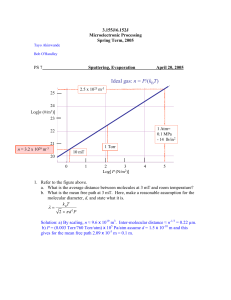

MSE 4121 Thin Film Technology and Nanocrystalline Coating 5. Application of Cold Plasma to Thin Film Deposition Lecture: Dr. Zhiyuan Zeng Office: BOC-R7190 E-mail: zhiyzeng@cityu.edu.hk 1 Outline Classification of Deposition Process PVD Physical Vapor Deposition Sputter deposition (also reactive) Ion plating Reactive ion plating Activated reactive evaporation CVD Chemical Vapor Deposition Plasma enhanced CVD Plasma decomposition Chemical transport in plasma Plasma stream transport Surface Modification Ion nitriding Ion carburizing Plasma oxidation Plasma anodization Plasma surface treatment for polymers 2 Physical Vapor Deposition under Plasma Conditions • • • • • PVD (e.g. sputter deposition or ion plating) can be used in thin film deposition of Elemental metals Metal alloys Compounds such as carbides, nitrides or oxides PVD - used in industry Sputter Deposition - Features • Deposition - physical sputtering by ion bombardment • Various materials - metals, alloys and insulators can be formed • High melting point materials 3 IB: Thin Film Technology/Sputtering 5.1 Sputtering A sputtered particle induced at energetic impact of an ion Momentum transferred to atoms of a solid Relaxation: Repulsive forces among compressed atoms Ejection of surface atoms 4 Definition of Sputtering Yield • • Average number of atoms sputtered per incident ion Sputtering Yield is affected • Surface structure • Ion mass • Incident energy • Rather insensitive to temperature (in certain cases, decreasing sputtering yield with increasing the target temperature) 5 Sputtering Yield Depends on the Ion Energy • • • • • • Rises rapidly from a threshold energy Threshold 10 - 30 eV for metals Above 100 eV, increases ~ linearly Thereafter, a broad maximum and then decreases slowly Decrease with increasing ion energy – penetration depth too large to eject atoms from the deeper regions Light ions (H2, He) maximum at a few thousand eV – large penetration depth. Heavy ions (Xe, Kr ) - maximum at around 50 keV. Fig.5.1.1 Sputtering yield of some metals for Ar+ ions as a function of their energy. 6 Sputtering Induced by Different Ions • • • • • • Sputtering Yield for Different Ions Maximum for inert ions. Minimum for C, Mg, Al, Ca and Sc ions - sticking coefficient. Sputtering by neutrals – lesser significance. Energetic neutrals formed by neutralization of an ion beams for sputtering insulators. No sputtering is initiated by electrons. 7 Table 5.4.1 Sputtering Yield for argon ion bombardment at 600 eV Target Be Al Ti V Cr Fe Co Ni Cu Ge Zr Nb Yield 0.56 0.83 0.54 0.55 1.05 0.97 0.99 1.34 2.00 0.82 0.42 0.42 Target Mo Ru Rh Pd Ag Hf Ta W Os Ir Pt Au Yield 0.54 0.67 0.77 1.32 1.98 0.39 0.30 0.32 0.41 0.46 0.7 1.18 Target Al2O3 SiO2 TiO2 V 2 O3 Cr2O3 Fe2O3 ZrO2 Nb2O3 In2O3 SnO2 Sb2O3 Ta2O5 Yield 0.18 1.34 0.96 0.45 0.18 0.71 0.32 0.24 0.57 0.96 1.37 0.15 Target CdS GaAs GaP GaSb InSb SiC Yield 1.2 0.9 0.95 0.9 0.55 1.8 8 Deposition and Etching Relation between the deposition rate d’ of a film on the substrate and the etching rate r’ of a target is d’ = c r’ (5.4.1) c- constant determined from the geometrical configuration of the target and substrate, and the effect of scattering target atoms by gas particles in plasma. Etching rate r’ is proportional to the ion current density at the target surface ji, thus ji M a r' Y Nae r’ - etching rate ji - current density Y- sputtering yield Ma - atomic weight of the target - density in g/cm3. (5.4.2) 9 • • Sputtering yield Y - maximum at 10 – 50 keV. For the high deposition rate pressure must be optimized. • • Several keV at 10-3 – 10-2 Torr. • Current density ji = 0.1 – 1.0 mA/cm2 is necessary to obtain etching on the order of hundreds Å/min. MFP of the sputtered atoms and ions in comparison with the distance between target and substrate. Fig.5.4.1 Energy distribution of Cu atoms ejected from a single crystal Cu at Kr+ ion bombardment with energies from 80 – 1200 eV. 10 KE of sputtered atoms KE of sputtered atoms varies with • Mass of ions: the heavier the bombarding ion - the larger energy of the sputtered atoms. KE1>KE2>KE3 • Ion energy • Target material • • • Average energy of sputtered atoms and their atomic numbers Average velocity of sputtered atoms: v = (4 - 8) 105 cm/s. Remains a nearly constant