Modeling the Impact of Product Portfolio on the Economic

advertisement

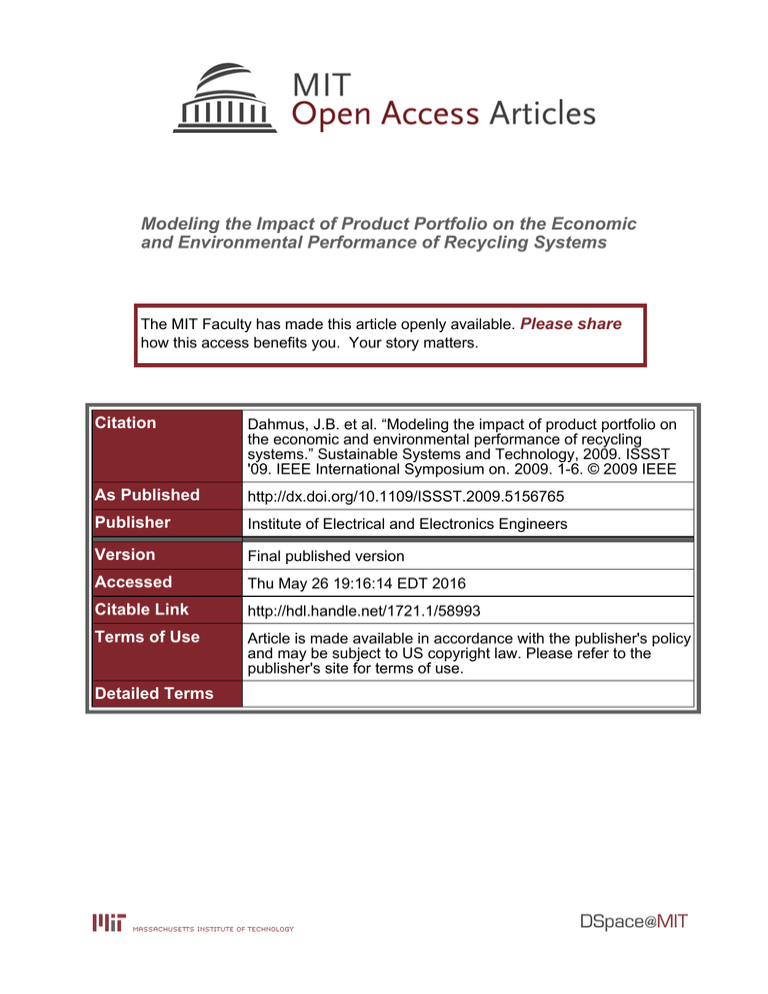

Modeling the Impact of Product Portfolio on the Economic and Environmental Performance of Recycling Systems The MIT Faculty has made this article openly available. Please share how this access benefits you. Your story matters. Citation Dahmus, J.B. et al. “Modeling the impact of product portfolio on the economic and environmental performance of recycling systems.” Sustainable Systems and Technology, 2009. ISSST '09. IEEE International Symposium on. 2009. 1-6. © 2009 IEEE As Published http://dx.doi.org/10.1109/ISSST.2009.5156765 Publisher Institute of Electrical and Electronics Engineers Version Final published version Accessed Thu May 26 19:16:14 EDT 2016 Citable Link http://hdl.handle.net/1721.1/58993 Terms of Use Article is made available in accordance with the publisher's policy and may be subject to US copyright law. Please refer to the publisher's site for terms of use. Detailed Terms Modeling the Impact of Product Portfolio on the Economic and Environmental Performance of Recycling Systems Jeffrey B. Dahmus, Elsa A. Olivetti, Susan A. Fredholm, Jeremy R. Gregory, and Randolph E. Kirchain Abstract— Through the development of a general model of electronics recycling systems, the effect of product portfolio choices on economic and environmental system performance is explored. The general model encompasses the three main functions of a recycling system – collection, processing, and system management – and allows for the effect of both contextual and architectural inputs – including product scope – to be explored. Overall model results indicate that collecting a broader portfolio of products can be economically favorable, even for cases in which lower-value products are added to a recycling system. In these cases, the higher total mass throughputs that are realized by the collection of additional product types can help to drive down the cost per unit mass collected. Expanding product scope can also yield improvements in environmental performance, as the energy per unit mass collected can also decrease with higher mass throughputs. Index Terms—electronics recycling systems, electronic waste, process-based cost models, product scope I. INTRODUCTION W ITH an increasingly broad scope of electronic products being produced, along with diminishing lifetimes for such products, the amount of consumer electronics reaching end-of-life has grown considerably over the past decade [1, 2, 3]. In response to this growth in electronic waste, recycling systems to handle such waste have become more widespread, with various systems currently implemented in Europe, North America, Asia, and elsewhere. As these existing systems mature, and as more such systems come online, understanding the economic and environmental performance of such systems becomes critical, both to enable improvement of existing systems and to inform the design of new systems. Previous work by the authors has focused on collecting and analyzing empirical data from existing electronics recycling systems [4]. While such information is important to understanding system performance, the sheer number of variables involved with each system – from architectural inputs such as product scope, number of collection points, and location of collection points, to contextual inputs such as population, population density, and factor costs – make direct comparison of performance results difficult. Moreover, using such comparisons to identify system variables that could be changed in order to improve system performance is virtually impossible. Given these difficulties, a modeling framework has been previously proposed and developed to analyze the economic and environmental performance of both existing and prospective recycling systems [5, 6]. This model, which comprehends the three main functions common to most recycling systems – collection, processing, and system management – can be used to explore the effect of different architectural and contextual variants. In this work, the architectural decisions around product portfolio selection are explored. Product scope, which refers to the types of products collected within a recycling system, is an important decision that system designers and system operators must make. It is also a decision in which there is variation, as shown in Fig. 1. This variation in product scope is particularly apparent in the state-based systems in the US, where different recycling systems collect various combinations of IT, telecommunication, and consumer equipment. Understanding the effect of such product portfolio decisions, on both the economic and environmental performance of a recycling