Proceedings of 7th Global Business and Social Science Research Conference

advertisement

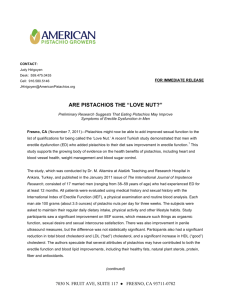

Proceedings of 7th Global Business and Social Science Research Conference 13 - 14 June, 2013, Radisson Blu Hotel, Beijing, China, ISBN: 978-1-922069-26-9 Challenges in Iranian Trade of Pistachio Ahmad Zomorrodi The purpose of this research is to investigate which kinds of International Standards is the most appropriate one to implement in pistachio‘s cultivation and preparation. Moreover, evaluating the possibility of implementing vertical integration system to inspire the whole standardization process and controlling the price is considered. The study setting is in Iran. In previous decades, Iran was the main producer and exporter of pistachio in the world. Recently, Iranians face a reduction in market share and sales due production quantities and yield of foreign competitors. The study found that applying modern knowledge and updated technologies, efficient research and development, standardizing all manufacturing process can capture customer values and provide customer satisfactions which are vital especially for developing countries firms to change such threats to opportunities to create competitive advantage in price and quality domestically and also remain competitive in international markets .The theoretical implications of my finding are also discussed. JEL Codes: L21, M16, M21 1. Introduction Iran is a country where 50% of the economy is centrally planned. The Iranian government policy affects macroeconomic factors such as unemployment rate, the inflation rate, and the rate of economic growth. Iran’s economy relies heavily on oil revenues. This revenue has been used to implement a range of policies. For instance, government subsidies - particularly on food and energy - have influenced the national economy for more than 30 years. Recently, Iranian government has decided to reduce subsidies (Majlis.ir, 2010). The cut of subsidies has had dramatic effect on many Iranian industries. The pistachio industry, as part of this economy, has affected too. The pistachio industry is one of the most important non-petroleum industries for the Iranian economy. Pistachio export earnings are the largest among non-petroleum export industries (Karimi, 2008). The pistachio industry has undergone significant change over the past few decades. Until 1979, the majority of Iranian pistachio harvest was exported to the United States. During the eighties, the Iranian pistachio industry faced a 283% tariff to Iranian shippers of raw pistachios and a 318% increase to roasted products (FAS, 2004). Since then, it became not feasible for Iran to export any pistachios to America because of these heavily increased taxes. Moreover, the growth of American pistachios industry consequently led to Iranian pistachios to be replaced by American ones (Abrishami, 1995; Sedaghat, 2006). As result of this, the Iranian pistachio exports shifted to European and Japanese markets. From 1981 to 1991 90,000 tones of pistachio were exported to these markets. In 1991, European countries and Japan imposed new quality standards for Aflatoxin (fungal metabolites exhibiting toxin). As a __________________________________________ 1-Ahmad Zomorrodi, PHD candidate in International Business and Economy, UIBE China. Email:zomorrodi_82@yahoo.com Proceedings of 7th Global Business and Social Science Research Conference 13 - 14 June, 2013, Radisson Blu Hotel, Beijing, China, ISBN: 978-1-922069-26-9 result of the new regulation, the majority of Iranian pistachios were rejected because they did not meet the new sanitary requirements (Abrishami, 1995; Alavi, 2006). The supply to these two markets was replaced partly by American pistachios consequently; Iran had to change their target market and focused on other markets such as China, Russia and South East Asia. At the moment, Iran exports most of its production to these markets. The world’s largest producers and exporters in the pistachio industry are Iran and the united States which, combined produce 80% of the pistachio world production (Abrishami, 1995; KarimKoshteh&Vardan, 2003). The pistachio production has increased significantly in recent years in both countries and therefore, they need to identify and develop new markets for their surplus produce. Both countries have different competitive advantages and aim to further increase their international competitiveness by using technical improvements and new marketing strategies (Sedaghat, 2008). However, the pistachio industry in Iran is facing some difficult challenges to improve their productivity and efficiency. Although, Iran continues to be the biggest producer and exporter of pistachios in the world, it has the lowest productivity yield per hectare compared to production efficiency levels achieved by other countries. Iran has increased the total area for pistachio production over the past years but the production efficiency has not improved (KarimKoshteh&Vardan, 2003).Several studies have focused on the comparative advantages of Iranian pistachios. This research aims is to