Document 13507716

advertisement

Diffusion of chloride-36 and carbon-14 in a backfill barrier composed of 75% basalt and 25% bentonite

by Craig G Rieger

A thesis submitted in partial fulfillment of requirements for the degree of Master of Science in

Chemical Engineering

Montana State University

© Copyright by Craig G Rieger (1985)

Abstract:

Effective diffusion coefficients were measured for chloride-36 at ambient temperature (~20°C), 60°C,

and 90°C in a water-saturated 75%/25% basalt-bentonite mixture. Three separate tests for each of the

given temperatures were run at two bulk3densities of the medium, i.e. , 1.6g/cm3 +•lg/cin and

1.8g/cnr+ . lg/cnr. The same tests were run for carbon-14, but the data could not be analyzed to find

diffusion coefficients.

The diffusion of chloride was found to increase with increasing temperature.

Increasing the bulk density of the diffusion medium inhibited the movement of chloride and reduced

the diffusion coefficient.

A one-dimensional model that was solved using the assumption of linear sorption of the tracer

described the diffusion of chloride well.

The effective diffusion coefficient of chloride is larger for experimental systems in which the tracer is

initially present in the diffusive medium compared with when it is initially present in a solution

adjacent to the medium.

The diffusion coefficients of carbon-14 were not measurable because it formed a precipitate or sorbing

complex with calcium and/or magnesium.

DIFFUSION OF CHLORIDE-36 AND CARBON-14 IN A

BACKFILL BARRIER COMPOSED OF 75% BASALT AND

25% BENTONITE

by

Craig G Rieger

A thesis submitted in partial fulfillment of

requirements for the degree

of

Master of Science

in

Chemical Engineering

MONTANA STATE UNIVERSITY

Bozeman, Montana

June 1985

N37?

Ii

APPROVAL

of a thesis submitted by

Craig Garland Rieger

This thesis has been read by each member of the thesis

committee (ex. John F. Relyea) and has been found to be

satisfactory regarding content,

English usage, format,

citation, biographical style, and consistancy, and is ready

for submission to the College of Graduate Studies.

6/o,/<sr S

v

Chairperson, Graduate Committee

Date

Approved for the Major Department

Datfe

Approved for the College of Graduate Studies

£ - /<?-*j~

~

Date

Graduate Dean

ill

STATEMENT OF PERMISSION TO USE

In presenting this

the requirements . for

thesis

a

in

master's

partial fulfillment of

degree

at Montana State

University, I agree that the Library shall make it available

to borrowers under

from this thesis

rules

are

of

the Library. Brief quotations

allowable without special permission,

provided that accurate acknowledgement of source is made.

Permission

for

extensive

quotation

from

or

reproduction of thesis may be granted by my major professor,

or in his absence,

by

the

Director

opinion of either, the proposed

use

scholarly purposes. Any copying

or

this thesis for financial gain

my written permission.

Signature

Date

A?

of Libraries when, in

of the material is for

use

of the material in

shall not be allowed without

iv

1

ACKNOWLEDGEMENTS

The author would like

of the

Chemical

to

Engineering

University for their help

thank the faculty and staff

Department

and

and John F. Relyea

at

Montana State

support during his six years

of attendance. The insights given

Dr. Douglas Smith presently at

at

by my two major advisors.

the University of New Mexico

Rockwell

Hanford Operations is much

appreciated.

Special thanks

goes

out

Donna Rieger for their

continual

attending school,

finally

and

whose concern and help for

on

in

the

university.

chemical

to

my

parents, Darwin and

encouragement while I was

to

Professor

H. A. Saner,

me and others motivated me early

engineering

curriculum

at

this

V

TABLE OF CONTENTS

Page

1.

LIST OF TABLES...................................

2.

LIST OF FIGURES.........

3.

ABSTRACT.....

x

4.

INTRODUCTION........ '............................

I

5.

6.

EXPERIMENTAL. .. .....................

12

13

15

16

...........

Materials............................,

Experimental Procedure..............

16

18

MATHEMATICAL MODELLING AND STATISTICAL ANALYSIS...

28

Procedure................................

7.

viii

^ in ao

The Backfill...

Related Work..’.

Clay Minerology

Chloride-36.......

Carbon-14......

Research Objective...............................

vii

RESULTS AND DISCUSSION.......... ................

Diffusion of Chloride-36:

Temperature Effects..........................

Bulk Density Effects...........................

Correlation of Data to Theoretical Model.......

Multiple Linear Regression of Data..............

Comparison of Results With OtherInvestigations.

Diffusion of Carbon-14........ ..............

Difficulties With Carbon-14.....................

31

34

34

36

38

43

44

47

51

8.

SUMMARY.....................

54

9.

RECOMMENDATIONS FOR FUTURE RESEARCH..............

56

vi

TABLE OF CONTENTS— Continued

Page

10. REFERENCES CITED.................................

58

APPENDICES.......... ................................

64

Appendix A-Computer Programs........

Appendix B-Raw Data For Tests Displayed In

Figures.............................

Appendix C-Specified Concentration of Ions

in SyntheticGroundwater..... ........

Appendix D-Nomenclature.........................

65

76

Ill

113

vi I

LIST OF TABLES

1.

2.

Relative Amounts of Sized Basalt Used...... .

16

Chloride-36 Diffusion Coefficients and Error

Terms...... .....................................

39

3* Coefficients of Correlation (r ) and Determination

(r ), and Percent Error in Slope................

40

4. Diffusion Coefficients For Tritium..............

45

5. Effective Diffusion Coefficients For Chloride;... ' 45

6 . Solubilities and Ion Amount Present in Synthetic

Groundwater............ :......... ...............

47

7. Fortran Program To Calculate Least-Squares Best

Fit For a Set of Data Points....................

66

8 . Fortran Program To Determine The Effect of Data

Errors on The Effective Diffusion Coefficient___

70

9. Program To Calculate a Multiple Linear Regression

75

Coefficients, Basic..................... ........

10. Specified Concentration of Ions in Synthetic

Groundwater

112

viii

LIST OF FIGURES

:

1.

2.

Engineered Barriers...................

^2^^

A Proposed Structure For Montmorillonite,

(Edelman and Fave jee)

....................

9

3. A Second Proposed Structure For Montmorillonite,

(Hofmann, et al.).................................

10

4. Diffusion Cell Parts..............................

20

5. Extruder..............................

6 . Core Slicer................................. . ...

26

7. Temperature Dependence of Chloride Diffusion...

35

8 . Dependence on Bulk Density of Chloride

Diffusion.............................