system, is the aim of this work. II. MODEL DEVELOPMENT J. B. D. is a Postdoctoral Associate in the Materials Systems Laboratory at the Massachusetts Institute of Technology (MIT), Cambridge, MA, 02139 (e-mail: jdahmus@mit.edu) E. A. O. is a Postdoctoral Associate in the Materials Systems Laboratory and at MIT (e-mail: elsao@mit.edu). S. A. F. was a Research Assistant in the Materials Systems Laboratory at MIT. She is now a Consultant at PE Americas (e-mail: s.fredholm@peinternational.com). J. R. G. is a Research Scientist in the Materials Systems Laboratory at MIT (e-mail: jgregory@mit.edu). R. E. K. is an Associate Professor in Materials Science and Engineering and in the Engineering Systems Division at MIT (e-mail: kirchain@mit.edu). As mentioned above, the system model developed to analyze recycling systems focuses on the three main functions in a recycling system, namely collection, processing, and system management [7]. It should be noted that while the model inputs described here are specific to electronics recycling, the broader model framework can be more generally applied, and can thus be adapted to model recycling systems for other consumer durable goods, in addition to electronics. Jurisdictions CA CT MD United States ME MN OR WEEE Category 3: IT and telecommunications equipment Monitor x x x x x Laptop Computer x x x x x Desktop Computer x x x Other (e.g. printers) x x x x WEEE Category 4: Consumer equipment Television x x Other (e.g. VCRs) x x x x x Canada BC SK TX WA AB x x x x x x x x x x x x x x x x x NS BE CH x x x x x x x x x x x x x x x x x x x x x x Europe NL NO x x x x SE x x x x x x x x x x x x Fig. 1. Comparison of product scopes for current electronics recycling systems. United States: CA = California, CT = Connecticut, MD = Maryland, ME=Maine, MN = Minnesota, OR = Oregon, TX = Texas; Canada: Canada: AB = Alberta, BC = British Columbia, SK = Saskatchewan, NS = Nova Scotia; Europe: BE = Belgium (Recupel), CH = Switzerland (SWICO), NL = Netherlands (ICT Milieu), NO = Norway (Elretur), SE = Sweden (El-Kretsen). Fig 2. shows a schematic overview of the recycling system analyzed here, and identifies the key model components. Consumer households, some with end-of-life electronics ready for disposal, and some without, are shown on the left side of Fig. 2. End-of-life electronics travel, typically by car, from the residential consumers to a local collection facility. Here, various types of end-of-life electronics, and perhaps other endof-life products and materials, are aggregated. From here, these larger collections of end-of-life electronics are transported, typically by truck, to a processing facility. At such a facility, product dismantling and separation occurs, with resalable materials, resalable components, and waste leaving the facility. Providing operational and financial oversight of the process, from the collection facility to the processing facility, is typically a system management function. Each of the main model functions are described briefly here, and important characteristics of each function are highlighted. Additional details regarding each of these models can be found in previous works [5, 6]. A. Collection As shown in Fig. 2, collection focuses on three main activities: the transport of end-of-life products from their point of final use to a collection facility, the collection facility itself, and the transport of aggregated end-of-life products from a collection facility to a processing facility. In modeling these activities, two distinct but integrated models are used: a logistics model, which accounts for the transportation of products, and a facility model, which accounts for the operation of the collection facility. System Management Materials Components Transport (car) Collection Facility Transport (truck) Collection Logistics Model and Facility Model Processing Facility Waste Processing Facility Model Fig. 2. An overview of the recycling system analyzed. The three main functions – collection, processing, and system management – are shown. Specific models are noted in grey text. Logistics Model. The logistics model is primarily concerned with calculating the distances that end-of-life electronics must travel and the total amount of electronic waste collected. While such information is obtainable when analyzing actual systems, when modeling alternative hypothetical scenarios, such logistics information must be generated. The starting locations of end-of-life electronics, which is typically the home of the final consumer, can be modeled using demographic data along with population distribution models [8]. Once such a characterization of locations takes place, collection facilities can then be sited based on this data. The