To Investigate the Effect of Process Parameters on Surface

advertisement

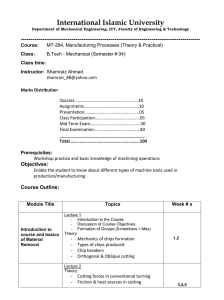

International Journal of Engineering Trends and Technology (IJETT) – Volume 25 Number 1- July 2015 To Investigate the Effect of Process Parameters on Surface Roughness of Aisi1045 Steel in Dry Machining with CBN Cutting Tool Using ANOVA Ramyasree Keerthi1, Anitha Lakshmi Akkireddy2 1 Department of Design for manufacturing, JNTU University, HYDERABAD, India 2 Department of Mechanical Engineering, JNTU University, HYDERABAD, India Abstract Machining without the use of any cutting fluid is becoming more popular due to concern regarding safety of the environment . Most of the industries spend around 16-20% of manufacturing cost on the cutting fluids/coolants. So the extravagant usage of these fluids can be restricted by using Dry/ Green machining. Dry Machining is a machining process without coolant and it is more popular as a finishing process. The purpose of this research project is to obtain a comprehensive understanding of the Relationships between input parameters i.e. cutting speed, feed and depth of cut and output parameter i.e. surface roughness (Ra) of AISI1045 in Dry Machining with Cubic Boron Nitride (CBN) cutting tool. In present study the experimentation will be carried out using orthogonal arrays designed using Taguchi technique. Analysis of the test results will be done using ANOVA. direct contact of coolants has lead to the following advancements: 1. An under-cooling system, where the coolant flows through channels located under the insert, then out to the environment, without any direct contact with the cutting zone. 2. Internal cooling by a vaporization system, in which a vaporizable liquid is introduced inside the shank of the tool and vaporized on the underside surface of the insert. 3. Cryogenic systems, where a stream of cryogenic coolant is routed internally through a conduit inside the tool. Keywords: Dry machining, surface roughness (Ra) and sensitivity analysis. I-INTRODUCTION Machining process is a metal cutting operation by which finished surface of desired shape and dimensions are obtained by separating a layer from the parent work piece by pressing a wedge shape device cutting tool to the work piece. 1.1.2 Concept of Dry Machining Dry machining is also a process of metal removal but it does not involve the use of wet cutting fluids that are hazardous to environment and also costs sufficiently high. Manufacturers all over the world are trying to discover new method to eliminate the use of cutting fluids. According to studies carried out. The United States of America 15% of the cost of the production is spent in purchase, storage, handling, utilization and safe disposal of the fluid. 4. Thermoelectric cooling systems, using a module of couples of thermoelectric material elements. When an electric current is passed through the thermoelectric elements, a cold junction and a hot junction is produced at the opposite ends of each of these elements. Another approach is to improve the properties of the tool material by making them more refractory or generate less heat during machining. There has been a continuous development in the field of cutting-tool materials starting with HSS, cobalt alloys, cemented tungsten carbide, coated carbide and coated HSS, cubic boron nitride and diamond. However, the need for machining with increasingly higher cutting speeds and also to machine difficult-tomachine materials is imposing pressure for the development of new tool materials. As a result, newer tool materials such as ceramics and also different types of coatings on the tool materials will address the problems in dry machining to some extent. 1.1.4 EFFECT MACHINING OF TEMPERATURE ON 1.1.3 DEVELOPMENTS IN DRY MACHINING To pursue dry machining, one has to compensate for the beneficial effects of cutting fluids. One approach towards dry machining is to have an indirect contact of coolants and thereby take away the heat generated. Research in the area of dry machining without the ISSN: 2231-5381 The performance of a cutting tool is dependent on the form stability of the cutting wedge, which in turn is mostly dependent on the effective/working hardness and thermal conductivity of the tool/work materials. The working hardness of the tool material is related to the hot-hardness characteristics of the tool material. Typical hot-hardness characteristics of different tool http://www.ijettjournal.org Page 15 International Journal of Engineering Trends and