even if the atomic number changes. Therefore, atoms with larger atomic number have larger average energies. v1 = v2 = v3 M1 > M 2 > M 3 Sputtered 11 Energy Distribution • • • • • Sputtered atoms slow down in collisions. Effect is called the thermalization. As sputtered atoms travel from the target to substrate their distribution is changed. Energy distribution of sputtered atoms at the substrate is sharper than for evaporated atoms. Distribution at which the sputtered atoms arrive at a substrate is strongly affected by the gas, the pressure and the distance between the substrate and the target. (a) d= 0 cm (b) d= 3 cm (c) d= 6 cm Fig.5.4.2 Change in Nb energy distribution with distance from target with Ar pressure 10 mTorr; a) 0 cm, b) 3 cm, c) 6 cm. 12 IB: Thin Film Technology/Sputtering 5.5 Reactor Configuration Sputter deposition system Configurations • Diode • Triode – 3rd electrodes with substrate. • Magnetron - sputtering device with magnetic field B crossing perpendicularly the E-field lines. Fig.5.5.1 I-V characteristics of three different methods used for sputtering 13 IB: Thin Film Technology/Sputtering DC Diode System -ve few kV target Water cooling Electrons Ar Ions + + + + + + + + Substrates Fig.5.5.1b • • • • • Power density 0.5 -15 W/cm2 Widely used because of simplicity DC glow discharge well understood Sputtering limited to metals and semiconductors DC sputter deposition requires ion current > 1mA/cm2 to obtain reasonable deposition rates 14 RF Diode System RF Water cooling Electrons Ar Ions + + + + + + + + Substrates 15 Effective bias Plasma Potential –Electrode Potential: Determine the Energy of Impact Ions Ion energy is proportional to e(Vp –VE) 16 Target is Surrounded by a Shield (normally grounded) • To avoid discharges at undesirable regions • To localize the sputtering to desired surface • Distance between the electrode and shield must be smaller than the twice of the width of the dark space in the pressure range employed • Shield acts as the floating capacitor of the electrode system - causes losses of RF power Fig.5.5.2 Cross sectional view of the electrode used for DC or RF diode sputtering 17 IB: Thin Film Technology/Sputtering Schematic Diagram of Sputtering Deposition System Fig.5.5.3 Schematic diagram of sputter deposition system 18 IB: Thin Film Technology/Sputtering Magnetron Sputtering • Magnetron – device with a magnetic field perpendicular to an electric field – crossed electric and magnetic fields. Several types of magnetrons • (i) Cylindrical; (ii) Planar: circular, rectangular • Operated using either DC or RF. • Plasma density increases in magnetically confined region - decrease in discharge impedance. • Higher ion current density, 10 - 100-times than that in the RF diode type. • Increase in deposition rate. • Deposition rate per unit power density at the target also increases. Fig.5.5.4 19 IB: Thin Film Technology/Sputtering Paschen Curve discharge threshold voltage Vg = f(pd) in Ar Non-magnetron discharge • (Vg)min at (pd)min = 1 – 3 Torr.cm Magnetron discharge • (pd)min shifts towards the lower side while maintaining the same value of (Vg)min. • • • • Fig.5.5.7 Comparison between the Pashen curves for magnetron (o) and non-magnetron (x) discharges. Lower value spans a wider range. Indicates more stable discharge. Maximum plasma density is ~ 3.5 1012 cm-3 at p = 0.3 Torr. Ionization is ~ 310-4, (~10-6 in the non-magnetron discharge). 20 IB: Thin Film Technology/Sputtering Circular Planar Magnetron A deposition area with 100 mm in diameter needs a target with ~120 mm in diameter and in distance ~6 cm to provide the thickness uniformity of ~5%. 21 IB: Thin Film Technology/Sputtering Rectangular Planar Magnetron Target Grounded shield Vacuum flange Water out Water in 22 IB: Thin Film Technology/Sputtering Assembly of Rectangular Planar Magnetron Grounded shield Flange Target fixture Target Cathode plate Magnet assembly Cathode casing Water out Water in 23 Deposition Systems with Two Magnetrons • Two unbalanced magnetrons • Closed mg field • Planetary motion Unbalanced Magnetrons? • Two magnets: outer magnet is strong while inner magnet is week magnetic field more open. • Trap fast electrons emitted from the hot electrode. • Yield higher ionization and higher ion current Higher sputtering yield, economical use of the target. 