siting of collection facilities for electronics recycling falls into a more general class of facility-siting problems, in which a limited number of supply points – in this case collection facilities – must be sited to serve a given population of demand points – in this case consumers with end-of-life electronics. Such a problem is common in location-allocation modeling; in fact, such problems arise in siting decisions for a broad range of different facilities, from hospitals to warehouses to retail outlets [9]. One common approach to this siting problem is the p-median model, an optimization approach that, when given a set of demand points, selects a set of supply points, p, such that the total sum of the distances from each demand point to its closest supply point, is minimized [9, 10]. The p-median problem has been shown to be NP-hard; thus, heuristic methods are often instead used to address this location-allocation problem [9, 10]. For the collection facility siting problem faced here, a k-means clustering algorithm is used. This approach locates a number of collection facilities, k, such that the variance in the distances that each customer must travel to reach a collection facility, is minimized. While this objective differs somewhat from that of the p-median problem, the two approaches appear to yield comparable location decisions for collection facilities. For siting of processing facilities, given a set of collection facility locations, similar clustering algorithms can again be used. It is important to point out that the k-means algorithms used here for facility siting, do not consider existing infrastructure; thus, siting is done assuming a blank slate. With locations for the population, collection facilities, and processing facilities, the travel distances for each of these transportation segments can then be calculated. Since these two different transportation segments are typically completed by different stakeholders using different classes of vehicles, the economic and environmental impacts of these segments can be quite different. Once locations for the population and facilities are established, the amount of mass collected must be determined. The amount of mass collected is dependent on a range of factors, from product scope to the penetration level of electronic products to the distance that a consumer must travel to reach a collection facility. The effect of distance in consumer participation rates is of particular interest in this work, as this effect can have profound impacts on the amount of mass collected at a given collection facility. Much of the recycling literature assumes participation rates to be constant over a certain distance; beyond that distance, participation rates drop to zero. However, the effect of distance on participation rates has been shown to follow more of an exponential decay – known as distance decay – with consumers close to a facility participating at high rates and those farther from a facility participating at considerably lower rates. This behavior has been observed in numerous cases, from shopping to commuting to courtship [11, 12, 13]. The effect of distance decay can be modeled using an exponential function: R = qe − λx , (1) where R is the distance-adjusted participation rate, q is the participation rate, λ is the decay rate with distance, and x is the distance from the customer to the collection facility [14, 15]. The participation rate, q, convolves a variety of factors, including the saturation of electronic products, the availability of other end-of-life disposal options, and customer awareness of collection centers, among others. Using this distance-adjusted participation rate, R, along with information about product masses and product scope, the amount of mass collected in total, along with the breakdown of that mass by product type, can be estimated. Facility Model. In modeling collection, the cost of operating a collection facility is also included. The collection facility is modeled using a process-based cost model (PBCM), which maps engineering requirements to process descriptions, process descriptions to facility requirements, and finally facility requirements to facility investments [16, 17]. The costs of the collection facility include capital costs, such as buildings, equipment, and other infrastructure, as well as operating costs, such as labor, electricity, and packaging material; all of these costs can vary with context. In this model, it is assumed that collection facilities are nondedicated. B. Processing During processing, electronic waste that has been collected and consolidated is broken down into resalable components, resalable material streams, and waste streams. The processing