identify those key factors that caused Iranian pistachio firms from competing with its foreign rivals especially American ones. During the last decade it has been a question for Iranian firm that how they can escape from such a crucial condition and changing threats like price and International Standards to opportunities, to create competitive advantage in price and quality domestically and also remains competitive in international markets. Nowadays, Iran has three different markets to export pistachio. The first one that contains European countries, Japan, and Canada; they do insist on safety and products quality. The second one contains Arabic countries; they request for product with delicious taste and good shape and the third group contains East Asia countries, they ask for low price products. Germany, Spain, Italy and Hong Kong are most importer of Iranian pistachio. However they are also pistachio exporters. Historically, pistachio prices fluctuated dramatically due to the biannual production cycle (Foreign Agricultural Service 2003). USA has stabilized both price and supplying of pistachio for two decades. Therefore, due to strong global demand, USA had sustainable growth in pistachio exportation. According to the FAO Statistical database (FAOSTAT), Germany is a main importer and broker of pistachios in global market. It imports the product from Iran and USA and export part of it to other European nations. 2. Literature Review During the last decade, especially because of political sanction and pressure, access to financial resources in Iran tends to be very difficult, interest rates are high, and often involves a very time-consuming. Financial institutions in Iran are mostly government based. In contrast, foreign pistachio stakeholders have easy access to low interest loans. Previous studying revealed that Iranian pistachio producers had no Proceedings of 7th Global Business and Social Science Research Conference 13 - 14 June, 2013, Radisson Blu Hotel, Beijing, China, ISBN: 978-1-922069-26-9 intention of investing in the development of their workforce. So, it is very difficult to find employees with the required skills to work in the sector. Generally, decision makers within a farm could have different levels of education. As a result it has been revealed that Iranian pistachio firms have followed two different strategies. The firms exporting to China, Russia, and similar markets claimed to have pursued a cost leadership strategy. This group is mainly integrated by less educated farmers who own the small-scale farms and represent 60% of total pistachio production. The other group, integrated by big farm owners, exporting to the EU and more demanding markets that are willing to pay a premium price, claimed to have pursued a differentiation strategy, emphasizing quality and service (Dr. Federico, 2011). In 2010, 20% of the total Iranian pistachio production was consumed in the domestic market; Even though the largest proportion of pistachio is consumed in international markets. Iranian domestic demand conditions have not supported the Iranian pistachio industry to develop competitive advantages. Most Iranian and American consumers have different preferences and value different attitude to pistachio products. Iranian consumers are concerned about the physical characteristics of pistachios and not very much interested in food safety standards. So, domestic consumers are not a valid point of reference for Iranian firms to anticipate the need of consumers in western industrialized countries such as America (BorhanZadeh, 2011). Iranian exporters point out many countries prefer to process and package pistachio in their own countries as part of their marketing strategy. Export firms do not have a clear marketing plan and usually they do not conduct any type of marketing research (Koshteh, 2005). Iranian-American producers, from California, pointed out that easy access to research outputs in modern pistachio farming techniques have improved the development of the industry. For instance, the application of modern technology has allowed minimizing the levels of toxins such as Aflatoxin. All farm owners revealed that they received support (via grants and loans) from financial institutions. This financial support has helped farmers to meet their growth plans. They also mentioned that government support has further contributed to the development of the industry (Zijuan Zheng,Sayed Saghaian,Michael Reed, 2012). Iran has a tariff on imported agriculture machinery. This tariff would, according to the government, protect and help the development of the national industry. Domestic machinery is of inferior quality than imported one. However, many farmers purchase Iranian farming machinery because of its competitive price. This is the part where American and foreign rivals producers have a clear competitive advantage in development and management of irrigation systems. The access to more modern irrigation systems results in higher harvest and a more efficient and sustainable utilization of underground water resources (Koshteh, 2005). 