3.044 MATERIALS PROCESSING Pilkington Sheet Glass Process Answer: Liquid Metal

advertisement

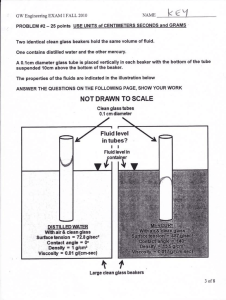

3.044 MATERIALS PROCESSING LECTURE 15 Pilkington Sheet Glass Process Pour molten glass on a liquid, let it settle/flatten and then let it cool · higher ρ than glass → ρglass = 2500 mkg3 · liquid temperature → between Trigid ∼ 550◦ C and Tworking ∼ 900◦ C · immiscible Answer: Liquid Metal Sn (tin) → ρSn = 7000 mkg3 The velocity of the sheet is determined by economic input: ⇒ need 750 tonnes/day to compete with block casting and grinding Vsheet = 10 Date: April 9th, 2012. m min 1 2 LECTURE 15 Two Physical Goals 1) Fluid Flow → flat, stable film, level glass 2) Heat Transfer → cool to 550◦ C from 900◦ C Fluid Flow: kg m3 2 = 10 Pa · s kg = 7000 3 m = 3 × 10− 3 Pa · s ρglass = 2500 μglass ρSn μSn 3.044 MATERIALS PROCESSING 3 How long does it take to remove the transient? How long does it take to get to steady-state? In Diffusion: τ = dimensionless time αt =1 L2 kinematic viscosity ν t τ= 2 L 2 L tss = μ ρ For glass: L = 0.007 m, μ = 102 Pa · s, ρ = 2500 ⇒ tss = 0.0001 s kg m3 For tin: μ = 3 × 10− 3 Pa · s, m ⇒ tss = 114 s, Vsheet = 10 min L = 0.007 m, Length of travel to achieve steady state: ≈ 20 m ρ = 7000 kg m3 4 LECTURE 15 Heat Transfer: W m2 K W Glass: k = 1.7 , mK hL Bi: = 0.04 k Vapor/glass interface: h = 10 L = 0.007 m Bi is Low! conduction is rapid in glass and convection is slow Tin: k = 35 W mK Compare the resistances of glass and Sn: resistance of Sn is low → Sn is a great heat sink How long does it take to cool? 3.044 MATERIALS PROCESSING τ =1 t ≈ 15 − 30 sec Summary of Fluid Flow ∂v̄ F¯ ∇P = ν ∇2 v̄ + − ρ ∂t ρ 2 ∂vx ∂ vx Fx 1 ∂P =ν 2 + − ρ ∂x ∂t ∂y ρ Navier-Stokes Equation: solve this with boundary conditions → laminar flow Fluids can transfer momentum to solids 5 6 LECTURE 15 Fluid Flow in a Pipe: Pipe: Vx = At the wall: τyx ΔP 2 R − r2 4Lμ ∂Vz = −μ ∂r r=R Stress on the Inner Pipe Wall: τ0 = μΔP ΔP · R 2R = 4Lμ 2L Kinetic Force: (drag force, total force exerted by the fluid on the solid) Fk = τ dA A ΔP R = 2πRL 2L Fk = ΔP πR2 MIT OpenCourseWare http://ocw.mit.edu 3.044 Materials Processing Spring 2013 For information about citing these materials or our Terms of Use, visit: http://ocw.mit.edu/terms.