Technology (IJETT) – Volume 25 Number 1- July 2015 materials are illustrated in Fig.1.3. It can be seen that, barring carbon steel and high speed steel (HSS) materials, all other tool materials exhibit a steady reduction in hardness with increase in temperature. [2] The temperature of machining is dependent on the cutting speed V and the type of material pair involved in machining and can be expressed as 1.1.5 THE DRY MACHINING CHALLENGE Fig.1.4 Typical hot-hardness characteristics of some tool materials 1.1.6 COMPARISION OF DRY MACHINING AND WET MACHINING The hardness of the tool material is selected so as to maintain consistent replication of its nose on the work surface, to maintain the desired surface texture. A reduction in tool material hardness with increase in temperature (due to the increased velocity) is to be limited so that a high degree of fidelity of nose replication can be maintained. This calls for limiting the temperature of machining, which can be attempted by limiting the speed of machining. The situation is more aggravated during the machining of heatinsulating materials. The significance of machining speed on the machining performance is illustrated in Fig.1.4. It is seen that a range of cutting speed can offer a highly efficient machining performance. This is again reflected in the need for controlling the machining temperature within limits for achieving good machining performance. This aspect of a temperature limit for economical machining has to be taken into consideration for dry machining. Metalworking is composed of a number of different machining operations that place different requirements on the lubricants. Other parameters that must be considered are the alloy of metal being machined, the machine tool and the cutting tool used in the process. Some machining operations are more amenable to dry machining than others. Open faced operations such as milling and boring can be effectively run dry, the resulting chips can be easily moved away from the tool/work piece interface. In these cases, there is no need of lubricity and heat generated can be managed. In contrast, closed face machining operations such as drilling and tapping cannot be efficiently run dry because the metal chip remains in close proximity to the tool/work piece interface. this possibility increases the prospects of chips damaging the tool and the work piece surface because there is no mechanism in place for their removal. Dry Machining Wet Machining Ecologically desirable. Coolants used contain harmful chemical reagents therefore not eco-friendly. Cost efficient. Coolants add up to some extra cost. Tool life is increased by Thermal shocks are a eliminating common thermal occurrence shocks. because of flood coolant. No residue is left on the Disposal and cleaning swarf causes reduced costs are more because and cleaning of the residual deposits disposal costs. Do on the swerve. not cause health Causes health problems. problems. Contact time of tool is Tool contact time is a short hence will last long. little longer which causes tool wear. Table 1.1 Comparison between dry machining and wet machining Fig.1.4. Illustration showing the significance of machining speed on machining performance ISSN: 2231-5381 http://www.ijettjournal.org Page 16 International Journal of Engineering Trends and Technology (IJETT) – Volume 25 Number 1- July 2015 1.1.7 DRY MACHINING OF COMMON METALS The dry machining of cast iron is not exactly new. Cast iron can be cut dry in turning and milling operations. The dry machining of cast iron has been attempted using ceramic cutting materials and CBN at high surface speeds and feed rates by Spur and Larchmont. They found that since CBN tools have the highest thermal conductivity compared with the ceramic type of tools, CBN was able to remove the heat efficiently from the cutting material. Hence they concluded that CBN tools were highly suited for the dry machining of cast iron at high cutting speeds. this reason dry machining can be recommended for interrupted cutting. Aluminum and its alloys are considered to be the most critical materials with regard to dry machining. Because of their higher thermal conductivity, the work piece absorbs considerable heat from the machining process and may cause deformation due to its higher thermal expansion capabilities. In addition aluminum alloys may cause problems related to chip formation. Hence in the machining of aluminum and its alloys, it is essential to use tools with suitable coatings. The main issues that have to be