9. Diffusion Test, Carbon-14 (D-C14-020-002)........

48

10. Diffusion Test, Carbon-14 (D-C14-020-011)........

50

11. Diffusion Test, Carbon-14 (D-C14-060-004)........

52

12. Diffusion Test, Carbon-14 (D-C14-060-016)........

53

13. Chloride-36 Diffusion Tests D-C136-020-002...... , 78

14. Chloride-36 Diffusion Test: D-C136-020-003........

79

15. Chloride-36 Diffusion Test; D-C136-060-004........

80

16. Chloride-36 Diffusion Test: D-C136-060-005........

81

17. Chloride-36 Diffusion Test: D-C136-060-006........

82

18. Chloride-36 Diffusion Test: D-C136-090-007........

83

19. Chloride-36 Diffusion Test: D-C136-090-008........

84

20. Chloride-36 Diffusion Test: D-C136-090-009........

85

21. Chloride-36 Diffusion Test: D-C136-020-010........

86

22. Chloride-36 Diffusion Test: D-C136-060-011........

87

23. Chloride-36 Diffusion Test: D-C136-020-013........

88

24. Chloride-36 Diffusion Test: D-C136-090-015........

89

25. Chloride-36 Diffusion Test: D-C136-020-016........

90

26. Chloride-36 Diffusion Test: D-C136-060-017........

91

27. Chloride-36 Diffusion Test: D-C136-090-018........

92

28. Chloride-36 Diffusion Test: D-C136-020-019........

93

29. Chloride-36 Diffusion Test: D-C136-020-020........

94

30. Chloride-36 Diffusion Test: D-C136-090-021........

95

31. Chloride-36 Diffusion Test: D-C136-060-022........

96

32. Carbon-14 Diffusion Test: D-C14-020-002...........

97

33. Carbon-14 Diffusion Test: D-C14-060-003.........

98

34. Carbon-14 Diffusion Test: D-C14-060-004...........

99

35. Carbon-14 Diffusion Test: D-C14-090-005...........

100

36. Carbon-14 Diffusion Test: D-C14-090-006..........

101

37. Carbon-14 Diffusion Test: D-C14-020-007...........

102

38. Carbon-14 Diffusion Test: D-C14-020-008...........

103

39. Carbon-14 Diffusion Test: D-C14-060-009...........

104

2

3

ix

LIST OF FIGURES— Continued

40.

41.

42.

43.

44.

45.

Carbon-14

Carbon-14

Carbon-14

Carbon-14

Carbon-14

Carbon-14

Diffusion

Diffusion

Diffusion

Diffusion

Diffusion

Diffusion

Test: D-C14-020-011.........

Test: D-C14-090-012.........

Test:D-C14-020-014.........

Test:: D-C14-060-016.........

Test: D-C14-020-020.........

Test: D-C14-020-021.........

Page

105

106

107

108

109

HO

X

ABSTRACT

Effective diffusion coefficients were measured for

chloride-36 at ambient temperature (~20°C), 60°C, and 90°C

in a water-saturated 75%/25% basalt-bentonite mixture. Three

separate tests for each of the given temperatures^were run

at two bulkgdensities of the medium, i.e. , 1.6g/cin +.Ig/cm3

and I .Sg/cm +.lg/cm . The same tests were run for carbon-14,

but the data could not be analyzed to find diffusion

coefficients.

The diffusion of chloride was found to increase with

increasing temperature.

Increasing the bulk density of the diffusion medium

inhibited the movement of chloride and reduced the diffusion

coefficient.

A one-dimensional model that was solved using the

assumption of linear

sorption of the tracer described the

diffusion of chloride well.

The effective diffusion coefficient of chloride is

larger for experimental systems in which the tracer is

initially present in the diffusive medium compared with when

it is initially present in a solution adjacent to the

medium.

The diffusion coefficients of carbon-I4 were not

measurable because it formed a precipitate or sorbing

complex with calcium and/or magnesium.

I

INTRODUCTION

In

1951,

electricity

nuclear fuel in the United

was

first

generated

using

States (I). Since then, nuclear

power has become an important alternate source of energy in

this

country.

Consequently,

the

safe

disposal

of

radioactive waste produced from atomic reactors and defense

work is an important national

problem (2). One of the most

attractive disposal alternatives

in deep,

stable

geologic

basalt (2). Basalt and

diagramed in Figure

I

(3).

is

barrier

specific waste

respect

to

form

the

salt, tuff,

ash and is consequently more

engineered

barriers will be used

of radionuclides into the biosphere

from these repositories

Each

i.e.,

are both volcanic formations,

the latter being derived from

to impede the movement

to deposit the wastes

formations,

tuff

porous. Both natural and

is

(3).

for

This

engineered

designed

chosen

geologic

generalized concept is

to

in

be

barriers in basalt

accordance

buried

environment

with the

and also with

that

controls the

stability of the repository (3).

In this investigation

the

medium

continuous

the

backfill barrier will be

of

interest.

The

backfill

layer

that

surrounds

the

barrier

waste

is

a

container,

filling all the void between the overpack and the host rock

Figure I. Emglneered Barriers

PLACEMENT ROOM FLOOR

WASTE FORM

BASALT

DISTURBED

ZONE

CANISTER

OVERPACK

BACKFILL

UNDISTURBED

BASALT

f

REPOSITORY

3

(4). To be an effective

have the capacity to

waste

material

sorb radionuclides diffusing from the

(4).

material should have

conductivity

for

of

Just

a

this

way,

radionuclide

etc.

composed of 75%

crushed

clay. This mixture is

important,

transfer,

canister leaks,

repositories

as

the

backfill

low permeability, adequate thermal

heat

fracture (4). In

inhibitor

backfill barrier, a substance must

In

proposed

the

this

work

and

candidate

for

be

backfill

migration

basalt

a

and

the

in

the

resistant

to

can

act as an

the

event

of

barrier will be

25% sodium bentonite

for

use in the basalt

Hanford

nuclear

waste

disposal area (5).

Certain standards of repository performance have been

set by the

Environmental

Nuclear Regulatory

must be shown to

Protection

Commission

satisfy

the

first

effective

steps

a

performance

in

diffusion

of

experimental

The repository

this

study must be undertaken to

of

study

coefficients

radionuclides through the proposed

range

(6 ).

these requirements before it can

be licensed (6 ). Therefore,

obtain data on the

(NRC)

Agency (EPA) and the

conditions

the repository. One of

i s . the

for

measurement of

the

various

backfill barrier (5). A

which

effect reaction

conditions and chemical transport properties in the area of

the repository must be included

in

the study (6 ). In this

4

work, temperature and bulk density

main variables,

have on the

will be

because

diffusion

chlbride-36

of

of

and

form,

behavior in the

the backfill are

the

radionuclides. The tracers

may

(7,8).

an

significant effects they

Although

each

clay

the

carbon-14,

water-saturated backfill.

used in anion

have been chosen as the

diffusing

through a

both radionuclides are

exhibit different types of

Therefore, the properties of

important

factor

in how the tracers

used

in the testing was

diffuse.

THE BACKFILL

The starting raw

bentonite

mainly a sodium bentonite

remaining

portions

clay,

included

as mentioned earlier. The

components

such

as quartz,

feldspars, and smaller amounts of other impurities (5).

Basalt is

prevalent

in

a

low-permeable,

the

geologic

repositories on the

the same order of

magmatic

formations

Hanford

of

rock

the

that is

proposed

Its permeability is on

-9

-15

magnitude as bentonite, i.e., 10 -10

m/s (9,10). This material

area.

will

be

used in the barrier in

the form of small, granular

particles (less than 16 mesh),

facilitating compaction of

the mixture. Therefore, because

of the

small

size

and

particles in the backfill,

low

it

permeability

is

not

of

the basalt

considered to be a

5

medium through which

diffusion

as a continuous medium for

volume throughout the

occurs. The bentonite acts

diffusion, and reduces the pore

compacted

by adsorbing water and

backfill(6). It does this

swelling

to

fill the voids in the

crushed basalt(7).

RELATED WORK

Several

factors,

also influence

the

porous solid.

the

diffusion

Temperature

varied in this

affects

besides

work.

