jace13944-sup-0001-SuppInfo

advertisement

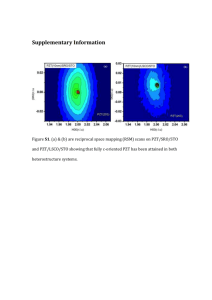

Supplementary Information Microstructure and X-Ray Diffractogram: Figure S 1: Microstructure of in situ laser annealed PZT 52/48 deposited using an ablation laser fluence ~1.7 J/cm 2 , pO 2 : 50 mTorr, target-substrate distance: 5 cm. The surface SEM suggests large grain sizes (~200 nm), but also shows unusual topography of the grains, that could be due to Pb-resputtering as mentioned in the manuscript. Figure S 2: X-ray diffractogram for in situ laser annealed PZT 52/48 film deposited using an ablation laser fluence ~1.7 J/cm 2 , pO 2 : 50 mTorr, target-substrate distance: 5 cm Ellipsometry: Figure S 3: ((a) and (b)) Model fits to spectroscopic ellipsometry data (ψ and Δ), (c) Dispersion of refractive index n extracted from the fits (comparison with data from Ref. 23 in the manuscript, extrapolated to higher wavelengths), (d) Layered structure used in the modeling (values indicated in the individual layers correspond to the b est fit thicknesses) Temperature Simulations Finite element modeling of laser heating was performed using the 1-D heat equation (1). Three (static) thicknesses of the PZT film were considered: 100 nm, 300 nm and 600 nm, while the substrate structure comprised of 100 nm Pt/10 nm Ti/1 μm SiO2/500 μm Si. 𝜌𝐶𝑝 𝜕𝑇(𝑧,𝑡) 𝜕𝑡 = ⃗∇. (𝐾𝑇ℎ ⃗∇𝑇(𝑧, 𝑡)) + 𝑄(𝑧, 𝑡) (1) Here, ρ: density, Cp: specific heat, T: temperature, t: time, KTh: thermal conductivity. Q is the heat source distribution in the sample as a function of depth (z) which in turn can be expressed in terms of the laser intensity (Io), the reflectivity of the surface (R) and absorption coefficient of PZT (α) as: 𝑄(𝑧, 𝑡) = 𝐼𝑜 (𝑡)(1 − 𝑅) 𝛼 exp(−αz) (2) The time evolution of the laser pulse intensity profile (Io) was modeled with a Gaussian-like function as follows (3) 𝐹 𝜏𝑝 𝐼𝑜 (𝑡) = ( ) exp [−4 ln 2 ( 𝑡−2𝜏𝑝 𝜏𝑝 2 ) ] (3) where F: laser fluence, τp: pulsewidth (Full Width at Half Maximum) of the laser The reflectivity 𝑅 = (𝑛−1)2 +𝑘 2 (𝑛+1)2 +𝑘 2 and the absorption coefficient 𝛼 = 4𝜋𝑘 𝜆 can be extracted from the complex refractive index 𝑛̃ = 𝑛 + 𝑖𝑘 of PZT. Since an as deposited film with no laser annealing had the pyrochlore phase, the complex refractive index for a pyrochlore film deposited on a glass substrate was extracted at 248 nm wavelength from spectroscopic ellipsometry (not shown) as n = 2.4 and k = 1.3. The material properties listed in Table S 1 were used for the modeling. Thermal properties for PZT were taken from Ref.7 in the manuscript. Certain caveats should be mentioned regarding the modeling. The temperature dependences of the various material properties have been neglected for these calculations, as was any latent heat due to a phase transition. The properties of PZT (52/48) and the PZT (30/70) seed layer were also assumed to be similar. Hence the simulated temperature profiles are only a guide. Table S 1: Material properties (taken from Ref. 7, 18 in the manuscript) PZT Pt Ti SiO2 Si ρ (kg/m3) 7500 21450 4500 2200 2330 Kth (W/(m.K) 1.8 69.1 17 1.6 152 Cp (J/(kg.K)) 370 134 528 740 700 Figure S 4: Temperature simulations for PZT with different thicknesses on Pt/Ti/SiO 2 /Si substrates, (a) 100 nm thick, (b) 600 nm thick. The laser pulse profiles are also shown. Electrical Properties (Polarization-Electric Field loops) Figure S 5: Nested polarization-electric field hysteresis loops for the various 𝒇𝑨𝒏𝒏𝒆𝒂𝒍 : (a) 𝒕 0.09, (b) 0.17, (c) 0.27, (d) 0.43, (e) 1 Table S 2: Summary of Remanent Polarization (P r ), Coercive Fields (E c ) and Leakage Currents for the various 𝒇𝑨𝒏𝒏𝒆𝒂𝒍 𝒕 𝒇𝑨𝒏𝒏𝒆𝒂𝒍 𝒕 1 0.43 0.27 0.17 0.09 (Pr++Pr-)/2 (μC/cm2) 18 22.5 25 26.3 22.4 (Ec++Ec-)/2 (kV/cm) 43 56 43 52 40 Leakage Current (at 3*Ec) (A/cm2) 1.4 x 10-8 1.6 x 10-6 2.8 x 10-8 8.4 x 10-8 1.5 x 10-8 Free energy schematic Figure S 6: Schematic representing the variation of free energies of the deposited metastable amorphous/pyrochlore phase and the stable perovs kite phase (adapted from Ref. 28,29 in the manuscript). The thermodynamic driving force for phase conversion (∆G v ) for an arbitrary substrate temperature is indicated