24 The Magnetron Sputtering of Magnetic Materials • Reducing saturation magnetization sputtering by heating to Curie temperature – It requires a special assembly with spacing and heating • Using thin target 25 Confocal sputtering Uniform coating provided by confocal sputter deposition and rotation of substrates Rotary substrate 26 IB: Thin Film Technology/Sputtering Cylindrical Magnetron 3D Magnetic Field Modeling for optimized “turn-around” erosion 27 IB: Thin Film Technology/Sputtering Cylindrical Magnetron 28 IB: Thin Film Technology/Sputtering 5.6 Reactive Sputter Deposition • • Target compounds - multiple elements with different volatilities (e.g. metal oxides or nitrides). Deposited film often differs from the composition of the target. • • Compounds decompose during the sputtering process. Decomposition varies according to the bond strength. • • Concentration of the volatile component such as oxygen or nitrogen, is reduced in the deposited film. Thus, both the target and film composition change. • Loss of dissociated volatile component is compensated by adding this component into plasma. 29 Reactive Sputter Deposition • • • • Sputter deposition technique employing plasma with a reactive gas and elemental metal target. Various compound films have been prepared by reactive sputter deposition and the reactive gases. Composition of the compound can be controlled by changing the partial pressure of the reactive gas added into an inert gas (Ar). Partial pressure of reactive gases (N2 or O2) affects the deposition rate and film properties. 30 IB: Thin Film Technology/Sputtering Table 5.6.1 Compound films formed by reactive sputtering 31 IB: Thin Film Technology/Sputtering Application Examples of Sputtering • • • • • • • • Wear resistant materials for tribological and cutting tool applications: binary and ternary composites TiC, TiN, iC-graphitic, MoST, ZrB2, AlTiN etc. Optical materials for lens characteristics: Typical MgF2, MgO, CeO2. Transparent conducting materials for example ITO (indium tin oxides used as large electrode in flat panel displays), SnO2, In2O3, ZnO, AlZnO, F:SnO2 (FTO) or SiO2. Metalization paths and levels in microelectronic devices: W-Ti, Al-Si, Al-Cu, etc. Thin film resistors: Ni-Cr, Cr-Si, Cr-SiO. Amorphous bubble memory devices. Typical are Gd-Co, Lu3Fe5O12, Gd3Ga5O12. Microcircuit mask blanks using such materials as Cr. Magnetic materials for data storage tapes employing Co-Ni, Tb-Fe, Co-Ni-NiCr. 32 Use of Sputtering Energy • Efficient signage • Gas turbine blade coatings • Outdoor display systems • Solar panels Lightening • Emission filters • Energy-efficient lighting • IR intensifiers • Traffic signals Optics • • • • • Anti-reflective/Anti-glare coatings Cable communications Laser lenses Optical filters for achromatic lenses Spectroscopy Medical • Angioplasty devices • Anti-rejection coatings • Radiation capsules Security • Markings and holograms for currency, etc. • Night vision/infrared equipment • One-way security windows Wear coatings • Anti-corrosion coatings • Anti-seize coatings • Dies and molds • Sewing needles • Tool and drill bit hardening Aerospace and defense • Heads-up cockpit displays • Jet turbine engines • Mirrors for optical and x-ray telescopes 33 • Night vision equipment Use of Sputtering Architectural Glass • Energy-producing glass • Low-emissivity glass Electronics Microelectronics • Flip-chip back side metallization • Gate dielectric • Interlayer dielectric • On-chip interconnects and interlevel bias • Passive thin film components • Printed circuit boards • Sensors • Surface Acoustic Wave (SAW) devices Automotive • Auto headlights and taillights • Auto trim components • Drive train bearings and components Data storage • CDs • DVDs • Laser disks • Magnetic disks (hard and floppy) • Microelectronic flash memory • Read/Write heads Decorative • Appliance trim • Building glass • Building hardware • Clothing • Jewelry • Packaging • Plumbing fixtures 34 • Toys Thin Films: Volmer – Weber growth • • • • Thin films do not growth in perfect ways. Only epitaxial growth is exception The first atomic layer forms islands on nucleation sites (Volmer – Weber growth) Islands laterally expands until they touch each other which is called percolation threshold. The film properties in this growth stage are very different from the bulk material properties. Percolation threshold 5 - 15 nm 35 Morphology and Characteristics of the Films • Films prepared by sputter deposition are often polycrystalline. Zone 1 • Structure caused by limited migration of incident atoms. • Effected by adsorbed atoms. • Structure is constructed from tapered crystallites with domed heads and contains voids in the grain boundaries. Thornton’s structural model Atoms of particle leave the sputter source with energies of several eV. Increasing the pressure reduces the energy particles to be deposited via scattering process- thermalization. 