3.051J/20.340J Lecture 19 Drug Delivery: Controlled Release

3.051

J / 20 .340

J

Lecture 19

Drug Delivery: Controlled Release

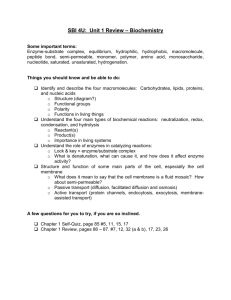

What do we mean by “controlled” release?

Control of: 1. delivery rate

2. release/activity

Need for Control drug concen.

toxic level

Traditional drug delivery

Therapeutic range t

1 t

2 time from administration longer period of dose efficacy = toxicity risk

1

3.051

J / 20 .340

J drug concen. toxic level

Controlled drug delivery

Therapeutic range time from administration

Types of Devices

1. Diffusion Controlled Delivery Devices

•

Monolithic Devices

•

Membrane Controlled Devices

•

Osmotic Pressure Devices

•

Swelling-Controlled Devices

2. Chemically Controlled Approaches

•

Matrix Erosion

•

Combined Erosion/Diffusion

•

Drug Covalently Attached to Polymer

•

Desorption of Adsorbed Drug

3. Electronic/Externally Controlled Devices

2

3.051

J / 20 .340

J

1. Diffusion Controlled Devices a) Monolithic Devices

Drug is released by diffusion out of a polymer matrix

Release rate depends on initial drug concentration i) Case of C

0

< C s

(drug concentration C

0

is below solubility limit in matrix C s

)

⇒

Diffusion through matrix limits the release rate

3 t

0

How can we control release rate? t

1

Rate control by choice of matrix : glassy matrix: D~10

-10

-10 rubbery matrix: D ~ 10

-6

-12

cm

2

-10

-7

cm

/s

2

/s t

2

3.051

J / 20 .340

J

Quantifying drug release

Governed by Fick’s Laws.

For 1D: The drug flux J is: J

= −

D dC dx

The change in drug concentration with time is:

∂

∂

C t

=

D

∂

∂

2 x

C

2

We want to calculate:

• dM t

•

M t

/dt = release rate

= amount released after time t

⇒

Solve Fick’s 2 nd

law with initial & boundary conditions.

Example: For a 1D slab loaded at an initial concentration of C

0

, with drug concentration in solution resulting in constant surface concentration of C i

.

δ

I.C.: C ( x ,0) = C

0

B.C. 1:

∂

C

∂ x x

=

0, t

=

0

B.C. 2: C(

δ

/2,t ) = C i

C

0

Solve for C(x,t) dM

Adt t

= −

D

( , ) dx x

= δ

/ 2

M t

A = cross-sectional area

C i

0

4

3.051

J / 20 .340

J

The amount of drug released is given by the series solution:

M t

M

∞

∞

∑

n

=

0

8

(

2 n

+

1

)

2 π

2 exp

⎡ −

⎣

D

(

2 n

δ

2

+

1

)

2 π

2 t

⎤

⎥

⎥ where: M ∞ = amount of drug released at long times

(e.g., total amt of drug: M ∞ = C

0

A

δ

= slab thickness

δ

)

M t

/M ∞

1

0.5

0

Release rate (from derivative) : dM t dt

=

2 M

∞

⎡

D

⎣ πδ

2 t

⎤ 1/ 2

⎦⎥ dM t dt

=

8 DM

∞

δ

2 exp

⎡ −

⎣

π

2

Dt

⎤

δ

2

⎥ time short times: ~ t

-1/2 long times: exponential decay

5

3.051

J / 20 .340

J dM t

/dt release rate

~ t

-1/2

NOTE: dM t

/dt and M t depend on geometry. See handout from

Encyclopedia of Controlled

Drug Delivery

~ exp(t )

0 time ii) Case of C

0

> C s

(drug concentration above solubility limit in matrix)

⇒

Drug dissolution in polymer matrix limits release rate

Higuchi model: assumes C i

= 0

M t

=

A DC s

(

2 C

0

−

C s

) t

⎤⎦ 1/ 2 dM t

=

A dt 2

⎣ DC s

(

2 C

0

−

C s

)