A

diffusion

states that diffusion

those

of

is

radionuclides through a

one

general

such

factor

that was

trend of how temperature

coefficient

increases

already mentioned,

is

with

known. Relyea(Il)

temperature, due to

the increase in the kinetic energy of the particles.

Eriksen et al. have run diffusion tests on bentonite,

using

chloride-36

and

iodide-131

as

tracers,

in

both

breakthrough and concentration profile tests (12). In these

experiments two

temperatures

air-dry bentonite was

were

compacted

used

before

(25oC,70°C), and

water uptake (and

saturation) occurred. They found considerable resistance to

the diffusion of

caused by

chloride-36

interactions

smaller interparticle

with

and

inhibit the diffusion of

and

iodide-131, most likely

the

clay-water

intralamellar

water

voids

system. The

seemed to

through the bentonite. The

6

larger intralamellar and interparticle voids were therefore

assumed to be the main passages of the anions.

In Kissel's

et

movement through

found that

the

al.

(13)

Houston

Black

larger

important pathways

investigation of chloride

swelling

(connected)

for

Cl

soil

movement.

clay,

they too

pores are often

Even though Cl can

move quickly through these pores, there was some resistance

to

the

Cl-

movement

due

to

interactions

structure and the negative

charge

of anions in

may

this

system

of

the clay

of the anions. Movement

also

be different than in

compacted clays, where there will be reductions in the size

and differences in the shape

of

Therefore, the interactions

and the clay/water

system

the voids and

between the radioactive anions

may

be different for compacted

and uncompacted clay. For

example,

Kissel et al. (13)

that

clay seemed

to

found

have

been

a

mobility of

the

reduces the

cross-sectional

and by doing this creates

Lai

factor

area

in anion diffusion.

were found to reduce the

Compaction

a

et al. (15), like

the negative charge of the

Repulsive forces that are created

anion.

pores(14).

of

the

clay further

available for diffusion

larger repulsive force of the

clay on the anion.

Dutt and Low(IG) postulated

repulsed by the negative

clay

that not only are anions

layers,

but they also have

7

difficulty entering

Eriksen

et

al.

concentration

the

(12)

of

clay

from

used

the

a

tracer

adjacent to the clay. .The

an adjacent solution.

test

was

where

present

the

in

initial

the fluid

radionuclide would then diffuse

into the clay as well as through it. Comparing with Hamid's

(17) results, Eriksen

et

al.'s

coefficient of iodide were

smaller. In Hamid's

work

coefficient within

clay

values

for the diffusion

one

to two orders of magnitude

(17),-

he measured the diffusion

soil

for

iodide. Therefore, the

postulate of Dutt and Low must have some validity.

In Dutt and Low's

diffusion of

alkali

(16)

work

chlorides

(DgO). They found very

they also compared the

with

little

that

of heavy water

difference between the size

of the values except that the diffusion coefficient for the

heavy water

interactions

was

larger.

of

the

This

clay

is

with

because the electrical

the

ions

reduced

the

mobilities of the ions (16).

The retention

of

studied by B. Allard et

iodine

was

found

especially in the

found iodide to

to

iodine

al.

be

sorbed

various substances was

(19). A significant amount of

be

presence

in

sorbed

of

onto

by

chloride.

montmorillonite,

Hamid (17) also

clay soil. Consequently,

Hamid (17) found the diffusion coefficient for I-ions to be

lower

than

that

for

Cl-ions.

This

implies

that

Cl ,

8

although also an anion,'is

clay

than

I .

Because

properties of the ions

ion

is

less

much

likely

they

are

should

larger

to be sorbed by a

both

halogens,

the

be similar (19). The iodide

though,

and

the

electrostatic

interactions of the clay layers with the ion may be greater

and

consequently

a

difference

in

sorption

properties

results.

Other studies have been

radionuclides

in

radionuclides,

compacted

which

conditions are sorbed

bentonite

exist

by

processes. Movement of

through the

performed on the movement of

as

the

the

interlamellar

(12,15,20).

cations

Many

under repository

clay due to cation-exchange

cations

as

well

can

as

be assumed to be

the intralamellar

space, unlike anions (12).

CLAY MINEROLOGY

Two idealized lattice structures for montmorillonite,

the major

component

Figures 2 and 3

neutral,

of

(8).

although

of

These

This

the

charge

clay

atoms

(7).

is

is

platelet

isomorphous substitution of the

Cr, Zn and other

rock

are

depicted in

structures depict the clay as

montmorillonite

negative charge (7).

composition

bentonite

known

have

a

created because the

can

trivalent

That

to

vary

due

to

Al with Mg, Fe,

is, aluminum, with its

9

Figure 2. A Proposed Structure For

Montmorillonite

a on

a OM

T he Proposed Structures

M o n t m o r il l o m t e ( idealised )

for

10

Figure 3. A Second.Proposed Structure For

MontmoriIIonite

± 14&

!si

40+20H

4 AL

4 0 + 2 OH

4 Si

V

60

'T

he

P roposed Strvctvres

for

M o n tm o r illo n it e ( idealised )

11

higher positive valence is replaced

valence. The

tetravalent

Si

by elements of a lower

itself

will occasionally be

replaced by Al in the structure (7).

The layer structures are

with van der

waals

these layers

and

containing

clay

forces

form

(7).

add

the

pressure

more

water(7).

If

up

is

that

the

water

which

the size

used

the

tracers

(7).

the oxygen-

The

resulting

to four monomolecular

is

put on the clay,

layers can cause the uptake

separate by more than lo1£,

of

with

layers of clay (7). Depending

repulsion of like-charged clay

of

bonds

surfaces

can

layers of water between

on how little the

The water will penetrate

hydrogen

platelet

interlamelIar swelling

weakly bonded to each other

causes

the

plates to

is more than three times

in

this investigation, a

second stage of swelling occurs

(7). This type of swelling

will cause the

to

bentonite

clay

expand

to much larger

volumes and disperse into a finely divided suspension (7).

Because

the

crystal

layers

carry

a

net negative

charge, this charge is

compensated for by cations adhering

to the surface of

layers

the

these cations will tend

to

(7). When water is present,

diffuse

due to a lower concentration

away from the surface

in the bulk solution (7). The

resulting double layer thickness then contains cations that

are readily exchangeable

(7).

Diffusing cations therefore

12

may have movement hindered due to sorption on the clay (7).

Anions , on the other hand, will be repelled by the negative

clay

layers

and

remain

in

the

bulk

water

of' the

intralamellar space (7).

The double layer can be

of

electrolyte

concentration

present

can

varied in size by the amount

(21).

cause

In

swelling

this

of

way, electrolyte

the

clay

and

a

reduction of its porosity (21). Consequently, the resulting

double layer will be decreased

become

more

clogged

with

(7,21). For

from

monovalent

3

0.01-10Ommol/dm ,

in width and the pores will

increasing

ion

concentration

counter-ion concentrations varying

the

thickness varies from 1000

approximate

down

to

double

layer

10A (7). For divalent

counter-ions in the same concentration range, the thickness

varies from 500-5^ (7). The pH of the clay solution is also

known to affect the

where

aluminum

double

ions

are

layer, especially at the edges

exposed

tendency to become positive at

the clay an ability

to

sorb

low

(7).

The

edge

has a

pH (7). This will give

anions, albeit small amounts

compared to the net negative charge of the clay (7,22).