2.1. International standard and Competition As international competition occurs intensively in pistachio, global market members search and pursue different and modern approaches, technologies and knowledge to create competitive advantage and use opportunities which is generated or existed in home or host countries to gain much more profits. There is no denying that International Standards are the kinds of Product and Testing management Proceedings of 7th Global Business and Social Science Research Conference 13 - 14 June, 2013, Radisson Blu Hotel, Beijing, China, ISBN: 978-1-922069-26-9 certifications which are categorized as Nontariff Barriers which are the kinds of governmental supervisions on international trade. Any government regulations, policy, or procedure other than a tariff that has the effect of impeding international trade may be labeled a nontariff barrier (NTB) (Ricky W. Griffin, 2008). The International Organization for Standardization (ISO) has been working to develop and refine an international set of quality guidelines (Ricky W. Griffin, International Business: A Managerial Perspective 2008). ISO 9000 is a kind of standards which is applied for quality management systems. ISO 22000 is a kind of standards which is applied for food safety. ISO 22005 is a kind standard which is applied for traceability in the feed and food chain. Hazard Analysis Critical Control Point or HACCP is a systematic preventive approach to food safety and pharmaceutical safety that addresses physical, chemical, and biological hazards as a means of prevention rather than finished product inspection. HACCP is applied in the food industry to recognize possible food safety dangers, so that essential activities can be done to decrease or eliminate the risk of the dangers being understood. It goes without saying that Iranian governmental subsidies implemented in the eighties changed the structure of the industry from one dominated by big farms to one dominated by small ones (Dr. Federico, 2011).It seems easier to implement changes in an industry dominated by few big players with a strong financial situation than in an industry dominated by many small players with a diverse level of education and financial situations. All these factors have allowed the American pistachio industry to quickly respond to the new Aflatoxin standards and hence gaining a big part of the market share in the EU and UK. According above mentioned, one of Iranian exporter’s barriers in foreign markets has been facing these standards that is one of the core research question of this project which is discussed in the following. 2.2. Vertical Integration in Pistachio Because the production of most manufactured goods needs different kinds of raw material, parts, and other resources, the first problem an enterprise production manager confronts is to decide how to obtain those inputs. Supply chain management is the combination of processes and steps a firm applies to obtain the different kinds of resources it requires to make its products. The first step to extend a supply chain management strategy is to set the suitable degree of vertical integration. Vertical Integration is the extent to which a firm either provides its own resources or obtains them from other sources (Ricky W. Griffin 2008). From one point of view, companies which apply relatively high levels of vertical integration are involved in entire step of operations management process as goods are developed, transformed, packaged, and sold to customers. From another point of view, companies which have little vertical integration are engaged in only one or few steps in the production chain. They may purchase their inputs and component parts from other suppliers, do one operation or transformation, and finally sell their products to other companies or consumers (BorhanZadeh, 2011). The extent of a firm‘s vertical integration is the result of a series of supply chain management decisions made by production managers (Ricky W. Griffin, 2008). The firm can make the inputs itself, or it can buy them from outside suppliers. This choice is called the make-or-buy decision (Ricky W. Griffin, 2008). A decision to buy rather than make dictates the need to choose between long-term and short-term supplier. A Proceedings of 7th Global Business and Social Science Research Conference 13 - 14 June, 2013, Radisson Blu Hotel, Beijing, China, ISBN: 978-1-922069-26-9 decision to make rather than buy leaves open the option of making by self or making in partnership with others. The make-or-buy decision can be affected by a company‘s size, extent of operations, and technological expertise and by the nature of its product. Also, a firm will select to make or buy easily whether it can provide the resource cheaper by producing it internally or by purchasing it from an external supplier. If a company faces high potential for competitive advantage and high degree of strategic vulnerability, it should keep strategic control by producing internally. However, if it faces low potential for competitive advantage and degree of strategic vulnerability, it should keep strategic control by providing externally. At