⎦⎤

1/ 2 t

−

1/ 2 drug conc.=

C s in matrix where A = surface area of the slab drug-rich

2nd phase

6

3.051

J / 20 .340

J

For C s

<< C

0

: dM dt t

=

A

⎡

2 DC C s 0

2 ⎣⎢

⎤ 1/ 2 t

⎥

How can we control release rate? b) Membrane Controlled Devices

Drug release is controlled by a semi-permeable membrane

⇒

Diffusion through membrane limits the release rate

Advantage: A constant flux device!

7

Semi-permeable membrane

Neat or concentrated therapeutic agent

Release rate thru membrane described by Fick’s 1 st

law.

For 1D:

J

= dM

Adt t

= −

D dC dx

Typical flux units: g/cm

2 s

3.051

J / 20 .340

J i) Nonporous semi-permeable membranes

⇒

Drug diffusion through swollen polymer membrane

Conc. inside membrane = C

2 dM t dt

=

DKA

δ

(

C

2

−

C

1

)

M t

=

DKA

δ

(

C

2

−

C

1

) t

K = membrane “partition” coefficient (unitless metric of drug solubility in membrane)

Which D is referred to?

Conc. outside membrane = C

1

δ dM t

/dt

Early release rate independent of time

8

0

Is this release profile advantageous? time

3.051

J / 20 .340

J ii) Porous semi-permeable membranes

⇒

Drug diffusion through membrane pores

Requires replacing D by D eff

:

D

= eff

D pore

ε

τ

ε = porosity 0 <

ε < 1

τ = tortuosity

τ ≥

1

9

Cross-section of porous semi-permeable membrane c) Osmotic Pressure Devices

Osmotic pressure build-up from water in-flux across semi-permeable membrane forces drug release through orifice piston

δ delivery orifice semi-permeable membrane osmotic “engine”

(NaCl) http://www.alza.com/alza/duros drug reservoir

Ex: DUROS Implant (ALZA)

•

Ti housing, 4mm

×

45 mm

•

~ 1 year duration

• in use for prostate cancer therapy

3.051

J / 20 .340

J

Release rate proportional to change in volume of drug reservoir: dM t

= dV dt dt

C

=

Ak

∆

δ

π

C

A = membrane area

∆π

= osmotic pressure differential

C = drug concentration in reservoir k = membrane permeability coefficient (~10

-6

-10

-7 g/cm/s) dM t

/dt zero-order release kinetics

10

0 time

Controlled Release via Solute Choice for Osmotic Engine (

∆π

)

Solute body tissue

Osmotic Pressure

(atm)

7

NaCl 356

KCl 245 sucrose 150 dextrose 82 potassium sulfate 39

3.051

J / 20 .340

J d) Swelling Controlled Devices

¾

Drug dispersed in a glassy, hydrophilic matrix

¾

Swelling in aqueous medium allows drug release glassy polymer matrix with dispersed drug

H

2

O swelling provides mobility for drug release

11

Complex release kinetics: modeled by fitting experimental data to power law expression.

M t

=

' n

M

∞ ln( M t

/M ∞ ) n = 1 ln( k’ ) ln( t )

3.051

J / 20 .340

J

2. Chemically Controlled Approaches a) Eroding Monolithic Device

Drug is incorporated into a bioerodible or dissolvable polymer matrix

12 t

0 t

1 t

2 i) Surface Erosion Devices dM t dt

= k A e e release rate = strong function of device geometry

A e

= instant surface area k e

= rxn or dissolution rate const.