36 Morphology and Characteristics of the Films • Films obtained by sputter deposition are usually polycrystalline. Zone T • Appears only in sputter films • Regarded as a transition region • Film reveals fibrous structure crystallites grown perpendicular to the surface • Crystallites develop close each other • Density is nearly equal to that of the bulk material • Surface is relatively smooth • Film has large tensile strength and hardness values 37 Morphology and Characteristics of the Films • Films obtained by sputter deposition are usually polycrystalline. Zone 2 • Migration of atoms on the substrate surface becomes considerable. • Structure is constructed of the columnar grains. • Grain size increases with increasing T/Tm Zone 3 • Structure controlled by interdiffusion of atoms. • Thus, the film surface becomes smooth. • Recrystallization progress in the film during film formation. • Film becomes, therefore, isotropic and randomly oriented polycrystals 38 Stress in Deposited Films • • • Energy of the sputtered atoms is large: Inter-mixing and mutual diffusion between the substrate and incoming atoms. Therefore, the adhesion is stronger than that by evaporation or plasma enhanced CVD. Adhesion strong enough to bend substrate Stress 1. THERMAL STRESS • Film prepared at temperatures higher than RT temperatures. Upon cooling to RT the difference between expansion coefficient causes thermal stress. 2. INTRINSIC (INTERNAL) STRESS: up to 0.1 - 10 GPa • Subtraction of thermal stress from apparent stress: arises from microstructure; may dominate at T less than 20% of melting point, because of incomplete structural ordering 39 Deposition Temperature Affects the Film Stress Intrinsic Stress associated with microstructure Depends on deposition temperature since the microstructure is affected by T Often decreases with increasing T. Thermal Stress Different thermal expansion coefficients of substrate and film invoke thermal stress upon cooling. Significant whenever the intrinsic stress is small Example: Ni/glass deposition 25 oC: Thermal stress is 5% of intrinsic 75 oC: Thermal stress is prevalent Total stress has a minimum. Ratio between the intrinsic and thermal stress depends on the preparation method. 40 Parameters Affecting Intrinsic Stress of Films • • • • • • • • • • • • Substrate temperature Difference between the temperatures of the deposited film and substrate temperature (influences thermal stress). Variation in temperature during deposition Deposition rate Incident angle Film thickness Gas environment Phase transitions- crystallinity, stoichiometry Electrostatic effect – free charges consequences – modification of stress Lattice mismatch Dislocations, lattice defects Variation in stress with depth – curling when it peels off 41 Two Types of Internal Stress Substrate Tensile • concave Tensile stress convex (look at interface) Substrate bends concave High tensile stress: • Microvoids in the thin film, because of the attractive interaction of atoms across the voids. • Defects in deposited films Compressive • Compressive Stress (look at interface) • Substrate bends convex Energetic particle bombardment during deposition results in packing the atoms more tightly. 