputtering to form the lower electrode. The 1-µm-thick PZT thin film was deposited by the sol-gel method. The PZT was patterned by wet etching using buffered hydrofluoric acid (BHF) to expose the lower electrode. The 0.1-µmthick Al thin film for the top electrode was then thermally deposited. The top electrode patterns were defined by all dry mask deposition. The cavity was formed by etching the silicon substrate from the back with an inductively coupled plasma (ICP) etcher. The thicknesses of the films in the diaphragm part are Al (0.1 µm)/PZT (1.0 µm)/Pt/Ti (0.2 µm)/SiO2 (1.5 µm). The top electrode was previously defined using a photolithography method including Al wet etching solution [8]. However, we suspected that this wet etching process might be harmful for the PZT diaphragm. Therefore, the Al electrodes in this research were defined using a mask deposition process in which no wet etching processes was included. Figure 5 shows the photographs of the PZT surface before immersing in an Al etching solution (a) and after immersing the PZT in the Al wet etching solution for 30 s (b). Most of the PZT film was removed after 30 s. Therefore, the Al wet etching process to define the top electrodes could damage the PZT capacitors. (a) (b) Fig. 5: PZT thin film deposited on Pt/Ti coated substrate (a) and the PZT surface immersed in Al wet etching solution for 30 s (b). After 30 s, all the PZT film was removed. estimate the suitable load resistance R, the following measurements were performed. Figure 6 shows comparison of the power comsumed at the load resistor for the PZT acoustic power generator with a diamter of 1.2 and 2.0 mm fabricated using the dry Al electrode fabrication process, and with a diameter of 2.0 mm fabricated using the Al wet process. As shown in Fig. 3, a variable resistor was connected to the PZT energy harvester, and the resistance was varied from 10 Ω to 1 MΩ. The voltage between both terminals of resistance was measured and recorded using an oscilloscope. The sound pressure of approximately 100 dB at the first resonance frequencies was irradiated. The effective electric power delivered to the load resistance R was calculated from the measured voltage amplitude V using the relationship P = V2/2R. The relationships between the power delivered to the load and the load resistance were well described using Eq. (1). The output power was proportional to R when R was small, and was inversely proportion to R when R was large. The maximum power delivered to the load was derived when the load resistance was approximately 550 Ω for the device fabricated using the Al wet process, and the power decrease below 550Ω. In contrast, the generated power of the devices fabricated using the Al dry process continued to increase until the load resistance reaches around 75 Ω. Thus, it can be speculated that the Al wet etching process make the internal resistance larger resulting in the reduction of the generated power. DETERMINATION OF LOAD RESISTANCE , (1) where P is the extracted power, V is the voltage across the load resistance, I is the current across the load resistance, and E is the generated voltage. Note that the extracted power P is maximum at an appropriate R. To extract the largest power from the power source, the load resistance R should be selected correctly. To Generated power (W) 10−9 After improving the process (Diameter1.2[mm]) After improving the process (Diameter2[mm]) Before improving the process (Diameter2[mm]) 10−10 Al dry process 10−11 10−12 Al wet process 10−13 10 100 1000 10000 Load resistance (ohm) Fig. 6: Measured relationships between the power delivered to the load and the load resistance. 