facility model, which captures this process, focuses on both the operations within the facility itself, as well as on the material flows into and out of the facility. Like the model for the collection facility, the model for the processing facility is also a PBCM, built up from engineering requirements, in this case requirements for end-of-life electronics processing. This PBCM again takes in a number of contextual inputs, including factor costs such as capital costs, labor costs, and electricity costs. However, it also takes in information from the collection logistics model, both regarding the total mass of electronics waste collected, as well as regarding the breakdown of that mass total by product type. C. System Management The system management component of the model accounts for the management and oversight of the entire system. These costs are largely administrative, and are heavily dependent on the fee structures and oversight mechanisms that are put in place; as fee structures become more complex, and as oversight increases, system management costs increase. In general, these costs can be modeled simply, with labor and related expenses often the dominant costs. III. CASE STUDY To explore the implications of product portfolio decisions on the economic and environmental performance of recycling systems, a case study was conducted using the models described above. The contextual inputs and architectural inputs – outside of those related to product scope – are based loosely on the demography, electronics recycling system structure, and factor costs for the state of Maine. The electronics recycling system analyzed here focuses on the collection of end-of-life monitors and printers from residential consumers. The total population covered by this system is approximately 1.3 million people, distributed over an area of roughly 80,000 square kilometers. Given this population, and a population distribution based on recent census data for Maine [18], collection facilities were sited using the k-means clustering algorithm described earlier. Participation rates at these facilities were determined using the exponential form of distance decay, as shown in (1), with the distance decay calibrated such that 75% of the participants at a given collection facility live within 10 km of that facility. For the processing facility, the outgoing material streams were priced using current market data [19]. System management costs, based on literature on the Maine electronics recycling system, were a fixed amount, and did not scale with either the amount of mass collected or the number of collection sites [7]. The three product portfolios considered in this analysis were: 1) monitors only, 2) printers only, and 3) both monitors and printers. While both monitors and printers incur a net cost for recycling, monitors, with a relatively high metal content, represent a more-valuable waste stream; printers, typically dominated by plastics, represent a less-valuable waste stream. 6 Printers Monitors Monitors and Printers Total Mass Collected (million kg) 5 4 3 2 1 0 0 50 100 150 200 250 300 Collection Facilities Fig. 3. Total mass collected as a function of the number of collection facilities for three systems with different product portfolios: 1) printers, 2) monitors, and 3) monitors and printers. 1.6 Total System Cost per Unit Mass Collected ($/kg) A. Economic Performance Results Product scope plays an important role in the amount of mass collected in each scenario. As shown in Fig. 3, an electronics recycling system based on collecting only monitors – estimated to be 25 kg each – collects significantly more mass than a recycling system based on collecting only printers – estimated to be 10 kg each. Not surprisingly, a system that includes both monitors and printers is able to collect significantly more mass than if either product is collected separately. It is also clear from Fig. 3 that the number of collection facilities has a profound effect on the amount of mass collected, particularly at lower numbers of collection facilities. Fig. 4 shows the total system cost per unit mass collected for the three different product portfolios. These costs include the collection facility, transportation by truck, the processing facility, and system management. The cost borne by the consumer, in transporting the end-of-life electronics from their home to the collection facility, is not included in Fig. 4. Overall, each of the portfolios follows the same general curve. The cost per unit mass collected at very low numbers of collection facilities, is largely driven by the costs of processing and system management. In the case of processing, the low mass totals at low numbers of collection facilities, lead