CHLORIDE-36

Radiotracers have found

study of water movement through

increasing importance in the

porous media (23). In this

13

investigation, chloride-36 has been

water

diffusion

chosen due

to

through

the

the

with

as a tracer of

backfill. This

tendency

through the pore water

chosen

of

the

tracer was

chloride to diffuse

little chance of being sorbed

onto the clay (24).

There are some

differences

between

the movement of

water and chloride through a clay because of the influences

of the negative potential in the pore volume (7). Rolfe and

Aylmore (25) reported that diffusion can at least partially

compensate

for

noticeable at

these

higher

differences,

flow

rates

suggests that chloride movement

that of water at

which

through

in

the

would

be more

the clay. This

clay is much like

low pressures. Therefore, the chloride-36

tracer should describe the

transport

of water through the

bentonite with some accuracy. Tritium, in the form of heavy

water,

should

even

transport in the clay,

Cl

be

better

but

at

describing

the water

the differences between it and

should also be small(16).

CARBON-14

Carbon-14 (half-life:5730yrs.)

is a potential

long-term

biological

form of carbonate, which is

the

in

radioactive waste

hazard

(26). In the

tracer used in this work,

it can react with Ca++ or Mg++ in the groundwater to form a

14

weak complex or precipitate (27). Consequently, sorption of

the complex or precipitate on the bentonite can occur (26).

The formation of

precipitates

the

magnesium

depend

concentrations of

on

the

the

species as well, such

as

calcium complexes and

temperature,

ionic

(26,28). Carbon-14 may react

or

species

with

in

pH,

Eh,

and

the groundwater

hydrogen and form other

carbonic acid and HCOg ion (26).

There is also a chance that the carbonic acid will react to

form CO2 and water, depending on where the equilibrium lies

(28).

Allard et al.

(26)

carbon-14 sorption using

investigated

the possibility of

various geologic media, including

sodium montmorillonite and

also a bentonite/quartz (10/90)

mix. Using several contact

times (3days-6mos.), they found

that while there was no sorption on sodium montmorillonite,

there was some on

the bentonite/quartz mix. They explained

this by

out

pointing

that

the

calcium, which gave a

higher

in the liquid. It

therefore

is

bentonite used contained

concentration of calcium ion

possible that there is no

carbonate sorption on the bentonite if it is a sodium clay.

However, to determine

the

sorption, the effects of

actual

other

importance of carbonate

variables

established ,e.g., calcium concentration.

will have to be

15

Besides the information

already given, 14C-Carbonate

tracer is expected to have the same anion interactions with

the clay as

chloride-36,

of the larger

negative

possibly more pronounced because

charge

the actual role that the

on the

diffusion

of

different size and shape may have

the

Carbonate is expected

of the carbonate. However,

to

two

radionucides is uncertain.

have

a smaller diffusivity than

chloride because of its larger size (11), i.e., about 2.81%

and 1.81%, respectively

(29,30).

calcium carbonate

can

behavior of

(31),

clay

cause

Also,

it

variations

is known that

in

which

may

affect

this

research

the swelling

its diffusion

properties.

RESEARCH OBJECTIVE

The

objective

effective

diffusion

carbon-14

through

densities,

coefficients

a

mixture. The tests

temperatures,

of

will

i.e.,

i.e.,

compacted

1.6

relationship between

be

20,

and

the

for

to

measure

chloride-36

and

75/25 basalt/Na-bentonite

performed

60,

was

and

90°C,

I.Sg/cm3 .

effective

at three different

From

and

two

the

bulk

data,

a

diffusion coefficient

and the two variables is to be determined. The experimental

results should also develop

a

better understanding of the

mechanism of anion movement through swelling clays.

16

EXPERIMENTAL

MATERIALS

■ •

The basalt used was taken from the Columbia Basin area

in the state of

from

Washington.

outcroppings

near

the

basalt was chosen due to

formations of the

The rock was originally picked

Hanford

area.

This specific

its availability in the underlying

proposed

radioactive waste repository on

the Hanford site. Only those

samples that did not appear to

be weathered, i. e. , yellowed or eroded, had been chosen. The

rock

was

then

crushed

to

smaller

sizes

before

it was

available for use in this investigation.

The rock was

further

crushed

relative amounts of each appropriate

in

a

shadow box. The

mesh size are given in

Table I.

Table I. ^Relative Amounts of Sized Basalt Used

**Mesh

I-16+60 I-60+120|-120+230|-230+325|-325+400|-400|

Amount(g)| 1558 |

Total of

All Mesh=2000g

120

|

174

|

58

|

30

| 60 |

These amounts are relative because 4000g were prepared

and then this amount was split in half with a riffle

splitter

AA- - means that it passes through this mesh size

+ means that it will not pass through this mesh size

a

-

17

A technician determined

grain

mixture

using

to

the

3

2.89g/cm

be

pycnometer. The procedure

of

sample

in

a

vial

density

a

involves

with

of the basalt

air

equilibration

putting a known amount

water

(32).

The

necessary

parameters such as water density are known.

The sodium bentonite used

was

specific location is unknown. The

powdered form

and

contained

such as quartz and feldspars

due to its ability

to

mined in Wyoming. The

bentonite came in a fine

small

amounts of impurities

(5). The bentonite was chosen

swell

and

fill voids in rock, but

also due to its low permeability and retardation properties

(7). The grain density

of

the bentonite was determined to

be 2.69g/cm^ by R.A. Carlson, a fellow worker (33).

A 666.7g portion of bentonite was stirred in with the

basalt mixture to form a

75/25 mix of basalt to bentonite.

The resulting blend

was

split

splitter for mixing

purposes,

four

and

times

then

with a riffle

split into eight

portions, archived, and stored.

To obtain portions

small

enough

tests, the larger containers were

split down

into

procedure, the

8-18g

portion

mixed as before and then

individual

that

for the individual

portions.

During this

was

to

be

thoroughly before each

splitting.

It

was found that this

method would appear to

give

a

split was mixed

more accurate splitting of

18

the material. Once enough

small

portions were made, e.g.,

there were two for,each test, the samples were archived and

stored.

The moisture content

was determined to be

of the basalt/bentonite mixture

1.5%

in

March of 1984. The moisture

content was redetermined in July

be

2.7%.

The

procedure

for

contents was ASTM D2216-80.

of

a

backfill

sample

110°C+5oC. The first

backfill

used

a

determining

the

approximately

heated

moisture

drying

1984 and was found to

moisture

The method involved the drying

for

GCA/Precision Scientific

of

vacuum

content

oven,

as

I

day

in

a

dessicator set at

measurement on the

called

for

in

the

procedure, instead of a heated vacuum dessicator. The other

measurement of the

moisture

content

the dessicator because

it

dry around the

sample.

drying

readings of the test

the core)

safely

were

contain

cores,

possibly

the

kept

the atmosphere thoroughly

For other moisture content

the samples (1-2.Sg slices of

contaminated

radioactivity,

dessicator could conveniently be

oven could not.

of the backfill, used

put

with

the

a tracer. To

heated

vacuum

in a hood whereas an

19

EXPERIMENTAL PROCEDURE

A piece

of

equipment

fabricated by craftsmen

called

for

a

diffusion cell was

thisinvestigation.

The cell

contains two half cells , depicted in Figure 4b. There is a

surrounding cylinder with

total cell as

it

screw

appears

on

caps

the

on the outside. The

outside is pictured in

Figure 4a.