42 Gas Environment and Internal Stress Compressive Substrate bends convex at low Ar pressure -higher particle energies. Tensile • • • • Substrate bends concave Changes to a tensile stress as pressure increases -possible void formation Transition pressure increases nearly linearly with increasing atomic number. Transition pressure is higher for heavier inert gases. Figure 5.7.2 Ar pressure dependence on internal stress 43 Transition Pressure: Compressive to Tensile Stress Fig.5.7.3 The transition pressure from compressive stress to tensile stress in films as a function of atomic weight of sputtering metals 44 Internal stress in sputter deposited metal films can be caused by • • • • Sputtered atoms with high energy and neutral gas atoms reflected back from cathode. Knocking the metal atoms into interstitial lattice sites. Sputtered atoms and gas atoms themselves incorporated into the substrate material as interstitial atoms. Both phenomena are called the atomic shot peening. Internal stress is induced by atomic shot peening • • When +ve bias voltages are applied - tensile stress. When -ve bias voltages are applied - compressive stress. 45 • • • • • • • • • • Ion Plating Methods often used: – Evaporation carried out in a plasma. – Cathodic Arc deposition with 3rd biased electrode Evaporated metal atoms are ionized in plasma. Ions are accelerated toward the substrate. Substrate negatively biased - Simultaneous deposition and sputtering. Deposition rate is higher than the sputter-etched rate. Working gas - inert (Ar) Plasma without a working gas in only metal vapor. Through the introduction of the reactive gases such as N2 or O2, compound films can be deposited. Many types of ion plating systems have been developed. Their characterization – in accordance with the combination of discharge type for generating plasma and evaporation source. 46 Ion Plating using Resistance Heated Source • • Resistance heated filament as an evaporation source DC glow discharge generated by applying negative high potential to the substrate. Fig.5.8.1 Diagram of ion plating DC glow discharge for generating plasma and resistance heated filament as an evaporation Fig.8.1 Ion Plating 47 Ion Plating using EBE • • Resistance heated evaporation source – materials below ~ 1300 oC. Electron beam evaporation - materials up to ~ 3000 oC. Fig. 5.8.2 Ion plating apparatus using DC glow discharge and an EBE. 48 Activated Reactive Evaporation (ARE) • • • • • Metal evaporated by an EBE source reacts with a reactive gas plasma and deposit as a compound film Plasma is generated between the grounded chamber wall and probe with positive potential DC voltage Probe currents 40 - 170 mA/ 20 – 80 V. Reactive gases, as in sputter deposition - listed in Table Pressure during deposition ~ 10-3 – 10-4 Torr. Fig.5.8.3Activated Activated reactive reactive evaporation Fig.5.8.3 evaporation 49 Ion Plating using an Inductively Coupled RF • • • Ion plating technique that uses an inductively coupled RF discharge for generating plasma Coil 7 cm in dia Turns 4 -7 Fig.5.8.4 Schematic setup of an ion plating apparatus using RF inductively coupled discharge 50 Effects at Ion Plating • • • • • • Substrate is sputter cleaned by Ar+ ion bombardment. Films are continuously exposed to the bombarding ions. Substrate temperature increases due to this ion bombardment. Mutual diffusion layer forms in the film –substrate interface. Higher ion energies – intermixing evaporated and substrate materials. Stronger adhesion than at conventional evaporation. Characteristic features of ion plated films • • Strong adhesion, low porosity, high corrosion resistance and significant mechanical properties (hardness and wear resistance). Surface roughness depends on the method of preparations. 51 Variety of metals and compound films produced by ion plating: • (a) Metals - Cr, Cu, Ag, Au; (b) Oxides – Y2O3, Al2O3, In2O3, Bi2O3; (c) Nitrides – TiN, Ti2N, HfN, TaN, CrN, Cr2N, Si3N4;(d) Carbides – TiC, ZrC, HfC, VC, NbC, TaC; • (e) Others – CdS, Nb3Ge. Some applications - Examples 1. Metal films such as Ag and Au for anticorrosion, wear resistance, or for use as high quality optical and decorative coatings. 2. Refractory compounds such as metal carbides or nitrides represented by TiN, ZrN, TiC, or Al2O3 for cutting tools and watch parts - extreme hardness and excellent wear resistance under adhesive, abrasive and erosive wear conditions. 3. Metal oxides such as TiO2, In2O3, SnO2 or SiO2 for optical coating for laser mirrors and antireflection coatings. 52 Variation of microhardness with nitrogen pressure during deposition of TiNx film Fig.5.8.5 Microhardness of TiNx film as a function of N2 pressure 1) Reactive ion plating 2) Activated reactive evaporation 3) Reactive evaporation N2 53