100000 1200μm 1400μm 0.1 電圧〔mV〕 E P = VI = RI 2 = R ⋅ R+r 2 0.12 Generated voltage (V) It is necessary to demonstrate that the harvesters can deliver power to a load resistance. When an internal resistance r exists in a power source, the output electric power consumed at the load resistance R is expressed using 1600μm 1800μm 0.08 2000 1200 1600μ 1400 1800 2000μm 0.06 0.04 0.02 0 0 2000 4000 6000 8000 10000 12000 14000 16000 18000 周波数〔Hz〕 Frequency (Hz) Fig. 7: Frequency dependences of the generated voltage E of the PZT energy harvester with different diaphragm diameters from 1.2 to 2.0 mm. Figure 7 compares the generated voltage E for the PZT power generators with different diaphragm diameters. The resonance frequency increases as the diameter size decreased. Figure 8 compares the load resistance dependences for the PZT power generators investigated here. Note that smaller diameter devices exhibited the larger generated power. This may be due to the fact that higher frequency sound was applied to the devices with the smaller diaphragm diameters. CONCLUSION Generated power (W) 10-9 10 polarization than the PZT film investigated here. The PZT acoustic energy harvester with the diaphragm diameter of 1.2 mm fabricated using a sol/gel process generated the highest energy density of 98 µW/m2 at the sound pressure level of 100 dB (0.01 W/m2). The energy density was the largest ever reported. 1200μm 1400μm 1600μm 1800μm 2000μm -10 10-11 10-12 10-13 10-14 ACKNOWLEDGEMENTS 10 100 1000 10000 100000 Load resistance (ohm) Fig. 8: Measured relationships between the power delivered to the load and the load resistance for PZT acoustic PZT power generators with different diaphragm diameters. Table I compares the performances of the PZT power generators by Horowitz et al., Shinoda et al., and this work. The dramatic improvement in the energy density was due to the reduced internal resistance of the PZT capacitor. DISCUSSION The improved performances of the PZT acoustic energy harvesters compared to those of Horowitz et al. and Shinoda et al. are most possible due to the reduced internal resistance, and it is strongly related with the top electrode fabrication process of the PZT capacitors. The energy harvesters reported by Horowitz et al. have structures and dimensions similar to those of the devices investigated here. They used the PZT thin film with the thickness of 0.27 µm. In contrast, the PZT film used in the devices was 1 µm thick. It has been reported that the polarization charge of sol-gel PZT films rapidly decreases when the PZT film thickness is below 0.625 µm [10]. Therefore, it is assumed that the PZT film investigated by Horowitz et al. had smaller The authors express their sincere acknowledgements to staffs of the Micro Functional Device Research Center, CST, Nihon University, and to Dr. Takeshi Kobayashi and Dr. Ryutaro Maeda of the National Institute of Advanced Industrial Science and Technology (AIST) for the technical assistances. REFERENCES [1] Sudou M, Takao H, Sawada K, Ishida M 2008 Sens. Actuators A 145-146 343. [2] Horowitz S B, Sheplak M, Cattafesta N, Nishida T 2006 J. Micromech. Microeng. 16 S174. Gross S J, Tadigadapa S, Jackson T N, TrolierMcKinstry S, and Zhang Q Q 2003 Phys. Lett. 83 174. [4] Yamashita K, Katata H, Okuyama M, Miyoshi H, Kato G, Aoyagi S, and. Suzuki Y 2002 Sens. Actuators A 97–98 302. [5] Itoh T, Lee C, Suga T 1996 Phys. Lett. 69 2036. [6] Kim K and S. Y. Lee 2007 Microelectron. Eng. 84 1976. [7] Jung J, Joo H, Park J, Kang S, Kim H, Choi D, Kim J, Lee E, Kong Y, Kim H, Jung D, Kang Y, Lee S, Jeong H, Kim K 2007 Jpn. J. Appl. Phys. 46 1934. [8] Shinoda S, Tai T, Itoh H, Sugou T, Ichioka H, Kimura S, Nishioka Y 2010 Jpn. J. Appl. Phys. 04DL21 [9] Kobayashi T, Ichiki M, Tsaur J, Maeda R 2005 Thin Solid Films 489 74. [10] Amanuma K, Mori T, Hase T, Sakuma T, Ochi A, Miyasaka Y 1993 Jpn. J. Appl. Phys. 32 4150. [3] Table I Comparisons of PZT acoustic energy harvesters. Sound pressure level was 100 dB (0.01 W/m2). S. B. Horowitz et al [1] S. Shinoda et al. [2] This work Diaphragm Diameter (mm) Resonance Frequency (Hz) 2.4 13568 Generated Power (W) Power density 2 (µW/m ) Internal resistance (ohm) 1000 6.0x10 -12 1.0 0.054 1000 3.6 5232 7.0x10 -13 1.5 24020 1.1x10 -11 4.9 550 1.3 550 2.0 18020 5.1x10 -12 1.2 16700 1.4x10 -10 98 75 4.0x10 -11 10 70 2.0 6400