Name:________________________ PHGN/CHEN/MLGN435/535 Pre-lab #10

advertisement

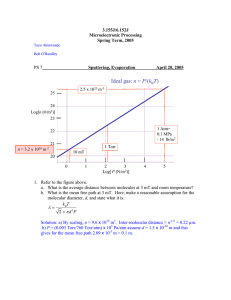

Name:________________________ PHGN/CHEN/MLGN435/535 Pre-lab #10 Due Tuesday, March 29, 2016 at the beginning of class Topic: Physical Deposition: Evaporation and Sputtering Reading: Campbell chapter 12 This will give you some background on metallization techniques used in the industry. 1. Assume you have a vacuum system with a pressure of 5x10-5 torr and that this is primarily water vapor (that was trapped on the walls of the chamber). Calculate the approximate number of monolayers of water that will form on a sample surface each second that it is in this chamber. Eq. 12.2 might help. Assume the system is at room temperature, that the atomic spacing between water molecules on the surface is about four angstroms, and that the sticking coefficient is one. This will tell you how fast you need to evaporate a metal (monolayers per second) to avoid having too many impurities trapped in the film. (show your work) 2. It is desirable to deposit a mixture of Ga and Al using a single source evaporator. If the deposition temperature is 1000C, the mixture in the crucible is initially 50% molar, and both components have a sticking coefficient of one, what would the starting deposited film composition be (approximately)? How will this change with time (qualitatively)? Think about using expression 12.2 for flux as a function of temperature and atomic mass where the pressure of each species is its partial pressure given in Fig. 12.2. 3. Step coverage is a key issue in metallization. a) In your own words explain why step coverage is so important. A simple sketch might help. b) Which gives better step coverage, sputtering or thermal evaporation? c) Step coverage can be improved in a sputtered film by applying an RF bias to the substrate. Why does this help? d) Will step coverage be an issue in your MOSFET design? 4. If I wanted to deposit Ag, could I thermally evaporate it? If the answer is yes, what approximate temperature would be good to use with Ag. Now answer the same two questions for Mo. In both cases, be sure to explain your answers. Fig. 12.2 will be helpful. 5. The melting point of Cu is 1083C (1356 K). Using figure 12.21, if Cu is deposited by sputter deposition at a temperature of 270C and at a chamber pressure of 1 Pa, what morphology (grain size or shape, reflectivity of the film etc.) might we expect the film to have?