Investigational Analysis of NO Reduction in x

advertisement

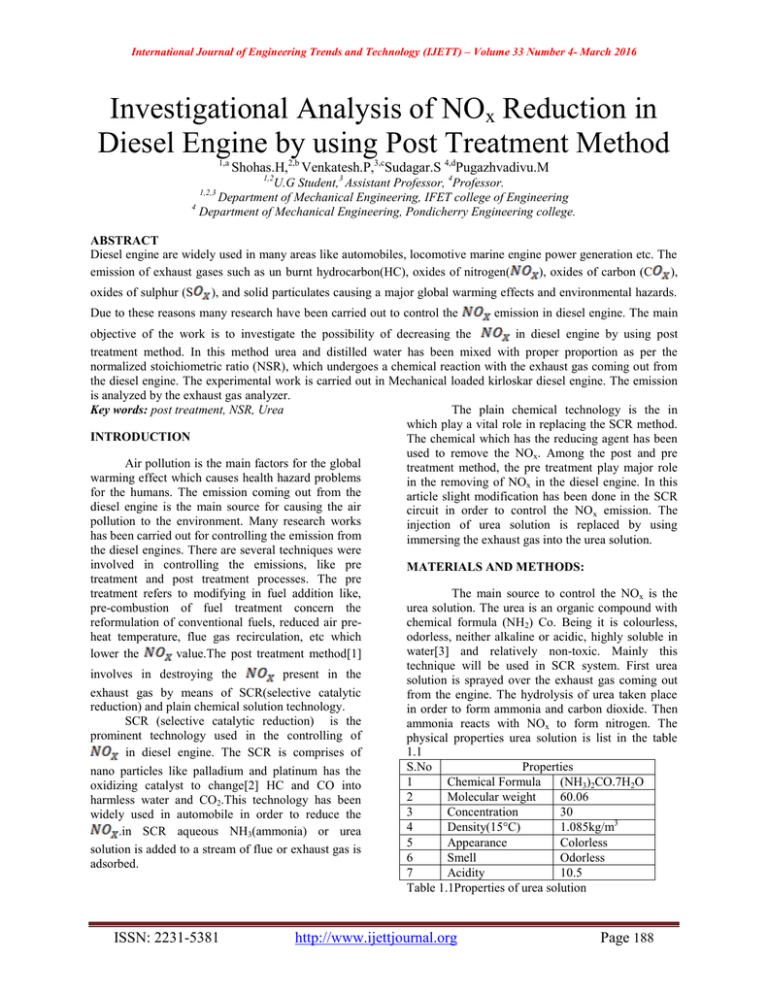

International Journal of Engineering Trends and Technology (IJETT) – Volume 33 Number 4- March 2016 Investigational Analysis of NOx Reduction in Diesel Engine by using Post Treatment Method 1,a Shohas.H,2,b Venkatesh.P,3,cSudagar.S 4,dPugazhvadivu.M 1,2 U.G Student,3 Assistant Professor, 4Professor. Department of Mechanical Engineering, IFET college of Engineering 4 Department of Mechanical Engineering, Pondicherry Engineering college. 1,2,3 ABSTRACT Diesel engine are widely used in many areas like automobiles, locomotive marine engine power generation etc. The emission of exhaust gases such as un burnt hydrocarbon(HC), oxides of nitrogen( ), oxides of carbon (C ), oxides of sulphur (S ), and solid particulates causing a major global warming effects and environmental hazards. Due to these reasons many research have been carried out to control the emission in diesel engine. The main objective of the work is to investigate the possibility of decreasing the in diesel engine by using post treatment method. In this method urea and distilled water has been mixed with proper proportion as per the normalized stoichiometric ratio (NSR), which undergoes a chemical reaction with the exhaust gas coming out from the diesel engine. The experimental work is carried out in Mechanical loaded kirloskar diesel engine. The emission is analyzed by the exhaust gas analyzer. The plain chemical technology is the in Key words: post treatment, NSR, Urea which play a vital role in replacing the SCR method. INTRODUCTION The chemical which has the reducing agent has been used to remove the NOx. Among the post and pre Air pollution is the main factors for the global treatment method, the pre treatment play major role warming effect which causes health hazard problems in the removing of NOx in the diesel engine. In this for the humans. The emission coming out from the article slight modification has been done in the SCR diesel engine is the main source for causing the air circuit in order to control the NOx emission. The pollution to the environment. Many research works injection of urea solution is replaced by using has been carried out for controlling the emission from immersing the exhaust gas into the urea solution. the diesel engines. There are several techniques were involved in controlling the emissions, like pre MATERIALS AND METHODS: treatment and post treatment processes. The pre treatment refers to modifying in fuel addition like, The main source to control the NOx is the pre-combustion of fuel treatment concern the urea solution. The urea is an organic compound with reformulation of conventional fuels, reduced air prechemical formula (NH2) Co. Being it is colourless, heat temperature, flue gas recirculation, etc which odorless, neither alkaline or acidic, highly soluble in water[3] and relatively non-toxic. Mainly this lower the value.The post treatment method[1] technique will be used in SCR system. First urea involves in destroying the present in the solution is sprayed over the exhaust gas coming out exhaust gas by means of SCR(selective catalytic from the engine. The hydrolysis of urea taken place reduction) and plain chemical solution technology. in order to form ammonia and carbon dioxide. Then SCR (selective catalytic reduction) is the ammonia reacts with NOx to form nitrogen. The prominent technology used in the controlling of physical properties urea solution is list in the table 1.1 in diesel engine. The SCR is comprises of S.No Properties nano particles like palladium and platinum has the 1 Chemical Formula (NH3)2CO.7H2O oxidizing catalyst to change[2] HC and CO into 2 Molecular weight 60.06 harmless water and CO2.This technology has been 3 Concentration 30 widely used in automobile in order to reduce the 4 Density(15°C) 1.085kg/m3 .in SCR aqueous NH3(ammonia) or urea 5 Appearance Colorless solution is added to a stream of flue or exhaust gas is 6 Smell Odorless adsorbed. 