to limited economies of scale, and thus higher costs; in the case of system management, the amortization of system management costs over a relatively small amount of mass, leads to high costs per unit mass collected. As the number of collection facilities increases, the overall cost of operating all these facilities also increases. At higher numbers of collection facilities, this proves to be the main system cost driver. The product portfolio selected also has an important impact on the cost per unit mass collected of the electronics recycling system. For a system focused on recovering only printers, the cost per unit mass collected is quite high, as can be seen in 1.4 1.2 1 0.8 0.6 0.4 Printers Monitors Monitors and Printers 0.2 0 0 50 100 150 200 250 300 Collection Facilities Fig. 4. Total system cost per unit mass collected as a function of the number of collection facilities for three systems with different product portfolios: 1) printers, 2) monitors, and 3) monitors and printers. Fig. 4. This is due in part to the fact that printers, with a large mass fraction of plastics, do not yield particularly valuable outgoing material streams from the processing facility. However, the larger cost driver is the fact that a system based around collecting only printers does not accumulate large amounts of total mass. Thus, opportunities to amortize costs – in particular collection facility costs and system management costs – are not realized. For a system focused on recovering only monitors, the cost per unit mass collected is considerably lower, as seen in Fig. 4. While this is due in part to the fact that monitors have more valuable materials than in printers – including more bulk metals and precious metals – it is also due in large part to the larger total system masses collected. These higher mass totals lead to significant reductions in the cost per unit mass.. Of the three product portfolios considered, the lowest cost portfolio is that which includes both printers and monitors. This combination results in the most mass collected, which drives down the total system cost per unit mass. The fact that the portfolio with both printers and monitors offers the lowestcost solution has important ramifications for recycling system design. It appears that once a system is established, collecting as much mass as possible – which often means collecting a portfolio of products – can offer cost advantages over systems with more limited product scopes. With collection facilitiy costs and system management costs largely driven by fixed costs, an effective approach to reducing these costs per unit mass collected is to simply collect more mass. Also, with economies of scale in processing, more mass results in lower processing costs per unit mass processed. Even in a system in which printers – a generally lower-value product – are added to monitors, the resulting combination leads to lower costs per unit mass collected than a system in which only monitors are collected. Thus, while collecting and processing printers by themselves can be quite expensive, adding such a product to existing systems can in fact drive down total costs per unit mass collected. This is an important consideration when making product portfolio decisions for electronics recycling systems. 3500 Total Transportation Energy (GJ) 3000 2500 2000 1500 1000 Printers 500 Monitors Monitors and Printers 0 0 50 100 150 200 Collection Facilities 250 300 Fig. 5. Total transportation energy as a function of the number of collection facilities for three systems with different product portfolios: 1) printers, 2) monitors, and 3) monitors and printers. Printers 8 Total Transportation Energy per Unit Mass Collected (MJ/kg) B. Environmental Performance Results Combining model outputs with environmental data can allow the environmental performance of different recycling scenarios to be evaluated. For example, the energy burden of transportation, which is a topic of interest in any product takeback system, can be analyzed for the various product portfolios considered. Fig. 5 shows the total transportation energy, both from private automobiles – used to transport endof-life electronics from the consumer’s home to the collection facility – and from trucks – used to transport collected end-oflife electronics from the collection facility to the processing facility. Data on the environmental burden of these transportation modes comes from the ecoinvent database [20]. For all three of the product portfolios examined, there are two competing trends that determine the total transportation energy. At low numbers of collection facilities, fewer consumers participate in the system, but each participant must travel a longer distance. At