considered for the dry machining of non-ferrous metals Cast iron can also be dry milled with the cermets type of tools at high speeds. Here the high speed employed is not to reduce the machining time, but to reduce the tool and work piece contact time to prevent the heat of the chip penetrating the tool. are the achieving of higher spindle speeds, the improvement of chip ejection geometry and the design of better tooling. Diamond tools will be a major enabler of this technology because of their high thermal coefficient, fast heat diffusion, no affinity for Drilling is the most widely used process in the steel industry due to the assembly of components. The main problem associated aluminum and the possibility of diamond being used as a coating for other shaped tools. with the dry drilling of steel is the removal of chips from the drilled hole. One approach to reduce this problem is to enlarge the flutes 1.1.8 Advantages and Limitations Machining :A. Advantages of Dry Machining of Dry and thereby giving the chips more space, helping them to come out of the hole. Another problem that can be encountered is the jamming of the drilled hole due to the expansion of the drill at high temperatures. One way of correcting this problem is to give more drill taper towards the shank. For the continuous high speed machining of super alloys and titanium, cooling B. LIMITATIONS OF DRY MACHINING is necessary. However, in an interrupted cutting environment, the coolant if used induces thermal shocks on any cutting material. For ISSN: 2231-5381 Complete elimination of harmful cutting fluid It eliminates costs involved in purchase, storage, handling, utilizing and safe disposal of the fluid. High cutting speeds can be achieved with improved surface finish. Reduction in overall production time and improved working conditions. While the technology to carry out dry machining has improved, metalworking fluid is needed to ensure that higher speeds and feeds can be used and to ensure that the surface finish of work pieces meets expectations. The new tool coatings have been helpful but still the problem exists that machining cannot be done dry at http://www.ijettjournal.org Page 17 International Journal of Engineering Trends and Technology (IJETT) – Volume 25 Number 1- July 2015 the rate needed to achieve the productivity found with using metalworking fluids. 3. Closely related to the ANOVA is a linear model fit with coefficient estimates and standard errors. 2. ANALYSIS OF VARIANCE 4. TAGUCHI METHOD 2.1.1 WHAT IS AN ANALYSIS OF VARIANCE? a Taguchi’s parameter design offers a systematic statistical method used to compare two or approach for optimization of various parameters with more means regard to performance, quality and cost. Analysis Inferences of Variance about (ANOVA) means are is made by analyzing variance (therefore it is not called analysis of mean) ANOVA is used to test general rather than specific differences among means You might be wondering why you should learn about ANOVA when the Turkey test is better. One reason is that there are complex What is Taguchi method? The design of experiments using the orthogonal array is, in most cases, efficient when compared to many other statistical designs. The minimum number of experiments that are required to conduct the Taguchi method can be calculated based on the degrees of freedom approach. 4. RESEARCH METHODOLOGY types of analyses that can be done with ANOVA and not with the Tukey test. A Considering the input parameters of cutting second is that ANOVA is by far the most speed, feed rate and depth of cut, the L9 commonly-used technique for comparing Orthogonal means, and it is important to understand parameters is proposed, using Taguchi ANOVA in order to understand research techniques through the design of experiment. reports. The machining is done using the obtained array of optimized input optimized input parameters and the surface it roughness values are recorded. Then the is used for multiple purposes. As a consequence, it is Analysis of variance (ANOVA) is used to difficult to define concisely or precisely. find which parameter has significant effect "Classical ANOVA for balanced data does three on output parameter i.e. surface roughness. things at once: After developing the model, confirmation ANOVA is the synthesis of several ideas and 1. 