The half cells were

respects for each

cell,

to

be packed similarity in most

i.e .,

backfill composition, bulk

density, except that one half cell contained a tracer while

the other did not.

For diffusion to occur, one of the half

cells containing the

other half

cell

tracer

containing

was

put in contact with the

only

the

saturated backfill

mixture.

Two bulk densities,

I.Sg/cm

3

and I.Sg/cm

3

were used

in this

investigation, although for the carbon-14 tests

3

only l.Sg/cm was used. To produce test cores that were of

the right bulk

density,

groundwater was put with

mixed. The amount of

a

certain

the

water

amount of a synthetic

air-dry backfill samples and

to

be

used

was given by the

following equations (34):

Amount of Air-dried Backfill:

X=(BD)(Vh )(1+W)

Total Porosity of Backfill-water Mixture:

Pt=I-EXlC(F1/PD1)+<F2/PD2 >3/CVh (l+W)D

20

Figure 4.

Diffusion Cell Parts

OUTER CYLINDER

4"

HALF CELLS

HALF CELL WALL

21

Amount of Water To Be Added To Dry Backfill:

Y-w = (P-HPW)

(Vn

k )-(W) (X)

L

X=amount of air-dried backfill Ig)

BD=specified bulk density (g/cmJ)

Vh =Volume of half cell (yvB. 3cm-5)

W=Kioisture content of backfill

Pt=total porosity of the resulting backfill-water mixture

F.=weight fraction of the ith component in the backfill

(75% basalt/25% bentonite)

PDi=grain density of the ith component in the backfill

PW=density of water (Ig/cin )

Y = amount of water (g) needed to be added to air-dry

backfill sample to get specified bulk density

Since two mixtures were

water amount

mixture,

was

i.e.,

prepared

for each test cell, each

measured

separately.

without

the

groundwater was measured out

aside. For the tagged

the measured water amount

40]j1 for the carbon-14

for

tests.

taken from the tagged mixture

tracer,

on

mixture,

a

the

synthetic

20pl spike was added to

the chloride-36 tests and a

Two

20pl samples were then

to be counted for an initial

determination.

Also,

(containing a

phosphor)

added

purposes of counting on

the untagged

a scale (+O.OOlg) and set

concentration

were

For

15ml

to

each

of

instagel

sample for

the Packard (Tri-carb 4000 series)

scintillation machine.

The water samples, tagged and untagged, were added to

the two backfill samples and stirred thoroughly. (Note: The

mixtures were

stirred

again

after

an

hour.) The sample

22

containers containing

humidity

chamber

the

mixtures

(dessicator

filled

equilibration overnight. The teflon

cell

were

put

under

water

saturation of the parts. The

were

with

put

water)

in a

for

parts of the diffusion

overnight

next

then

to

insure

total

day the total weight of

the parts (+0.Olg) was determined.

The half cells were packed starting with the untagged

mixture. First, small amounts

of

into the half

the

cell.

Second,

the mixture were spooned

mixture was packed down

with a stainless steel rod until saturation was reached, or

rather

until

the

continued until the

material

half

glistened.

cell

was

This

process was

filled to about 1/16"

above the top. The packed material was then levelled with a

straight-edged blade. This

procedure

was repeated for the

tagged mixture.

Once both half cells

placed

between

the

together. This unit

half

was

were

packed, a teflon disk was

cells

then

as

they

were

brought

loaded into the surrounding

cylinder. The diffusion cell was then reweighed in order to

determine the amount of

material

packed

in the cell. The

cell was equilibrated after weighing

for as long as deemed

necessary

concentration

to

reach

uniformity

tagged half cell. For chloride-36

of

in the

this period was only one

day because it is a fast moving tracer.

23

After the

time

for

equilibration

teflon disk was

removed

from

allow diffusion

of

tracer.

the

diffusion cell was placed

at one of the

between

had

the

During

passed, the

half cells to

this period, the

in a humidity chamber controlled

three temperatures (ambient~20,60,90°C). For

the 60°C environment a New Brunswick Controlled Environment

Incubator Shaker was used. For

the 90°C environment a Blue

M Stabil-therm oven was used.

The diffusion was allowed to

continue until the tracer went a sufficient amount into the

untagged portion of the diffusion

In order to determine a

cell but not to the end.

correct amount of time, some extra

trials had to be used.

After the diffusion

cell

was

removed

time

from

had expired, the diffusion

the

given

Approximate diffusion times were

as

about five hours for

the

ambient

for the 6O0C

and

3)

tests,

humidity

chamber.

follows: I) They were

tests; 2) about 3 hours

about

2

hours for the 90°C

tests. For the 60°C and 90°C tests the cells were put in an

ice bath for five minutes

be frozen in

liquid

first,

nitrogen

inner clay core was extruded

Figure 5. First, the

the can

pictured

on

for

five minutes (35). The

using the machine depicted in

outer

the

and then the cells would

shell was removed. Then, using

left

(backfill) core was extruded.

of

Figure

5,

the inner

24

Figure 5- Extruder

CORE PUSHER

LIP TO HOLD

CAN OR OUTER

CYLINDER DUREXTRUSION

BAR TO GIVE ARM

SUPPORT DURING

EXTRUSION

'WHERE HALF CELLS WITH

BACKFILL CORE ARE CONTAINED

FOR EXTRUSION

25

The core was sliced

using

the

Starting with the untagged end,

blade

by

the

core

pusher

threaded bolt connected to

0.5cm was pushed under the

and

the

machine in Figure 6„

sliced

off.

(Note: The

core pusher has 10 threads

per cm.) The sample was caught

in a metal can and dried in

the heated

to

vacuum

dessicator

determine

its moisture

content. The procedure used was ASTM D2216-80, as mentioned

before. The

bulk

density

was

then

determined using the

equation (34):

BULK DENSITY=!/C(1/2.84) + MOISTURE CONTENT]

where

BULK DENSITY=Ms/V

and

W

pw

V s=Fi(Ms )/pV F 2 (Ms)/pD2

Mw ZMs=W

M =water mass

Mr=SOlid mass

P^=water density

V =water volume

v =solid volume

V=total volume

W=moisture content

F1=Lasalt fraction

Fi=Lentonite fraction

PD1=Lasalt grain density

PDg=Lentonite grain density

26

Figure 6. Core Slicer

CONTAINER WHERE LIQ.

N2 CAN BE PLACED ~

TO COOL SLICES

CORE PUSHER

27

In this manner, the final

bulk density can be checked with

that originally calculated. The

0.1cm

slices

being

scintillation vials

containing

the

sliced

process was continued with

off

the

core

until

the

core

interface

was

marked.

containing the interface may

vials. This was because

have

of

the

was

and

put into

gone.

The vial

The

been

actual

vial

off by one or two

difficulty in finding the

interface due to the uniformity in appearance of the core.

For scintillation

deionized water

and

counting

IOml

of

of

the

instagel

slices, IOml of

were

added. Upon

shaking of the vials, a suspension of the solid would form.

