Introduction to Bongo Better Brewing Company Project Brief

advertisement

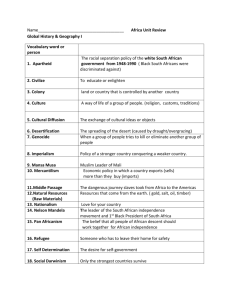

Introduction to Bongo Better Brewing Company Project Brief Preamble The Bongo Better Brewing Company (BBBC) is the premier brewer and distributor of fine beers in the central and northern African region. Its flagship products are: Leopard Lager Baboon Bitter Dikdik Draught Silverback Stout Its success is due, in no small part, to not only the pursuit of excellence, research and community involvement but also its unique ingredients and secret brewing processes. In particular, the BBBC is especially proud to support indigenous groups in its distribution areas by purchasing vast quantities of local farkleberries and sub-Saharan millet crops. These are processed, using an amazingly prolific strain of locally developed yeast, into the fine range of successful products available through all good public houses and reputable liquor outlets. This brief describes another project that is linked to the BBBC’s mission to bring increased pleasure to beer drinkers worldwide and to provide higher benchmarks and improved standards for beer makers worldwide. BBBC has established a working partnership with SimuLab to pilot the development of an Australian production facility to make beer in the African style and with African ingredients, but customised to meet local tastes and preferences. Objectives of the Brief The BBBC is targeting Australia as a potentially appreciative and lucrative market, after the extraordinary success of the acceptance and marketing trials conducted last year using fully imported product. This undertaking has already commenced with a pilot brewing plant, currently nearing completion on Kooragang Island on the East Coast of Australia. The plant will pilot local manufacture of a range of products and address a number of matters and potential problems before scale up to full production with the entire product range. The objectives of this project brief for the pilot plant in Australia are: Obtain authorisation to import and use key African ingredients in manufacturing beer products for sale in Australia. Put all necessary systems (required by regulatory obligations) into place to ensure ongoing, trouble-free access to the volume of all necessary imported ingredients. Formulate and manufacture BBBC beer products for the Australian market, based on our successful African products, but customised to meet Australian preferences. Solve all technical, organoleptic, and quality problems brought about by combining locally sourced, high volume Australian ingredients and processed outputs with the correct quantities of African ones. Produce a consistent, high quality product, identifiable immediately as the unique BBBC lager, ale or stout it purports to be. Meet all regulatory obligations for OH&S, environmental and food safety standards requirements for the manufacturing process. Determine specifications, systems, procedures, and protocols for: raw materials’ procurement and handling; all production stages including manufacture, packaging, storage, and distribution; housekeeping; waste management; and other aspects of large-scale production. Document and report all necessary information. Partnership arrangement details between BBBC and SimuLab All original recipes specifications, methods and procedures will be issued from the parent African enterprise. Experienced managers, supervisors and operational staff will operate the pilot plant. These people know the African product and processes well and have exceptional sensory sensitivities for the full range of intermediates and products. The plant manager, Mr Ian Patrick Daly, will have overall responsibility for running the plant, including: procuring, handling and storing of all in-feed of appropriate quality, maintaining appropriate infrastructure and utilities, organising work teams and systems of production determining the trial schedules, diagnosing faults, troubleshooting and fine-tuning all processes appropriate handling, storage and disposal of by-products, wastes and emissions. Mr I. P. Daly will consult with SimuLab technical services on all aspects of technical service delivery. Subject to the time allowances specified in the contract, Mr I. P. Daly and will have final say on the volume and scope of SimuLab support activities, the interpretation of test results and how the information will be used. SimuLab has been contracted because of its expertise with a number of sensitive issues, which BBBC believes are vital to the success of our project. Specifically, SimuLab will take a leadership role to ensure successful utilisation of the African sourced ingredients, in terms of meeting local obligations and production conditions. Additional details for the three key ingredients are shown here: 1. Yeast African strain isolated from secret African sources and improved by BBBC technology. To be used to create a secondary product stream, which will be added to the bulk of production, made using locally supplied brewer’s yeast. Batching trials will be needed to establish the performance of the yeast using local water and other ingredients and to establish the blending ratios needed to meet enterprise quality standards as well as legal requirements specified by ANZFA Food Standards code, Trade Practices and other obligations. Technical issues related to maintenance of the integrity of the yeast strain and appropriate production conditions also need to be solved. 2. Sub-Saharan Millet Critical ingredient in the African brewed products for which patent rights are held. To be used to create a secondary product stream, which will be added to the bulk of production, made using locally supplied barley. Batching trials will be needed to meet the legal and technical requirements in point 1 above. 3. Farkleberry extract Used in Africa, by the BBBC, to supplement poor hop quality and to exploit the traditional local use of the parent material. Farkleberries, which are extracted to produce this bitter and aromatic additive, are an important local cash crop and have traditionally been used for centuries to make home based, fresh and fermented beverages. In recent times the BBBC has achieved commercial success by using and promoting its farkleberry content. Farkleberries have an unproven reputation for improved fertility, libido enhancement and promoting general feelings of well being and good health. Demographic studies have shown it contains no toxic or otherwise harmful compounds. Local African statistics quite clearly show, in comparison to nearby communities where farkleberries do not grow, below average incidences of common diseases and above average life-spans for generations of family members who are regular users of farkleberry products. This product will be imported as a free flowing, purple – mauve powder, with a faint odour, not dissimilar to pyrolidone. The active ingredients have been isolated and studied and consist of oxygenated variations of the diterpene STANDOLONE – named for its botanical origins Rutabaga Standolii. Batching trials will be needed to meet the legal and technical requirements in point 1 above.