2. As exploratory data analysis, an ANOVA is tests are conducted with values, within the an data range of selected machining parameters. The decomposition, and its sums of squares error percentage is then determined using the indicate the variance of each component of experimental values, obtained from the the decomposition (or, equivalently, each set confirmation tests and predicted values, of terms of a linear model). calculated from the mathematical model. Comparisons of mean squares, along with F- International Conference on Advances in tests ... allow testing of a nested sequence of Design and Manufacturing organization of an additive models. ISSN: 2231-5381 http://www.ijettjournal.org Page 18 International Journal of Engineering Trends and Technology (IJETT) – Volume 25 Number 1- July 2015 II-LITERATURE REVIEW Reference [1]has reviewed the impact of dry machining in the coming future and found that dry machining requires suitable measures to compensate for the absence of coolants. Dry machining is only possible when all the operations can be done dry. Technology has to be further improved if dry cutting is to be fully employed in industries. As the costs for machine will continue to turn out parts under the occasional supervision of an operator. The machine is controlled electronically via a computer menu style interface, the program may be modified and displayed at the machine, along with a simulated view of the process. The setter/operator needs a high level of skill to perform the process. The CNC lathe greatly reduces human error overall and can lead to a more productive and efficient manufacturing environment. Dry turning is done on the work piece material using CNC lathe Siemens 802 D SL as shown in the fig.3.1. The specifications of the CNC lathe are mentioned in the table 3.1. waste each parameter preliminary experiments had to be conducted. These preliminary experiments showed that the value of surface roughness is less between the speeds from 100 m/min to 250 m/min and feed rate from 0.02 mm/rev. to 0.04 mm/rev. The final result shows the significance of each machining parameter individually on the surface integrity and a model to predict the value of surface roughness between that Fig.3.1 CNC Lathe 802 D SL particular range of cutting parameters. III. EXPERIMENTATION 3.1 INTRODUCTION In this chapter the machinery, instrumentation and other equipment used during the course of the project are clearly discussed. Taguchi’s design of experiments and the step by step experimentation are elaborately discussed. By using plan of tests to study the influence of input parameters i.e. cutting speed, feed rate and depth of cut on output parameter i.e. surface roughness of AISI 1045 steels can be acknowledged. Analysis can be conducted using a statistical tool with aid of various plots like main effect plots and surface plots which are discussed. By using Anova is developed and sensitivity analysis carried out to measure the relative significance of the input parameters on AISI1045 steel with respect to the output parameters. 3.2 CNC LATHE Computer numerical controlled (CNC) lathes are rapidly replacing the older production lathes (multi spindle, etc.) due to their ease of setting, operation, repeatability and accuracy. They are designed to use modern carbide tooling and fully use modern processes. The part may be designed and the tool paths programmed by the CAD/CAM process or manually by the programmer, and the resulting file uploaded to the machine, and once set and trialed the ISSN: 2231-5381 Table 3.1 Specifications of CNC Lathe 802 D SL 3.2 DIGITAL SURFACE ROUGHNESS TESTER Digital surface roughness tester is used for quick, easy and accurate measurement of the surface roughness values of a machined component. The fig.3.2 represents the digital surface roughness tester used for the measurement of surface roughness values(Ra)Ra is http://www.ijettjournal.org Page 19 International Journal of Engineering Trends and Technology (IJETT) – Volume 25 Number 1- July 2015 defined as the arithmetic averageroughness. Fig.3.2 Digital surface roughness tester This accurate and reliable instrument offers complete flexibility and simplicity: - Parameter Options to suit your application - Fast Measurement Cycle - Intuitive Menu Structure - Unique Stylus Lift Mechanism for total flexibility - Long Traverse Length and extended Pick-up reach - Storage of up to 100 readings - Powerful software option - Worldwide technical support experimental runs to be carried out without affecting the quality of the analysis. These orthogonal arrays are derived using factorial design which can be a full factorial design or a fractional factorial design. A full factorial design is the one in which