high numbers of collection facilities, a much larger number of consumers participate, but each participant only needs to travel a short distance. The reduction in distance travelled per customer eventually dominates, thus explaining the decline in transportation energy as the number of collection sites increases. In comparing the transportation energy across the different product portfolios, the portfolios with more mass lead to higher energy expenditures, as additional truck trips are necessary. However, despite this increase in the total transportation energy with broader product scopes, as seen in Fig. 5, the transportation energy per unit mass collected, as seen in Fig. 6, decreases. Thus, much like in the cost analyses earlier, the most resource-efficient approach, on a per-unit-mass basis, is the scenario with the broadest product scope. As before, larger total masses serve to drive down the impacts – both 9 Monitors 7 Monitors and Printers 6 5 4 3 2 1 0 0 50 100 150 200 250 300 Collection Facilities Fig. 6. Total transportation energy per unit mass collected as a function of the number of collection facilities for three systems with different product portfolios: 1) printers, 2) monitors, and 3) monitors and printers. economic and environmental – per unit mass collected. Perhaps the more important environmental issue regarding product recycling systems is whether or not the environmental benefits of recycling outweigh the environmental impacts of collection. Combining the models developed here with energy data for transportation and material production – both primary and secondary [21, 22, 23, 24] – can provide preliminary answers to such questions. In a best-case scenario, assuming high material recovery rates of both plastic and metals, and assuming energy savings equal to the difference between the energy required for primary material production and the energy required for secondary material production, recycling any of the three product portfolios examined here makes sense from an energy perspective. That is, the energy savings from using secondary material streams far outweighs the burden of collection logistics. A more in-depth analysis would account for other potential energy requirements – including other material preparation and processing steps – as well as actual recovery yields. Reasonable scenarios do exist in which the environmental decision is less clear. For example, with a product such as printers, which feature a high plastic content, efficient recovery of these plastics is critical to the overall energy balance. If plastics cannot be recovered – either for recycling or for energy recovery – and if the metals in the product cannot be recovered at high enough yields, scenarios exist in which a recycling system can transition from providing a net energy savings to being a net energy burden. Fig. 7 shows two such scenarios for electronics recycling systems focused on collecting only printers. For the case in which none of the plastics and 80% of the metals in a printer are recovered, this crossover occurs around 40 collection facilities. With fewer collection facilities, the energy burden from transporting endof-life electronics outweighs the energy savings from recycling; with more collection facilities, the energy savings from recycling outweighs the energy burden from 6 Energy Savings or Burden (million MJ) 0% Plastics, 80% Metals 0% Plastics, 50% Metals 5 Transportation [4] 4 [5] 3 2 [6] 1 [7] 0 0 50 100 150 200 Collection Facilities 250 300 Fig. 7. The energy savings and energy burden of an electronics recycling systems focused on printers. The energy savings from material recovery for two scenarios – one with no plastics recovery and 80% metal recovery, and one with no plastics recovery and 50% metal recovery – are plotted. The energy burden from the transportation logistics is also shown, allowing energy crossover points – in terms of the number of collection facilities – to be identified. transportation. With lower metal recovery rates, additional mass must be collected, in order to break even; this scenario, with a metal recovery rate of 50%, is also shown in Fig. 7. Again, it should be noted that these analyses represent bestcase scenarios for recycling. In practice, there are additional energy burdens that should be considered. IV. CONCLUSION [8] [9] [10] [11] [12] [13] [14] [15] The development of detailed models to analyze electronics recycling systems helps to provide important insights into how such systems can be designed and modified to maximize economic and environmental performance. The analyses presented here around product portfolio decisions indicate that broader product scopes can lead to systems that are both economically