Applications of Hydrate Technology in Food Industry: A Sapna Kungrani Ketan Joshi

advertisement

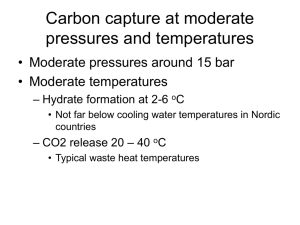

International Conference on Global Trends in Engineering, Technology and Management (ICGTETM-2016) Applications of Hydrate Technology in Food Industry: A Review of Experimental Studies Sapna Kungrani#1 Ketan Joshi*2 Guide: Prof. S. L. Bhagat#3, Prof. R. S. Jadhao*4 #1,2 Student, 3,4Faculty, Department of Chemical Engineering 3 Pravara Rural Engg.College, Loni Abstract: Gas hydrate formation as a separation technology shows tremendous potential, both from a physical feasibility (in terms of effecting difficult separations) as well as an envisaged lower energy utilization criterion. It is therefore a technology that should be considered as a future sustainable technology and will find wide application, possibly replacing a number of current commercial separation processes. In this article, we focus on presenting a brief description of the positive applications of clatharate hydrates and a comprehensive survey of experimental studies performed on concentration process using gas hydrate formation technology. Thus a new tomato and orange juice concentration technology using CO2 hydrate formation is Presented. The CO2 hydrate equilibrium conditions were measured by the isochoric pressure search method and tomato juice concentration experiments were carried out in a high-pressure stirred reactor. Moreover, the dehydration ratio was defined and CO2 hydrate formation rate constants were calculated. . The effects of feed pressure, temperature, and juice volume on the dehydration ratio were investigated. The results show that the tomato and orange juice used in this work has almost no effect on CO2 hydrate phase equilibrium conditions, but can accelerate CO2 hydrate formation and the results also demonstrated that removal of water with the help of CO2 hydrate is an efficient technology for tomato and orange juice concentration. Keywords: carbon dioxide, clathrate hydrate, concentration, orange juice, separation, tomato juice. I. Å and is relatively large, so that it is too big for the small cavity of structure I.[3] INTRODUCTION: Gas hydrates (clatharate hydrates) are crystalline solid structures consisting of water and small molecules such as CO2, N2, CH4, H2, etc. which are formed under conditions of low temperature and specified (generally high) pressure [1]. They belong to a general class of inclusion compounds commonly known as clatharate. A clatharate is a compound of molecular cage structure made of host molecules encapsulating guest molecules. It is also considered a chemical substance consisting of a lattice of one type of molecule trapping and containing a second type of molecule. Natural gas clatharate owe their existence to the ability ofH2O molecules to assemble via hydrogen bonding and form polyhedral cavities.[8] Natural gas hydrate is a naturally occurring ice-like solid, which is made of water molecules as the cage forming host and other molecules (mostly methane and carbon dioxide) as the guest. The guest molecules, like methane or carbon dioxide, are of an appropriate size such that they fit within cavities formed by the host material. Common clatharate compounds of interest are those formed from CO2/H2O and CH4/H2O mixtures.[2] CO2 hydrates can be formed at moderate temperature and pressure conditions (such as 5 °C,15 bar); at room temperature and ambient pressure they decompose again. Simple pure carbon dioxide hydrates form I type hydrates with large cavities. The CO2 molecule has a diameter of 5,12 ISSN: 2231-5381 Figure 1: Structure I hydrate (sI) withCO2 molecule Fresh fruits and fresh juices from vegetables and fruits are very good sources of valuable nutrients and completed our diet with essential vitamins(especially hydro soluble vitamins) and minerals, dietary fibers, small quantities of lipids and proteins, being in the same time good sources of carbohydrates.