all the treatments are taken in to consideration for the machining purpose. If the treatments in a full factorial design is too high to be logistically feasible, a fractional factorial design may be considered, in which some of the possible combinations (usually at least half) are omitted. Experiment CUTTING FEED DEPTH OF No. SPEED (mm/rev)F CUT (m/min) EED (mm) 1 100 0.04 0.2 2 100 0.06 0.3 3 100 0.08 0.4 4 140 0.04 0.2 5 140 0.06 0.3 6 140 0.08 0.4 7 180 0.04 0.2 8 180 0.06 0.3 9 180 0.08 0.4 Depth of cut 3.3 DESIGN OF EXPERIMENTS Table 3.2 Machining parameters Design of experiment is a specially designed experimental method developed for evaluating the effects of process parameters on performance characteristics. It determines the process parameter conditions for optimum response variables. Application of robust design of experiment requires careful planning, accurate layout of the experiment, and analysis of results. Key terms used in the Design of Experiments are Factors which are the Input Parameters used for machining. 3.4 EXPERIMENTAL PROCEDURE Initially a 1350 mm X 25 mm bar of AISI1045 Steel is taken and cut in to nine 50 mm long segments using a Band saw machine shown in the fig.3.3. The hardness of the material is measured using Rockwell hardness tester shown in fig.3.4 under the load of 150 kg and the indent used is diamond point. The measured hardness value is HRC 75. Levels indicate the experiments performed at different factor values. Outcome is the Response or Output Parameters. Treatments are the number of trials or experiments performed which are obtained using the expression level factors. During experimentation, a large number of experiments have to be carried out as the number of machining parameters increases. Taguchi’s design of experiments involves proper selection of an orthogonal array to accommodate input variables (control factors) and their interactions. The use of statistically derived orthogonal arrays for planning the experiments drastically reduces the number of ISSN: 2231-5381 Fig.3.3 Band saw Machine http://www.ijettjournal.org Page 20 International Journal of Engineering Trends and Technology (IJETT) – Volume 25 Number 1- July 2015 Table Machining Work piece AISI105 Steels Cutting tool Tool Holder Cubic Boron Nitride(CNMG120408LO-B CBN-10) PCLNL 2525 M-12 Cutting speed(m/min) 100, 175 , 250 Depth of cut (mm) 0.100 , 0.125 , 0.150 Feed rate(mm/rev) 0.02 ,0.03 ,0.04 Fig.3.5 Machined workpieces TABLE 3.3 Rockwell hardness tester The AISI1045 pieces are then dry turned using the input parameter combinations obtained from the Taguchi design. The table 3.2 represents the machining parameters. The input parameters considered are cutting speed, feed rate and depth of cut which play a vital role in obtaining a finished surface. Three levels are considered for each input parameter for machining purpose which is a 3x3 array as shown in the table 3.3. L09 orthogonal array is designed using a statistical tool which works on the Taguchi principal of orthogonal arrays. Table 3.4 represents the designed L09 orthogonal array used for machining. Using the above combinations the twenty seven work pieces are dry turned using CNC Lathe 802 D SL as mentioned earlier. Fig.3.5 nine work pieces which are machined using CBN cutting tool. Experime CUTTIN FEED DEPTH (Ra) nt No. G (mm/re OF CUT SURFACE SPEED v)FEED (mm) ROUGHNE Depth of SS (m/min) cut (μm) 1 100 0.04 0.2 1.515 2 100 0.06 0.3 0.575 3 100 0.08 0.4 0.470 4 140 0.04 0.2 0.435 5 140 0.06 0.3 0.245 6 140 0.08 0.4 0.465 7 180 0.04 0.2 0.285 8 180 0.06 0.3 0.830 9 180 0.08 0.4 0.430 The surface roughness values (Ra) of the machined pieces are determined using digital surface roughness tester. The knob of the tester is made to contact with the surface of the workpiece material through certain length. The average of surface roughness values through that length is displayed in the tester. The surface roughness values obtained are listed in the table 3.5. Factors Level 1 Level 2 Level 3 Cutting speed (m/min) 100 140 180 Feed rate (mm/rev) 0.04 0.06 0.08 Depth of cut (mm) 0.2 0.3 0.4 TABLE 3.5 SURFACE ROUGHNESS VALUES 3.6 SUMMARY CNC lathe used is Siemens 802 D SL for dry turning, Band saw cutter is used to cut the work pieces, Rockwell hardness tester is used to test the hardness of the material and other equipment like Digital surface tester is used to measure the surface roughness. Taguchi Techniques are used in design of the experiment. Analysis of the experimental results is further discussed IV.RESULTS