middle stages which force the company to moderate control, special ventures or contract arrangements may be most suitable (BorhanZadeh, 2011). Companies specifically should make preferences between costs and control, investment, flexibility and risk. Producing a component internally improves the company‘s supervision and control over product quality, design changes, delivery schedules and costs. A firm that purchases from external suppliers may faces more dependability to those suppliers. If those suppliers exit the sector, raise their prices or makes poor-quality materials, the company will lose its source of inputs, face its costs increase or quality-related problems. An appropriate example for vertical integration in pistachio production is Paramount Farms which is the world's largest vertically integrated supplier of pistachio. Paramount Farms has 30,000 acres of pistachio orchards which are the largest in the Western Hemisphere of California‘s San Joaquin Valley. Paramount Farm‘s products can be obtained under the Sunkist® and Everybody‘s Nuts™ brand names worldwide. It presents a full range of in-shell and shelled pistachio products. 3. The Methodology and Model The purpose of the research project is to describe the problems in Iranian pistachio production and trade globally by referring to major growers, producers and exporters. Which kinds of International Standards is the most appropriate one to implement in pistachio‘s cultivation and preparation? What kinds of problems can be faced by implementing International Standards? How the problems can be solved and implementation is applicable? Is it possible to implement vertical integration system to inspire the whole standardization process and controlling the price? Which kinds of investments (including locations and other parameters) are the most appropriate investment criteria? The essential data have been gathered from library resource like books, scientific journals and internet base resources like internet gateways, online services, FAO (Food and Agriculture Organization) database, published documents, reports of prior research studies and organization‘s own data archive. The time dimension of the project is cross-sectional. The topical scope of the project is statistical. The research environment of the project is field condition. The type of research design is two-stage design that means both qualitative research and quantitative research has been used in the research project. To increase confidentiality of the project and be sure on research conclusion, Individual Depth Interview (IDI) has been done with ten selected Proceedings of 7th Global Business and Social Science Research Conference 13 - 14 June, 2013, Radisson Blu Hotel, Beijing, China, ISBN: 978-1-922069-26-9 pistachio producers and intermediaries (see Appendix) and Self-Administered Survey (see Appendix) has been done with some pistachio growers, producers, researchers, exporters and finally the people who are involved in pistachio supply chain. The sampling method which has been used in the interview is non-probability, restricted purposive sampling. The type of the interview is structured interview. The instruments which have been used are paper-and-pencil and Computer Assisted Personal Interview (CAPI). The sampling method which has been used in survey is probability, restricted cluster sampling. The type of the survey is Self-Administered survey which has been performed by email, fax and cell phone. The type of measurement scales which have been used in survey are ranking (choice) scale, multidimensional, both balanced and unbalanced and finally unforced scales. Also, multiple choice, single response scale and Likert scale have been used in survey. 4. The findings According to the challenges and problems which were described, some data were to gather and analyze quantitatively which were done by Self Administered Survey (see Appendix). Also, some information has collected by Individual Depth Interview. All of the gathered information and data helps to provide appropriate solutions and recommendations for problems and challenges which can pistachio producers have been faced. The target population for Individual Depth Interviews was Bazaar of Tehran pistachio intermediaries. The target population for Self Administered Survey was pistachio growers, producers, researchers, exporters and finally the people who are involved in pistachio supply chain. The sample size was determined by following approach; Expected Interval estimate of Population Proportion = ±10 Z = 1.96 (Confident level of 95%) σp = ±0.1Z = ±0.11.96 = 0.051 Standard error of the proportion (Donald R. Cooper 2008) pq = 0.5*0.5 = 0.25 Sample Dispersal Measure; assumed high values to be included n = sample size (Donald R. Cooper 2008) The survey was done and responses were gathered .According to the frequencies and descriptive statistics of question 1 responses, 43% of respondents indicated HACCP as the most appropriate standard in order to apply in pistachio production. However, 29% respondents had no opinion about appropriate standards for pistachio production. The