[5]. Thus it is really important to bring them in our daily diet. Orange juice is made by squeezing the fresh orange, drying and later re-hydrating the juice, or concentration of the juice and later adding water to the concentrate. It is known for its health benefits, particularly its high concentration of vitamin C. A cup serving of raw, fresh orange juice, amounting to 248 grams or 8 ounces, has 124 mg of vitamin C http://www.ijettjournal.org Page 215 International Conference on Global Trends in Engineering, Technology and Management (ICGTETM-2016) (>100% RDI).It has 20.8 g of sugars and has 112 Calories. It also supplies potassium, thiamin, and folate. Citrus juices contain flavonoids (especially in the pulp) that may have health benefits. Orange juice is also a source of the antioxidant hesperidins. Because of its citric acid content, orange juice is acidic, with a typical pH of around 3.5.[4,5] Fruit juice concentration is recognized worldwide as a way to preserve fruit and reduce transport costs. Despite recent advances in fruit juice concentration, there remain numerous challenges. Evaporation, membranes (ultra filtration, reverse osmosis and membrane distillation), and freeze concentration have been developed for concentrated juice processing [1--4]. However, the evaporation process is usually carried out in evaporators at high temperature, which causes valuable constituent losses (for example aroma compounds) and decreases the final product quality. Membrane concentration is regarded as a good alternative to the thermal methods of juice concentration, but the membrane could get dirty as the product is concentrated and the concentration process is costly [2,3]. Regarding the third method, concentrate quality is also satisfactory but it consumes a lot of energy, in particular during the ice nucleation step [4]. The concentration of dilute aqueous solutions using clatharate hydrate formation is, similar to but, more economically feasible than freeze concentration because clatharate hydrates can be formed at temperatures above the normal freezing point of water.[1] In this paper various applications of hydrate technology in the food industry are considered. Applications such as concentration of orange and tomato juice are discussed. As the juice concentration is necessary to reduce the transport cost and also the concentrated juice acquires less space and hence the minerals, vitamins and other acids are retained even after concentration. II. PROCEDURE FORMATION FOR HYDRATE The procedure for concentration of orange juice as well as tomato juice follows the same technique. The reactor was designed to produce hydrates in rapid manner, with hydrate formation times of few minutes. Moreover the new-improvedconfiguration is suitable for hydrate formation both through bubbling gas into the liquid phase and through spraying aqueous solution into the gas phase as shown in fig. In this set of experiments, the reactor was used to produce carbon dioxide hydrates through spraying aqueous solution into the gas phase according to the procedure described below [6]. ISSN: 2231-5381 Figure 2: process of concentrating The same principle works for the tomato juice. The established amount of aqueous solution is firstly uploaded and the reactor is filled with carbon dioxide from gas bottles until the internal pressure equals the experimental pressure and then cooled. Gas is bubbled into the liquid phase through five check valves. A Seafloor Process Simulator (SPS) consisting of a 72 L vessel was used for mesoscale experiments investigating the nature of hydrate nucleation and dissociation at pressures and temperatures required for stability of hydrates of CO2. The same experiments were duplicated in a smaller (0.45 L). it was found that experiments in the SPS resulted in hydrates consistently forming at lower over pressures and in shorter induction times than equivalent experiments in the smaller vessel. The variability of pressure and/or induction time for hydrate formation was not eliminated by using the SPS, but it appeared to be less dramatic (small coefficients of variation) when compared with a 450 mL. Parr vessel. The observed differences were attributed to increased bubble surface area, gas concentration, lifetime of bubbles, total volume of the SPS, or a combination of the above. Thus conclusion comes that mesoscale experiments such as those in the SPS, may perhaps be more representative of hydrate accumulation in the natural environment.