AND DISCUSSION 4.1 MAIN EFFECT PLOTS FOR MEANS Table 3.4 orthogonal arrays FIG 4.1 RESIDUAL PLOTS OF Ra ISSN: 2231-5381 http://www.ijettjournal.org Page 21 International Journal of Engineering Trends and Technology (IJETT) – Volume 25 Number 1- July 2015 causes increase in temperature on account of The main effect plots are used to plot data increase in frictional heat due to more contact means when there are multiple factors. The between tool and work material. Thus higher points in the plot are the means of the machining temperature leads to thermal response variable at the various levels of each softening of work material resulting in less factor, with a reference line drawn at the surface roughness. Therefore, from fig.4.1 it grand mean of the response data. The main effect plots are used for is found that the machining at 180 m/min comparing cutting speed with 0.02 mm/rev feed rate and magnitudes of main effects. It is observed 0.140 mm depth of cut produced lower from the above fig.4.1 that as the cutting surface roughness. speed increases from 100 m/min to 140 m/min, the surface roughness gradually sno Speed feed decreases. Further increase in the cutting 1 2 100 100 0.04 0.06 Depth cut 0.2 0.3 3 100 0.08 0.4 0.470 4 140 0.04 0.3 0.435 5 140 0.06 0.4 0.245 6 7 8 9 140 180 180 180 0.08 0.04 0.06 0.08 0.2 0.4 0.2 0.3 0.465 0.285 0.830 0.430 speed to 180 m/min increases the surface roughness. The above trend of decreasing and increasing the surface roughness with an increase in cutting speed is because of the thermal softening effect that prevails in machining of AISI1045 STEELS. As the AISI1045 STEELS has low thermal diffusivity, the rate of heat transferred to the surrounding from the machining region is very less. As a result, more heat gets accumulated in the machining zone. of Surface roughness (Ra) 1.515 0.575 TABLE 4.1. SURFCE ROUGHNESS VALUES The 3D surface plots are used to evaluate the relationship between three variables at once. These plots use interpolation to produce a continuous surface i.e. surface plot or grid i.e. wireframe plot of z values that fit the data. It is observed from fig.4.1 that as the feed rate increases from 0.04 mm/rev to 0.06 mm/rev, the surface roughness increases gradually. Further increase in the feed rate to 0.08 mm/rev causes drastic increase in the surface roughness. At higher feed rate, the friction between work material and cutting tool will be higher due to larger cross sectional area in deformation zone and therefore surface roughness increases. It is observed from the above main effect plot i.e. fig.4.1 that as the depth of cut increases Fig.4.2 Pareto chart of the standardized Effects for surface roughness (Ra) from 0.100 mm to 0.120 mm, the surface roughness remains constant. However, further increase in the depth of cut to 0.140 mm causes reduction in surface roughness. From the fig.4.2, it is observed that minimum surface roughness is produced when the feed rate is 0.04 mm/rev and cutting speed is 140 m/min. But when the feed rate increases from 0.06 mm/rev to 0.08 mm/rev However, further increase in depth of cut ISSN: 2231-5381 http://www.ijettjournal.org Page 22 International Journal of Engineering Trends and Technology (IJETT) – Volume 25 Number 1- July 2015 and when the cutting speed changes from 140 m/min to 180 m/min, the surface roughness increases. datasets and experimental values are tabulated in Table 4.2. Mean square error for the production datasets is 0.0051865. From this it can be said that the error between the predicted and the experimental data sets is very less and thus the results obtained are satisfactory. The terms R-Sq = 96.84% indicates that the model is best and it cover all the variation provided by different process parameters. The results obtained from conformation test shows that the error in experimental and predicted values is 0.0387 % which is less fig .4.3 Normail plot of the standard effects than 10 %. It shows that our experimental results are fit to the best. The effect of inserts From the fig.4.3, it is observed that minimum surface roughness is produced when depth of cut is 0.12 mm and feed rate is in the range of 0.02 mm/rev to 0.03 mm/rev. But when feed rate increases from 0.03 mm/rev to 0.04 mm/rev, the surface roughness increases .From the fig.4.3, it is observed that the surface roughness is increased when the depth of cut is 0.12 mm and cutting speed is in the range of 200 m/min to 250 m/min. But it is found to be decreased when depth of cut is 0.15 mm and cutting speed from 150 m/min to 200 m/min Post training the Anova predicts the response values, that is, the surface roughness values. The values are then tabulated against the values obtained by experimental means. It is observed that the predicted values based on Anova model are very close to that of experimental observation. The validation of surface roughness values using Anova is shown below in table Table 4.2 Validation of results for surface roughness using Anova shape on surface roughness is minimum at low cutting speed. 