7 Acidity 10.5 Table 1.1Properties of urea solution ISSN: 2231-5381 http://www.ijettjournal.org Page 188 International Journal of Engineering Trends and Technology (IJETT) – Volume 33 Number 4- March 2016 EXPERIMENTATION: The experiments were carried out in the I.C engine with mechanical loaded system. The specifications of IC engine were listed in the table 1.2. The experiment was conducted at different load condition[4] and the NOx were analyzed by using gas analyzer. During the experimentation process urea solution has been prepared as NSR ratio of 30% of urea per liter of water. The solution is kept in a separate tank as shown in the fig1.1. In this experimentation process injection of urea solution is replaced by immersing the exhaust gas into the urea solution in order to achieve emission control. Name Specification Make Kirloskar Bore 87.5mm Stroke 110mm Orifice Dia 0.02m Speed 1500rpm Comp.Ratio 16:1 Coolant water Table 1.2 Specifications of I.C Engines. The following reaction has been taken place in order to reduce the NOx. (NH2)2 2CO + 7H2O CO2 + 2NH3 Nitrogen oxides conversion: 4NO +4NH3+O2 6NO2 + 8NH3 After the reaction the exhaust gas is lead to the atmosphere through the pipeline of length 200mm, which placed at the top of the tank as shown fig 1.1& 1.2. The gas analyzer has been placed at the end of this pipe (outlet pipe line) in order to test the emission of the diesel engine. Fig1.2 Setup Diagram Result and discussion: With different load conditions the NOx value were analysed for no treatment and post treatment technology [5] the results were tabulated in the tabulation 1.3 &1.4. It indicates the lower of NOx take place only in the post treatment technology (Immersing the exhaust into the urea solution). First tabulation indicates the emission test carried out without any treatment of the exhaust gas from the engine. 4N2+6H2O 7N2 + 12H2O S.No Load Exhaust CO temp. Units kW °C % 1 0 52 0.91 2 0.6 60 0.103 3 1.2 72 0.135 4 1.8 80 0.150 Table1.3 Without post treatment CO2 NOx % 2.92 4.27 5.38 6.41 PPM 1121 2087 3045 4163 The second tabulation indicates the post treatment method by means immersing the exhaust gas into the urea solution. Fig1.1 Line Diagram of Tank SETUP DESCRIBTION: The urea solution is prepared as the NSR ratio and it is kept inside separate tank, of length 500m.the exhaust pipeline from the engine has been inserted into the tank at the length of 400m.the pipeline which is inserted have been pierced about 200mm in order to reduce the pressure inside the cylinder and also to react with the solution properly. ISSN: 2231-5381 S.No Load Exhaust CO CO2 temp. Units kW °C % % 1 0 37 0.030 2.50 2 0.6 45 0.042 3.54 3 1.2 57 0.058 4.52 4 1.8 60 0.062 5.33 Table1.4 urea solution (post treatment) http://www.ijettjournal.org NOx PPM 0558 0957 1937 2542 Page 189 International Journal of Engineering Trends and Technology (IJETT) – Volume 33 Number 4- March 2016 CNCLUSION: In this investigation it is analyzed that carbon monoxide and nitrogen oxides are controlled by post treatment technology (Immersing the exhaust gas into the urea solution) in the diesel engine the following conclusion have been achieved. Comparing with the normal emission in diesel engine, the NO x emission is lowered in post treatment. REFERENCES: [1]Mary Kay Camarillo, William T. Stringfellow, Kyle A.Watson and Jereny S. Hanlon, “ Investigation of selective catalytic reduction for control of nitrogen oxides in full-scale dairy energy production ”, Applied energy, (June 2013), Vol.106,Pg. 328-336. [2] Sounak Roy, M.S.Hedge and Giridhar Madras, “ Catalysis for NOx abatement – Review ”, Applied Energy, (Nov-2009), Vol.86, Pg. 2283-2297. [3] Zengying ziang, Xiaoqian Ma, Hai Lin and Yuting Tang, “ The Energy Consumption and Environmental impacts of SCR technology in china ”,Applied energy, (April 2011), Vol.88, Pg. 1120-1129. [4] Lei Jiang, “ Unregulated emissions from a diesel engine equipped with vanadium-based urea-Selective Catalytic Reduction System catalyst ”, Journal of Environmental Sciences 2010, 22(4) 575–581. [5]Hidekatsu Fujishima, Kenichi Takekoshi, Tomoyuki Kuroki, Keichi Otsuka, Masaaki Okubo and Atsushi Tanaka, “ Towards ideal NOx control technology for Bio-Oils and a gas multi-fuel boiler system using a plasma-chemical hybrid process”, Applied energy, (Nov 2013), Vol.111, Pg. 394-400. ISSN: 2231-5381 http://www.ijettjournal.org Page 190