Chemically quenched

standards

known amount of spike

instagel. Optically

into

to cover the same range

The

vials

scintillating, just as

standards

0.15-0.Sg

especially for the purpose.

prepared

by adding a

three vials containing 15ml of

quenched

range of slices from

testing.

were

were

made from a

from an untagged core made

Only

five standards were used

that was expected with slices from

were

with

made

other

into

a

sample

suspension

for

slices, and to

each vial a given amount of tracer spike was added. For any

other

details

or

procedures

of

the

beta

liquid

scintillation analysis used in this investigation, refer to

ASTM D3648-78.

28

MATHEMATICAL MODELLING AND

STATISTICAL ANALYSIS

For

diffusion

of

anions

in

soil

the

transport

equation is given by (36):

LU

D32C/8x2=dC/at+(pb /Qv )3S/at

where:

D=diffusion coefficient

C=concentration of anion in soil

S=amount of anion sorbed by soil

p.=soil bulk density

Q^=Volumetric moisture content of the saturated soil paste

A linear relationship in

terms

is assumed for sorption onto

the

of the anion concentration

clay. If the surface and

solution phases are in local equilibrium, then:

L21

where K, is a constant called the distribution coefficient,

d

Combining equations I and 2 gives the following:

D32C/dx2= (l+K,(p. /Q ))3C/dt

'd Hb *v

L33

29

Defining the retardation factor, Rq , as KdPfcZQv , equation I

may be written;

(D/(l+Ro ))d2C/ax2=dC/at

[4]

where D/(!+Rq )=D'=Effective diffusion coefficient,

and for the final form of equation I:

D yB2CZax2=BCZdt

For the system in

[5 ]

this

work

(seeFigures 13-31, App. B) ,

the initial and boundary conditions are:

C(x<0,0)=Initial concentration=^

C61

C(x>0,0)=0 ■

C(-oo,t> =0)=Co

C(oo,t>=0)=0

The solution of this model then is (37):

C=0.5CQerfc(xZ (21fIPT) )

00

[?]

?

where: erfc(z)=(2 Z i D /

exp(-n )dn

xZ(2ilTt)

Equation 7 may be rearranged to yield:

30

C/C =1/ Jiirf

-x/ (-J2D't )

exp( -zZ/2)dz

C83

-OO

The above

equation

is

cumulative probability

similar

of

a

to

the

formula

for the

standard normal distribution

(38) :

z

2

P=I/JSir/ expC-tz/23dt

—00

[9]

The definition of a probit

or probability unit is given as

(39) :

P=l/f2Vf

Y-5

exp(-u /2)du

—00

The CZCq values can

probit values found

for

be

converted to percentages and

these

Finney (39). A regression

the axial distance (x)

[10]

of

will

percentages from tables in

the probit values (Y) versus

then

give an equation of the

form:

Y=-bx+a

a=5

[11]

For a perfect match

by the least-squares estimators,

and

and

b=l/(^20't),

the

effective

diffusion

coefficient can be found from:

D'=l/(2b2t)

[12]

31

PROCEDURE

An IBM PC and LOTUS 123 software were used to perform

all

calculations

of

the

regression

analysis

and error

I

analysis involving the slope and diffusion coefficient. The

following are the equations for the standard deviation of x

and y (38):

?

?

I /?

SDEV(x)=[(Zx -(Zx) /N)/(N-I)]

[13]

SDEV(y)=C(Zy2-(Zy)2ZN)/(N-l)31/2

C143

where N=the number of data points

x=independent variable

y=dependent variable

The equations for the

slope

and

y-intercept are given as

(38) :

b=CZxy-(ZxZy)/NI/CZx2-(Zx)2ZNll

ClBl

a=(Zy-bZx)ZN

C163

The following equation is that for the sampling correlation

coefficient,

r

(38).

Cr=I

for

a

perfect

linear

relationship]

1/2

r=b*SDEV(x)/SDEV(y)=SDEV(Xy)/ESDEV(x)SDEV(y)I

E173

32

The

error

in

the

slope

consequently the error

in

(and

the

standard

deviation), and

diffusion coefficient, are

given as follows (40). The errors are given in terms of two

standard deviations of the slope.

SDEV(b )=C(E (y-a-bx))/C(N-2)(Ex2-(Zx)2/N))]1/2

[18]

Percent Error in Slope=2(SDEV(b))(100)/b

[193

Error Term For

Diffusion Coeff.=2(SDEV(b))(D')/b

Multiple linear regression

chloride-36

data,

coefficient is

density

and

where

the

inverse

of

can

Iog10

variable

the

independent variables (x ^ X g ) .

diffusion coefficient

analysis

the

dependent

[203

was done on the

of

(y)

temperature

In

be

the

diffusion

and the bulk

are

the

two

this way, the effective

found for other conditions

within the range tested. The equations are based on methods

utilized in Steel and Torre (41).

y=Bo+Blxl+B2x2

where

B2=(A1^A3/(A2-A4 ))/(A1 /(A2-A5))

B1 =(A3 -A1 ^B2 )ZA2

Bo=(Sy-B1ASxl-B2ASxz)ZN

and

[213

33

A1=Ex1X2-Zx1Zx2ZN

A2=Zx3^2-(Zx1 )2ZN

A 3=Zx1J-Zx1ZyZN

A4 =Zx2J-Zx2Zy ZN

A 5=Zx 22-(Ex 2 )2/N

Sy=Ey

The average activation, energies were determined from

the

diffusion

coefficients

found

for

chloride-36.

The

activation energy, Ea , is given by (42):

E=

-RTlnD' + RTlnA

where

A=Arrhenius frequency factor

R=gas constant

[22]

34

RESULTS AND DISCUSSION

A concise edition of

the

data and results discussed

in this thesis.is presented in Appendix B. The raw data for

the

individual

tests

are

displayed in

plot

form. The

corresponding regression curve for the data is presented in

each of the figures.

DIFFUSION OF CHLORIDE-36:

TEMPERATURE EFFECTS

The diffusion coefficient

is

expected

to vary as a

function of temperature. The Arrhenius expression generally

describes

diffusion

this

behavior.

coefficients

3

(±0.1g/cm ) were fitted

the

Arrhenius

at

to

equation

energies. The program used

is listed in Appendix

(Ea ), presented as

In

Figure

coefficient

7,

the

the

to

to

two

the effective

bulk densities

natural logarithm form of

determine

the

activation

fit the data, called BEFIT,

information,

for 1.6g/cm3 and,

J /mole and 10000 J/mole, respectively.

the

to

data for

A. The resulting activation energies

general

1.8 g/cm3 are 14000

The

general

decrease

tendency of

with

the diffusion

increasing

inverse

temperature, i.e., to increase with increasing temperature.

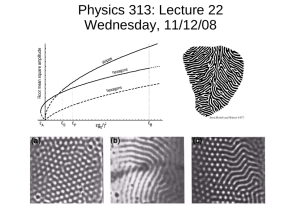

Figure 7.

Temperature Dependence of

Chloride Diffusion

LOGARITHM OF DIFFUSION COEFFICIENT VERSUS INVERSE TEMPERATURE

-5.0

— 5.2 -5.3 -

LOG(D)

-5.4 -5.5 — 5.6 -5.7 -5.8

-

6.0

0.0031

0.0027

□

EXPERIMENTAL

I /TEMPERATURE (K )

REGRESSION

0.0033

36

is displayed. The figure

is

presented in logarithmic form

and a regression line of

the

entire set of data is shown.

Note that the variation in

account, and the

data

bulk

scatters

density is not taken into

around

a temperature. In

fact, as the temperature increases, the scatter in the data

becomes larger. These

effects

will

be

discussed in more

depth later.