median is 5 which mean that more than half of the respondents have indicated HACCP and no opinion responses and others have indicated ISO standards. The mode is 5 which means that HACCP is the most favorable to be applied in pistachio production. The result is leptokurtic with negative skew (see Table 1) Proceedings of 7th Global Business and Social Science Research Conference 13 - 14 June, 2013, Radisson Blu Hotel, Beijing, China, ISBN: 978-1-922069-26-9 Table 1: Frequencies and Descriptive Statistics of Question 1 To be sure about the result, hypothesis is stated as below; Null H0: Accept the results Alternative HA: Reject the Results Proceedings of 7th Global Business and Social Science Research Conference 13 - 14 June, 2013, Radisson Blu Hotel, Beijing, China, ISBN: 978-1-922069-26-9 With 95% confident level (α = 0.05), Z score is mentioned in descriptive statistics to be 0.286727 (see Table 1). Then, Z score is put in standard normal distribution to find the area between mean and Z score which is 0.11258. To determine Power of test, β is calculated as below; β = 0.5 – 0.11258 = 0.38742 Power of test = 1 – β = 1 – 0.38742 = 0.61258 To determine P value, Z score is put in standard normal distribution to find the area between mean and Z score which is 0.11258. Then, P value is calculated as below; P value = 0.5000 – 0.11258 = 0.38742 Therefore, with 61% Power of test, confident level of 95% and P value of 0.38742, it can be mentioned that 43% of Iranian pistachio producers indicated HACCP as appropriate standard in pistachio production, following 9% ISO 9000, 8% ISO 22000, 7% ISO 22005 and 4% ISO 31000 respectively. Also, 29% of Iranian pistachio producers had no opinion about appropriate international standards in pistachio production (see Figure 1). Figure 1: Discovering Appropriate International Standards in Pistachio Production According to the frequencies and descriptive statistics of question 2 responses, totally 74% of respondents agreed the execution of International Standards in pistachio production. However, 19% of respondents totally did not agree execution of International Standards in pistachio production. The median is 4 which mean that more than half of the respondents have agreed about the statement and others did Proceedings of 7th Global Business and Social Science Research Conference 13 - 14 June, 2013, Radisson Blu Hotel, Beijing, China, ISBN: 978-1-922069-26-9 not. The mode is 4 which mean that agree choice is the most favorable ones. The result is playkurtic with negative skew (see Table 2). Table 2: Frequencies and Descriptive Statistics of Question 2 To be sure about the result, hypothesis is stated as below; Null H0: Accept the results Alternative HA: Reject the Results With 95% confident level (α = 0.05), Z score is mentioned in descriptive statistics to be 0.235154 (see Table 2). Then, Z score is put in standard normal distribution to find the area between mean and Z score which is 0.0929. To determine Power of test, β is calculated as below; β = 0.5 – 0.0929 = 0.4071 Power of test = 1 – β = 1 – 0.4071 = 0.5929 To determine P value, Z score is put in standard normal distribution to find the area between mean and Z score which is 0.0929. Then, P value is calculated as below; P value = 0.5000 – 0.0929 = 0.4071 Therefore, with 59% Power of test, confident level of 95% and P value of 0.4071, it can be mentioned that 40% of Iranian pistachio producers agreed the execution of Proceedings of 7th Global Business and Social Science Research Conference 13 - 14 June, 2013, Radisson Blu Hotel, Beijing, China, ISBN: 978-1-922069-26-9 International Standards in pistachio production, following 34% strongly agree, 17% disagree, 6% no opinion and 3% strongly disagree respectively( see figure 2). Figure 2: Execution of International Standards in Pistachio Production According to the frequencies and descriptive statistics of question 3 responses, totally 51% of respondents agreed to apply vertical integration in pistachio production. However, 44% respondents did not agree the statement. The reason seems to be the threats that members of pistachio supply chain may face due to the profits which they gain and loose them when the entry to their sector would be increases. The median is 4 which mean that more than half of the respondents agreed to apply vertical integration in pistachio production and others did not. The Mode is 4 which mean that agree choice is the most favorable one. The result is playkurtic with negative skew (see Table 10.4). To be sure about the result, hypothesis is stated as below; Null H0: Accept the results Alternative HA: Reject the Results With 95% confident level (α = 0.05), Z score is mentioned in descriptive statistics to be 0.291954 (see Table 3). Proceedings of 7th Global Business and Social Science Research Conference 13 - 14 June, 2013, Radisson Blu Hotel, Beijing, China, ISBN: 978-1-922069-26-9 Table 3: Frequencies and Descriptive Statistics of Question 3 Then, Z score is put in standard normal distribution to find the area between mean and Z score which is 0.11486. To determine Power of test, β is calculated