4.5. SUMMARY From the above analysis the optimum conditions: 140 m/min cutting speed, 0.04 mm/rev feed rate and 0.150 mm depth of cut are obtained. The ANOVA is conducted and the most significant factor affecting the output parameter, surface roughness is determined. It is found that depth of cut has most significant impact on surface roughness. The confirmation tests are conducted to verify the fitness of the above developed mathematical model. It is observed that the mathematical model is practically accurate. The conclusions of the work are further discussed. V. CONCLUSION From the results obtained it can be concluded that by dry machining AISI1045 steels with CBN10 tool with cutting speed, Feed and Depth of Cut as input parameters, surface roughness as output parameter it is observed that feed is the most significant input parameter which is effecting the surface roughness(Ra). VI. ACKNOWLEDGMENT The authors would like to thank Gokaraju Rangaraju institute of engineering and technology for providing resources in completing the project successfully and for their support and guidance in completing the project. REFERENCE S=0.137974, R-Sq = 96.84%, R-Sq (adj) =87.36% The percentage errors calculated from the predicted values which are obtained by training the experiment ISSN: 2231-5381 [1]Vikas B. Magdum ,VinayakrNaik International Journal of Engineering Trends and Technology (IJETT) - Volume4Issue5May 2013 ISSN: 2231-5381 http://www.ijettjournal.org Page 1564 Evaluation and Optimization of Machining Parameter for turning of EN 8 steel [2] P.S. Sreejith, B.K.A. Ngoi, "Dry machining: Machining of the future", Journal of Materials Processing Technology, Vol.101, 2000, pp.287±291. [3] BalaRaju.J1 , Anup Kumar.J2 , Dayal Saran.P3 , Dr.C.S.Krishna Prasad Rao4 Application of Taguchi Technique for Identifying http://www.ijettjournal.org Page 23 International Journal of Engineering Trends and Technology (IJETT) – Volume 25 Number 1- July 2015 Optimum Surface Roughness in CNC end Milling Process (IJETT) – Volume 21 Number 2 – March 2015 [4] Yung-Kuang Yang, Ming-Tsan Chuang, Show-Shyan Lin, "Optimization of dry machining parameters for high-purity graphite in end milling process via design of experiments methods", Journal of Materials Processing Technology, Vol.209, 2009, pp.4395– 4400. [5] A. Devillez, F. Schneider, S. Dominiak, D. Dudzinski, D. Larrouquere, “Cutting forces and wear in dry machining of Inconel 718 with coated carbide tools", Wear, Vol.262, 2007, pp. 931–942. [6]Rony Mohan , Josephkunju Paul C , Benny Paul Multi Output Optimization of CNC High Speed Hard Turning of AISI 52100 Bearing Steel using Taguchi Method and Fuzzy Logic Unit [7] R.K.Suresh, G.Krishnaiah, "Parametric Optimization on single objective Dry Turning using Taguchi Method",International Journal of Innovations in Engineering and Technology, Vol.2 issue 2, April 2013. [8] P Subhash, Chandra Bose & C S P Rao , “Evaluation of Optimum Cutting Parameters In Turning of [9] HariSingh& Pradeep Kumar, “Tool wear optimization in turning operation by Taguchi method”. Indian Journal of Engineering & Materials Sciences Vol. 11, February 2004, pp. 19-24. (IJETT) – Volume 15 Number 3 – Sep 2014 [10] Subeg singh ,sanjeev kumar and sunikumar “Optimize the Surface Roughness During Machining of EN-8D Steel Using Taguchi Approach” IJRMET ISSN : 2249-5770 2-MAY-OCT2014 Ms.RAMYASREEKEERTHI pursued her engineering education in mechanical engineering at CMR college of engineering and technology, Hyderabad, India and pursuing M.Tech (Design for Manufacturing) at GRIET Gokaraju Rangaraju institute of engineering and technology,Hyderabad,India. Miss.ANITHALAKSHMI AKKINEREDDY pursued her engineering education in mechanical engineering at JNTUH University, Hyderabad and She is presently working as an Associate Professor of Mechanical Engineering at Griet Gokaraju Rangaraju institute of engineering and technology, Hyderabad, India. she has 10 years of teaching experience. ISSN: 2231-5381 http://www.ijettjournal.org Page 24