For a slab:

A e

≈

2 M

∞

C

0

δ

≈ const dM t

=

2 dt k M e

∞

C

0

δ

⇒

zero-order release kinetics

δ

3.051

J / 20 .340

J dM t

/dt

0

For other geometries, A e is a function of time: dM t

= k A ( ) e e dt

For various geometries, the solution to this expression is: time

M t

M

∞

⎡

⎢

1 1

⎢

⎣

C

0

δ

2

⎥

⎦

⎥

⎥

⎤ n

Geometry

δ n cylinder diameter 2

13

3.051

J / 20 .340

J

Matrix Examples:

• polyanhydrides

poly(sebacic acid anyhydride)

O O

(-(CH

2

)

8

C -O- -)

N

• poly ortho esters DETOSU

14 ii) Bulk Erosion Devices

¾ uniform hydrolysis of bulk matrix polymer

¾ hydrolysis rate vs. drug diffusion controls release rate dM t ~ t n dt

Matrix Example: poly(lactide-co-glycolide)

⇒

n = -1/2 drug diffusion limited

O O

(-O-CH(CH

3

)-C -) x

r -(-O-CH

2

-C-) y

lactic acid glycolic acid

3.051

J / 20 .340

J iii) Pulsed release systems

Mixture of eroding particles with different degradation rates

Degradation Profile for Single Eroding Component (schematic)

% degrad.

100

50

0 drug concen. in vivo time in vivo

15 time from administration

3.051

J / 20 .340

J

Degradation Profile for Mixture of Components (ex., microspheres)

% degrad.

100

50

0 drug concen. in vivo time in vivo

16 time from administration

Applications Example: “one shot” vaccines with multiple antigens

TT tetanus toxoid

DT diptheria toxoid

HBSA hepatitis B surface antigen

SEB staphylococcal enterotoxoid B

Vaccines stimulate Ab production

⇒

How can we achieve different degradation rates?

3.051

J / 20 .340

J

Factors influencing degradation:

•

Composition (e.g., PLGA copolymer LA:GA ratio)

•

Geometry iv) Regulated systems

Incorporate a component that responds to the in vivo environment

•

Enzyme that catalyzes degradation in presence of a substrate

Example: GOD-regulated insulin release

Glucose + O

2

+ H

2

O

→

Gluconic acid + H

2

O

2

GOD pH drop promotes acid hydrolysis or swelling of matrix

17

3.051

J / 20 .340

J b) Polymer-Drug Conjugates

18

Therapeutic agent is covalently or ionically bound to a polymer through a cleavable bond

Purposes:

¾ increase resistance to proteolysis (protein drugs)

¾ reduce antigenicity/immunogenicity

¾ prolong plasma circulation lifetime

¾ enhance water solubility of hydrophobic agents

¾ reduce toxicity

Example 1: Therapeutic proteins tethered to polyethylene glycol (PEG) protein

⇒

Increases intravascular lifetime—why?

PEG

Some clinical systems:

•

PEG-adenosine deaminase (FDA appr. immunodeficiency therapy)

•

PEG-asparaginase (FDA appr. for lymphoblastic leukemia)

•

PEG-hemoglobin

•

PEG-interluekin 2

•

PEG-alpha interferon

•

PEG-colony stimulating factor

3.051

J / 20 .340

J

Example 2: Chemotherapeutic agent attached to water-soluble or hydrolysable backbone

19 vinyl benzyl fluorouracil

(CH CH

2

-) n maleic anhydride

(CH CH-) m

O=C C=O

O

C=O

N O hydrolysis

F

O

N

H

(CH CH

2

-) n

(CH CH-) m

O=C C=O

+

C=O

OH

OH OH

H

N O

F

O

N

H

5-fluorouracil

3.051

J / 20 .340

J

Example 3: Dendrimer Drug Conjugates (early development)

Dendrimers – sequentially synthesized, hyperbranched macromolecules

20

1 st

generation

2 nd

generation 3 rd

generation

Two strategies for controlled drug delivery drug-conjugated chain ends

Drug-filled core

(diffusion-controlled)

References

Encyclopedia of controlled drug delivery vol. 1, E. Mathiowitz, ed., John Wiley & Sons, NY, 1999.

Encyclopedia of controlled drug delivery vol. 2, E. Mathiowitz, ed., John Wiley & Sons, NY, 1999.

Biomaterials Science: An introduction to materials in medicine, B.D. Ratner et al., eds., Academic

Press, NY 1996.