as below; β = 0.5 – 0.11486 = 0.38514 Power of test = 1 – β = 1 – 0.38514 = 0.61486 To determine P value, Z score is put in standard normal distribution to find the area between mean and Z score which is 0.11486. Then, P value is calculated as below; P value = 0.5000 – 0.11486 = 0.38514 Therefore, with 61% Power of test, confident level of 95% and P value of 0.38514, it can be mentioned that 29% of Iranian pistachio producers agreed to apply vertical integration in pistachio production, following 28% disagree, 22% strongly agree, 16% strongly disagree and 5% ISO no opinion respectively (see Figure 3). Proceedings of 7th Global Business and Social Science Research Conference 13 - 14 June, 2013, Radisson Blu Hotel, Beijing, China, ISBN: 978-1-922069-26-9 Figure 3: Application of Vertical Integration in Pistachio Production According to interviewee‘s expressions, pistachio is the essential and strategic product due to its nutritional and medical values. It is cultivated in both traditional and modern approaches depend on political, economical and environmental conditions of pistachio producing countries. But success in production depends on pursuing mechanization, applying modern knowledge and technologies, owning adequate harvested area and experience in production, establishing efficient infrastructures, pricing systems, advertisements and well supply chain management. They indicated alternate bearing, pests and diseases, nutritional and environmental factors as critical factors in pistachio production. Also, they demonstrated the Aflatoxin contamination as critical factors in exportation which restricts international trade of pistachio. To dominate such a challenge, the pistachio producers should apply international standards in cultivation; production and etc. 5. Summary and Conclusions The problems which cause challenges in international trade of pistachio are classified in two categories; problems in production and problems in trade. The problems in production which were considered such as delayed harvest, blank nuts, alternate bearing, pest and diseases dangers and Aflatoxin contamination are only controlled by correct and efficient operation management and applying modern knowledge and technologies. Problems in trade contain the countries economical, political conditions, trade barriers, nontrade barriers and governmental relationships among nations which may facilitate or restricts the international trades. The cases in this category which were considered before are international standards and free trade agreements that affect export quantities and pistachio‘s price in intensive competition. As results of survey Proceedings of 7th Global Business and Social Science Research Conference 13 - 14 June, 2013, Radisson Blu Hotel, Beijing, China, ISBN: 978-1-922069-26-9 illustrate that large share of respondents (43%) have indicated that HACCP is the most efficient standard in pistachio production, however considerable share of those has had no opinion about appropriate standards in pistachio production. It can be done by directing hazard analysis, recognizing critical levels of dangers and setting a critical limit, performing supervision activities, corrective actions and record keeping procedures to ensure product‘s safety. It facilitates Iranian firms to export pistachio easily to international market especially European nations. Moreover, transnational strategy helps Iranian firms to join the benefits of global scale efficiencies such as location efficiencies with the advantages and benefits of local responsiveness. Location efficiencies can be obtained by locating facilities anywhere worldwide which charges the firm the lowest production and distribution costs or helps it to improve quality of service it offer to customers. Foreign Direct Investment helps to achieve location efficiencies through ownership and control of capitals in foreign countries. For example, to achieve benefits of global free trade agreements and unions, Iranian firms can own factories and facilities in other pistachio producing nations such as China, Mexico Morocco and Tunisia based on production and distribution cost in host countries, distance to target markets and global organizations, unions and free trade agreements which host countries are member in them. References Abdolahiezatabadi, M., 2008. Role of uncoordinated policy making in unsustainable pistachio acreage expansion with regards to water resources. Journal of the agricultural planning and economic research institute, p. 9. Alavi., 2007. iran-daily.com. [Online] Available at: http://web.archive.org/web/20080617044222/irandaily.com/1386/2887/html[Accessed 29 November 2010]. Arize, A., 2001. Traditional Export Demand Relation and Parameter Instability. Journal of Economic Studies, pp. 378-396. Bahmani-Oskooee, 1986. Determination of International Trade Flows. Journal of Development Economics, Volume 20, pp. 107-123. Berck, P. and J. M. Perloff, 1985. A Dynamic Analysis of Marketing Orders,Voting, and Welfare.. American Journal of Agricultural Economics, pp. 487-96. BorhanZadeh, A., 2011. Research on History, Market