and environmentally more-efficient than systems with limited product scopes. [16] ACKNOWLEDGMENT [19] The authors would like to thank Edgar Blanco from the MIT Center for Transportation and Logistics for his participation in the development of the collection logistics model. [20] REFERENCES [1] [2] [3] United States Environmental Protection Agency – US EPA “Management of Electronic Waste in the United States, Fact Sheet.” EPA530-F-08-014, July 2008. Available online at http://www.epa.gov/osw/conserve/materials/ecycling/docs/fact7-08.pdf (Accessed March 25, 2009). United States Environmental Protection Agency – US EPA “Electronics Waste Management in the United States, Approach 1.” EPA530-R-08009, July 2008. Available online at http://www.epa.gov/osw/conserve/materials/ecycling/docs/app-1.pdf (Accessed March 25, 2009). United States Environmental Protection Agency – US EPA “Management of Electronic Waste in the United States, Approach 2.” [17] [18] [21] [22] [23] [24] EPA530-R-07-004b, April 2007. Available online at http://www.epa.gov/osw/conserve/materials/ecycling/docs/app-2.pdf (Accessed March 25, 2009). S. A. Fredholm, J. R. Gregory, and R. E. Kirchain, "Characterizing Architectural Options for Electronic Waste Recycling Systems," IEEE International Symposium on Electronics and the Environment, Burlingame, CA, May 19-21, 2008. J. B. Dahmus, S. A. Fredholm, E.A. Olivetti, J. R. Gregory, and R. E. Kirchain, "Modeling the Economic and Environmental Performance of Recycling Systems,” IEEE International Symposium on Electronics and the Environment, Burlingame, CA, May 19-21, 2008. J. B. Dahmus, S. A. Fredholm, E.A. Olivetti, J. R. Gregory, and R. E. Kirchain, "Modeling the Economic and Environmental Performance of Recycling Systems,” TMS Global Symposium on Recycling, Waste Treatment and Clean Technology, Cancun, Mexico, Oct. 12-15, 2008. J. R. Gregory and R. E. Kirchain, “A Framework for Evaluating the Economic Performance of Recycling Systems: A Case Study of North American Electronics Recycling Systems," Environmental Science and Technology, 42(18), pp. 6800-6808, 2008. T. Rand-Nash, R. Roth, and R. Kirchain, Massachusetts Institute of Technology, Personal Communication, February 6, 2008. Current, J., M. Daskin, and D. Schilling, “Discrete Network Location Models,” in Facility Location: Applications and Theory, Z. Drezner and H. Hamacher , Eds. Heidelberg, Germany: Springer-Verlag, 2002, pp. 81-118. Megiddo, N. and K. Supowit, “On the Complexity of Some Common Geometric Location Problems,” SIAM Journal of Computing, 13(1), pp. 182-196, February 1984. Farhan, B. and A. T. Murray, "Distance decay and coverage in facility location planning," The Annals of Regional Science, vol. 40, pp. 279295, 2006. Hurst, M. E. E. A Geography of Economic Behavior: An Introduction. North Scituate, Massachusetts, USA: Duxbury Press, 1972. Taylor, P. J. “Distance Transformation and Distance Decay Functions,” Geographical Analysis, vol. 3, pp. 221-238, 1971. Sheppard, E. "Modeling and Predicting Aggregate Flows," in The Geography of Urban Transportation, S. Hanson, Ed. New York, New York, USA: The Guilford Press, 1995, pp. 100-128. Fotheringham, A. S. and M. E. O'Kelly. Spatial Interaction Models: Formulations and Applications. Dordrecht, The Netherlands: Kluwer Academic Publishers, 1989. Field, F., R. Kirchain, R. Roth. "Process cost modeling: Strategic engineering and economic evaluation of materials technologies." JOM Journal of the Minerals, Metals and Materials Society, vol. 59(10), pp. 21-32. Kirchain, R.E. “Cost Modeling of Materials and Manufacturing Processes,” in Encyclopedia of Materials: Science and Technology, K.H.J. Buschow, et al., Eds. Oxford, England: Elsevier, 2001, pp. 17181727. US Census Bureau, Maine -- Place and County Subdivision, 2000. Available online at http://factfinder.census.gov. (Accessed March 29, 2009). "Recycler's World," Available online at www.recycle.net. (Accessed March 29, 2009). Ecoinvent database 2.0, Swiss Center for Life Cycle Inventories, 2009. Available online at http://www.ecoinvent.org. (Accessed March 29, 2009). Atlee, J. R. Operational Sustainability Metrics: A Case of Electronics Recycling. MS Thesis, Massachusetts Institute of Technology, June 2005. Habersatter, K. Ecobalance of packaging materials: state of 1990. Environmental Series No. 132. Berne, Federal Office of Environment, Forests, and Landscape (BUWAL), 1991. Keolian, G. A., K. Kar, M. Manion, and J. Bulkley. Industrial Ecology of the Automobile: A Life Cycle Perspective. Warrendale, Pennsylvania, USA: Society of Automotive Engineers, 1997. Graedel, T. E. and B. Allenby. Industrial Ecology and the Automobile. Upper Saddle River, New Jersey, USA: Prentice-Hall, Inc., 1998.