(Oak Ridge National Laboratory) investigated formation of a sinking carbon dioxide (CO2) hydrate composite as an alternative to direct liquid CO2 injection and pure CO2 hydrate formation for ocean carbon sequestration. Raman spectroscopy was used as a tool to understand the formation and spectroscopy of a semi-solid sinking CO2hydrate composite formed using a co flow injector in the 72 L and 0.45 L pressurized vessels at pressure and temperature conditions equivalent to approximately 1.3 km depth in the ocean. The temperature is controlled in order to achieve relatively uniform values inside the reactor. http://www.ijettjournal.org Page 216 International Conference on Global Trends in Engineering, Technology and Management (ICGTETM-2016) III. DISSOCIATION OF CO2 HYDRATES After CO2 is separated from juice as hydrates at the hydrate formation chamber, CO2 hydrates are transported to the separator, where CO2 hydrates are dissociated to water and gaseous CO2 again. It is also possible to send CO2 hydrates to the deep sea bottom without dissociation. The heat is 242,200MJ/h that needs to decompose hydrates. The hydrate phase can be later dissociated by depressurization and/or heating and consequently CO2 can be recovered [1] Where z is the compressibility factor of CO2 gas calculated by the SRK equation of state, and subscripts and e refer to component of the feed gas and equilibrium gas. The volume of CO2 gas was assumed constant throughout the hydrate formation process (volume changes due to the phase transitions were neglected). Physio-chemical properties The contents of reducing sugar, total acid, vitamin c, soluble solid and water content of orange and tomato juice used in this study are given in Table1 and 2 resp. Reducing sugar (g/100g) 4.42 Total acid (g/kg) 6.08 Vitamin C (mg/100g) 49.96 Soluble solid 10.5% Water cut 87.7% Figure 3: Carbon dioxide hydrates on the internal heat exchanger. Dehydration ratio. CO2 connects with water to form CO2 hydrate based on the following reaction equations: Table1: For orange juice Reducing sugar (g/100g) 2.51 Total acid (g/kg) 3.31 Vitamin C (mg/100g) 16.85 Soluble solid 5.5% Water cut 94.2% Table2: For tomato juice IV. CALCULATION METHOD The moles of gas consumed. The number of moles of CO2 gas that has been consumed during hydrate formation can be calculated as Where n is the hydrate number of CO2 hydrate. V. ECONOMY OF THE CLATHARATE TECHNOLOGY Hydrate technology requires 151kJ/kg, where the evaporation requires 2055kJ/kg water. As less heat is required hence less energy is consumed The thermodynamic analysis of the process enable us to estimate capacities, sizes, abilities, and so on of necessary equipments like the compressor, the heat exchanger, the hydrate formation chamber, and so on. According to these specifications the cost of facilities can be decided. Also energy cost can be calculated. VI. RESULTS AND DISCUSSION A first set of experimental runs were carried out for CO2 hydrate production. Effects of additives, such as THF and SDS, were tested. The amount of additives was chosen according to the optimal ranges of concentration. Typical profiles of internal ISSN: 2231-5381 http://www.ijettjournal.org Page 217 International Conference on Global Trends in Engineering, Technology and Management (ICGTETM-2016) pressure and temperature for an experimental run of 15 min are shown in Fig. Those profiles are for experimental run 2. In particular, internal temperature is calculated as the average of the two temperature values measured by two thermocouples in two different positions.