BULK DENSITY EFFECTS

In Figure 8, the logarithms of the,chloride diffusion

coefficients are plotted versus

at each temperature, there is

a tendency for the diffusion

coefficient to decrease with

stands

to

reason,

since

pathways in which the

of

the

pathways

bulk density. For the data

increasing bulk density. This

there

are

smaller

pore water

anion can diffuse. The circumference

should

also

decrease,

electrostatic interactions between the

anion to increase. Consequently,

is further hindered at

causing

the

clay layers and the

the diffusion of chloride

higher bulk densities, which agrees

with what was found experimentally.

The reduction of

due

to

bulk

density

the chloride diffusion coefficients

,

effects, is also noticed

bulk water. The diffusion

i.e.,

when

porosity

comparing

coefficient

and

tortuosity

them to those in

of chloride in bulk

Figure 8. Dependence on Bulk Density

Chloride Diffusion

of

LOGARITHM OF DIFFUSION COEFFICIENT VERSUS BULK DENSITY

-5.0

-5.1

— 5.2 -

LOG(D)

-5.4 -

— 5.6 -5.7 — 5.8 -5.9 —

6.0

1.56

□

1.64

20 deg.C

1.68

1.76

1.8

BULK DENSITY (g/cm3)

60 deg. C

o

1.84

90 deg. C

1.88

38

water at 25°C is 2.03x10 ^ cm^/s (42), or roughly one order

of magnitude

basalt

greater

mixture.

than

the

Comparing

diffusion coefficients

coefficient

this

at

1.6

(and 25°C) assuming sorption

value

in

the clay

the effective

3

I .8g/cm bulk density

and

to

is negligible, the tortuosity

factors of the backfill are determined to be 2.46 and 3.38,

respectively. The porosity of the backfill decreases 16% as

3

the bulk density increases from 1.6 to I.Sg/cm , while the

tortuosity increases 37%. Therefore, the effects of bending

the pore water pathways appears to become more important in

hindering diffusion of

As you would expect,

chloride

at higher bulk densities.

long straight pathways are apparently

the most conducive to diffusion of the anion.

CORRELATION OF DATA TO THEORETICAL MODEL

The C/C o data

dimensional

model

for

each

,

test

previously

was

presented.

effective diffusion coefficients and

fitted to the 1The

resulting

error terms are given

in Table 2.

The error term

indication of the

data

presented

deviations

coefficients and

scatter

determined using

two

in

standard

of

in

Table 2 gives an

the individual diffusion

the

data.

deviations

The

of

scatter was

the slope,

which for normal statistics covers a 95% confidence region.

39

Table 2. Chloride-36 Diffusion Coefficients (cm^/s) and

Error Terms

Test

IConditions(°C,g/cm3 )I Diffusion Coeff,. I Error Termj

20-002

20-003

60-004

60-005

60—006

90-007

90-008

90-009

20-010

60-011

20-013

90-015

20-016

60-017

90-018

20-019

20-020

90-021

60-022

26,1.63 7

23,1.64

60,1.63

60,1.63

60,1.63

90,1.57

90,1,59

90,1,57

27,1.86

60,1.81

26,1.81

90,1.90

25,1.81

60,1.71

90,1.77

25,1.68

25,1.59

90,1.81

60,1.75

3.32E-06

3.22E-06

5.99E-06

5.99E-06

5.14E-06

8.17E-06

9.01E-06

8.80E-06

3.7OE-06

2.89E-06

1.14E-06

3.07E-06

2.36E-06

5 o14E-06

3.7IE-06

2.86E-06

3.25E-06

7.35E-06

3.95E-06

Although the error term

the diffusion coefficients

is

from

best be detected by referring

the

data

to

the

model.

coefficient for each test

determination

are

the

slope

presented to

indicate

.

useful, the deviation of

the theoretical model can

to the linear correlation of

In

Table

3

the

correlation

and the resulting coefficient of

presented.

variation of

3.61E-07

2.53E-07

7.29E-07

2.72E-07

5.29E-07

5.26E-07

9.66E-07

1.13E-06

I .83E-07

5.18E-07

2.12E-07

9.83E-07

I .36E-07

6.56E-07

6.99E-07

3.11E-07

1.64E-07

7.88E-07

3.78E-07

(2

how

varies with the correlation.

In

addition,

standard

much

the

the

percent

deviations) is also

error

in the slope

Table 3. Coefficients of Correlation (r) and Determination

(r ), and Percent Error in Slope

Test

ICorrelation Coeff.ICoeff. of Deter.I% Err in Slope|

20-002

20-003

60-0-04

60-005

60-006

90-007

90-008

90-009

20-010

60-011

20-013

90-015

20-016

60-017

90-018

20-019

20-020

90-021

60-022

-.9883

-.9931

-.9768

-.9977

-.9870

-.9949

-.9859 .

-.9801

-.9970

-.9768

-.9751

-.9415

-.9971

-.9841

-.9785

-.9884

-.9975

-.9887

-.9921

.9767

.9862

.9541

.9954

.9742

.9898

.9720

.9606

.9940

.9541

.9508

.8864

.9942

.9685

.9575

.9769

■ .9950

.9775

.9843

For all but one data

the

data

variation

relationship

not

between

correlation

the

slope

where the correlation is

almost doubles to 32.01%.

for

probit

distance.

expect. For test 20-013 the

percent error in

there is only 0.5-5% of

accounted

the

percentages) and axial

gets larger as the

point,

10.89

7.86

12.16

4.54

10.28

6.43

10.72

12.80

4.95

17.91

18.58

32.01

5.76

12.75

18.86

10.86

5.05

10.73

9.56

by

values

Ttie

error

the

(of

linear

C/C

O

in the slope

gets smaller, as you would

correlation is -0.9751 and the

is

18.58%.

-0.9415,

Although

the

For test 90-018,

error in the slope

the correlation of the

test data with the

theoretical

intercepts still vary from 5,

This, in fact happens with

the y-intercepts

from

is

the

all

the

generally good, the yvalue for an exact fit.

the tests. The majority of

tests

range

between 4.00 and

4.75. The relationship between correlation and proximity to

the exact value of

the y-intercept is not straightforward.

Even if the correlation of one test is better than another,

the deviation of the y-intercept from 5 for the test may be

larger. To trace the causes

intercept, a

program

of

was

this fluctuation in the y-

written

which

change in the diffusion

coefficient

raw data.

of

The

listing

the

would

due

test the

to errors in the

program

can

be found in

Appendix A.

In the program,

from

the

a

theoretical

set

model

coefficient and time.

A

normal curve was then

added

standard

deviation

of

CZCq ratios was produced

using

random

of

error

to

the

a

the

typical

diffusion

generated to fit a

C/C o values at a set

normal

curve.

Diffusion

coefficients were then produced using the same mathematical

(probit) analysis

standard

deviation

coefficient

respective

standard

as

used

of

deviated

only

from

correlation

deviations

for

of

was

the

experimental

0.001,

the

the

original

only

0.896.

error,

the

data. For a

new

by

diffusion

35%.

The

For

increasing

new

diffusion

42

coefficients deviated

further

and

the correlation became

worse. The y-intercept values started at values larger than

5 (sdev=0.001) and

then

increasing standard

gradually

deviation.

noticed for the initial

though the standard

of' 0.05.

