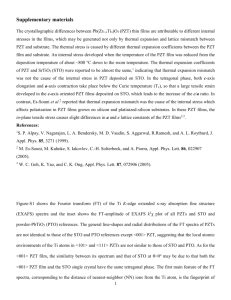

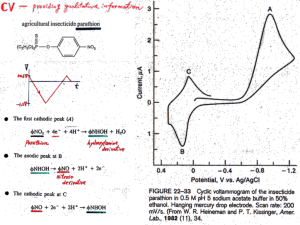

We obtained that the work function of PZT film is

advertisement

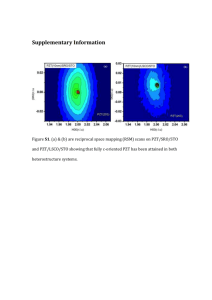

Electronic Supplementary Information Enhanced photocathodic behaviors of Pb(Zr0.20Ti0.80)O3 films on Si substrates for hydrogen production Xiaorong Cheng, Wen Dong, Fengang Zheng, Liang Fang, and Mingrong Shen* College of Physics, Optoelectronics and Energy, Collaborative Innovation Center of Suzhou Nano Science and Technology, Photovoltaic Research Institute of Soochow University & Canadian Solar Inc., and Jiangsu Key Laboratory of Thin Films, Soochow University, 1 Shizi street, Suzhou 215006, China. E-mail address: mrshen@suda.edu.cn Experimental Section Preparation of Si-pn+/ITO/PZT photocathode: We prepared pn+ junction from multi-crystalline silicon (mc-Si) wafers (15.615.60.18 cm3, p-type, specific resistance ρ=1-3 Ω.cm, GCL company, China) with a standard process of phosphorus doping on a mass production line of mc-Si solar cells. The pit-shape texture of mc-Si was achieved via a standard process of acid etching. First, the mc-Si wafers were etched in HF/HNO3/H2O (HF in 70 g/L, HNO3 in 450 g /L) mixture solution at 10 0C for 2 min. The wafers were then cleaned by deionized water (ρ=18 MΩ) for 25 s. Second, the wafers were etched in KOH/H2O solution (KOH in 35 g/L, 20 0C) for 40 s. After cleaned by deionized water for 25 s, the wafers were dipped in a HF/HCl/H2O (HF in 30 g/L, HCl in 40 g/L) mixture solution at room temperature for 30 s in order to remove SiO2 on the surface and ions such as Pt2+, Au3+, Ag + and Cu2+. Finally, the wafers were cleaned by deionized water and dried by hot air (50 0C) for 25 s. Aluminum bottom electrodes were fabricated by a standard screen printing process. The ITO layer (with a ratio of Sn:In=90:10) was deposited on the pn+ Si junction by sputtering method (5 mTorr Ar pressure, 400 0C deposition temperature, 550 0C annealing for 30 min under vacuum). Then a Pb(Zr0.20Ti0.80)O3 (PZT) film was also deposited by sputtering (15 mTorr, O2:Ar =10:90 for 1 hour, 500 0C deposition S-1 temperature). After the deposition, PZT film was crystallized at 650 0C for 30 min in air. Sample characterizations: The PZT films were characterized by Rigaku D/MAX 3C x-ray diffractometer using CuKα radiation. Scanning electron microscope surface and cross-section images were checked by a Hitachi SU8010. For PEC measurements the Si-pn+/ITO/PZT electrodes were cut into 1.51.5 cm2. Tinned copper wire was connected to the aluminum bottom electrodes by gallium-indium eutectic (Sigma-Aldrich). The exposed backside, edges, and some part of the front of the electrodes were sealed with an industrial epoxy (PKM12C-1, Pattex). The current-voltage curves of samples were measured by an electrochemical workstation (CHI660D, CH Instrument) with a 100 mW cm-2 Xe lamp (Oriel, Newport Co.) as light source and 0.1 M Na2SO4 solution as electrolyte. During the measurement, Si-pn+/ITO/PZT served as working electrode, a Pt wire as the counter electrode and an Ag/AgCl electrode as the reference electrode. The potentials were re-scaled to the ones versus the reversible hydrogen electrode (RHE) according to the following equation: E(RHE) = E(Ag/AgCl) + 0.197 V at pH = 0. Potentiostatic electrochemical impedance spectroscopy was carried with an AC potential frequency range from 100 000 to 0.1 Hz. The incident photo-to-current conversion efficiency (IPCE) was measured with a 100 mW cm-2 Xe lamp illumination in a 0.1 M Na2SO4 solution. The IPCE value was calculated using the following equation: IPCE (%) = (1240I / (Jlight)) 100%, where I is the photocurrent density (mA cm-2), Jlight is the power density of the incident illumination (mW cm-2) and is the incident light wavelength (nm). Poling the PZT film in Si-pn+/ITO/PZT: The poling of PZT films was carried out using an electrochemical workstation (CHI660D) in 0.1M Na 2SO4 electrolyte. During the poling, +10 V or -10 V pulsed voltage was added between ITO and the Pt reference electrode. The measurement of hydrogen evolution: The hydrogen and oxygen evolution by PEC water splitting was conducted in the air-tight photo-reactor which was made of quartz glass. In the photo-reactor, the photocathode and the counter Pt electrode were S-2 separated in different tubular chambers, which avoid the mixing of hydrogen generated on the photocathode and oxygen on the Pt counter electrode. The measurements were conducted in a solution containing 0.1 M Na2SO4 under 100 mW cm-2 Xe lamp illumination. The amount of hydrogen was determined by a gas chromatography equipped with TCD (Tianmei, GC 7890T). Fig. S1 SEM images of Si-pn+ substrate fabricated by normal acid etching process. Fig. S2 The optical reflectance spectra of planar Si wafer before (in black) and after acid etching (in red).The reflectance of the Si-pn+ substrate after acid etching was less than that of the planar Si wafer. S-3 Fig. S3 Polarization-electric field loop for the /ITO/PZT/Pt capacitor on Si-pn+ substrate. About 40 nm thick Pt top electrodes with diameters of 0.28 mm were sputtered onto the PZT film. Hysteresis loops were then examined using a radiant precision ferroelectric analyzer from Radiant Technology. Fig. S4 The enlarged J-V curves for the Si-pn+ /ITO/PZT photoelectrodes with as-prepared (a) and negatively (b) poled PZT films, respectively. S-4 Fig. S5 J-V curves for Si-pn+/ITO/TiO2 electrode with as-prepared (black), negatively (red) and positively (blue) poled TiO2 films, respectively. The TiO2 layer was deposited on Si-pn+/ITO substrate by sputtering method under 10 mTorr Ar pressure for 30 min and annealed at 400 0C for 2 hours in air. The thickness of TiO2 is also about 300 nm. Without the efficient polarization-induced internal electric field the J-V curves show no obvious difference after positively or negatively poling the TiO2 film. Only a small photocurrent (about -10 A cm-2 at 0 V vs. RHE) can be observed in Si-pn+/ITO/TiO2 electrodes. Fig. S6 J-V curves for Si-pn+ /ITO electrode, showing negligible photocurrent in the cathodic region from 0 to -0.4V vs. RHE. S-5 Fig. S7 The SEM surface morphology of the Si-pn+/ITO/PZT photocathode with positively poled PZT film before (a) and after (b) 3 hours continued PEC reaction. A Si-pn+/ITO/PZT sample was cut into two pieces. One was taken to SEM analysis directly and the other was taken to SEM analysis after 3 hours of continued PEC reaction. There is no obvious corrosion on the film surface observed after the continued PEC reaction. S-6