[6]. Both SDS and THF promote formation of gas hydrates with a short reaction time, suitable for industrial in-continuo applications X. DISADVANTAGES OF CONCENTRATED JUICE As the time elapses between making of juice and its consumption, more vitamins are lost. XI. in SDS 300 ppm—experimental run 2 Water spraying starts at t = 2 Fig. Pressure and temperature profile with elapsing time for CO2 hydrate formation min. VII. ADVANTAGES OF THE HYDRATE TECHNOLOGY High product quality due to lowtemperature operation Absence of a vapor-liquid maintaining original flavors. Hydrate technology produces a superior product. process at low temperature, High retention of volatile aroma interface VIII. DISADVANTAGES OF THE HYDRATE TECHNOLOGY Uniform maintenance of temperature and pressure values sometimes becomes difficult. IX. ADVANTAGES OF CONCENTRATED JUICE the concentrated juice reduces space requirements it also reduces time requirements ISSN: 2231-5381 However essential antioxidants and vitamins are volatile and are lost with the passing time CONCLUSION The dehydration ratios were 20.2 and 99.3% with initial pressure at 2.10 and 4.43 MPa, respectively. The results demonstrated that removal of water by formation of CO2 hydrate is a potential technology for orange juice concentration. The concentrated orange juice always saves time and space requirements. The more amounts of nutrients are present in concentrated juice. The present investigation on Studies on Development of orange soy RTS beverage were undertaken to remove the beany flavor, to formulate the product that is soy RTS beverage, to analyze the different proportions blends of Orange RTS beverage with respect to physico-chemical composition and analyze the Organoleptic characteristics of prepared orange RTS beverage. Organoleptic evaluation of beverages showed that orange concentrated beverage prepared from 80% orange juice proved to be best according to physico- chemical properties. Followed by the 70% orange juice blend, 60, and 50% orange juice blended in found to have good taste and overall acceptability. Study reveals that fruits could be used in making the beany flavor thus promoting acceptability of soymilk. This could be beneficial to communities where cow’s milk is unacceptable, unavailable or unaffordable or due to lactose intolerance. A novel separation process was developed for tomato juice concentration on the basis of CO2 hydrate formation. The CO2 hydrate equilibrium conditions in the presence tomato juice were measured by the isochoric pressure search method. The tomato juice concentration experiments were carried out in a high-pressure stirred reactor under different conditions of feed pressure, temperature, juice volume, and stirring speed. The hydrate equilibrium results show that the tomato juice used in this work has little effect on CO2 hydrate phase equilibrium conditions, but can accelerate CO2 hydrate formation. The dehydration ratio increased with increasing the feed pressure and decreasing the temperature. The optimum tomato juice volume was 80 mL and the http://www.ijettjournal.org Page 218 International Conference on Global Trends in Engineering, Technology and Management (ICGTETM-2016) stirring speed has almost no effect on the dehydration ratio. The CO2 hydrate formation constants in tomato juice were the same order of magnitude as the results of CH4 hydrate in the presence of surfactants. XII. REFERENCES [1] Ali Eslamimanesha, Dominique Richona February 2012, ―Application of gas hydrate formation in separation processes: A reviewof experimental studies”, J. Chem. Thermodynamics 46 (2012) 62–71 [2] An introduction to natural gas hydrate/ clatharate, Journal of Petroleum Science and Engineering 56 (2007) 1–8 [3] BaerbelEgenolf-Jonkmanns,Stefano Bruzzano, ―Properties And Application Of Additiveenhanced Co2 Hydrates”, 7th International Conference on Gas Hydrates (ICGH 2011) [4] Shifeng Li,Yanming, ―Experimental Study Ofconcentration Of tomatojuice By Co2 Hydrate Formation”, Chem. Ind. Chem. Eng. Q. 21 (3) 441−446 (2015) [5] Laura Corpas, Ariana-Bianca Velciov ―Physico-chemical characterization of some fruits juices fromRomanian hypermarket fruits,”, Journal of Agroalimentary Processes and Technologies 2012, 18 (1), 95-99 [6] Beatrice Castellani, ―Carbon Dioxide Capture Using Gas Hydrate Technology”,Journal of Energy and Power Engineering (2013) 883-890 [7] Fumio Kiyono, Akihiro Yamazaki, and Keiichi Ogasawara,”Cost Estimation Of Co2 Recoverytechnology Using Hydrates”,Fuel Chemistry Division Preprints 2002, 47(1), 78 [8] Veronica R. Blackwell,‖ Formation of clathratehydratesof carbon dioxide and methane”, California institute of technology Pasadena, California, 1998 ISSN: 2231-5381 http://www.ijettjournal.org Page 219