It

The

standard

deviation

appears

that

coefficient is sensitive to

decreased

below 5 for

greatest changes were

deviation of 0.001, even

was increased by increments

the

value

of

the diffusion

the values of the experimental

data using the probit analysis method. The variation in the

y-intercept values

expected

was

produced

with

therefore

fluctuations. Since

the

tests were so good,

it

possible

caused

correlation

is

cause

inconsistancies along

method

probably

may

the

all

have

outer

from that

by

coefficients

reasonable

sources of fluctuation affected

way. One

this

data

of the

to assume that any

the data in a similar

been

radius

due

of

to packing

the core, in

other words, small gaps or nonuniformities in radius. Since

the initial concentration

for

each

test

was taken as an

average of several slices, the average values may have been

too large.

This

effect

would

cause concentration values

smaller than expected and the resulting y-intercept to also

be reduced.

A

better

method

determine the diffusion

of

analysis

coefficients

could

be

used

to

from the theoretical

43

solution, i.e ., one that is less sensitive to errors in the

data. One method would be

to

CZCq plot

distance),

(versus

axial

areas predicted from

a

determine the area under the

Gaussian

and

compare it with

distribution for various

values of the diffusion coefficient.

Although better methods could

mathematical analysis

thing can

be

of

concluded

the

the line determined in

diffusion

about

describe the results. Because

the

have been used for the

the

the

coefficient, one

actual

model used to

data correlated well to

probit analysis (excluding any

errors in the intercept) ,. the theoretical solution with the

linear sorption

assumption

was

valid

in

describing the

of

the

data.

MULTIPLE LINEAR REGRESSION OF DATA

An

equation

for

diffusion coefficient (D)

the

logarithm

effective

versus inverse temperature (1/T)

and bulk density (BD) was determined to be:

log D = -1.786442 - 577.6931/T - 1.07452KBD)

This equation may not best describe the relationship of the

diffusion coefficient to the

Arrhenius

behavior

into

variables,

account.

The

but does take the

program

used

to

perform the

regression

is

correlation

coefficient

presented

was

0.855

in

Appendix A. The

and

the

resulting

coefficient of determination was 0.732. Therefore, 26.8% of

the variation was due

to variables besides temperature and

bulk density. Referring to

Figure

the diffusion coefficients tend

bulk density. Some of this

of the

mixture

when

8,

to

it can be seen that

scatter more at higher

scatter is due to the "dryness"

packing.

During

the

time that the

equilibration disk was removed from between the half cells,

and especially at the

90°C

tests, the interface would dry

exceptionally fast. Therefore, at higher bulk densities the

drying effects became

more

of

a

area around the interface would

problem. In effect, the

have to resaturate and the

diffusion

of

chloride

would

slow

diffusion

coefficients

would

therefore

expected. The results in Figure

coefficient values that could

With test 90-015 (Table

3)

down.

The

be

resulting

smaller than

8 do depict some diffusion

correspond to these effects.

the correlation coefficient of

this 90°C test is even noticeably worse than the others.

COMPARISON OF RESULTS WITH OTHER INVESTIGATIONS

Eriksen et al. (12)

chloride in bentonite

magnitude

smaller

that

than

found diffusion coefficients for

are

approximately 2 orders of

those

obtained

in

1this

45

investigation. The reason

found by looking at

that

the

is

adjacent

anion must first diffuse

solution

and

the

the

anion

at

in with the

the tracer was initially

to the clay. Thereforef the

Since

an

the

diffusion coefficient

mixed

through the interface between the

clay.

charged, there will be

of

initially

investigation

placed in a solution

values are smaller is

experimental setup. While in this

investigation the tracer

clay, in Eriksen's

his

the

clay

is

negatively

additional barrier to diffusion

interface.

is

caused

The

decrease

in

the

by diffusion resistances

due to charge repulsions between the clay and the anion.

McIntyre

(43)

measured

tritium-labelled water under

diffusive, medium

as

used

diffusion coefficients

diffusion

the

in

for

same conditions and same

this

the

coefficients for

work.

Values

different

of the

conditions are

given in Table 4.

Table 4. ^Effective Diffusion Coefficients For Tritium

(cmT/s)

Temperature (0C)I 20@5 C

Bulk D.I 1.61 I 2.89E-06

(cr/cm"3) I 1.79 I 2.56E-06

*Average values

density.

In Table 5

chloride are

of

the

listed

the

I

60°C

7.15E-06

6.85E-06

coefficient

90°C

I.56E-05

1.47E-05

I

at

an

I

average bulk

effective diffusion coefficients for

for

bulk

densities

of I .6g/cm3 and

46

I.SgYcm^ at the

same

three

These values are taken

temperatures as listed above.

from the multiple linear regression

equation.

Temperature (0C) I.

20+5°C

Bulk D.I■ 1.60 I 3.3SE-06

(cr/cm ) I 1.80 I 2.03E-06

. 5.75E-06

3.50E-06

The similarity of the

coefficients

is

especially

density.

Since

neutral tracer, its diffusion would

rapid

than

with

7.99E-06

4.88E-06

chloride and tritium diffusion

evident,

temperature and bulk

UJ

O

O

n

O

n

S

Table 5. Effective Diffusion Coefficients For Chloride

• (cm /s)

chloride.

at

the

lower

tritiated water is a

be expected to be more

McIntyre

confidence level and the Student-t

found

with

a

95%

test that there is some

adsorption. Some process of tritium exchange with water may

therefore be

present.

present,

should

it

If

sorption

likewise

of

have

chloride was also

noticeably

smaller

diffusion coefficients, which it does not. This would imply

that chloride is not significantly sorbed by the clay.

The ratio of the effective diffusion coefficients for

tritium and chloride (Temp.~20°C)

their molecular

I .6g/cm^

bulk

diffusivities

density,

the

compared to the ratio of

(42)

are

as follows: D A t

ratio

is

0.868 (effective)

47

compared to 1.1,

and

2)

at

1.6g/cm3 ,

the ratio is 1.26

(effective) compared to 1.1. TIie self-diffusion of water is

larger than the diffusion

does not move faster in

of

chloride

in bulk water, but

the clay where other variables are

affecting the movement of tritium. Obviously at higher bulk

density the effects

of

the

affect chloride more than

negative

charge

of the clay

tritium, although the hindrances

for tritium movement may still be there.

DIFFUSION OF CARBON-14

The movement of

straightforward

as

carbon-14

that

for

through

clay

chloride.

was not as

Although

de­

carbonate is also an. anion, its chemistry is different from

chloride in many

ways.

In

the

first

few tests run with

carbon-14 tracer, little movement was noticed. This type of

behavior

is

depicted

explanation is the

in

Figure

reaction

magnesium to form a

of

The

water is 0.0012

parts

Ca3+,

approximate

Mg3+,

amounts

most

likely

carbonate with calcium or

solubility

per

100

magnesium, it is 0.0106 parts

i.e.,

The

precipitate or cationic complexes that

could be sorbed.

The solubilities of

9.

the

and

of

groundwater in Table 6.

of

calcium carbonate in

parts

of water (44). For

per 100 parts of water (44).

individual ions present together,

CO^

these

,

are

ions

compared

in

the

to

the

synthetic

Figure 9- Diffusion Test,Carbon-14

D - C I4-020-OO2

C A R B O N - 14 C/Co

120 %

100%

-

□□

D