and International Trade of Pistachio Industry in Iran. [Online] Available at: http://www.dissertationtopic.net/doc/1509584. [Accessed 2011]. Charles W.L, H., 2009. International Business: Competing In the Global Marketplace. Seventh ed. New York: McGraw-Hill. Dahl, F., 2009. http://www.reuters.com/article/2008/10/09/us-iran-pistachiosidUSTRE49806E20081009. [Online] Available at: http://www.reuters.com [Accessed 2011]. Dr. Federico, G. T. B. M. G. T. M., 2011. A Critical Analysis of the Competitiveness of the Iranian Pistachio Industry. International Journal of Business and Social Science. FAO, 2004. Impact of food safety standards on food and agricultural trade in the near east.. Doha, Qatar, FAO. Proceedings of 7th Global Business and Social Science Research Conference 13 - 14 June, 2013, Radisson Blu Hotel, Beijing, China, ISBN: 978-1-922069-26-9 Kader,C.M. Heintz,J.M. Labavitch and H.L. Rae, 1982. Studies related to the description and evaluation of pistachio nut quality. Journal of the American Society for Horticultural Science, p. 107. Kader,Mitchell and N.F. Sommer, 1980. Quality and Safety of Pistachio nuts as influenced by postharvest handling procedures. The Pistachio Assoc. Ann. Rpt, pp. 44-52. KarimKoshteh, M., and Vardan, U, 2003. ttp://www.economics.ca/2003/papers/0460.pdf. [Online] Available at: http://www.economics.ca/2003/papers/0460.pdf [Accessed 14 May 2011]. Koshteh, K., 2005. Global pistachio production and marketing challenges. Indian Journal of Economics and Business, Volume Vol. 4 Nbr. 1. Majlis, 2010. http://www.majlis.ir/new-majlis.swf. [Online] Available at: http://www.majlis.ir/new-majlis.swf[Accessed 15 July 2011]. Ricky W. Griffin,Michael W. Pustay, 2008. International Businees: A Managerial Perspective.. s.l.:Pearson International Edition - Prentice Hall. Sedaghat, R., 2008. An economic analysis of pistachios production, processing and trade in Iran, Bangalore, India: University of Agriculture Sciences. Zijuan Zheng,Sayed Saghaian,Michael Reed, 2012. Factors Affecting the Export Demand for U.S. Pistachios. International Food and Agribusiness Management Review, Volume 15(3, 2012). Proceedings of 7th Global Business and Social Science Research Conference 13 - 14 June, 2013, Radisson Blu Hotel, Beijing, China, ISBN: 978-1-922069-26-9 Appendix Self Administered Survey Questionnaire 1. Which International Standards that are indicated below are appropriate for pistachio production? 1) ISO 9000 2) ISO 22000 3) ISO 22005 4) ISO 31000 5) HACCP 6) No Opinion 2. Indicate your idea in form of multiple choice options about below statement; ―As establishment and running International Standards in pistachio production is cost-consuming (expensive), pistachio producers should establish and run International Standards in production process‖. 1) Strongly Disagree 2) Disagree 3) No Opinion (Neither Agree nor Disagree) 4) Agree 5) Strongly Agree 3. Indicate your idea in form of multiple choice options about below statement; ―To succeed in production, pistachio producers should be active in all parts of supply chain. It means that they should establish their own orchards, owning preparation and processing facilities, owning distribution and transportation equipment and exporting‖. 1) Strongly Disagree 2) Disagree 3) No Opinion (Neither Agree Nor Disagree) 4) Agree 5) Strongly Agree Individual Depth Interviews 1. How big is the world‘s pistachio market regarding unit size and sales volumes? 2. Do the pistachio producers have the same experience all around the world? 3. Do the customers have the same expectations all around the world? 4. Do the pistachio producers sell their products with same price all around the world? 5. Do the customers have the same purchasing power and purchasing habits all around the world? 6. Do the pistachio producers use the same knowledge and technology for production all around the world? Proceedings of 7th Global Business and Social Science Research Conference 13 - 14 June, 2013, Radisson Blu Hotel, Beijing, China, ISBN: 978-1-922069-26-9 7. Which set of pistachio producers have been successful in production and which not? What was the reason of their success? 8. What are the major factors that reduce the quantity of Pistachio Production? 9. What are the major factors that reduce the quality of Pistachio Production? 10. How much is the rate of wastes or damages in pistachio‘s production and distribution in Iran? 11. What are the main problems in selling and exporting of the pistachio in terms of trade barriers and non-trade barriers aspect? 12. What are the main foreign competitor‘s characteristics in terms of size? 13. What are the main foreign competitor‘s characteristics in terms of utilization capacity? 14. What are the main foreign competitor‘s characteristics in terms of strengths and weaknesses? 15. What are the main foreign competitor‘s characteristics in terms of supply sources? 16. What is domestic and foreign competitor‘s performance regarding of market share and sales growth? 17. What changes have happened in foreign rival‘s performance? 18. What is the future prospect of pistachio‘s international trade?